Abstract

The study of gas sorption characteristics is important for practical assessment of coal bed methane (CBM) production and CO2 sequestration in coal seam. Adsorption isotherm is one of the critical parameters for the establishment of production as well as injection well. Adsorption isotherm provides information about the reservoir conditions and critical desorption pressure as well as volume of gas that can be sequestered in deep coal seam. Alteration in sorption isotherm reflects the increase or decrease of the gas production as well as CO2 sequestration. Therefore, in this paper, experimental investigation was carried out to determine the CO2/CH4 sorption capacity of five different coal samples taken from different locations of Jharia coalfield (Moonidih area) of Gondwana basin. Gas sorption capacity was determined at 27 °C temperature and up to 7.5 MPa pressure. CO2 adsorption was observed to be higher than that of the CH4. The sorption ratio of CO2/CH4 varied from 1.6:1 to 1.2:1 for all coal samples. Furthermore, the experimental results were correlated using established Langmuir, Freundlich, Temkin and D–R isotherm models. Experimentally obtained values satisfactorily fitted to the Langmuir and Freundlich model with comparable accuracy. The excess adsorption capacity of coal was also compared with different rank parameters to understand the variation of sorption capacity with rank of coal.

Similar content being viewed by others

Introduction

At present, climate change and global warming are the most debated topics. CO2 is one of the dominant causes of greenhouse gas effect (GHG) and global warming due to its higher concentration in the atmosphere. Thermal generation capacity of India will be 290 GW in 2047, out of which 253 GW will be coal based and 37 GW gas based (1). Increasing demand of energy also increases CO2 emission. Concentration of CO2 in the atmosphere was found to be 396 ppmv in 2013 which was 40% higher than that in mid-1800s (2). The rate of emission was 2 ppmv/year for the last 10 years (2) alarming the world for advancement towards technology for the reduction of CO2 concentration in atmosphere. The CO2 concentration can be controlled by two ways: one to reduce CO2 emissions into the atmosphere and the other to reduce the present concentration of CO2 in the atmosphere to safe levels through application of various engineering principles. The second way is possible by CO2 storage in un-minable coal seams, depleted oil and gas reservoirs, abandoned and sealed mines, saline aquifers, oceans, etc. (Ishaq et al. 2009; Shi and Durucan 2005; Robertson 2010). Sequestration of CO2 in deep coal seam is one of the techniques to reduce CO2 concentration in the atmosphere and mitigation of global warming. Coal bed reservoir has the ability to store and retain large quantity of CO2 gas for very long time due to its porous nature (Shi and Durucan 2005; Robertson 2010). Injection of CO2 in coal seam also facilitates beneficial effect on enhanced coal bed methane recovery (ECBM) (Stevens et al. 1998; Seidle 2000; Pagnier et al. 2005). Estimation of CO2/CH4 sorption in deep coal seam requires critical experimental investigation (Hernandez et al. 2006; Vishal et al. 2015; Buscha and Gensterblumb 2011). Investigative effort has been undertaken elsewhere to estimate excess sorption capacity at different temperature and increasing pressure values (13; Prusty 2008; Chen et al. 2011). CO2/CH4 sorption ratio was reported to be 10:1 for low-rank coal and less than 2:1 for low- and medium-volatile bituminous coals (Deng et al. 2015). Variation in gas sorption capacity of coal based on proximate analysis, ultimate analysis and maceral contents has been reported elsewhere (Saikia and Sarkar 2013; Ghosh et al. 2014). The sorption isotherm gives estimated retention capacity of gas at in situ temperature and pressure of reservoir. Detailed sorption isotherm of CO2 and CH4 is required as input for production simulation in CBM and ECBM operations (Ghosh et al. 2014). The investigation suggests the variation of rate of sorption depends upon the pore size and porosity of the coal, molecular size of the gas and critical temperature and pressure (19; Suman and Harpalani 2019; Ali et al. 2018).

In this investigation, the sorption capacity of CO2 and methane on five different coal samples (namely JH-MD-S1, JH-MD-S2, JH-MD-S3, JH-MD-S4 and JH-MD-S5) from Jharia coalfield (Moonidih area) was carried out experimentally. Excess CO2/CH4 sorption capacity was obtained at 27 °C with incremental gas pressure from 0 to 7.5 MPa at varying depth from 400 to 580 m. Sorption isotherms were plotted using experimentally obtained values. The experimentally obtained data were compared with four different established isotherm models, namely (Langmuir, Freundlich, Temkin and D–R isotherm models) to obtain the best-fit isotherm model for the study area. The rank parameters such as moisture content, ash content, volatile matter (daf basis), fixed carbon (daf basis) and vitrinite reflectance were correlated with CO2 and CH4 excess sorption amount to determine the effect of these parameters on sorption amount of coal.

Geological setting of Jharia coal bed basin

Coal sample for the sorption study was collected from the underground mine of Jharia coal bed basin (Moonidih Area) (Fig. 1) which is located in Dhanbad district of Jharkhand, India. It is bounded between 23°37′N and 23°52′N and longitudes 86°05′E and 86°30′E. Mostly these mines are full of gassy environment with elevated strata temperature (Daniel and Bustin 2007) (Guo 2003).

Sample preparation and experimentation

The sorption study was carried out on coal samples obtained from freshly exposed coal surface at depth varying from 400 to 580 m. The lump of samples was crushed and passed through a sieve of size 72 BSS mesh (212 µm). The moisture content of the samples was estimated as per standard [ASTM D 3173–11]. Proximate analysis of these samples was estimated as per the standard method [ASTMD 3172–07a] and ultimate analysis using CHNS Analyzer [Make Evisa Vario EL III- CHNS analyzer] as per the standard methods [ASTM D 3176–09].

Volumetric sorption setup was used to estimate the sorption capacity of coal. The setup consists of reference cell, sample cell, flow line, digital pressure transducer, data acquisition system, etc. (Figs. 2, 3). The volumetric setup was kept immersed in water bath maintained at uniform temperature of 27 °C (± 1 °C). The volume of excess sorption was determined at constant temperatures as a function of pressure at equilibrium.

Determination of sorption capacity

About 100 g of coal sample was taken in the calibrated sample cell. The setup was evacuated to remove unwanted gas present in coal using vacuum pump (make: Scientific Instrument Services, Inc., USA). Helium gas was injected at 0.68–3.5 MPa pressure to determine the volume of sample as well as reference cell using volume expansion method as follows (Zhang et al. 2013):

where Vs is the volume of sample cell, \(\psi\) is the constant with iron ball in the sample cell, \(\xi\) is the constant without iron ball in sample cell, Vsb is the total volume of the iron ball, Ps2 and Ps1 are the pressure of helium gas in sample cell before and at the equilibrium condition, Pr2 and Pr1 are the pressure of helium gas in reference cell before and at the equilibrium condition, Zs2, Zs1, Zr2, Zr1 are the compressibility factor at the respective pressure. Similarly, the volume of reference cell was determined as (Zhang et al. 2013):

Compressibility factor was calculated using American gas association report no. 8, 1992 (GAS Calc.5.0). Void volume (Vv) was calculated as (Zhang et al. 2013):

Mole transferred was determined as

where ntotal is the mole transferred to the reference cell, R is the gas constant and T is the temperature at which the experiment was conducted (27 °C).

CO2 gas (99.99% pure) was first filled in the reference cell at regular interval of 0.68 ± 0.068 MPa.

Total mole transferred to the reference cell was determined as (Zhang et al. 2013):

The sorption of gas was estimated through mole balance. Gas adsorbed was determined from the difference between mole injected and mole present in void:

Results and discussion

The results of proximate and ultimate analyses are shown in Table 1. VM (daf basis) varies between 21.02 and 34.48, while FC (daf basis) found in between 65.52 and 78.98 indicates medium-volatile bituminous coal. Variation in moisture and ash content from 0.93 to 1.4 and 9.01 to 20.64 reflects medium-volatile bituminous coal. Value of vitrinite reflectance was determined using the established Rice formula (Rice 1993) as.

where R0 is the vitrinite reflectance (%) and VM(daf) is the volatile matter (dry ash-free basis) (%).

The variation of R0 between 0.92 and 1.51 indicates medium-volatile bituminous coal as per the rank parameter discussed elsewhere (Diessel 1992) (Table 1). The values of vitrinite reflectance observed in this study lie in between the threshold value of 0.7–2.0% which confirms commercial CBM prospects as described elsewhere (Chandra 1950).

Sorption capacity of coal bed

Sorption capacity was measured at the highest pressure of 7.5 MPa for methane and 5.5 MPa for CO2 at 300 K. CO2 and CH4 sorption capacity varied from 11.11 to 20.52 and 9.49 to 13.29 cc/g, respectively (Table 2). Sharp increase in sorption capacity was observed with increase in depth of coal seam (Figs. 4, 5). Increase in sorption capacity with depth is due to the increase in carbon content as well as porosity of coal and reduction in moisture content. The sorption ratio of CO2/CH4 was from 1.6:1 to 1.2:1. Adsorption of CO2 was observed to be higher than that of CH4 with an increase in pressure. The difference between adsorption amounts is due to the higher density of CO2 and its interaction with coal than that with CH4. It is also due to the variation in molecular diameter of CO2 (0.33 nm) than CH4 (0.38 nm). This increase in maturity and higher rank of coal allow more sorption. CO2 sorption capacity of coal of study area was also compared with different coalfields worldwide (Table 3).

Determination of sorption isotherm based on experimental data

The sorption capacity of CO2 and CH4 in coal was studied and sorption isotherm was plotted (Figs. 6, 7). Experimental values were compared with other isotherm models such as D–R, Temkin, Freundlich and Langmuir, respectively, using linear regression method. Values were analysed statistically to determine the regression coefficient of all isotherm models. Freundlich and Langmuir models were observed to be best fitted to the experimental values. This is due to the monolayer as well as multilayer sorption of gas in coal obtained from different depths of occurrence.

The constant for each model is shown in Tables 4 and 5. Constant, qm obtained from Langmuir isotherm model indicates monolayer sorption process. Values of 1/n and Kf were determined from Freundlich isotherm model. The values of 1/n were found below 1 and above 1 indicating normal as well as cooperative sorption process. Thus, the monolayer as well as multilayer deposition of gas was observed in gas sorption process in coal. Temkin isotherm and D–R isotherm models were less fitted to the experimental values; therefore, the constants associated with the Temkin and D–R isotherms were not discussed in the results. The fitting of the Langmuir as well as Freundlich isotherm models to the experimental values is due to well-developed pores, pore size distribution and porosity in coal samples.

Langmuir volume and pressure

Langmuir volume and pressure are widely acceptable parameters in reservoir engineering. In a physical sense, the Langmuir volume constant (VL) represents the maximum amount of gas that can be sorbed onto the given sample at infinite pressure. When pressure equals the Langmuir pressure constant (PL), gas content is equal to half of VL. Thus, the Langmuir pressure constant represents the half-saturation pressure, i.e. the pressure at which the coal holds one-half the maximum gas volume. Langmuir pressure and volume were determined for all coal samples as shown in Table 6. Langmuir volumes of CO2 and CH4 sorption were 11.11–20.53 and 9.5–13.29 cc/g at pressures 1.52–2.9 and 3.59–5.32 MPa, respectively, at 27 °C. The Langmuir pressure and volume are important to determine the saturation level as well as critical desorption pressure in initial reservoir conditions.

Effect of moisture content on sorption capacity of coal

The moisture content of coal at varying depths was correlated with CO2 as well as CH4 sorption capacity and an increasing trend of gas sorption capacity with a decrease in moisture content was observed. Linear correlation with R2 of 0.81 and 0.84 was observed between sorption capacity and moisture content reflecting a strong influence of moisture content on gas sorption capacity of coal (Fig. 8a, b). Increase in gas sorption capacity with loss of moisture content is due to increases in porosity and gas sorption site in coal. The moisture in coal occupies more sorption sites and restricts the sorption of gas. Presence of moisture in coal is also responsible for matrix shrinkage and decrease in gas sorption capacity. The reduction in moisture content in coal facilitates more sorption site by producing more micro-pores and porosity in coal matrix.

Effect of ash content on sorption capacity of coal

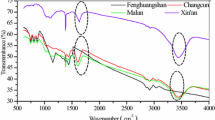

Results obtained in experimentation reflect the reduced sorption capacity of both CO2 as well as CH4 with enrichment of ash content in coal. Linear correlation with R2 of 0.93 and 0.97 was obtained between excess sorption amount and ash content reflecting the strong correlations between them (Fig. 9a, b). Decrease in gas sorption capacity of coal with ash content is attributed to the infilling and blockage of pores, cleats and fracture system with inherent and extraneous mineral matter such as clays and carbonates in coal. The infilling of the pores is also indicated in the FESEM image shown in Fig. 10.

Effect of fixed carbon (daf basis) on sorption capacity of coal

Experimentally obtained sorption isotherm of both CO2, as well as CH4, was correlated with fixed carbon (daf basis) of coal samples (Fig. 11a, b). Linear and positive correlation with R2 0.90 and 0.95 was obtained with CO2 as well as CH4 excess sorption capacity, respectively, reflecting strong influence of fixed carbon on sorption capacity of coal. Increased sorption capacity was observed with fixed carbon (daf basis). Increase in fixed carbon develops more micro- as well as meso-pores and facilitates gas sorption site in coal matrix (Ali et al. 2018).

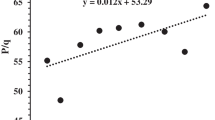

Effect of vitrinite reflectance on sorption capacity of coal

The correlation was established with excess CO2 as well as CH4 sorption amount of coal and percentage of calculated vitrinite reflectance of coal (Fig 12a, b). Linear and positive correlation with R2 0.90 and 0.93 was obtained with CO2 as well as CH4 excess sorption capacity, respectively, reflecting strong influence of vitrinite reflectance on sorption capacity of coal. Increased sorption capacity was observed with vitrinite reflectance. It is attributed to increase in porosity, pore size distribution, and specific pore surface area with increase in vitrinite reflectance of coal (19, Suman and Harpalani 2019; Ali et al. 2018). The vitrinite reflectance value of the coal in study area indicates medium-ranking coal (medium-volatile bituminous coal) which is favourable for meso- and macro-pores. These pores are favourable to sorption, diffusion, and migration of coal bed methane as well as injection of CO2 in coal matrix.

Thus, from the above investigation, it was observed that the depth of occurrence, molecular size of gases, affinity of gas towards coal, density, porosity, coal rank, etc. are the major controlling factors for the adsorption capacity of the coal.

Conclusion

The following conclusion is drawn from the observation of coal under investigation at Jharia coalfield (Moonidih area).

-

Coal of study area was found in between medium and low volatile bituminous rank.

-

Maximum sorption capacity of coal was observed to be 20.53 cc/g for CO2 and 13.29 cc/g for CH4 at 580 m depth.

-

Carbon dioxide sorption capacity of coal was observed to be higher than that of the methane due to the higher density of CO2 and its interaction with coal than that with CH4. It is also due to variation in molecular diameter of CO2 (0.33 nm) than CH4 (0.38 nm).

-

Monolayer as well as multilayer sorption of gas was exhibited by the coal samples at variable depths of occurence.

-

Increase in gas sorption capacity was observed with fixed carbon, vitrinite reflectance and decrease in ash content and moisture content, respectively.

References

Ali K, Richard S, Grigore M, Sokolova A (2018) Gas sorption capacity, gas sorption rates and nanoporosity in coals. Int J Coal Geol 200:77–86

Buscha A, Gensterblumb Y (2011) CBM and CO2-ECBM related sorption processes in coal: a review. Int J Coal Geol 87:49–71

Chandra K (1950) Alternative hydrocarbon resources in the next millennium. Geohorizons 2:1–12

Chen KC, Irawan S, Sum CW, Tunio SQ (2011) Preliminary study on gas storage capacity and gas-in-place for CBM potential in Balingian coalfield: Sarawak Malaysia. Int J Appl Sci Technol 1:82–94

Daniel RJK, Bustin M, R (2007) Impact of mass balance calculations on adsorption capacities in microporous shale gas reservoirs. Fuel 86:2696–2706

Deng H, Tang D, Liu S, Xu H, Tao S (2015) Characterization of mineral composition and its influence on microstructure and sorption capacity of coal. J Nat Gas Sci Eng 25:46–57

Diessel CFK (1992) Coal-bearing depositional systems. Springer, Berlin, p 721

Garnier C, Finqueneisel G, Zimny T, Pokryszka Z, Lafortune S, Defossez PDC, Gaucher EC (2011) Selection of coals of different maturities for CO2 storage by modelling of CH4 and CO2 adsorption isotherms. Int J Coal Geol 87:80–86

Gensterblum Y, Hemert PV, Billemont P, Battistutta E, Busch A, Krooss BM, Weireld GD, Wolf KHAA (2010) European inter-laboratory comparison of high pressure CO2 sorption isotherms II: natural coals. Int J Coal Geol 84:115–124

Ghosh S, Jha P, Vidyarthi AS (2014) Unraveling the microbial interactions in coal organic fermentation for generation of methane—a classical to metagenomics approach. Int J Coal Geol 125:36–44

Gruszkiewicz MS, Naney MT, Blencoe JG, Cole DR, Pashin JC, Carroll RE (2009) Adsorption kinetics of CO2, CH4, and their equimolar mixture on coal from the Black Warrior Basin, West-Central Alabama. Int J Coal Geol 77:23–33

Guo HX (2003) Applied chemical engineering kinetics, vol 16. Chem Ind Press, Beijing, pp 12–18

Hernandez GA, Bello RO, Vay DAM (2006) Evaluation of the technical and economic feasibility of CO2 sequestration and enhanced coalbed-methane recovery in Texas low-rank coals. In: Proceedings of the SPE Gas technology symposium. Mature fields to new frontiers. 515–530

Ishaq UM, Bijaksana S, Nurhandoko BEB (2009) Porosity and fracture pattern of coal as CBM reservoir. In: Proceedings of the 3rd Asian physics symposium (APS 2009)

Kim HJ, Shi Y, He J, Lee HH, Lee CH (2011) Adsorption characteristics of CO2 and CH4 on dry and wet coal from subcritical to supercritical conditions. Chem Eng J 171:45–53

Maphala T (2012) Effects of carbon dioxide storage in coal on the physical 1 and chemical properties of coal. In: Ph.D thesis submitted in Faculty of Engineering and the Built Environment. University of the Witwatersrand. Johannesburg

Mares ET, Radliński AP, Moore TA, Cookson D, Ilavsky TPJ, Klepp J (2009) Assessing the potential for CO2 adsorption in a subbituminous coal, Huntly Coalfield, New Zealand, using small angle scattering techniques. Int J Coal Geol 77:54–68

Pagnier HJM, Bergen FV, Kreft E, Meer LGH, Simmelink HJ (2005) Field experiment of ECBM-CO2 in the upper Silesian Basin of Poland (RECOPOL). In: Proceedings of the 67th European Association of Geoscientists and Engineers. EAGE conference and exhibition. 3013–3015

Prusty BK (2008) Sorption of methane and CO2 for enhanced coal bed methane recovery and carbon dioxide sequestration. J Nat Gas Chem 17:29–39

Rice DD (1993) Composition and origins of coalbed gas. Am Assoc Pet Geol Stud Geol 38:159–184

Robertson PE (2010) Enhanced coal bed methane recovery and CO2 sequestration in the Powder River Basin. Idaho National Laboratory Idaho Falls, Idaho

Saghaf A (2010) Potential for ECBM and CO2 storage in mixed gas Australian coals. Int J Coal Geol 82:240–251

Saikia K, Sarkar BC (2013) Coal exploration modelling using geostatistics in Jharia coalfield: India. Int J Coal Geol 112:36–52

Seidle JP (2000) Reservoir engineering aspects of CO2 sequestration in coals. In: Proceedings of the SPE/CERI Gas technology symposium. Alberta. Canada

Shi JQ, Durucan S (2005) CO2 storage in deep unminable coal seams. Oil Gas Sci Technol 60:547–558

Song Y, Xing W, Zhang Y, Jian W, Liu Z, Liu S (2015) Adsorption isotherms and kinetics of carbon dioxide on Chinese dry coal over a wide pressure range. Int J Adsorpt 21:53–65

Sripada P, Khan MM, Ramasamy S, Trivedi J, Gupta R (2018) Influence of coal properties on the CO2 adsorption capacity of coal gasification residues. Energy Sci Eng 6:321–335

Stevens SH, Spector D, Riemer P (1998) Enhanced coalbed methane recovery using CO2 injection. Worldwide resource and CO2 sequestration potential. In: Proceedings of the 6th international oil & gas conference and exhibition in China (IOGCEC ‘98), pp 489–501

Suman S, Harpalani S (2019) Anisotropy of coal at various scales and its variation with sorption. Int J Coal Geol 201:14–25

Vishal V, Ranjith P, Singh T (2015) An experimental investigation on behaviour of coal under fluid saturation, using acoustic emission. J Nat Gas Sci Eng 22:428–436

Wang Z, Li Y, Liu H, Zeng F, Guo P, Jiang W (2017) Study on the adsorption, diffusion and permeation selectivity of shale gas in organics. Energies 10:142

Zhang L, Ren TX, Aziz N (2013) A study of laboratory testing and calculation methods for coal sorption isotherms. J Coal Sci Eng 19:193–202

UGI Energy Ministry of Power, Central Electricity Authority New Delhi 2017: Coal and Gas Power. 1–52

International Energy Agency (IEA analysis of gas market report): market analysis and forecasts 2014. 1–20

Acknowledgements

The authors acknowledge the financial assistance provided by SERB, DST, vide Approval no: SB/S4/ES-697/2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kumar, H., Mishra, M.K. & Mishra, S. Sorption capacity of Indian coal and its variation with rank parameters. J Petrol Explor Prod Technol 9, 2175–2184 (2019). https://doi.org/10.1007/s13202-019-0621-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-0621-1