Abstract

Capillary and interfacial forces are of great influences of trapping hydrocarbon in porous media after primary and secondary recovery processes. The trapped crude oil in the reservoir can be mobilized and produced by reducing these forces. Thus, surfactant flooding, as a main enhanced oil recovery (EOR) method, is usually applied to reduce the interfacial tension (IFT) of crude oil–water system in porous medium and improves the oil recovery. This study focused on the effect of [C8Py][Cl] and [C18Py][Cl] ionic liquids (ILs), as a new family of surfactant, in combination with various salts including sodium chloride, potassium chloride, magnesium sulfate and potassium sulfate on IFT reduction. EOR injection solutions were prepared from mixing the ILs at different concentrations of 100, 250, 500 and 1000 ppm with the salts ranging from 500 to 80,000 ppm. Obtained results showed that the minimum IFT value from both ILs was achieved when the concentration of the ILs was about 1000 g/mL, and the concentrations of KCl, K2SO4, MgSO4 and NaCl were 1000, 2000, 500 and 80,000 ppm, respectively. The minimum IFTs were achieved when NaCl and ILs concentrations were the maximum and MgSO4 concentration was the minimum.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Oil production from the matured and currently producible reservoirs is continuously declining. According to the global energy reports, the demand on oil is increasing. Discovering new oil reservoirs is difficult, and high amount of the oil is remained trapped in reservoir after the primary and secondary recovery techniques (Ali et al. 2019; Abtahi et al. 2003). Thus, in order to keep the oil production stable and increased, researchers and oil companies are focused on applications of EOR methods. Among various EOR methods, the surfactant flooding has a high potentiality in displacing the residual oil toward the production wells (Qi et al. 2014). Capillary forces have a significant role in causing oil to be trapped in the reservoir (Ahmadi et al. 2014; Ali et al. 2018a), which is mostly happened in carbonate oil-wet reservoir (Ahmadi and Shadizadeh 2013; Gupta et al. 2009; Jarrahian et al. 2012; Lu et al. 2014; Pordel et al. 2012; Seethepalli et al. 2004; Bortolotti et al. 2010). Since waterflooding has shown the low performance in this kind of reservoirs, IFT reduction and wettability alteration are the main EOR mechanisms of increasing the oil recovery (Golabi et al. 2009; Ali et al. 2018b).

Surfactant flooding is basically applied to achieve the above-mentioned mechanisms, and more precisely the IFT reduction (Hezave et al. 2013a). The IFT reduction can be obtained when the Marangoni effect and mass transfer along an interface between two liquids occur through diffusion and/or convection mechanisms (Hezave et al. 2014). The IFT between water and oil can be modified using ionic liquids by increasing the length of the hydrophobic chain. Wherein, more adhesion to two different phases and more separate distance between hydrophilic and hydrophobic heads can be obtained with the longer the length of the hydrophobic chain; consequently, the trapped oil would be forced to be moved and produced (Hezave et al. 2013b). On the other hand, changing the ionic compound of the injection water can lead the oil–water IFT to another direction, such as KI, K2SO4, MgSO4, Na2SO4, NaCl, CaCl2, MgCl and KCl salts (Nowrouzi et al. 2018, 2019a, b; Manshad et al. 2017). For instance, Manshad et al. reported that little dissolution of 2000 ppm of K2SO4 in water can reduce IFT of water–oil system up to 57% (Manshad et al. 2016), and Lashkarbolooki et al. (2014) indicated that MgCl4 concentration with 30,000 ppm concentration can reduce the IFT by 82%.

Surfactant flooding was first introduced by Howard in 1927 to produce oil from the oil bearing sands (Howard 1927). Afterward, numerous research studies have been performed on the surfactant flooding to enhance oil recovery as shown in Table 1. During last decades, several types of conventional surfactants have studied and used in enhanced oil recovery; wherein, high amount of surface was usually lost on the surface of reservoir rocks due to its harsh condition of salinity and temperature (Hezave et al. 2013a, b). Dehghan et al. (2015) conducted an experimental study on the application of some surfactant in different conditions of reservoir, types of rocks, reservoir fluids and salinity ranges. They reported that the effect of the used surfactants on IFT reduction was interfered by the influences of the mentioned factors, and optimized when with the optimal salinity level (Daghlian et al. 2016). Rodriguez (1992) investigated the amount of surfactant adsorption on the surface of the carbonate rock, and it was identified that the surfactant adsorption was increased with increasing the flowrate at constant surfactant concentration and temperature. Currently, ionic surfactants, as green agents, are widely used to reduce the oil–aqueous phase IFTs in depleted reservoirs because of their significant characteristics including high ionic conductivity, non-flammability, high chemical and physical stability and negligible vapor pressure (Hezave et al. 2013a, b). Hezave et al. (2013a, b) studied the effect of two ILs families, such as pyridinium ([C12Py][Cl] and [C8Py][Cl]) and imidazolium ([C12mim][Cl] and [C8mim][Cl]) on IFT reduction. They identified that the high reduction of IFT can be achieved using these ILs, especially when the salinity was the minimum. Additionally, Lashkarbolooki and Ayatollahi (2018) investigated effects of pyridinium and imidazolium ILs including [C8mim][Cl] and [C8Py][Cl] on the IFT of oil–aqueous phase in the presence and absence of MgCl2 salt. Their results demonstrated that both IL families reduced IFT with a great performance, which was extremely influenced by the crude oil and IL types. The ultimate goal of this study is to identify the effect of two pyridinium-based ILs including [C8Py][Cl] [C18Py][Cl] on the interfacial tension reduction in the presence of KCl, K2SO4, MgSO4 and NaCl salts. The salts were used in four different levels of concentration ranging from 500 to 80,000 ppm.

Materials and methodology

Materials

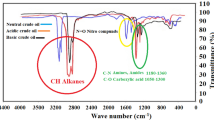

All materials for synthesizing the ILs and salts used in this study including sodium chloride (NaCl), potassium chloride (KCl), magnesium sulfate (MgSO4) and potassium sulfate (K2SO4) were purchased from MP Biomedical Company in Netherlands. The properties of these salts are given in Table 2. Dead crude oil extracted from Sarvestan oilfield located in central Iran with API of (29°) and the specifications contained in Table 3 were used.

Synthesis of ionic liquids

On the basis of the synthesis procedure ILs reported by Wasserscheid and Welton (2008), the pyridinium-based ILs used in this study, namely [C8Py][Cl] and [C18Py][Cl], were synthesized by reacting 1-methylimidazolium or pyridine with excess amount of the 1-chlorododecane or 1-chlorooctane without any additional solvent in a round-bottomed flask fitted with a reflux condenser (heating and stirring at 70 °C for 48–72 h). The resulting viscous liquid was cooled down to room temperature and then washed up using diethyl ether. Finally, the clean solvent was dried overnight at 100 °C, and it is subjected to a 1H-NMR spectroscopy analysis to investigate its purity.

Taguchi method

In order to minimize the number of the experimental tests, and save the time and the cost, the experimental work of this study was designed using Taguchi method which is widely used in planning the laboratory experiments. This method was introduced by Taguchi in the late 1940s in Japan and has been developed in the early 1960s (Wasserscheid and Welton 2008). In order to obtain the impact of the studied parameters accurately, the effective parameters must be selected precisely. The salts and ILs used in this study were selected as the main effective parameters that can influence the amount of reduction in IFT of the oil–aqueous phases. The concentration of the selected parameters was divided into four levels as shown in Table 4. It should be noted that both ILs were used separately with the salts, and their distribution through the levels must be considered separately.

Interfacial tension measurement

Interfacial tension apparatus designed by Fars EOR (IFT400) was to measure the value of IFT in this study (Fig. 1). After hanging the droplet of the crude oil within the aqueous phase, the device takes a photograph for it by employing the axisymmetric drop shape analysis (ADSA) technique. IFT can be determined using the following equation:

where Δρ is the difference in the density of the droplet and bulk fluid (g/cm3), g is the gravitational acceleration of the earth (cm/sec2), D is the large diameter of the droplet (cm), and H is the droplet shape factor which is a function of S = d/D, and d the horizontal diameter calculated at a distance D above the droplet.

Schematic diagram of the IFT400; 1: bulk flow pump, 2: adjustable light source, 3: indicator and temperature and pressure controller, 4: high-pressure valve, 5: cell, 6: camera, 7: drop needle, 8: cell content drainage line, 9: drop fluid pump, and 10: Computer equipped with device software (Manshad et al. 2017)

The experimental design of the IFT test was mainly composed of two syringes connected to rotary knobs, and a cell with three thermal elements and two glass valves (one against the adjustable lighting bar and the other against 2-megapixel CCD HD camera). The device is equipped with a marker, temperature and pressure controller. IFT400 has a capability of supplying a pressure tolerance of up to 3000 psi with a precision of 0.5% full scale, a maximum allowed temperature of up to 453.15 K with a precision of ± 0.3, and measuring the IFT with the accuracy of ± 0.2–0.5 mN/m. In this study, the IFT 400 was used to measure the value of IFT between crude oil and aqueous phases including ILs and salts at ambient temperature and pressure during various time steps.

Result and discussion

Equilibrium IFT measurement

As mentioned earlier, the Taguchi method was used to design the experimental plan of this study; accordingly, the ILs and salts used in this work were divided into four different levels of concentrations (Table 4). In each level, the concentration of salts is varied. In order to study the effect of ILs more precisely at different concentrations of 100, 250, 500 and 1000 ppm with all salts, the experimental plan was expanded to 16 tests as shown in Table 5. Both ILs were used with four different concentrations (100, 250, 500 and 1000 ppm). However, the concentrations of the selected salts were different; KCl (1000, 2000, 10,000 and 20,000 ppm), K2SO4 (0, 500, 1000 and 2000 ppm), MgSO4 (0, 500, 1000 and 2000 ppm) and NaCl (2000, 20,000, 40,000 and 800,000 ppm).

The IFT measurements for all the prepared solutions were performed using IFT400. Totally, 32 tests have been run for [C8Py][Cl] and [C18Py][Cl] ILs with KCl, K2SO4, MgSO4 and NaCl at different concentrations. Figure 2a illustrates the values of IFTs between oil and aqueous phases with the presence of [C8Py][Cl] and four salts at different experimental levels. The highest value of IFT about 23 mN/m was measured in test 1 (T1) between crude oil and the solution contains 100 ppm of IL, 1000 ppm of KCl, 0 ppm of K2SO4, 500 ppm of MgSO4 and 2000 ppm of NaCl. From keeping the concentration of [C8Py][Cl] at 100 ppm and changing the level of salt concentrations from T1 to T4, the IFT reduction was increased with changing the Taguchi levels from 1 to 4 and 14.93 mN/m was obtained in T4. This reduction in the IFT was due to the effect of salt concentrations, especially for KCl and NaCl. However, when increasing the IL concentration to 250 ppm and keeping it constant, the IFT was firstly reduced to 13.16 mN/m in T5 with the level 1 and then increased to above 20 mN/m with changing the Taguchi levels from T5 to T8. This change in IFT value was mostly due to the effect of NaCl concentration because it was reduced from 80,000 to 40,000, 20,000 and 2000 ppm during tests T5–T8. Furthermore, when concentration of [C8Py][Cl] IL was increased to 500 (T9 to TT12) and 1000 ppm (T13 to T16), various values of IFTs were measured depending on the amount of salts mixed in each test (Manshad et al. 2017). For the tests, when 500 ppm of IL was used, the minimum IFT was achieved within T11 which was 12.11 mN/m. This is where the concentrations of KCl and NaCl were the maximum 10,000 and 80,000 ppm, respectively, and K2SO4 was 1000 ppm. Additionally, the lower IFTs were measured when the concentration of IL was increased to 1000 ppm, and the lowest IFT of 11.03 mN/m was determined within T14; wherein, the concentration of NaCl was 80,000 ppm, that of KCl was 2000 ppm, K2SO4 was 1000 ppm, and MgSO4 was 500 ppm. Hence, NaCl was identified to be the most effective salt with [C8Py][Cl] IL, and the minimum IFT was achieved between oil and ionic solution of 1000 ppm [C8Py][Cl] IL and 80,000 ppm NaCl.

In addition, Fig. 2b shows the measured values of IFTs when [C18Py][Cl] was used with different concentrations of salts in four different levels depending on the Taguchi method. Generally, sixteen tests have been performed and less IFTs were measured for the all the tests compared with [C8Py][Cl] solutions, which indicates that [C18Py][Cl] is more effective than [C8Py][Cl]. The average value of IFT among all 16 tests when [C8Py][Cl] was used was 16.72 mN/m and reduced to 3.68 mN/m for the tests with [C18Py][Cl]. In Fig. 2b, it is clear that the minimum value of IFT between crude oil and aqueous phase was achieved in test T14, which was 1.76 mN/m. In comparison with the highest value measured in T1, IFT was reduced by 70% from 5.89 to 1.76 mN/m. This significant reduction was mostly due to the high concentration of NaCl which was 80,000 ppm.

Dynamic IFT measurement

The dynamic data of the IFT measurements during time for both ILs are shown in Fig. 3a, b. The measurements were taken each 300 s in six steps during 30 min. Generally, the IFT reduction was increased with increasing the ILs concentrations. From both IL solutions, IFTs were reduced during the time for all tests, but with different ranges. For instance, the minimum IFTs were achieved in T14, where the concentration of ILs was 1000 ppm and NaCl was 80,000 ppm. However, T1 for both [C8Py][Cl] and [C18Py][Cl] provided maximum IFTs during 300, 600, 900, 1200, 1500 and 1800 s time steps, which were 24.59, 24.12, 23.78, 23.27, 23.09 and 22.9 mN/m and 5.89, respectively. Generally, [C18Py][Cl] showed a better performance in reducing the IFT in all sixteen tests during all time steps compared with [C8Py][Cl].

Data analysis

In this part, the statistical analysis on the IFT results to identify the effectiveness of the selected parameters including [C8Py][Cl], [C18Py][Cl], KCl, K2So4, MgSO4 and NaCl has been made. In this analysis, degree of freedom (DoF), sum of squares, variance, pure sum and percent factors have been determined. Statistical results of this analysis for IFT values measured while using [C8Py][Cl] and [C18Py][Cl] are shown in Tables 6 and 7, respectively. According to the statistical factors selected in the study, NaCl had a significant and the most effective role in reducing the IFT value while using [C8Py][Cl] ionic solutions (Table 6). The role of NaCl was about 71% compared with [C8Py][Cl], KCl, K2SO4 and MgSO4. Additionally, the effectiveness of the IL was 23.61% and lower than the impact of NaCl but higher than other salts. However, KCl, K2SO4 and MgSO4 had a very small influence on IFT reduction.

Furthermore, the statistical results of the IFT between crude oil and [C18Py][Cl] ionic solutions with the presence of the selected salts depending on the Taguchi concentration levels are shown in Table 7. In this section of tests, the effect of [C18Py][Cl] on IFT reduction was higher than the influences of the all used salts. Despite using KCl, K2SO4 and MgSO4 salts in different concentrations, they had very small impact on IFT reduction and less than 1%. About 57% of the reduction in IFT between oil and aqueous phases was due to the performance of [C18Py][Cl] IL, and about 42% was because of the NaCl role. Totally, the performance of [C18Py][Cl] IL was much higher compared to the second IL ([C18Py][Cl]) in IFT reduction, and among the four used salts, NaCl showed the best performance and was the most effective Fig. 4a, b.

Conclusions

Interfacial tension of solutions containing ionic liquids [C8Py][Cl] and [C18Py][Cl] as surfactant and oil by pendant method was obtained, and the salinity effects of dissolving KCl, K2SO4, MgSO4 and NaCl salts on their performance were investigated in the reduction in interfacial tension. Accordingly:

Ionic liquids [C8Py][Cl] and [C18Py][Cl] work well in reducing IFT, and the values obtained can be effective in tertiary oil recovery.

The design of IFT experiments using the Taguchi method can reduce the volume of experiments and predict these tests with high precision.

Ionic liquids [C8Py][Cl] and [C18Py][Cl], in contrast to conventional surfactants, are compatible with salinity and are useful additives for reservoir conditions.

The minimum IFTs were achieved when NaCl and ILs concentrations were the maximum and MgSO4 concentration was the minimum.

It is suggested that the effect of ionic liquids on the wettability alteration of the reservoir rock can be investigated for further studies.

References

Abdullah MM, AlQuraishi AA, Allohedan HA, AlMansour AO, Atta AM (2017) Synthesis of novel water soluble poly (ionic liquids) based on quaternary ammonium acrylamidomethyl propane sulfonate for enhanced oil recovery. J Mol Liq 233:508–516

Abtahi N, Reza R, Faramarz G (2003) Biosurfactant production in MEOR for improvement of Iran’s oil reservoirs’ production experimental approach. In: Proceedings of SPE international improved oil recovery conference in Asia Pacific. https://doi.org/10.2523/84907-ms

Ahmadi MA, Shadizadeh SR (2013) Implementation of a high-performance surfactant for enhanced oil recovery from carbonate reservoirs. J Petrol Sci Eng 110:66–73

Ahmadi MA, Arabsahebi Y, Shadizadeh SR, Behbahani SS (2014) Preliminary evaluation of mulberry leaf-derived surfactant on interfacial tension in an oil-aqueous system: EOR application. Fuel 117:749–755

Ahmadi MA, Galedarzadeh M, Shadizadeh SR (2015) Wettability alteration in carbonate rocks by implementing new derived natural surfactant: enhanced oil recovery applications. Transp Porous Media 106(3):645–667

Ali JA, Kolo K, Manshad AK, Mohammadi AH (2018a) Recent advances in application of nanotechnology in chemical enhanced oil recovery: effects of nanoparticles on wettability alteration, interfacial tension reduction, and flooding. Egypt J Pet 27(4):1371–1383. https://doi.org/10.1016/j.ejpe.2018.09.006

Ali JA, Kolo K, Manshad AK, Stephen KD, Keshavarz A (2018b) Modification of LoSal water performance in reducing interfacial tension using green ZnO/SiO2 nanocomposite coated by xanthan. Appl Nanosci. https://doi.org/10.1007/s13204-018-0923-5

Ali JA, Kolo K, Manshad AK, Stephen KD (2019) Low salinity polymeric nanofluid enhanced oil recovery using green polymer coated ZnO/SiO2 nanocomposite in upper qamchoqa formation in Kurdistan region-Iraq. Energy Fuels 33(2):927–937

Bortolotti V, Macini P, Srisuriyachai F (2010) Wettability index of carbonatic reservoirs and EOR: laboratory study to optimize alkali and surfactant flooding. In: International oil and gas conference and exhibition in China, 8–10 June, Beijing, China, Society of Petroleum Engineers, SPE-131043-MS

Daghlian SJ, Sharifi M, Sarapardeh AH (2016) Toward mechanistic understanding of natural surfactant flooding in enhanced oil recovery processes: the role of salinity, surfactant concentration and rock type. J Mol Liq 222:632–639

Dehghan AA, Masihi M, Ayatollahi S (2015) Interfacial tension and wettability change phenomena during alkali–surfactant interactions with acidic heavy crude oil. Energy Fuels 29(2):649–658

Golabi E, Seyedeyn-Azad F, Ayatollahi S (2009) Chemical induced wettability alteration of carbonate reservoir rocks. Iran J Chem Eng 6(1):67

Gupta R, Mohan K, Mohanty KK (2009) Surfactant screening for wettability alteration in oil-wet fractured carbonates. In: SPE annual technical conference and exhibition, 4–7 October, New Orleans, Louisiana, Society of Petroleum Engineers, SPE-124822-MS

Hezave AZ, Dorostkar S, Ayatollahi S, Nabipour M, Hemmateenejad B (2013a) Effect of different families (imidazolium and pyridinium) of ionic liquids-based surfactants on interfacial tension of water/crude oil system. Fluid Phase Equilibr 360:139–145

Hezave AZ, Dorostkar S, Ayatollahi S, Nabipour M, Hemmateenejad B (2013b) Investigating the effect of ionic liquid (1-dodecyl-3methylimidazolium chloride ([C12mim] [Cl])) on the water/oil interfacial tension as a novel surfactant. Colloids Surf A Physicochem Eng Asp 421:63–71

Hezave AZ, Dorostkar S, Ayatollahi S, Nabipour M, Hemmateenejad B (2014) Mechanistic investigation on dynamic interfacial tension between crude oil and ionic liquid using mass transfer concept. J Disper Sci Technol 35(10):1483–1491

Howard A (1927) Recovery of petroleum from oil-bearing sands. Google Patent

Jarrahian K, Seiedi O, Sheykhan M, VafaieSefti M, Ayatollahi S (2012) Wettability alteration of carbonate rocks by surfactants: a mechanistic study. Colloids Surf A Physicochem Eng Asp 410:1–10

Lashkarbolooki M, Ayatollahi S (2018) Investigation of ionic liquids based on pyridinium and imidazolium as interfacial tension reducer of crude oil–water and their synergism with MgCl2. J Petrol Sci Eng 171:414–421

Lashkarbolooki M, Ayatollahi S, Riazi M (2014) The impacts of aqueous ions on interfacial tension and wettability of an asphaltenic–acidic crude oil reservoir during smart water injection. J Chem Eng Data 59(11):3624–3634

Lu JA, Goudarzi P, Chen DH, Kim M, Delshad KK, Mohanty K, Sepehrnoori UP, Weerasooriya GA (2014) Enhanced oil recovery from high-temperature, high salinity naturally fractured carbonate reservoirs by surfactant flood. J Petrol Sci Eng 124:122–131

Manshad AK, Olad M, Taghipour SA, Nowrouzi I, Mohammadi AH (2016) Effects of water soluble ions on interfacial tension (IFT) between oil and brine in smart and carbonated smart water injection process in oil reservoirs. J Mol Liq 223:987–993

Manshad AK, Rezaei M, Moradi S, Nowrouzi I, Mohammadi AH (2017) Wettability alteration and interfacial tension (IFT) reduction in enhanced oil recovery (EOR) process by ionic liquid flooding. J Mol Liq 248:153–162

Nowrouzi I, Manshad AK, Mohammadi AH (2018) Effects of dissolved binary ionic compounds and different densities of brine on interfacial tension (IFT), wettability alteration, and contact angle in smart water and carbonated smart water injection processes in carbonate oil reservoirs. J Mol Liq 254:83–92

Nowrouzi I, Manshad AK, Mohammadi AH (2019a) Effects of ions and dissolved carbon dioxide in brine on wettability alteration, contact angle and oil production in smart water and carbonated smart water injection processes in carbonate oil reservoirs. Fuel 235:1039–1051

Nowrouzi I, Manshad AK, Mohammadi AH (2019b) Effects of dissolved carbon dioxide and ions in water on the dynamic interfacial tension of water and oil in the process of carbonated smart water injection into oil reservoirs. Fuel 243:569–578

Pordel MS, Shadizadeh S, Jamialahmadi M (2012) A new type of surfactant for enhanced oil recovery. Pet Sci Technol 30(6):585–593

Qi ZY, Wang FY, Xu XL (2014) Effects of interfacial tension reduction and wettability alteration on oil recovery by surfactant imbibition. Adv Mater Res Trans Tech Publ 868:664–668

Rodriguez A (1992) Surface charge behavior and adsorption of surfactants on carbonate rocks. King Fahd University of Petroleum & Minerals

Saien J, Hashemi S (2018) Long chain imidazolium ionic liquid and magnetite nanoparticle interactions at the oil/water interface. J Petrol Sci Eng 160:363–371

Seethepalli A, Adibhatla B, Mohanty K (2004) Wettability alteration during surfactant flooding of carbonate reservoirs. In: SPE/DOE symposium on improved oil recovery, 17–21 April, Tulsa, Oklahoma, Society of Petroleum Engineers, SPE-89423MS

Wasserscheid P, Welton T (2008) Ionic liquids in synthesis. Wiley, Hoboken

Zhou H, Zhu Y, Peng T, Song Y, Xu JA, Zewen L, Yuqian Y, Jia SH (2016) Systematic study of the effects of novel halogen-free anionic surface active ionic liquid on interfacial tension of water/model oil system. J Mol Liq 223:516–520

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Najimi, S., Nowrouzi, I., Manshad, A.K. et al. Investigating the effect of [C8Py][Cl] and [C18Py][Cl] ionic liquids on the water/oil interfacial tension by considering Taguchi method. J Petrol Explor Prod Technol 9, 2933–2941 (2019). https://doi.org/10.1007/s13202-019-0688-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-0688-8