Abstract

Either pressure-transient analysis or rate-transient analysis can be interpreted by four methods: (1) conventional straight-line analysis, (2) type-curve matching procedure, (3) ACMM (automatic computer modeling matching), and (4) TDS (Tiab’s direct synthesis) technique. The first three methods have serious drawbacks and are commonly misused by engineers. It does not mean they are useless since they provide good results if used properly. For example, combination of (4), (1), and (3) are strongly recommended by the authors since type-curve matching are tedious and use trial-and-error procedures. ACMM is not only the most used method, but also the most risky methodology since the non-linear regression analysis used to match the pressure test with the model output leads to multiple solutions (none uniqueness of the solution). Moreover, some engineers employ it as an inverse problem when pretending to define the model by matching the data with any model. For those who do not know the way, any transportation means is good for. This is a very wrong alternative since engineers must choose the reservoir model and the ACMM helps to find out the solution. Type-curve matching is not only risky, but tedious and it fails to provide accurate results in short tests. Conventional analysis has no way of verification and some engineers confuse the flow regimes and draw the straight line on the wrong region leading to wrong interpretations. TDS technique may be the panacea to the above-mentioned problems since it uses direct analytical solutions with information coming from characteristic points found on the pressure and pressure derivative vs. time log–log plot on which the interpreter can better define flow regimes and verify results from different sources. In this paper we demonstrate the practicability and accuracy of TDS technique with some detailed examples and results are quite well. The intention of this paper is to encourage people the use of TDS technique and provide a state-of-the-art of it. Although not mentioned, TDS technique has been used by common well test interpretation software. The power of TDS is not only based upon the accuracy and capability verification, but also the possibility of artificially created non-existing flow regimes to further estimate/verify reservoir parameters. This means the best and only accurate option for short pressure test interpretations is TDS technique. Then, an engineer is welcome to use the output results with ACMM to obtain an accurate matching.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Transient test analysis has been used for more than 60 years as an accurate and cost-effective reservoir characterization tool. Gringarten (2008) presents a very detailed and outstanding work on the state-of-the-art in transient-pressure analysis. He implies there are two remarkable facts that have revolutionized well test interpretation: (1) introduce of pressure derivative in 1983 and (2) introduce of deconvolution for further penetration inside the reservoir.

Four methodologies are currently available for pressure/rate transient test interpretation. (1) Conventional straight-line analysis is the oldest one. It basically consists of plotting pressure against a given time function (t, log t, t0.25, t0.5, 1/t0.5, etc.) which depends upon the reservoir model. Then, the slope and intercept of such plot is used to find reservoir parameters. The main drawbacks of this method are the incapability to verify the estimated parameters and the definition of a given flow regime. The last disadvantage can be overcome with the aid of the pressure derivative curve. (2) Type-curve matching was introduced for a better definition of the flow regimes since these can be easily distinguish on the type curve. Its flaw rests on the fact it is basically a trial-and-error method. If the type curve is slightly displaced 1 mm an error of about 200 psi is introduced. Having more than one curve (such as pressure and pressure derivative) can reduce the risk of wrong matching. Additionally, there is no availability for such many type curves to completely characterize all the reservoirs. (3) Automatic computer modeling matching (ACMM) consists of matching the test data with a given mathematical model capable to reproduce the well and reservoir conditions. The variables are changed until the model fits with the actual pressure data. The process is automatically performed using non-linear regression analysis to approach an objective function finding a local minimum. Most engineers are not aware that this technique has a huge drawback related with the non-uniqueness of the solution. To overcome this, we suggest apply TDS technique to obtain reservoir parameters and used them as input values in the ACMM simulation. (4) TDS technique, the latest methodology introduced by Tiab (1993, 1995), which uses characteristic points and feature found on the pressure and pressure derivative vs. time log–log plot to obtain direct analytic expressions for reservoir parameters determination. In other words, the methodology takes separately any flow regime and obtains its governing equation. Since most of flow regimes obey a straight-line governing equation, these equations are intercepted to each other so reservoir parameters can be found from other sources for verification purpose.

Since the introduction of TDS technique in 1993, more than 100 technical articles have been introduced to the hydrocarbon literature to try to cover most of the reservoir models, well models, fluid types and scenarios for complete well test interpretation. Some recent studies focused on this technique have been summarized by Escobar (2008, 2012, 2015) and a fundamental book has been already accepted for publication in 2017 by Intech—Open Science Open Minds.

This paper presents a state-of-the-art on TDS technique which comprises from vertical wells, fractured wells, heavy oil, gas reservoirs, transient-rate analysis, reservoir average pressure estimation, horizontal wells, interference testing, fractal reservoirs, double-porosity reservoirs, double permeability reservoirs, fall-off testing and channelized systems. Additionally, TDS technique is the only accurate option for short well test interpretation. Therefore, three detailed and practical examples are worked out to demonstrate the practicability, accuracy and power of this novel and revolutionary technique which is also demonstrated in this work that TDS technique is currently used by most common commercial well test interpretation software.

State-of-the-art on TDS technique

TDS technique is a more practical technique since it only uses the pressure and pressure derivative curves and has specific equations for the different flow regimes. It also provides ways of verifying the obtain parameters and could be applied to non-existing flow regimes, meaning this, that a flow regime can be artificially “made-up” without incurring in an error. Examples are presented for fractured wells, a vertical well with missing radial flow regime, and a well in a homogeneous bounded reservoir when radial flow regime is missing.

TDS technique was born in the University of Oklahoma in the early nineties. The pioneer paper, (Tiab 1993), was presented in a SPE conference in Oklahoma City and, then, it was published in a reputed petroleum engineering journal, (Tiab 1995). This first case presented equations for pressure test interpretation for a vertical oil wells including wellbore storage and skin effects. Wellbore storage does not only depend on fluid density and annular size, but also has an indirect relationship with formation permeability which helps/avoids the change in fluid level inside the wellbore. Therefore, for vertical unfractured wells, (Tiab 1993, 1995) correlated skin factor, permeability and wellbore storage coefficient with the maximum point displayed during the transition period from wellbore-storage dominated flow to radial flow. This paper only characterized radial flow regime and wellbore storage. Later on, characterization of pseudosteady-state period was given by Tiab (1994) when providing TDS technique for infinite-conductivity fractured wells. Tiab et al. (1999b) and Tiab (2005) worked on finite-conductivity fractured wells. They combined the governing equations of linear, bilinear, birradial, and pseudosteady-state period to verify the estimations of half-fracture length and fracture conductivity. The elliptical or birradial flow model introduced by Tiab (1994) depends on well-drainage area which implies running the test long enough for a complete characterization. In reality, there is no need of such long test since the intersection point between the birradial and radial flow regime lines can be used to find half-fracture length. This situation, however, may not be easy to see by a novel TDS technique user. To overcome this issue, Escobar et al. (2014l) presented a new elliptical model free of area. In this work, they also complement the work of Tiab (1994, 2005) and Tiab et al. (1999b) to include naturally fractured reservoirs, following the work of Tiab and Bettam (2007), by incorporating a heterogeneity parameter, ξ, which is equals to the unity for homogeneous reservoir and equals to the storativity ratio for naturally fractured formations. Conventional analysis for this case was presented by Escobar et al. (2006). Escobar et al. (2016a, b, c) also provided TDS technique for fractured wells with face skin which involves the existence of pseudolinear flow regime. As far as, transient-rate analysis for fractured wells with the use of TDS technique is concerned, the reader can be referred to the work by Escobar et al. (2014d) and the papers published by Berumen et al. (1997, 2000) and Escobar et al. (2017) were focused on asymmetry hydraulic infinite-conductivity fractures and Tiab et al. (2010) worked the case of finite-conductivity fractures. Zhao et al. (2016) studied the behavior of composite reservoir drained by a vertical fractured gas well. A couple of works have concentrated their attention on geomechanical aspects. In this field we can name the work of Berumen and Tiab (1997) and Escobar et al. (2007a, f, 2018a, b). The last one concentrated on naturally-fractured reservoirs. Igbokoyi and Tiab (2008b, 2010) presented TDS technique for partially penetrating infinite conductivity fractures in naturally-fractured reservoirs. Zerzar et al. (2004) extended TDS technique for multiple hydraulically fractured horizontal wells.

Estimation of distance from vertical wells to multiple boundaries without type-curve matching was presented by Ispas and Tiab (1999) and Jongkittinarukorn and Tiab (1996a). Jongkittinarukorn and Tiab (1996b) and Al Rbeawi and Tiab (2011b) extended TDS technique for horizontal wells in closed-boundary systems and multi-boundary systems, respectively. Escobar et al. (2014j) studied pressure behavior in wedge and T-shaped reservoirs. Jongkittinarukorn et al. (1998) used the boundary element method to provide a TDS interpretation technique for horizontal wells in complex systems. They also study multilayer case and snake-shape horizontal wellbore behavior. Existence of hemispherical flow regime and its characterization is seen in horizontal wells with zonal isolations. The interpretation of such situation was given by Al Rbeawi and Tiab (2011a) using TDS technique and by Escobar et al. (2014k) using conventional analysis. Moncada et al. (2005) worked on partial completed and partial penetrated hydrocarbon vertical wells, so the characterization of both spherical and hemispherical flow regimes allowed finding several equations to estimate the tridimensional (spherical or hemispherical) permeability and spherical/hemispherical radius. They also found the limiting values of both wellbore storage coefficient and penetration ratio for masking the hemispherical/spherical flow regime. Slimani and Tiab (2005) worked on partial penetration vertical wells on naturally fractured formations. They studied the impact of the penetration ratio on the minimum point (trough) during the transition period from heterogeneous to homogeneous behavior and provided new expressions for the estimation of the interporosity flow parameter and the storativity ratio. Igbokoyi and Tiab (2007) performed an interesting study on naturally fractured reservoirs drained by a partially penetrated hydraulic fractured wells.

Another neat contribution falls on the characterization of elongated systems resulting from channels, deltaic deposition or faulting. Escobar et al. (2007d) classified the formation linear flow into two different types: single linear—also called hemilinear when a unique linear flow goes from the formation to the well, and dual linear—when there exist two flow regimes at both sides of the reservoir. In this work, they also included the parabolic flow regime which was further studied by Escobar et al. (2005). The effect of the geometric skin factor created by the convergence from radial to dual linear flow and from dual linear to hemilinear flow was treated by Escobar and Montealegre (2006). Escobar and Montealegre (2007a, b, c) also developed conventional analysis for elongated systems. Escobar et al. (2007g) included anisotropy effects on long systems, so if reservoir width is known, areal anisotropy can be determined without the need of running an interference test. A further research on elongated reservoirs was presented by Escobar et al. (2010e) to study the effect of changes in reservoir width or reservoir permeability. Extension of this case to conventional analysis was also presented by Escobar et al. (2009b). TDS technique for long heterogeneous reservoirs was presented by Escobar et al. (2010b). Determination of drainage area for constant-pressure systems requires a special manipulation since the reservoir geometry and well position determine the development of steady-state period. Escobar et al. (2010a) provided TDS technique and Escobar et al. (2015a) provided conventional analysis for these systems.

It is normally expected that the transition period during a pressure test run in a heterogeneous reservoir shows during radial flow regime. However, if the well is fractured the trough possibly shows up during bilinear or linear flow regimes, before radial flow, or after radial flow regime in elongated reservoirs. In transient-rate analysis is possible to see the trough on the pseudosteady-state period. Interpretation methodologies for these cases are given by Escobar et al. (2010d), and Tiab and Bettam (2007) for TDS technique and Escobar et al. (2009a) using conventional analysis.

Transient-rate analysis for elongated system in both homogeneous and naturally fractured systems was presented by Escobar et al. (2012g, h) with conventional analysis and TDS technique, respectively. The good point is that reservoir area, reservoir width, and well position can be estimated and verified successfully. In elongated systems is feasible to estimate four or five times the well-drainage area.

Moving to naturally fractured double-porosity single-permeability formations some works can be cited. The first work on this field was provided by Engler and Tiab (1996a) for vertical wells, Engler and Tiab (1996b) for horizontal wells in homogeneous reservoirs and Engler and Tiab (1996c) for horizontal wells in naturally fractured formations. TDS technique for dual-permeability naturally formations were presented by Escobar et al. (2012i) for vertical wells and Lu et al. (2009c, 2015) for horizontal wells. Transient-rate analysis and transient-pressure analysis via TDS technique in horizontal wells inside elongated systems was presented by Escobar et al. (2016b, c). They included the presence of hemilinear and parabolic flow regimes. As far as triple-porosity reservoirs is concerned, we can cited the works by Escobar et al. (2004b, 2014g) for triple-porosity single-permeability reservoirs, for triple-porosity dual-permeability reservoirs (Escobar et al. 2014c). It is worth to mention the works of Igbokoyi and Tiab (2008a) who provided a new methodology for naturally fractured reservoirs based upon the elliptical flow. Tiab et al. (2007a) presented a study for determining fracture porosity from pressure-transient data. They proved that when the total matrix compressibility and the total fracture compressibility are assumed to have the same value, the estimation of hydrocarbon reserves can be more hugely overestimated.

Methodologies concerning interference testing were given by Escobar et al. (2008c, 2018a, b) for vertical wells. Cherifi et al. (2002) for hydraulic fracture orientation in vertical wells, Houali and Tiab (2004) for horizontal wells in anisotropic reservoirs and Malekzadeh and Tiab (1991) for horizontal wells in isotropic reservoirs, and Ma and Tiab (1995) for vertical wells in naturally fractured reservoirs. Lu et al. (2009b) studied the pressure behavior of multiple wells in a closed cylindrical reservoir.

Besides the work of Engler and Tiab (1996b, c) on horizontal wells, some other developments have been included. Baba and Tiab (2001) considered the horizontal wellbore to be of finite-conductivity to develop and interpretation technique. Bettam et al. (2005) concentrated their efforts on horizontal wells with multiple fractures and Al Rbeawi and Tiab (2012, 2013) extended the work for inclined fractures. Dinh and Tiab (2009a, 2010) included inclined fractures in vertical wells. Chacon et al. (2004) introduced the TDS technique to find average reservoir pressure in both vertical and horizontal wells. They also provided new ways from estimating the Dietz shape factor. An excellent methodology for the average reservoir pressure determination in naturally fractured formation using multi-rate tests was presented by Molina et al. (2005). Escobar et al. (2007e) proposed a methodology to obtain average reservoir pressure without shutting-in the well by means of a multi-rate test. This procedure could be economical attractive since avoids running a long pressure buildup test which causes money loss from impeding the hydrocarbon production during the test. Escobar et al. (2011d) treated the model of a vertical fractured well for a horizontal well to find average reservoir pressure. Toufik et al. (2003) studied the effect of non-Uniform skin on finite-conductivity horizontal wells. Martinez et al. (2012) presented a new model for the elliptical flow regime. Since a new model was introduced, then, conventional analysis also needed to be implemented. Such are the works by Escobar and Montealegre (2007a, b, c, 2008a, b) for characterization of the elliptical flow.

Several works for extending the TDS technique to injections tests and variable injection cases have been introduced for both vertical and horizontal wells. As far as, vertical wells is concerned, the first one was introduced by Boussalem et al. (2002) to study the effect of the mobility ratio between the injected and resident crude oil. In the same year, Hachlaf et al. (2002) introduce TDS technique for variable injection and fall-off tests complementing the work of Jokhio et al. (2001b) on constant injection and fall-off tests with unity and variable mobility ratio. Mongi and Tiab (2000), Tiab et al. (1999c) and Hachlaf et al. (2002) extended TDS technique to multi-rate testing in vertical wells in homogeneous reservoirs. For heterogeneous reservoirs, the reader is referred to the work by Tiab and Boulenouar (2004). Khelifa et al. (2002) and Merzouk et al. (2002) worked on multi-rate testing on horizontal wells. A recent work by Wu et al. (2015) presented a model to find the leakage factor for a finite aquifer using fall-off tests in coalbed-methane reservoirs. They formulated a methodology to find the value of the leakage factor from more than one source. In a similar work, Escobar, Srivastav and Wu (2015h) are able to estimate reservoir permeability when radial flow is absent using the second pressure derivative. This work, however, was conducted obtaining the second derivative numerically. Anyhow, on field data, the pressure derivative is estimated numerically.

Of course, TDS technique has been involved for characterization of faults. Ispas and Tiab (1999) provided the formulation to estimate the distance to sealing fault and lateral boundaries. Escobar et al. (2003a) worked on a fault intersecting a finite-conductivity hydraulic fracture. Escobar et al. (2003b) characterized leaky boundaries. Escobar et al. (2013a) characterized finite-conductivity faults. They provided several ways to estimated fracture conductivity. Conductivity faults are more common than people believe. Escobar et al. (2013c) extended the work for finite-conductivity faults with mobility contrast at both sides of the fault. Bensadok and Tiab (2004) developed an interpretation technique, following the TDS philosophy, for two intersecting leaky faults. For leaky boundaries in heterogeneous reservoirs the interpretation TDS methodology has been given by Boussila et al. (2003).

Concerning enhanced oil recovery, TDS technique has focused on systems that have been subjected to thermal changes or injection of a non-Newtonian fluid such a gel or foam. In any case, a composite system is dealt with. The first work was presented by Escobar et al. (2011b) for interpretation of thermal recovery process in which reservoir temperature is different in two zones in the reservoir. For injection of a hot fluid the reader is referred to the work by Escobar et al. (2008a). Later on Escobar et al. (2012c) presented another work for a three region composite reservoir. In any of the two cases, distance to the thermal front and mobility ratios can be estimated by several sources.

As mentioned before, TDS technique has played an important role in non-Newtonian fluids. For the case of EOR, as just mentioned, there are two studies on the pressure behavior of injecting either a pseudoplastic fluid or dilatant fluid in the near wellbore region. The reservoir fluid is assumed to behave Newtonianly. Escobar et al. (2010c) and Martinez et al. (2011), for pseudoplastic and dilatant injected fluid, respectively. Katime-Meindl and Tiab (2001) presented for the first time the pressure derivative behavior of a pseudoplastic fluid, which is believed is observed by heavy oils. As the fluid becomes more non-Newtonian the pressure derivative during radial flow regime moves further away from flat behavior and becomes inclined as the flow index decreases. They provided TDS technique for homogeneous reservoirs in infinite and faulty systems. Escobar et al. (2012a) extended the interpretation for power-law flow in an infinite-conductivity fractured vertical well. Escobar et al. (2012f) worked on constant-pressure and closed reservoir providing a methodology to estimate drainage area. Escobar et al. (2011a, b, c, d) characterized non-Newtonian power-law behavior in double-porosity reservoirs. They provided several expressions to estimate the naturally fractured reservoir parameters. Conventional analysis for this case was presented by Escobar et al. (2013b). Escobar et al. (2012d) developed an interpretation technique for spherical power-law flow. It is worth to point out when the flow index takes the value of 0.5, the pressure derivative during radial flow is flat as for the case of Newtonian flow. Escobar et al. (2015e) included non-Newtonian behavior in fractal geometry reservoirs. Escobar et al. (2015c) presented a neat procedure to estimate naturally fractured parameters in fractal reservoirs. Escobar et al. (2013d) presented an interpretation methodology for fall-off testing analysis of non-Newtonian pseudoplastic fluids. The unique work on non-Newtonian Bingham fluids in horizontal wells was presented by Owayed and Tiab (2008). They showed an upward behavior of the pressure behavior as the fluid becomes more non-Newtonian. Still, pressure and pressure derivative keep their straight line, which is not the case of vertical wells as described by Martinez et al. (2011) using numerical simulation. They showed that the pressure derivative goes up and then down during radial flow regime forming a maximum point. This maximum increases as the fluid is more Bingham.

There are some fluid and permeability conditions which require a threshold pressure gradient for the fluid to start flowing. Lately, TDS technique has also been involved in this situation. Escobar et al. (2015b) and Zhao et al. (2015) studied the effect of threshold pressure gradient in fracture vertical wells and Escobar et al. (2014f) worked on horizontal wells. It is worth to notice that the radial flow regime is the only one affected for such condition. However, wellbore storage affects the presence of threshold pressure gradient as shown and worked by Escobar et al. (2015a, b, c, d, e, f, g, h) for vertical wells.

Needless to say there are several works on gas reservoirs. Nunez et al. (2003) presented TDS technique for finite-conductivity fractured in vertical wells. Escobar et al. (2007c) studied the impact of the pseudotime function on the estimation of reservoir area and provided TDS technique using rigorous time and pseudotime in closed gas reservoirs. Escobar et al. (2012e) also worked with pseudotime in vertical fractured wells and naturally-fractured formations. An analogous work on horizontal wells was presented by Escobar et al. (2011c). The work of Escobar et al. (2012e) was extended by Escobar et al. (2008b) for transient-rate analysis. Recently, Escobar et al. (2014e) formulated an interpretation technique in a composite gas reservoir having two zones. Condensate and multiphase behavior was performed by Munoz et al. (2006), Escobar et al. (2007b) and Escobar and Montealegre (2008a, b).

TDS technique has been also extended for shale reservoirs as show by the works by Bernal et al. (2014) and Escobar et al. (2014b, h, 2015d).

Some miscellaneous cases are finally grouped. Escobar et al. (2014a) observed that the radial superposition function is always used without considering the existence of a given flow regime. They concluded that using the unappropriated superposition function will lead to errors of estimating hydraulic fracture parameters. Recently, Escobar et al. (2015b) characterized the spherical stabilization, which displays a 3/2 slope on the pressure derivative vs. time log–log plot, and provided a TDS and conventional methodologies to find reservoir permeability when radial flow is masked by an upper or lower constant boundary. The effect of variable wellbore storage was conducted by Escobar et al. (2014i). Escobar et al. (2012b) studied pressure behavior in partially penetrated slanted wells. They characterized the ellipsoidal flow regime and provided TDS Methodology to interpret pressure test in such systems. Finally, Escobar and Montealegre (2007a, b, c) showed the impact on drainage area, skin, and permeability calculations when the initial pressure of the tests has not been corrected by considering the normal reservoir declination. They provided corrections for both conventional and TDS methodologies.

With the above discussion, it is provided more than 90% of the TDS technique contribution for well test interpretation. This provides a general comprehension of the application of its use and the purpose of this paper is to invite the reader to use TDS technique. More complex cases may not be solved by methods (1), (2), and (3) mentioned in the abstracts because could be: for (1), there are no equations, for (2) there not exist type curves and for (3) the software may not have the necessary analytical/numerical model.

Following the idea of Gringarten (2008) we state here that there are three, instead of two, facts or “blessings” revolutionizing well test interpretation: (1) introduce of pressure derivative in 1983, (2) introduce of deconvolution for further penetration inside the reservoir and (3) introduce of TDS technique in 1993/1995.

Data processing

Tiab’s direct synthesis (TDS) technique was introduced by Tiab (1993, 1995) to interpret pressure tests using characteristic features found on the log–log pressure of pressure and pressure derivative vs. time.

The following are the dimensionless time, pressure and pressure derivative quantities used for vertical fractured wells:

Equation (1) applies to unfractured wells if the characteristic length is well radius instead of half-fracture length. Additionally, it applies to a finite reservoir if the half-fracture length is changed by drainage area.

For unfractured vertical wells, the characteristic length, xf, is changed by the wellbore radius, rw.

Tiab (1993, 1995) presented an important expression to obtain formation permeability using the pressure derivative value, (\({t^*}\Delta {P^\prime }\))r, read from the plateau formed on the pressure derivative curve during radial flow regime:

If formation permeability is known, (\({t^*}\Delta {P^\prime }\))r, can be solved from Eq. (4):

Tiab (1993, 1995) determines skin factor by taking the ratio of the governing pressure equation to the pressure derivative during radial flow regime.

Equation (5) uses the (\({t^*}\Delta {P^\prime }\))r mentioned before and value of ΔPr read at any arbitrary time, tr, during radial flow. At this point is good to point out that Eqs. (4) and (6) are used in the latest well test interpretation monograph by Spivey and Lee (2013), pages 91 and 92, without providing the appropriate reference and naming the procedure as “Manual Log–Log Analysis” instead of calling it TDS technique as customary. Actually, Eq. (5) looks in their book a little different since the number 7.43 is placed as 1688 in the denominator of the natural logarithm term.

For unfractured wells, Tiab (1993, 1995) proposed the below correlations using the coordinates, tx and (\({t^*}\Delta {P^\prime }\))x, of the “hunch” seen during wellbore storage dominated period:

Once permeability is known, (\({t^*}\Delta {P^\prime }\))r is found from Eq. (5) and plugged into Eqs. (10) and (11).

More equations are given as the examples require more parameters to be estimated. The examples were all worked with the aid of software written by the main author of this paper. That is the reason several digits are used.

Data interpretation

Example 1: fractured well-bilinear flow is observed

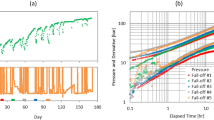

Information for a buildup test run in a re-fractured well in South America is given below. Pressure data are given in Table 1 and Fig. 1. It is required to characterize such test using the power of TDS technique.

Solution From Fig. 1 it is only observed wellbore storage and bilinear flow regime. Radial flow is absent. A value of (\({t^*}\Delta {P^\prime }\))BL1 of 25.052 psi is read from the plot given in Fig. 1. Tiab et al. (1999c) and Tiab (2005) presented the following expression to find fracture conductivity:

Parameter ξ in the above and following expressions accounts for the heterogeneity of the formation. For a naturally fractured formation, ξ = ω, while takes a value of unity for homogeneous formations. Using Eq. (12), then:

So far, this is the interpretation we can deal with. However, going even further, let us solve for (\({t^*}\Delta {P^\prime }\))r from Eq. (5);

We can now artificially create the radial flow regime by drawing a horizontal line throughout the value of (\({t^*}\Delta {P^\prime }\))r as shown by the dashed line in Fig. 2. Notice that the unit-slope line during wellbore storage was also drawn. Arbitrary coordinates of the unit-slope are read from Fig. 2:

Tiab (1993, 1995) also provide an equation for the estimation of the wellbore storage coefficient:

Then, use of Eq. (13) leads to find:

Tiab (1993, 1995) also presented an expression to find formation permeability from the point of intersect formed by the early unit-slope and radial lines:

Using Eq. (14) permeability results to be:

which matches very well the value found from a former test.

Tiab et al. (1999c) and Tiab (2005) presented an equation to find fracture conductivity from the point of intersection formed by the bilinear and radial flow lines, tRBLi; recalling that this point is also artificially created since radial flow is unseen on the test:

From Fig. 2, tRBLi = 15.64 h. Using this value into Eq. (15);

Tiab (2001) proposed expressions to estimate either half-fracture length or fracture conductivity;

Since, radial flow is unobserved to estimate skin factor, we fly to an expression presented by Cinco-Ley and Samaniego (1981):

Assuming that the last pressure point of the test is the end of the bilinear flow regime, then, ΔPebf = 140.63 psi, then, use of Eq. (18) leads to:

From the definition of dimensionless fracture conductivity, Cinco-Ley and Samaniego (1981);

Solving for the half-fracture length from the above expression;

Solving for skin factor from Eq. (17), it yields;

Application of Eq. (20) leads to:

Example 2: unfractured well—homogeneous reservoir—radial flow unseen

Table 2 and Fig. 3 presents drawdown pressure and pressure derivative data for Example 4.1 given by Horne (1990). After normally working the example, we will assume that radial flow does not exist (Table 3).

Solution The following information is obtained from Fig. 3.

Wellbore storage coefficient is found with Eq. (13);

Use Eqs. (4) and (14) to find reservoir permeability:

These permeability values are closed enough to the value of 77.1 md reported by Horne (1990) in page 71 using straight-line conventional analysis.

The mechanical skin factor is determined with the aid of Eq. (6);

which is certainly closed to the value reported of 6.09 reported by Horne (1990) in the same page.

Now, reservoir area can be estimated using TDS technique by three equations. The first equation uses the point of intersection between radial flow regime and late pseudosteady-state lines, Tiab (1994):

Chacon et al. (2004) obtained another equation to find well drainage area using an arbitrary point, tpss and (\({t^*}\Delta {P^\prime }\))pss, during the late pseudosteady-state regime:

The above equation, however, is better used with averaged values of such points. To do so, the unit-slope line is extrapolated and read the pressure derivative, (\({t^*}\Delta {P^\prime }\))p1, at a time of 1 h. Then. Equation (22) becomes;

Equations (21) through (23) provide the area in ft2. Application of Eq. (21) gives:

Using Eq. (23) provides:

The above drainage area values match very well with the value of 45.218 Ac reported by Horne (1990), page 83, obtained from the Cartesian plot (conventional) analysis.

Now, let us see the power of TDS technique. As the reader sees in Fig. 3, some points are darker than the others. Let us assume for a moment those lighter points do not exist. These types of tests are typically seen in fall-off testing in which wellbore storage effects mask the complete radial flow regime. Using ACMM is so risky since so many values of permeability can provide a good matching. Reading the coordinates of the peak from Fig. 4.

Using the correlation given by Eq. (7):

Plugging the above permeability value on Eq. (5),

After plotting this straight-line in Fig. 4, our intuition tells us the need of tuning up the choosing of the maximum point. Then, a new point obtained from Fig. 5 is given here:

Using, again, Eq. (7), a new value of permeability is obtained:

Once again, plugging the above permeability value in Eq. (5),

This essentially reproduces the horizontal line in Fig. 3. Skin factor is calculated with Eqs. (9) and (10).

Example 3: unfractured well—homogeneous reservoir—only late pseudosteady-state period is seen

A situation similar to this took place in a pressure buildup test run in a Colombian gas well. Since we are not authorized to publish the data, a synthetic drawdown test for an oil reservoir will attempt to recreate the given situation. The well was shut-in for a buildup and memories were taken out once the pseudosteady-state period was suspected to be reached as the test was designed. The operator noticed that no data were recorded in both gauges. At the same time another gauge was running down into the well to continue the test to know fluid gradient. To overcome the situation it was decided to run the test for a 100 h more. Formation permeability was known from a previous test. With the remaining data, well-drainage area was estimated since it was the sole interest of the operator. A synthetic test is generated with the below information and reported in both Table 4 and Fig. 6.

Figure 6 displays the expected pressure and pressure derivative. More than 30 h of test are missing. We took the remaining information and set the initial pressure to zero time and filled with times between zero and 31.93 h, corresponding values of pressures between 5000 and 4987.11 psi were made up. Figure 7 shows the rebuild pressure derivative which falls on the actual values. Notice that radial flow regime is not the objective point, then, the drawn points are neglected since they were used just to help to promote the estimation of the pressure derivative. It was verified that the pseudosteady-state period was reached which cannot be perfectly demonstrated with the Cartesian plot.

Anyhow, reservoir area can be found from the slope of a drawdown Cartesian plot using the equation proposed by Jones (1956):

For a buildup test, the Cartesian slope, \({m^*}\), is found using an expression given by Bossie-Codreanu (1989);

Since formation permeability is known from a previous test, the radial flow regime, (\({t^*}\Delta {P^\prime }\))r, can be solved from Eq. (5), as follows:

Then, radial flow regime line is artificially built throughout the value of 0.7055 psi, as shown by the horizontal dashed line in Fig. 7. Two characteristic points are read from such plot:

Drainage area is found from Eqs. (21) and (23), respectively:

Another way to estimate pressure derivative, during late pseudosteady-state period, consists of estimating the area with either Eqs. (24) or (25), from conventional analysis. Then, solve for the pressure derivative from Eq. (22), since time data are given, the pressure derivative is estimated using each time. This estimation is also reported in Table 5 using the average area obtained by Eqs. (21) and (23). Notice that the pressure derivative is fairly close to the other two values. A better representation is given in Fig. 8.

Pseudosteady-state actual pressure derivative vs. time log–log plot for example 3 and pressure derivative obtained from Eq. (17)

Final comments

As we saw in the worked examples, TDS technique is both accurate and powerful. Especially since parameters can be easily verified, is easy to use and is the best option for short test. Since most engineers prefer automatic pressure matching, we encourage doing so, once TDS technique has been used to find the range of the parameters used for the simulation. Actually, we assume that all the most popular computer software for transient-pressure analysis uses TDS technique. To avoid commercialism, they will be referred ad software 1, 2, 3 and 4. The first one is sold by a company and the standalone version has an option called “specialized lines” which can be displayed once the pressure derivative plot is built. See Fig. 9. The user can plot and move the different straight lines by choosing from the given menu. The same company—workstation version—has in the main menu a button “Tools” that displays the window given in Fig. 10. The user can select type of wellbore storage, well model, reservoir model and boundary model. Any of them will give a straight line on the pressure derivative plot and the results are given instantaneously.

It can be seen from the examples that the results match quite well, and some parameters can be easily verified from different sources. Once the parameters are known, they may be used in ACMM to obtain a faster and accurate solution.

An American company has software 2. See Fig. 11. It looks that is no longer being sold. As much as Software 1, the user can select a line to be placed on the pressure derivative plot. Once that is done, the result of the calculated parameter is given attached to the drawn line.

When pressure derivative plot is seen in Software 3, Fig. 12, the user can see in the upper-middle part of the screen a menu with different slopes (1, 0, 0.5, − 0.5, 0.25 and − 1). As of the former Software for well test interpretation, the user can draw a given line and obtain the reservoir parameters. Actually, this software reports intersection points. Finally, software 4, see Fig. 13, used to belong to a Canadian company, has a similar behavior. Once the pressure derivative is available, a panel shows up and the user can select and draw the desires line and results will be displayed near the drawn line.

Why do we assume that all the mentioned software use TDS technique, even when they do not mention it? To demonstrate it, let us see the following straight-line equations:

From simple algebra, these lines are not parallel to each other and they intersect at point (5, 2), as demonstrated below by combining Eqs. (26) and (27);

Then x = 5 and y = 2. A similar situation takes place with the pressure derivative plot. By looking at Fig. 14, two straight lines are well defined with their respective governing Equations.

According to Tiab (1993, 1994, 1995), both radial flow regime and pseudosteady-state period are defined by:

At the intersection point of those lines—referred by Tiab (1994) as trpi—Eqs. (28) and (29) are equaled, then:

Bringing Eq. (1), but changing the characteristic length by area,

Plugging the definition of dimensionless time based upon area into Eq. (30), it yields:

Solving for area, Eq. (21) is readily obtained:

Which means that unique equations can only be obtained and then used by the above-mentioned commercial software.

Conclusions

-

a)

TDS technique has been shown to be a practical, accurate and easy to use tool for well test interpretation. It is the best accurate option for short test and can be used to artificially create non-existing flow regimes.

-

b)

TDS technique has covered several scenarios, but its used is not well spread which is seen by the impact of our publications. However, we have made an educated assumption that TDS technique is widely used by most popular commercial software.

-

c)

TDS technique is the only alternative to interpret pressure tests in some complex systems. Such as non-Newtonian fluids, fractal reservoirs, short tests, among others which do not have mathematical models already programmed in commercial well test interpretation software.

Abbreviations

- A :

-

Well-drainage area, Ac

- B :

-

Volume factor, rb/STB

- C :

-

Wellbore storage coefficient, bbl/psi

- c t :

-

Total system compressibility, psi−1

- h :

-

Reservoir thickness, ft

- k :

-

Formation permeability, md

- k f w f :

-

Fracture conductivity, md-cp

- \(m^{*}\) :

-

Slope of the P vs. t plot during late pseudosteady-state period

- P :

-

Pressure, psi

- P i :

-

Initial reservoir pressure, psi

- q :

-

Flow rate, BPD

- r w :

-

Wellbore radius, ft

- s :

-

Skin factor

- t :

-

Drawdown time, h

- Δt :

-

Shut-in time, h

- t D :

-

Dimensionless time coordinate

- \(t^{*}_{\text{D}}P^{\prime}_{\text{D}}\) :

-

Dimensionless pressure derivative

- \(t^{*} \Delta P^{\prime}\) :

-

Pressure derivative

- x f :

-

Half-fracture length, ft

- Δ:

-

Change, drop

- ξ :

-

Heterogeneity parameter, ξ = 1 for homogeneous reservoir, ξ = ω for naturally-fractured reservoir

- φ :

-

Porosity, fraction

- µ :

-

Viscosity, cp

- ω :

-

Storativity ratio, for naturally fractured reservoir

- BL:

-

Bilinear flow regime

- BL1:

-

Bilinear flow regime read at 1 h

- D:

-

Dimensionless

- ebf:

-

End of bilinear flow

- i:

-

Initial, intersection of early unit-slope and radial lines

- pss:

-

Pseudosteady-state period

- p1:

-

Pseudosteady-state period read at 1 h

- r:

-

Radial

- RBLi:

-

Intersection point formed between the extrapolation of both radial flow regime line and bilinear flow regime line

- rpi:

-

Intersection of radial and pseudosteady-state period lines

- x:

-

Maximum point during wellbore storage dominated flow

- wf:

-

Well flowing

- ws:

-

Well static

References

Al Rbeawi S, Tiab D (2011a) Effect of the number and length of zonal isolations on pressure behavior of horizontal wells. In: Presented at the SPE production and operations symposium, proceedings. pp 587–604

Al Rbeawi S, Tiab D (2011b) Pressure transient analysis of horizontal wells in a multi-boundary system. In: Presented at the SPE production and operations symposium, proceedings. pp 729–749

Al Rbeawi S, Tiab D (2012) Transient pressure analysis of a horizontal well with multiple inclined hydraulic fractures using type-curve matching. In: Presented at the proceedings—SPE international symposium on formation damage control. pp 62–81

Al Rbeawi SA, Tiab D (2013) Pressure behaviours and flow regimes of a horizontal well with multiple inclined hydraulic fractures. Int J Oil Gas Coal Technol 6:207–241. https://doi.org/10.1504/IJOGCT.2013.050772

Baba A, Tiab D (2001) Effect of finite conductivity horizontal well on transient-pressure behavior. In: Presented at the proceedings of the permian basin oil and gas recovery conference. pp 88–105

Bensadok A, Tiab D (2004) Interpretation of pressure behavior of a well between two intersecting leaky faults using TDS technique. In: CIP2004-123, proceedings, Canadian international petroleum conference, 7–10 June

Bernal KM, Escobar FH, Ghisays-Ruiz A (2014) Pressure and pressure derivative analysis for hydraulically fractured shale formations using the concept of induced permeability field. ARPN J Eng Appl Sci 9:1952–1958

Berumen S, Tiab D (1997) Interpretation of stress damage on fracture conductivity. J Pet Sci Eng 17:71–85

Berumen S, Rodriguez F, Tiab D (1997) An investigation of fracture asymmetry on the pressure response of fractured wells. Soc Pet Eng. https://doi.org/10.2118/38972-MS

Berumen S, Tiab D, Rodriguez F (2000) Constant rate solutions for a fractured well with an asymmetric fracture. J Petrol Sci Eng 25:49–58. https://doi.org/10.1016/S0920-4105(99)00053-4

Bettam Y, Tiab D, Zerzar A (2005) Interpretation of multi-hydraulically fractured horizontal wells in naturally fractured reservoirs. In: Presented at the IIORC 05-2005 SPE international improved oil recovery conference in Asia pacific, proceedings. pp 1–8

Bossie-Codreanu D (1989) A simple buildup analysis method to determine well drainage area and drawdown pressure for a stabilized well. Soc Pet Eng. https://doi.org/10.2118/15977-PA

Boussalem R, Tiab D, Escobar FH (2002) Effect of mobility ratio on the pressure and pressure derivative of wells in closed composite reservoirs. In: Presented at the SPE western regional/AAPG pacific section joint meeting. pp 623–628

Boussila AK, Tiab D, Owayed J (2003) Pressure behavior of well near a leaky boundary in heterogeneous reservoirs. In: Presented at the proceedings—SPE production operations symposium. pp 349–361

Chacon A, Djebrouni A, Tiab D (2004) Determining the average reservoir pressure from vertical and horizontal well test analysis using the Tiab’s direct synthesis technique. In: Presented at the SPE Asia pacific oil and gas conference and exhibition, APOGCE. pp 1387–1399

Cherifi M, Tiab D, Escobar FH (2002) Determination of fracture orientation by multi-well interference testing. In: Presented at the SPE—Asia pacific oil and gas conference. pp 999–1009

Cinco-Ley H, Samaniego VF (1981) Transient pressure analysis for fractured wells. Soc Pet Eng. https://doi.org/10.2118/7490-PA

Dinh AV, Tiab D (2009a) Transient-pressure analysis of a well with an inclined hydraulic fracture using tiab’s direct synthesis technique. In: Presented at the SPE production and operations symposium, proceedings. pp 387–415

Dinh AV, Tiab D (2010) Pressure-transient analysis of a well with an inclined hydraulic fracture. SPE Reserv Eval Eng 13:845–860

Engler T, Tiab D (1996a) Analysis of pressure and pressure derivative without type curve matching, 4. Naturally fractured reservoirs. J Pet Sci Eng 15:127–138

Engler T, Tiab D (1996b) Analysis of pressure and pressure derivative without type-curve matching, 5. Horizontal well tests in naturally fractured reservoirs. J Pet Sci Eng 15:139–151

Engler T, Tiab D (1996c) Analysis of pressure and pressure derivative without type-curve matching, 6. Horizontal well tests in anisotropic media. J Pet Sci Eng 15:153–168

Escobar FH (2008) Recent advances in well test analysis for long and narrow reservoirs. In: Montclaire KL (ed) Petroleum science research progress, chap 6. Nova Science Publishers, pp 275–308

Escobar FH (2012) Transient pressure and pressure derivative analysis for non-Newtonian fluids. In: Gomes JS (ed) New technologies in the oil and gas industry, chap 7. InTech, Rijeka, pp 163–180

Escobar FH (2015) Recent advances in practical applied well test analysis. Nova Science Publishers, Inc, New York

Escobar FH, Montealegre M (2006) Effect of well stimulation on the skin factor in elongated reservoirs. CT y F Ciencia Tecnologia y Futuro 3:109–119

Escobar FH, Montealegre M-M (2007a) A complementary conventional analysis for channelized reservoirs. CT y F Ciencia Tecnologia y Futuro 3:137–146

Escobar FH, Montealegre M (2007b) Conventional analysis for the determination of the horizontal permeability from the elliptical flow of horizontal wells. In: Presented at the SPE production and operations symposium, proceedings. pp 54–61

Escobar FH, Montealegre M (2007c) Application of TDS technique to developed reservoirs. J Pet Sci Eng 57:347–353. https://doi.org/10.1016/j.petrol.2006.11.001

Escobar FH, Montealegre MM (2008a) Application of TDS technique to multiphase flow. CTyF Ciencia Tecnologia y Futuro 3:93–105

Escobar FH, Montealegre MM (2008b) Determination of horizontal permeability from the elliptical flow of horizontal wells using conventional analysis. J Pet Sci Eng 61:15–20. https://doi.org/10.1016/j.petrol.2007.10.005

Escobar FH, Tiab D, Berumen-Campos S (2003a) Well pressure behavior of a finite-conductivity fracture intersecting a finite sealing-fault. In: Presented at the SPE—Asia pacific oil and gas conference. pp 643–658

Escobar FH, Tiab D, Jokhio SA (2003b) Characterization of leaky boundaries using transient pressure analysis. In: Presented at the proceedings—SPE production operations symposium. pp 315–324

Escobar FH, Saavedra NF, Escorcia GD, Polania JH (2004b) Pressure and pressure derivative analysis without type-curve matching for triple porosity reservoirs. In: Presented at the SPE Asia pacific oil and gas conference and exhibition, APOGCE. pp 849–863

Escobar FH, Munoz OF, Sepulveda JA, Montealegre M (2005) New finding on pressure response in long, narrow reservoirs. CT&F Ciencia Tecnología y Futuro. 2(6):151–160 (ISSN 0122-5383)

Escobar FH, Montealegre M, Cantillo JH (2006) Conventional analysis for characterization of bi-radial (elliptical) flow in infinite-conductivity vertical fractured wells. CT y F Ciencia Tecnologia y Futuro 3:141–147

Escobar FH, Cantillo JH, Montealegre MM (2007a) Pressure and pressure derivative analysis for vertical gas and oil wells in stress sensitive homogeneous and naturally fractured formations without type-curve matching. CT y F Ciencia Tecnologia y Futuro 3:71–84

Escobar FH, Garcia-Rocha H, Suaza IM, Cantillo JH (2007b) Well pressure behavior for a vertical well in a gas condensate naturally-fractured reservoir. In: Presented at the proceedings of the SPE Latin American and Caribbean petroleum engineering conference. pp 989–998

Escobar FH, Lopez A-M, Cantillo JH (2007c) Effect of the pseudotime function on gas reservoir drainage area determination. CT y F Ciencia Tecnologia y Futuro 3:113–124

Escobar FH, Hernández YA, Hernández CM (2007d) Pressure transient analysis for long homogeneous reservoirs using TDS technique. J Pet Sci Eng 58:68–82. https://doi.org/10.1016/j.petrol.2006.11.010

Escobar FH, Ibagon OE, Montealegre MM (2007e) Average reservoir pressure determination for homogeneous and naturally fractured formations from multi-rate testing with the TDS technique. J Pet Sci Eng 59:204–212. https://doi.org/10.1016/j.petrol.2007.03.009

Escobar FH, Munoz OA, Brinez DF, Guzman JC, Cantillo JH (2007f) Effect of the elastic constants on the pressure behavior of vertical wells. In: Presented at the proceedings of the SPE Latin American and Caribbean petroleum engineering conference. pp 978–988

Escobar FH, Tiab D, Tovar LV (2007g) Determination of areal anisotropy from a single vertical pressure test and geological data in elongated reservoirs. J Eng Appl Sci 2(11):1627–1639 (ISSN 1816-949X)

Escobar FH, Martínez J-A, Montealegre MM (2008a) Pressure and pressure derivative analysis for injection tests with variable temperature without type-curve matching. CTyF Ciencia Tecnologia y Futuro 3:83–91

Escobar FH, Sánchez JA, Cantillo JH (2008b) Rate transient analysis for homogeneous and heterogeneous gas reservoirs using the TDS technique. CTyF Ciencia Tecnologia y Futuro 3:45–59

Escobar FH, Cubillos J, Montealegre MM (2008c) Estimation of horizontal reservoir anisotropy without type-curve matching. J Pet Sci Eng 60:31–38. https://doi.org/10.1016/j.petrol.2007.05.003

Escobar FH, Martinez J-A, Montealegre M (2009a) Conventional pressure analysis for naturally fractured reservoirs with transition period before and after the radial flow regime. CTyF Ciencia Tecnologia y Futuro 3:85–107

Escobar FH, Montealegre M, Carrillo-Moreno D (2009b) Straight line methods for estimating permeability or width for a two-zone composite channelized reservoir. CTyF Ciencia Tecnologia y Futuro 3:107–124

Escobar FH, Hernández Y-A, Tiab D (2010a) Determination of reservoir drainage area for constant-pressure systems using well test data. CTyF Ciencia, Tecnologia y Futuro 4:51–62

Escobar FH, Hernández DP, Saavedra JA (2010b) Pressure and pressure derivative analysis for long naturally fractured reservoirs using the TDS technique. DYNA (Colombia) 77:102–114

Escobar FH, Martínez J, Montealegre M (2010c) Pressure and pressure derivative analysis for a well in a radial composite reservoir with a non-Newtonian/Newtonian interface. CTyF Ciencia Tecnologia y Futuro 4:33–42

Escobar FH, Martinez JA, Cantillo JH (2010d) Pressure-transient analysis for naturally fractured reservoirs with transition period before and after the radial-flow regime. In: Presented at the SPE Latin American and Caribbean petroleum engineering conference proceedings. pp 469–485

Escobar FH, Montealegre M, Carrillo-Moreno D (2010e) Pressure and pressure derivative transient analysis without type-curve matching for elongated reservoirs with changes in facies or width. CTyF Ciencia Tecnologia y Futuro 4:75–86

Escobar FH, Zambrano A-P, Giraldo D-V, Cantillo-Silva JH (2011a) Pressure and pressure derivative analysis for non-newtonian pseudoplastic fluids in double-porosity formations. CTyF Ciencia Tecnologia y Futuro 4:47–60

Escobar FH, Martínez-Pérez J-A, Bonilla-Camacho LF (2011b) Pressure and pressure derivative analysis without type-curve matching for thermal recovery processes. CTyF Ciencia Tecnologia y Futuro 4:23–36

Escobar FH, Munoz YEM, y Cerquera WM (2011c) Pseudotime function effect on reservoir width determination in homogeneous and naturally fractured gas reservoir drained by horizontal wells. “Entornos” J 24:221–231 (ISSN 0124-7905)

Escobar FH, Cantillo JH, Santos N (2011d) A practical approach for the estimation of the average reservoir pressure from multi-rate tests in long horizontal wells. “Fuentes El Reventon Energético” J 9(1):13–20 (First Semester 2011. ISSN 1657-6527)

Escobar FH, Bonilla DF, Cicery YY (2012a) Pressure and pressure derivative analysis for pseudoplastic fluids in vertical fractured wells. ARPN J Eng Appl Sci 7:975–979

Escobar FH, Corredor C-M, Gomez B-E, Cantillo JH, Prent L-A (2012b) Pressure and pressure derivative analysis for slanted and partially penetrating wells. ARPN J Eng Appl Sci 7:932–938

Escobar FH, Martinez J-A, Bonilla L-F (2012c) Pressure and pressure derivative analysis for a three-region composite reservoir. ARPN J Eng Appl Sci 7:1235–1245

Escobar FH, Martinez LY, Mendez LJ, Bonilla LF (2012d) Pseudotime application to hydraulically fractured vertical gas wells and heterogenous gas reservoirs using the TDS technique. ARPN J Eng Appl Sci 7:260–271

Escobar FH, Martínez J-A, Bonilla L-F (2012e) Transient pressure analysis for vertical wells with spherical power-law flow. CTyF Ciencia Tecnologia y Futuro 5:19–36

Escobar FH, Vega L-J, Bonilla L-F (2012f) Determination of well-drainage area for power-law fluids by transient pressure analysis. CTyF Ciencia Tecnologia y Futuro 5:45–56

Escobar FH, Rojas MM, Cantillo JH (2012g) Straight-line conventional transient rate analysis for long homogeneous and heterogeneous reservoirs. DYNA (Colombia) 79:156–163

Escobar FH, Rojas MM, Bonilla LF (2012h) Transient-rate analysis for long homogeneous and naturally fractured reservoir by the TDS technique. ARPN J Eng Appl Sci 7:353–370

Escobar FH, Vega J, Diaz MR (2012i) Pressure and pressure analysis for double-permeability systems without type-curve matching. ARPN J Eng Appl Sci 7:1314–1320

Escobar FH, Martínez J-A, Montealegre M (2013a) Pressure transient analysis for a reservoir with a finite-conductivity fault. CTyF Ciencia Tecnologia y Futuro 5:5–18

Escobar FH, Martinez A, Silva DM (2013b) Conventional pressure analysis for naturally-fractured reservoirs with non-Newtonian pseudoplastic fluids. “Fuentes” J 11(1):27–34 (ISSN 1657-6527)

Escobar FH, Martinez JA, Montealegre M (2013c) Pressure and pressure derivative analysis in a reservoir with a finite-conductivity fault and contrast of mobilities. “Fuentes” J 11(2):17–25 (ISSN 1657-6527)

Escobar FH, Ascencio JM, Real DF (2013d) Injection and fall-off tests transient analysis of non-newtonian fluids. ARPN J Eng Appl Sci 8:703–707

Escobar FH, Alzate HD, Moreno-Collazos L (2014a) Effect of extending the radial superposition function to other flow regimes. In: Presented at the SPE Latin American and Caribbean petroleum engineering conference proceedings. pp 2350–2368. Also, Escobar FH, Alzate HD, Moreno-Collazos L (2016) Effect of extending the radial superposition function to other flow regimes. Paper SPE 169473, proceedings, SPE Latin American & Caribbean petroleum engineering conference, Maracaibo, Venezuela, 21–23 May 2014

Escobar FH, Bernal KM, Olaya-Marin G (2014b) Pressure and pressure derivative analysis for fractured horizontal wells in unconventional shale reservoirs using dual-porosity models in the stimulated reservoir volume. ARPN J Eng Appl Sci 9:2650–2669

Escobar FH, Camacho RG, Rojas JD (2014c) Pressure and pressure derivative analysis for triple-porosity and single-permeability systems in naturally fractured vuggy reservoirs. J Eng Appl Sci 9(12):2500–2512 (ISSN 1819-6608)

Escobar FH, Castro JR, Mosquera JS (2014d) Rate-transient analysis for hydraulically fractured vertical oil and gas wells. ARPN J Eng Appl Sci 9:739–749

Escobar FH, Zhao YL, Zhang LH (2014e) Interpretation of pressure tests in hydraulically fractured wells in bi-zonal gas reservoirs. Ingenieria e Investigacion 34:76–84. https://doi.org/10.15446/ing.investig.v34n2.39607

Escobar FH, Zhao YL, Zhang LH (2014f) Interpretation of pressure tests in horizontal wells in homogeneous and heterogeneous reservoirs with threshold pressure gradient. ARPN J Eng Appl Sci 9:2220–2228

Escobar FH, Rojas RF, Rojas JD (2014g) Pressure and pressure derivative analysis for triple-porosity and single-permeability systems in naturally fractured vuggy reservoirs. ARPN J Eng Appl Sci 9:1323–1335

Escobar FH, Montenegro LM, Bernal KM (2014h) Transient-rate analysis for hydraulically-fractured gas shale wells using the concept of induced permeability field. ARPN J Eng Appl Sci 9:1244–1254

Escobar FH, Olaya DA, Medina MV (2014i) Approximation of the starting time of radial flow regime under variable wellbore storage conditions in vertical wells. ARPN J Eng Appl Sci 9:1047–1052

Escobar FH, Polanco MP, Benavides W (2014j) Pressure and pressure derivative analysis for a vertical well in wedged and T-shaped reservoirs. ARPN J Eng Appl Sci 9:845–851

Escobar FH, Meneses AR, Losada LM (2014k) Straight-line conventional transient pressure analysis for horizontal wells with isolated zones. DYNA (Colombia) 81:78–85

Escobar FH, Ghisays-Ruiz A, Bonilla LF (2014l) New model for elliptical flow regime in hydraulically-fractured vertical wells in homogeneous and naturally-fractured systems. ARPN J Eng Appl Sci 9:1629–1636

Escobar FH, Fahes M, Gonzalez R, Pinchao DM, Zhao YL (2015a) Determination of reservoir drainage area for constant-pressure systems by conventional transient pressure analysis. J Eng Appl Sci. 10(12):5193–5199 (ISSN 1819-6608)

Escobar FH, Ghisays-Ruiz A, Srivastav P (2015b) Characterization of the spherical stabilization flow regime by transient pressure analysis. ARPN J Eng Appl Sci 10:5815–5822

Escobar FH, Lopez-Morales L, Gomez KT (2015c) Pressure and pressure derivative analysis for naturally-fractured fractal reservoirs. ARPN J Eng Appl Sci 10:915–923

Escobar FH, Rojas JD, Ghisays-Ruiz A (2015d) Transient-rate analysis for hydraulically-fractured horizontal wells in naturally-fractured shale Gas reservoirs. ARPN J Eng Appl Sci 10:102–114

Escobar FH, Salcedo LN, Pinzon-Torres C (2015e) Pressure and pressure derivative analysis for fractal homogeneous reservoirs with power-law fluids. ARPN J Eng Appl Sci 10:4857–4863

Escobar FH, Zhao YL, Pournik M, Liu QG, Olaya-Marin G (2015f) Interpretation of pressure tests in uniform-flux fractured vertical wells with threshold pressure gradient in low permeability reservoirs. ARPN J Eng Appl Sci 10:9364–9372

Escobar FH, Zhao YL, Fahes M (2015g) Characterization of the naturally fractured reservoir parameters in infinite-conductivity hydraulically fractured vertical wells by transient pressure analysis. ARPN J Eng Appl Sci 10:5352–5362

Escobar FH, Srivastav P, Wu X (2015h) A practical method to determine aquifer leakage factor from well test data in CBM reservoirs. ARPN J Eng Appl Sci 10:4763–4772

Escobar FH, Gonzalez RA, Hernandez LA, Hernandez CM (2016a) Pressure and pressure derivative analysis for hydraulically fractured vertical wells with face skin. ARPN J Eng Appl Sci 11:8268–8273

Escobar FH, Pabon OD, Cortes NM, Hernández CM (2016b) Rate-transient analysis for off-centered horizontal wells in homogeneous anisotropic hydrocarbon reservoirs with closed and open boundaries. J Eng Appl Sci 11(17):10470–10486 (ISSN 1819-6608)

Escobar FH, Cortes NM, Pabon OD, Hernández CM (2016c) Pressure-transient analysis for off-centered horizontal wells in homogeneous anisotropic reservoirs with closed and open boundaries. J Eng Appl Sci 11(17):10156–10171 (ISSN 1819-6608)

Escobar FH, Caicedo CE, Ghisays-Ruiz A (2017) Pressure and pressure derivative analysis for asymmetry finite-conductivity fractured vertical wells. Revista Fuentes El reventón Energético 15(2):71–78

Escobar FH, Rojas E, Alarcon NT (2018a) Analysis of pressure and pressure derivative interference tests under linear and spherical flow conditions. Revista DYNA 85(204):44–52. https://doi.org/10.15446/dyna.v85204.64322

Escobar FH, Zhao YL, Urazan C, Trujillo CM (2018b) Pressure and pressure derivative interpretation for horizontal wells in compressible formations. J Geophys Eng 15:1551–1560. https://doi.org/10.1088/1742-2140/aaadc9

Gringarten AC (2008) From straight lines to deconvolution: the evolution of the state of the art in well test analysis. Soc Pet Eng. https://doi.org/10.2118/102079-PA

Hachlaf H, Tiab D, Escobar FH (2002) Effect of variable injection rate on falloff and injectivity tests. In: Presented at the SPE western regional/AAPG pacific section joint meeting. pp 119–127

Horne RN (1990) Modern well test analysis: a computer-aided approach, 4th edn. Petroway, Inc, Palo Alto

Houali A, Tiab D (2004) Analysis of interference testing of horizontal wells in an anisotropic medium. In: Presented at the SPE Asia pacific oil and gas conference and exhibition, APOGCE. pp 725–734

Igbokoyi AO, Tiab D (2007) Well test analysis in naturally fractured reservoirs using elliptical flow. In: Presented at the international petroleum technology conference 2007, IPTC 2007. pp 150–165

Igbokoyi AO, Tiab D (2008a) A new method of well-test analysis in naturally fractured reservoirs based on elliptical flow. In: Presented at the proceedings—SPE annual technical conference and exhibition. pp 4660–4680

Igbokoyi AO, Tiab D (2008b) Pressure transient analysis in partially penetrating infinite conductivity hydraulic fractures in naturally fractured reservoirs. In: Presented at the proceedings—SPE annual technical conference and exhibition. pp 4681–4699

Igbokoyi AO, Tiab D (2010) New method of well test analysis in naturally fractured reservoirs based on elliptical flow. J Can Pet Technol 49:53–67

Ispas V, Tiab D (1999) New method of analyzing the pressure behavior of a well near multiple boundary systems. In: Presented at the SPE Latin American and Caribbean petroleum engineering conference proceedings

Jokhio SA, Tiab D, Hadjaz A, Escobar FH (2001b) Pressure fall-off analysis in water injection wells using the Tiab’s direct synthesis technique. In: Presented at the proceedings of the permian basin oil and gas recovery conference. pp 232–244

Jones P (1956) Reservoir Limit Test. Oil and gas journal. June 18. p. 184–196

Jongkittinarukorn K, Tiab D (1996a) Analysis of pressure and pressure derivative without type-curve matching—a vertical well in multi-boundary systems. Pet Soc Can. https://doi.org/10.2118/96-52

Jongkittinarukorn K, Tiab D (1996b) Analysis of pressure and pressure derivative with and without type-curve matching—a horizontal well in closed-boundary system. Pet Soc Can. https://doi.org/10.2118/96-53

Jongkittinarukorn K, Tiab D, Escobar FH (1998) Interpretation of horizontal well performance in complicated systems by the boundary element method. In: SPE 50437, proceedings, SPE international horizontal well technology conference, Calgary, Alberta, Canada, November 1–4

Katime-Meindl I, Tiab D (2001) Analysis of pressure transient test of non-Newtonian fluids in infinite reservoir and in the presence of a single linear boundary by the direct synthesis technique. In: Presented at the proceedings—SPE annual technical conference and exhibition. pp 2213–2222

Khelifa M, Tiab D, Escobar FH (2002) Multirate test in horizontal wells. In: SPE 77951, proceedings, SPE Asia pacific oil and gas conference and exhibition, Melbourne, Australia 8–10 October 2002

Lu J, Zhu T, Dinh A, Tiab D (2009b) Pressure transient analysis of a multiple wells system in a circular cylinder reservoir. In: Presented at the SPE production and operations symposium, proceedings. pp 208–216

Lu J, Zhu T, Tiab D (2009c) Pressure behavior of horizontal wells in dual-porosity, dual-permeability naturally fractured reservoirs. In: Presented at the SPE middle east oil and gas show and conference, MEOS, proceedings. pp 568–590

Lu J, Zhu T, Tiab D, Escobar FH (2015) Pressure behavior of horizontal wells in dual-porosity, dual-permeability naturally-fractured reservoirs. ARPN J Eng Appl Sci 10:3405–3417

Ma Q, Tiab D (1995) Interference test analysis in naturally fractured reservoirs. In: Presented at the proceedings—SPE production operations symposium. pp 641–652

Malekzadeh D, Tiab D (1991) Interference testing of horizontal wells. In: Presented at the proceedings—SPE annual technical conference and exhibition. pp 717–727

Martinez JA, Escobar FH, Montealegre M (2011) Vertical well pressure and pressure derivative analysis for Bingham fluids in homogeneous reservoirs. DYNA (Colombia) 78:21–28

Martinez JA, Escobar FH, Bonilla LF (2012) Reformulation of the elliptical flow governing equation for a more complete well test data interpretation in horizontal wells. ARPN J Eng Appl Sci 7:304–313

Martínez JA, Escobar FH, Cantillo JH (2011) Applying Tiab’s direct synthesis technique to dilatant non-Newtonian/Newtonian fluids. Ingenieria e Investigacion 31:130–134

Merzouk K, Tiab D, Escobar FH (2002) Multirate test in horizontal wells. In: Presented at the SPE—Asia pacific oil and gas conference. pp 1010–1021

Molina MD, Escobar FH, Montealegre-M M, Restrepo DP (2005) Application of the TDS technique for determining the average reservoir pressure for vertical wells in naturally fractured reservoirs. CT&F Ciencia Tecnología y Futuro 2(6):45–55 (ISSN 0122-5383)

Moncada K, Tiab D, Escobar FH, Montealegre MM, Chacon A, Zamora RA, Nese SL (2005) Determination of vertical and horizontal permeabilities for vertical oil and gas wells with partial completion and partial penetration using pressure and pressure derivative plots without type-curve matching. CT&F Ciencia Tecnología y Futuro 2(6):77–95 (ISSN 0122-5383)

Mongi A, Tiab D (2000) Application of Tiab’s direct synthesis technique to multi-rate tests. In: Presented at the SPE/AAPG western regional meetings. pp 495–507

Munoz O-F, Escobar FH, Cantillo JH (2006) Capillarity and rapid flow effects on gas condensate well tests. CT y F Ciencia Tecnologia y Futuro 3:73–82

Nunez W, Tiab D, Escobar FH (2003) Transient pressure analysis for a vertical gas well intersected by a finite-conductivity fracture. In: Presented at the proceedings—SPE production operations symposium. pp 391–403

Owayed JF, Tiab D (2008) Transient pressure behavior of Bingham non-Newtonian fluids for horizontal wells. J Pet Sci Eng 61:21–32. https://doi.org/10.1016/j.petrol.2007.10.003

Slimani K, Tiab D (2005) Pressure transient analysis of partially penetrating wells in a naturally fractured reservoir. Pet Soc Can. https://doi.org/10.2118/2005-263

Spivey JP, Lee WL (2013) Applied well test interpretation. SPE textbooks series, vol 13. Society of Petroleum Engineers, Richardson, TX

Tiab D (1993) Analysis of pressure and pressure derivatives without type-curve matching: I-skin and wellbore storage. Soc Pet Eng. https://doi.org/10.2118/25426-MS

Tiab D (1994) Analysis of pressure and pressure derivative without type-curve matching: vertically fractured wells in closed systems. J Pet Sci Eng 11:323–333. https://doi.org/10.1016/0920-4105(94)90050-7

Tiab D (1995) Analysis of pressure and pressure derivative without type-curve matching: 1 skin and wellbore storage. J Pet Sci Eng 12:171–181. Also Tiab, D (1993, January 1)

Tiab D (2001) Advances in pressure transient analysis. UPTEC Training Manual, Norman

Tiab D (2005) Analysis of pressure derivative data of hydraulically fractured wells by the Tiab’s direct synthesis technique. J Pet Sci Eng 49:1–21. https://doi.org/10.1016/j.petrol.2005.07.001

Tiab D, Bettam Y (2007) Practical interpretation of pressure tests of hydraulically fractured wells in a naturally fractured reservoir. In: Presented at the proceedings of the SPE Latin American and Caribbean petroleum engineering conference. pp 238–248

Tiab D, Boulenouar D (2004) Multi-rate testing for vertical wells in naturally fractured reservoirs. In: Presented at the SPE Asia pacific oil and gas conference and exhibition, APOGCE. pp 877–889

Tiab D, Ispas IN, Mongi A, Berkat A (1999a) Interpretation of multirate tests by the pressure derivative—I. Oil reservoirs. Soc Pet Eng. https://doi.org/10.2118/53935-MS

Tiab D, Azzougen A, Escobar FH, Berumen S (1999b) Analysis of pressure derivative data of a finite conductivity fractures by the ‘Direct synthesis’ technique. In: SPE 52201, proceedings, 1999 SPE mid-continent production operations symposium, Oklahoma City, Oklahoma, 28–31 March 1999. Also Proceedings, 1999 SPE Latin American and Caribbean Petroleum Engineering Conference, Caracas, Venezuela, 21–23 April 1999

Tiab D, Ispas IN, Mongi A, Berkat A (1999c) Interpretation of multirate tests by the pressure derivative—I. Oil reservoirs. In: Presented at the SPE Latin American and Caribbean petroleum engineering conference proceedings

Tiab D, Igbokoyi A, Restrepo D (2007a) Fracture porosity from pressure transient data. In: Presented at the international petroleum technology conference 2007, IPTC 2007. pp 136–149

Tiab D, Lu J, Nguyen H, Owayed J (2010) Evaluation of fracture asymmetry of finite-conductivity fractured wells. J Energy Resour Technol Trans ASME 132:0129011–0129017. https://doi.org/10.1115/1.4000700

Toufik B, Tiab D, Jokhio S (2003) Effect of non-uniform skin on finite conductivity horizontal well. In: Presented at the proceedings—SPE production operations symposium. pp 511–522

Wu X, Srivastava P, Escobar FH (2015) A new model to determine leakage factor for a finite aquifer using pressure fall off test in CBM reservoir. In: Presented at the society of petroleum engineers—SPE Asia pacific unconventional resources conference and exhibition

Zerzar A, Tiab D, Bettam Y (2004) Interpretation of multiple hydraulically fractured horizontal wells. In: Presented at the 11th ADIPEC: Abu Dhabi international petroleum exhibition and conference—conference proceedings. pp 455–467

Zhao YL, Escobar FH, Jamili A, Olaya-Marin G, Ghisays-Ruiz A (2015) Effect of wellbore storage on the vertical well pressure behavior with threshold pressure gradient in low permeability reservoirs. ARPN J Eng Appl Sci 10:10659–10665

Zhao YL, Escobar FH, Hernandez CM, Zhang CP (2016) Performance analysis of a vertical well with a finite-conductivity fracture in gas composite reservoirs. ARPN J Eng Appl Sci 11:8992–9003

Acknowledgements

The authors thank Universidad Surcolombiana, and Chulalongkorn University for providing financial support for the completion of this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Escobar, F.H., Jongkittnarukorn, K. & Hernandez, C.M. The power of TDS technique for well test interpretation: a short review. J Petrol Explor Prod Technol 9, 731–752 (2019). https://doi.org/10.1007/s13202-018-0517-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-018-0517-5