Abstract

The productivity of shale gas well is often with high uncertainty because of the uncertainties in the characterization of formation properties, fracture properties, gas adsorption, and flow mechanisms. This paper provides an efficient method to probabilistically forecast shale gas production by combining the Markov chain Monte Carlo method (MCMC) and a semi-analytical model. A trilinear flow model is used to predict shale gas production with the consideration of gas desorption and multiple flow mechanisms. The parameters in the model are sampled with the MCMC. A workflow is proposed to predict the gas production and characterize the uncertainties. To make the study results helpful for the field use, a field case from a shale gas field in Southwestern China is applied in the analysis. In this case, we chose ten uncertain parameters to study their effects on eventual ultimate recoveries. Shale gas production is shown to be closely related to the properties of formation, fracture, and flow mechanisms. The fracture half-length and BHP have strong effects on gas production, particularly the production within 5 years. BHP also influences the production after 5 years because of the gas PVT properties and gas adsorption. The results also show that enough iteration number is needed to get a reasonable uncertainty quantification. The sensitivity analysis shows that at least 2000 iterations are required for this case. After that, the probable production could be predicted with a range rather than only one value, and P10, P50, and P90 can be obtained. For the case studied in this paper, there is 90% probability that the EUR for a well is ranging from 0.62 × 108 to 1.48 × 108 m3.

Similar content being viewed by others

Introduction

Shale gas resource has been commercially exploited in North America and China as the development of the multiple fractured horizontal well technology (Shar et al. 2017). The productivity of each horizontal well behaves differently depending on the formation properties, the stimulation results and controlling BHP. At present, many models, including empirical, analytical, semi-analytical, and numerical models, have been proposed to predict the eventual ultimate recovery (EUR) for each shale gas well. However, reservoir characterization for shale gas reservoirs often involves various uncertainties that should be carefully incorporated. The native permeability of a shale gas reservoir covers a wide range (US EIA 2013; Zou et al. 2015). Shale formations are rich of much organic matter, which provides an efficient place for gas adsorptions in the shale matrix (Ogiesoba and Hammes 2014). By far, several methods, like molecular simulation, analytical modeling, and associated experimental tests (Huang et al. 2018a, b, c; Li et al. 2018; Xianggang et al. 2018), have shown that the desorption mechanisms are rather complex in the formation for the supercritical condition. Moreover, the flow complexity through nanoscale pore throats makes an accurate measurement of permeability challenging (Javadpour 2009; Swami and Settari 2012; Sakhaee-Pour and Bryant 2012). Many other researchers also presented several models to evaluate flow in both macro- and nano-porous media in different conditions (Wu et al. 2015; Mozaffari et al. 2015, 2017; Darjani et al. 2017; Sun et al. 2017; Huang et al. 2018a). In addition, the formation properties are heterogeneous such as porosity, gas content, thickness and pressure, etc. On the other hand, fracture properties are with high uncertainty such as fracture length and fracture conductivity, which are difficult to measure. Many comprehensive models have been proposed to model the flow behavior in the complex fracture networks (Guo et al. 2015; Jia et al. 2016, 2018; Cheng et al. 2017; Zhang et al. 2017a, b; Wu et al. 2018), but the fracture heterogeneity characterization and assisted uncertainty quantification have been the major problem (Tang et al. 2017).

Quantifying the uncertainty in EUR prediction is of high significance. In addition, two methods have been proposed to probabilistically forecast the EUR of shale gas wells. The first method is using empirical models (Gong et al. 2014), and the parameters such as initial decline rate, decline exponent, and initial gas rate are sampled with MCMC. The second method is using numerical simulators in history matching (Panja and Deo 2016; Wantawin et al. 2017; Chai et al. 2018). However, there are some drawbacks in present uncertainty quantification methods. The prior distributions of the parameters in empirical models are difficult to obtain, because the present production history of shale gas wells which are relatively short and many wells is under constant rate control mode in the first several years. In addition, numerical simulations are time-consuming and too many parameters are required in simulation runs. Moreover, proxy models do not always converge and the predictions are often with much error. Alternative to the time-consuming numerical models, many semi-analytical and analytical models have been proposed, and they are very practical and efficient in transient analysis and production prediction (Brown et al. 2009; Bahrami et al. 2016; Wu et al. 2016; Zhang et al. 2017a, b; Huang et al. 2018b; Xue et al. 2018). However, there are few works done to probabilistically predict the EUR by combining analytical and semi-analytical models with MCMC.

In our previous research, we proposed a semi-analytical trilinear flow model for production prediction from shale gas reservoirs (Wu et al. 2016). Gas desorption from shale matrix and nonlinear flow mechanisms of shale gas is considered in the model. Therefore, we mainly analyzed the uncertainty and distribution of parameters in the model at first. Then, we introduced the MCMC methodology and proposed a workflow for uncertainty quantification in production forecasts. At last, a field example is used to show its utility.

Methodology

Physical model

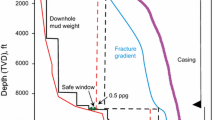

For multiple stages fractured shale gas reservoirs, a stimulated reservoir volume (SRV) is formed around the horizontal well, which is comprised of many induced fractures and hydraulic fractures. However, fracture parameters such as the orientation, length, position, and conductivity of each induced fracture could not be measured or interpreted from microseismic data. Therefore, the trilinear flow model is often used to characterize and model fracture tight and shale reservoirs. As shown in Fig. 1, the reservoir is comprised of three zones including the SRV, hydraulic fractures, and the reservoir beyond the hydraulic fractures (outer reservoir). The hydraulic fracture at each stage is assumed as biwing transverse fracture, and it is assumed to be with finite conductivity. The assumptions of the model are as follows:

-

(1)

The hydraulic fractures are assumed to be with the same length and perpendicular to the horizontal wellbore.

-

(2)

The length of the SRV is assumed to be equal to the half-length of hydraulic fractures.

-

(3)

The horizontal wellbore is assumed to be with infinite conductivity.

-

(4)

Gravity effect is neglected, and gas flow in each zone is assumed to be linear. Gas in the outer reservoir linearly flows into the inner zone, gas in the inner reservoir is assumed to linearly flow into the hydraulic fracture, and then linearly flow into the wellbore.

-

(5)

The reservoir is assumed to be with a constant thickness, and the temperature is assumed to be constant in the reservoir. If the temperature variation is addressed, there should be much more uncertainty in the production, because the gas PVT properties, the adsorption volume, and the flow mechanisms are all temperature dependent.

Mathematical model

In addition to the fracture networks created by multiple stage fracturing, shale reservoirs are normally regarded as self-sourcing reservoirs and the shale matrix is typically observed with very low permeability and rich of organic matter with much gas adsorption (Xu et al. 2013). The diameter of most pores of shale matrix is believed to range from 1 to 200 nm (Loucks et al. 2009; Honarpour et al. 2012). Gas flow in these nanopores is very complex, and it has been a hotpot previously. Many apparent permeability models have been proposed to characterize fluid transport in shale matrix (Javadpour 2009; Swami and Settari 2012; Wu et al. 2015). Therefore, production prediction models should consider gas desorption from the shale matrix and the complex flow mechanisms. In our previous work, we presented a trilinear flow model for production prediction for shale gas wells (Wu et al. 2016), gas desorption and flow mechanisms are considered in the model, and the model is solved semi-analytically to capture the nonlinearity of the equations. Therefore, the solution of the model is directly given in this paper.

The solution of the dimensionless rate in Laplace domain at constant BHP is given by

where \(f\left(s\right)\) is defined as

where \({q_{\text{D}}}\) is the dimensionless production rate, \({y_{{\text{FD}}}}\) is the dimensionless fracture length, \({y_{{\text{eD}}}}\) is the dimensionless outer zone region, \({\lambda _{{\text{IF}}}}\) is the interporosity flow coefficient between the inner zone and the fracture, \({\lambda _{{\text{Io}}}}\) is the interporosity flow coefficient between the inner zone and outer zone, \({\eta _{\text{D}}}\) is the diffusivity ratio, \(\omega\) is the storativity ratio, and \(s\) is the Laplace const. All the parameters are dimensionless, and the definitions are the same as our previous work (Wu et al. 2016).

Although the adsorption mechanisms are rather complex, the Langmuir isotherm is still widely used in practical (Yan et al. 2016; Hao et al. 2018). This is because the equation form is quite simple and it is rather efficient in matching experiment data. In this paper, this model is also used. If other isotherms are applied, we just need to change a form to calculate the adsorption volume instead of Eq. (4):

where \(V\) is the adsorbed gas volume, m3; \({V_{\text{L}}}\) is the Langmuir volume, m3; \({p_{\text{L}}}\)is the Langmuir pressure, MPa; and \({p_{\text{m}}}\) is the pressure in the matrix, MPa.

In this paper, we adopt the model proposed by Javadpour (2009) and Swami and Settari (2012) to model shale gas transport in the shale matrix:

where \({k_{{\text{app}}}}\) is the apparent permeability, mD; \({C_{\text{g}}}\) is the gas compressibility, MPa−1; \(D\) is the diffusion coefficient, 10− 15 m2/s; \(\mu\) is gas viscosity, mPa.s; \({k_{\text{D}}}\) is Darcy permeability, mD; \(R\) is gas constant, R = 8.314 J/mol/K; \(T\) is formation temperature, K; \(M\) is gas molar mass, kg/kmol; \({p_{{\text{avg}}}}\) is the average pressure, MPa; and \(\alpha\) is a tangential momentum accommodation coefficient, dimensionless. \({r_n}\) is the average hydraulic radius of the flow pipe, and it is defined as

Uncertainty analysis of model parameters

The semi-analytical model is used to predict shale gas production. However, many parameters cannot be determined for the reservoir; for example, we could obtain the properties of formation from core data and well logging, but this information just stands for a certain point rather than the whole reservoir. On the other hand, the SRV properties such as the fracture length, fracture conductivity and SRV permeability are often unknown. Therefore, many parameters are with uncertainty, which causes the uncertainty in the prediction of shale gas production and EUR. In this section, the model parameters are analyzed, including fracture parameters, formation parameters, and parameters about gas desorption and flow mechanisms.

Fracture parameters

In the model, the fractures are assumed to be vertical and are uniformly placed along the horizontal well. The fracture height is the same as the reservoir height. The width of the SRV is altered depending on the fracture spacing, which is calculated with the length of the horizontal well and numbers of fracture stages. Fracture width, fracture orientation, and fracture porosity remain constant. Fracture permeability and length are altered in the runs. The induced fractures and natural fractures are modeled with the enhancement of matrix permeability. Therefore, the width, length, and permeability of the SRV are altered in this study.

Formation parameters

The reservoir properties, namely, matrix permeability, initial reservoir pressure, and formation thickness, are varied. The reservoir temperature is given a constant value. In this study, the data are obtained from the published paper by Zou et al. (2015), which is gathered from several shale gas field in southwestern China. Because the permeability of the shale matrix from different shale gas fields is tested with different apparatus, some cores are even affected by micro-fractures, and many test results are not reliable. In this paper, we used the results of Changning field and Weiyuan field as suggested by Zou et al. (2015). The matrix permeability altered from 4 × 10−5 to 3 × 10−4 mD. For other shale gas reservoirs with different organic matter contents and pore size distributions, the desorption and flow mechanisms may not be the same, but this method could also be used to predict the production and associated uncertainty by changing formulations to calculate adsorption gas content and apparent permeability.

Parameters about gas adsorption and flow mechanisms

From the results presented by Zou et al. (2015), the initial adsorbed gas content varies from well to well, and the gas content would increase with the depth in the shale formation. On the other hand, the total organic content in the formation also varies a lot, so the adsorption isotherm varies from well to well. Moreover, the average pore diameter is different in a different formation, so parameters associated with gas flow mechanisms are different in different positions of the reservoir. Therefore, in this paper, we altered the parameters of gas adsorption and flow mechanisms.

Uncertainty quantification using MCMC

MCMC methods are a class of algorithms for sampling from probability distributions by constructing a Markov chain that has the desired posterior distribution. The stabilized state of the chain after a large number of steps is then used as an approximation of the desired distribution. The detail of this method is presented by Gong et al. (2014); here, we briefly introduced this method.

The Metropolis algorithm is often used for MCMC sampling for the cases that the posterior distribution is unknown. The overall workflow for MCMC by use the metropolis algorithm is as follows.

Step 1: Choose an initial value for each parameter; in this study, the median values are used.

Step 2: Generate a sample proposal from the proposal distribution for each parameter.

Step 3: Calculate acceptance ratio by use of Eq. (8).

Step 4: Generate a random number between zero and unity, if the random number is less than the acceptance ratio, accept the proposal. Otherwise, use the previous sample.

Step 5: If the maximum iteration is not reached, go to Step 2:

in which \({\theta _{\text{p}}}\) represents a proposed parameter vector; \({\theta _{s - 1}}\) represents the previously accepted parameter vector; \(y\) represents the historical production data; \(\pi\) is the likelihood function; \(p\) is the probability that a proposal is accepted; and \(q\) is the proposal density function of parameters.

The MCMC methodology is applied to the unknown parameters in the semi-analytical model. The performance of each sample is forecasted with the semi-analytical model. And then, we analyzed the posterior distribution of the ultimate shale gas recovery. We now illustrate the detailed workflow, as shown in Fig. 2. First, we assumed that the prior distribution of the parameters of fractures, formation, fluid desorption, and flow mechanism is independent. In this paper, the range and distribution of some parameters are shown in Tables 1 and 2. Second, MCMC is used for sampling from each prior distribution of the uncertain parameters, and the acceptance ratio is calculated for each proposed sample. Third, the semi-analytical model is used to simulate the production performance, and the ultimate shale gas reserve is obtained for each sample. Finally, when the preset maximum iteration is reached, the posterior distribution of the EUR can be obtained, and P90, P50, and P10 production forecasts can be calculated.

Results and discussion

Forecast and sensitivity analysis of production outputs

In this paper, the semi-analytical model is used for production performance forecast and ultimate recovery. It can be used efficiently as forecast and sensitivity analysis tools. Because there are several uncertain parameters in the model, as shown in Table 2, to show the effect of a certain parameter on the forecast, we just analyzed the fracture half-length and BHP on production performance. For the input parameters shown in Table 2, the forecast and the sensitivity analysis of the shale gas recovery are illustrated in Fig. 3. We could find that the fracture half-length has a strong effect on gas production. The cumulative production in 20 years seems to linearly increase with the increase of fracture half-length. This is because the fracture half-length determines the whole volume of SRV, which dominates the control volume of the wellbore when the permeability of the outer unstimulated reservoir is very low. In addition, we could also find that BHP also has a significant influence on production. We could also find that the cumulative production discrepancy among different fracture half-lengths is almost the same when the production time is larger than 5 years, while the discrepancy among different BHPs would be larger and larger with the increase of time. This is because the gas compressibility change at low pressures is larger than high pressures. Besides, the gas adsorption content declines faster at low pressures.

Sensitivity analysis of the number of iterations

As shown before, the Markov chain would converge to posterior distribution, and several iterations are used. Before uncertainty quantification for synthetic and field cases, we have to make sure how many iterations should be needed. If too many iterations are used, it would be time-consuming, and it would not converge if few iterations are used.

To find out how many iterations are required to generate small errors, seven simulations were run with MCMC iteration numbers ranging from 100 to 20,000 for a shale gas well with 20 year production. We calculated the cumulative distribution function (CDF) of the cumulative gas production for the well. As shown in Fig. 4a, the CDF is not stable and smooth if the iteration number is not small, but the distributions will converge to a single line, as the number of iterations is increased. Besides, we could also find this from the relative error curve in Fig. 4b, in which the result obtained from 100,000 iterations is assumed to be the actual value to calculate the relative error. The relative error would decline shapely as the increase of iteration number when the iterations are below 2000 times, and the curve flats when the iterations are above 2000 times. Therefore, 2000 iterations are enough for this case if the relative error is set to 5%, as shown in Fig. 4b. It should be noted that the CDF and relative error curves may not be the same with the same iterations, because the MCMC algorithm is applied, but the trend of the results would not change.

Uncertainty quantification

We further used this method to quantify the uncertainty of gas production. Uncertainties in EUR for the shale gas well after 20 years of production are shown in Fig. 5. The most probable EUR for a single shale gas well is approximately 0.88 × 108 m3 after 20 years of production, and the EUR is quite close to the result obtained by rate transient analysis in our previous work (Wu et al. 2016), which shows that 0.89 × 108 m3 shale gas could be produced from a well after 15 years. After 20 year production, the EUR of the analyzed well is supposed to be around 1.0 × 108 m3. Therefore, the EUR spreads over a reasonable range in the probability distribution function (PDF) plot. This is because the studied parameters in the model, as shown in Table 2, are given rational ranges. It should be noted that reasonable parameter ranges are significantly important to obtain a reasonable EUR estimation and uncertainty quantification. The results obtained with invalid parameters is useless in practice. The range of 5–95% in the PDF covers 0.62–1.48 × 108 m3 gas production. This means that there is 90% probability the production is within this region. P90, P50, and P10 could be calculated, and they are 0.70, 0.97 and 1.31 × 108 m3, respectively. It is interesting to find that the most probable EUR is quite different from the P50, and this is because the distribution of EUR is not symmetrical using the asymmetrical distributions, as shown in Table 2. This also shows the importance of reasonable distributions of model parameters on the final results.

Conclusions

Shale gas production is closely related to the properties of formation, fracture, and flow mechanisms. The fracture half-length and BHP have strong effects on gas production, particularly the production within 5 years. BHP also influences the production after 5 years because of the gas PVT properties and gas adsorption. Uncertainty quantification in production forecasts is of significance because of the uncertainty in these properties.

It is an efficient method to combine analytical and semi-analytical methods with MCMC to probabilistically predict the production and EUR of shale gas wells. The number of iterations in MCMC sampling is quite important in uncertainty quantification, and there is a compromise between relative error and computation time. The minimum numbers of iterations needed for MCMC uncertainty quantification could be predicted by analyzing the relative error with different iterations. The relative error would decline shapely as the increase of iteration number and then flats. For the case studied in this paper, 2000 iterations are enough.

In addition, reasonable range and distribution of the parameters in the model are required to guarantee a rational posterior distribution of EUR. The most probable production, P10, P50, and P90, can be obtained after the posterior distribution is calculated. For the case studied in this paper, there is 90% probability that the EUR range is 0.62–1.48 × 108 m3. The P90, P50, and P10 are 0.70, 0.97, and 1.31 × 108 m3, respectively.

References

Bahrami N, Pena D, Lusted I (2016) Well test, rate transient analysis and reservoir simulation for characterizing multi-fractured unconventional oil and gas reservoirs. J Pet Explor Prod Technol 6(4):675–689

Brown ML, Ozkan E, Raghavan RS, Kazemi H (2009) Practical solutions for pressure-transient responses of fractured horizontal wells in unconventional shale reservoirs. SPE Reserv Eval Eng 14(6):663–676

Chai Z, Tang H, He Y, Killough J, Wang Y (2018) Uncertainty quantification of the fracture network with a novel fractured reservoir forward model. In: Presented at the SPE annual technical conference and exhibition, 24–26 September, Dallas, Texas, USA

Cheng L, Fang S, Wu Y, Lu X, Liu H (2017) A hybrid semi-analytical model for production from heterogeneous tight oil reservoirs with fractured horizontal well. J Pet Sci Eng 157:588–603

Darjani S, Koplik J, Pauchard V (2017) Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the Gibbs adsorption isotherm. Phys Rev E 96(5):052803

Gong X, Gonzalez R, Mcvay DA, Hart JD (2014) Bayesian probabilistic decline-curve analysis reliably quantifies uncertainty in shale-well-production forecasts. SPE J 19(6):1047–1057

Guo C, Xu J, Wei M, Jiang R (2015) Pressure transient and rate decline analysis for hydraulic fractured vertical wells with finite conductivity in shale gas reservoirs. J Pet Explor Prod Technol 5(4):435–443

Hao Y, Wang W, Yuan B, Su Y, An J, Shu H (2018) Shale gas simulation considering natural fractures, gas desorption, and slippage flow effects using conventional modified model. J Pet Explor Prod Technol 8(2):607–615

Honarpour MM (2012) Characterization of critical fluid PVT, rock, and rock-fluid properties—impact on reservoir performance of liquid rich shales. In: Paper presented at the SPE annual technical conference and exhibition, San Antonio, Texas, USA, October 8–10

Huang S, Wu Y, Cheng L, Liu H, Xue Y, Ding G (2018a) Apparent permeability model for shale gas reservoirs considering multiple transport mechanisms. Geofluids 2018:1–18

Huang S, Ding G, Wu Y, Huang H, Lan X, Zhang J (2018b) A semi-analytical model to evaluate productivity of shale gas wells with complex fracture networks. J Nat Gas Sci Eng 50:374–383

Huang L, Ning Z, Wang Q, Qi R, Zeng Y, Qin H, Zhang W (2018c) Molecular simulation of adsorption behaviors of methane, carbon dioxide and their mixtures on kerogen: effect of kerogen maturity and moisture content. Fuel 211:159–172

Javadpour F (2009) Nanopores and apparent permeability of gas flow in mudrocks (shales and siltstone). J Can Pet Technol 48(8):16–21

Jia P, Cheng L, Huang S, Wu Y (2016) A semi-analytical model for the flow behavior of naturally fractured formations with multi-scale fracture networks. J Hydrol 537:208–220

Jia P, Cheng L, Clarkson CR, Huang S, Wu Y, Williams-Kovacs JD (2018) A novel method for interpreting water data during flowback and early-time production of multi-fractured horizontal wells in shale reservoirs. Int J Coal Geol 200:186–198

Li J, Chen Z, Wu K, Wang K, Luo J, Feng D, Li X (2018) A multi-site model to determine supercritical methane adsorption in energetically heterogeneous shales. Chem Eng J 349:438–455

Loucks RG, Reed RM, Ruppel SC, Jarvie DM (2009) Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian barnett shale. J Sediment Res 79(12):848–861

Mozaffari S, Tchoukov P, Atias J, Czarnecki J, Nazemifard N (2015) Effect of asphaltene aggregation on rheological properties of diluted athabasca bitumen. Energy Fuels 29(9):5595–5599

Mozaffari S, Tchoukov P, Mozaffari A, Atias J, Czarnecki J, Nazemifard N (2017) Capillary driven flow in nanochannels—application to heavy oil rheology studies. Colloid Surf A 513:178–187

Ogiesoba O, Hammes U (2014) Seismic-attribute identification of brittle and TOC-rich zones within the Eagle Ford Shale, Dimmit County, South Texas. J Pet Explor Prod Technol 4(2):133–151

Panja P, Deo M (2016) Factors that control condensate production from shales: surrogate reservoir models and uncertainty analysis. SPE Reserv Eval Eng 19(01):130–141

Sakhaee-Pour A, Bryant S (2012) Gas permeability of shale. SPE Reserv Eval Eng 15(4):401–409

Shar AM, Mahesar AA, Memon KR (2017) Could shale gas meet energy deficit: its current status and future prospects. J Pet Explor Prod Technol 8:957–967

Sun Z, Li X, Shi J, Zhang T, Sun F (2017) Apparent permeability model for real gas transport through shale gas reservoirs considering water distribution characteristic. Int J Heat Mass Transf 115:1008–1019

Swami V, Settari A (2012) A pore scale gas flow model for shale gas reservoir. In: SPE Americas unconventional resources conference. Paper presented at the SPE Americas unconventional resources conference, Pittsburgh, Pennsylvania USA, June 5–7

Tang H, Killough JE, Heidari Z, Sun Z (2017) A new technique to characterize fracture density by use of neutron porosity logs enhanced by electrically transported contrast agents. SPE J 22(04):1–034

US Energy Information Administration (2013) Technically recoverable shale oil and shale gas resources: an assessment of 137 shale formation in 41 countries outside the United States. Washington, DC, June

Wantawin M, Yu W, Sepehrnoori K (2017) An iterative work flow for history matching by use of design of experiment, response-surface methodology, and markov chain monte carlo algorithm applied to tight oil reservoirs. SPE Reserv Eval Eng 20(3):613–626

Wu K, Li X, Wang C, Yu W, Chen Z (2015) Model for surface diffusion of adsorbed gas in nanopores of shale gas reservoirs. Ind Eng Chem Res 54:3225–3236

Wu Y, Cheng L, Huang S, Jia P, Zhang J, Lan X, Huang H (2016) A practical method for production data analysis from multistage fractured horizontal wells in shale gas reservoirs. Fuel 186:821–829

Wu Y, Cheng L, Huang S, Jia P, Fang S, Wang S, Xu B (2018) A semi-analytical model for simulating fluid flow in naturally fractured reservoirs with non-homogeneous vugs and fractures. In: Presented at the offshore technology conference Asia, 20–23 March, Kuala Lumpur, Malaysia

Xianggang D, Zhiming H, Shusheng G, Rui S, Huaxun L, Chang J, Lin WAN G (2018) Shale high pressure isothermal adsorption curve and the production dynamic experiments of gas well. Pet Explor Dev 45(1):127–135

Xu B, Haghighi M, Li X, Cooke D (2013) Development of new type curves for production analysis in naturally fractured shale gas/tight gas reservoirs. J Pet Sci Eng 105(1):15–21

Xue Y, Wu Y, Cheng L, Huang S, Ai S, Yang Y (2018) An analytical model for multiple fractured shale gas wells considering fracture networks and dynamic gas properties. Arab J Geosci 11(18):551

Yan B, Wang Y, Killough JE (2016) Beyond dual-porosity modeling for the simulation of complex flow mechanisms in shale reservoirs. Comput Geosci 20(1):69–91

Zhang Q, Su Y, Zhang M, Wang W (2017a) A multi-linear flow model for multistage fractured horizontal wells in shale reservoirs. J Pet Explor Prod Technol 7(3):747–758

Zhang W, Xu J, Jiang R (2017b) Production forecast of fractured shale gas reservoir considering multi-scale gas flow. J Pet Explor Prod Technol 7(4):1071–1083

Zou C, Dong D, Wang Y, Li X, Huang J, Wang S, Guan Q, Zhang C, Wang H, Liu H et al (2015) Shale gas in china: characteristics, challenges and prospects (ii). Pet Explor Dev 43(2):182–196

Acknowledgements

The authors acknowledge that this study was partially funded by the Science and Technology Project of CNOOC China Limited (No. YXKY-2016-ZY-03) and the National Science and Technology Major Project (No. 2017ZX05037001). We also thank the National Natural Science Fund of China (No. U1762210 and 51574258) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Xu, B., Wu, Y., Cheng, L. et al. Uncertainty quantification in production forecast for shale gas well using a semi-analytical model. J Petrol Explor Prod Technol 9, 1963–1970 (2019). https://doi.org/10.1007/s13202-018-0598-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-018-0598-1