Abstract

A series of novel alkyl-hydroxyl-sulfobetaine zwitterionic surfactants (C n HSB, n = 12, 14, 16 or 18) were synthesized and their applicability for chemical enhanced oil recovery was studied. The interfacial tension measurements between C n HSB and Shengli crude oils from four different blocks indicated that C16HSB and C18HSB are adapted to high-temperature and high-salinity reservoirs conditions. The interfacial activity was also maintained high after interacting with sand. Furthermore, C16HSB and C18HSB are compatible with partially hydrolyzed polyacrylamide (HPAM). Physical simulation experiment showed that the oil recovery of surfactant/polymer flooding (0.3 wt% C18HSB + 0.15 wt% HPAM) can be improved by 18.6 % over water flooding.

Similar content being viewed by others

Introduction

Chemical flood is one of the most important enhanced oil recovery (EOR) techniques for oil production. Field applications have demonstrated that chemical flooding technologies, especially surfactant-polymer (SP) flooding can achieve good performance in terms of water cut decreasing and oil production increasing (Austan 1995; Sun et al. 2007; Wang et al. 2009). The mechanism responsible for surfactant EOR is to increase the capillary number by reducing the interfacial tension (IFT) between crude oil and water. The primary surfactant used for SP flooding is petroleum sulfonate (PS). To reach ultra-low IFT, PS is often mixed with complementary surfactants of different types. The combined surfactant system has been widely used and succeeded at relatively ideal reservoirs with low temperature and low salinity. However, with the progress of oil field development, the future SP flooding projects have to face more challenging reservoir conditions with high temperature and high salinity. Ultra-low IFT is no longer available by currently used surfactants under severe reservoir conditions and the performance of SP flooding will be affected accordingly. Great efforts have been focused on the development of heat-resistant and salt-tolerant EOR surfactant.

Zwitterionic surfactants are interesting in several respects. Depending on the nature of the polar groups, the zwitterionic surfactants often display excellent interfacial activity, and are known to be less irritating to human’s skin than many ionic surfactants. Also, changes in temperature, pH, and added electrolyte have minimal effects on zwitterionic surfactants. Compared with conventional anionic, cationic and nonionic surfactants, zwitterionic surfactants have better temperature resistance and salt tolerance. Hence, many researches on zwitterionic surfactants for oil extraction field have been reported in recent years (Harrison et al. 1998; Danov et al. 2004; El-Aila 2005). The betaine zwitterionic surfactants have usually acted as complementary surfactants in chemical flooding. Very few SP trials have been carried out using solely betaine and hydrolyzed polyacrylamide (HPAM). It is mainly due to the great adsorption loss of betaine surfactants in the formation which presents a major challenge for their applications in chemical flooding.

In this paper, a series of alkyl-hydroxyl-sulfobetaine zwitterionic surfactants were synthesized and the dynamic IFTs with Shengli crude oils from different blocks were investigated. The applicability of synthesized betaine surfactants to chemical EOR was studied comprehensively including thermal stability, adsorption loss, compatibility with polymer and displacement efficiency.

Experimental

Materials

C n HSB were synthesized in our laboratory with purity greater than 99 %. Epichlorokydrin, sodium bisulfite and tertiary amine were analytically pure, purchased from Shanghai reagent company. HPAM provided by Hengju Corporation, relative viscosity-average molecular weight of 22,000,000 and hydrolysis degree of 24.4 %.

Synthesis

The synthesis of C n HSB consists of two steps. First, epichlorokydrin was added slowly into dissolved sodium bisulfite with continuous stirring. The reaction may continue for 7 h at 40 °C. After recrystallizing with alcohol and drying, the white crystal of 3-chloro-2-hydroxyl propanesulfonate intermediate was obtained. The reaction equation of the intermediate is shown as follows:

Second, the intermediate was mixed with tertiaryamine (n = 12, 14, 16, or 18) at 1:1 mass ratio. The product was then concentrated by spinning evaporation. The equation of quaternary ammonium salt forming reaction is shown as follows:

Experimental condition

IFT experiments were performed under various reservoir conditions of several SP flooding areas. The reservoir parameters are listed in Table 1.

Interfacial tension (IFT) measurement

Dynamic IFT was measured by Texas-500C spinning drop interfacial tensiometer, at a rotating velocity of 5,000 rpm.

Viscosity measurement

Physica MCR 301 rotational rheometer was used to measure the viscosity of chemical solutions.

IFT after adsorption

The adsorption experiment is described here: mix 90 g of 0.3 wt% C n HSB solution with 30 g of sand; after shaking at a speed of 170 r/min in a water bath at formation temperature for 24 h, the supernatant was centrifuged for IFT measurement.

Compatibility with polymer

The experiment was carried out as follows: first prepare 0.5 wt% HPAM stock solution with plain water; dissolve 0.3 g C n HSB into 70 g saline solution with formation water and keep stirring for 15 min; then add 30 g HPAM stock solution into the prepared surfactant solution and keep stirring the binary system for at least 30 min. By doing so, the concentrations of C n HSB and HPAM in the binary system are 0.3 and 0.15 wt%, respectively. The viscosity was measured for single polymer solution and binary solution, while the IFT was measured for single surfactant solution and binary solution.

Thermal stability

First prepare the binary system of 0.3 wt% C n HSB and 0.15 % HPAM using the aforesaid method. The binary solutions are deoxygenized and then sealed in separated bottles. Keep the solution in a thermostatic chamber at reservoir temperature for as long as 45 days. Measure the dynamic IFT at regular intervals.

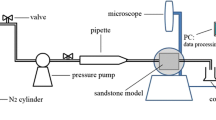

Displacement experiment

Core displacement experiments were conducted under class II high-temperature and high-salinity reservoir condition of Shengli oilfield. The temperature is 80 °C. The salinity of injected brine is 17,435 mg/L. Crude oil is from Shengtuo field with crude viscosity of 30 mPa s. The core model was a 300 × 25 mm single sand-packed tube model with permeability of 3,000 × 10–3 μm2. Injection speed was 0.24 mL/min.

Water flooding

Inject brine water until overall water cut is up to 100 %. The oil recovery is water flooding recovery.

Chemical flooding

Perform routine water flooding until water cut is up to 94 %, inject 0.3 PV of chemical slug, then resume water flooding until overall water cut is 100 %. The improved recovery is the difference between final recovery and water flooding recovery.

Results and discussion

Structural characterization

The structure of synthesized C n HSB was characterized by infrared spectrum. From Fig. 1, 3386.4 cm–1 is O–H expansion vibration peak; 2925.5 and 2854.2 cm–1 are –CH2– asymmetrical and symmetrical expansion vibration peaks, respectively; 1207.2 cm–1 is –SO3 asymmetrical expansion vibration peak; 624.8 cm–1 is –SO3 out-of-plane bending vibration peak; 1052.9 cm–1 is quaternary amine C–N expansion vibration peak. Hence, alkyl-hydroxyl sulfobetaine was confirmed from the infrared spectrum.

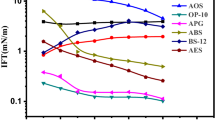

Oil/water IFT

IFT between surfactant solution and crude oil is the primary parameter to evaluate the performance of surfactant in tertiary oil recovery. IFTs between 0.3 wt% C n HSB solutions and Shengli crude oil from various blocks were examined and depicted in Fig. 2. It can be seen that C16HSB and C18HSB can reduce the IFT to an order of 10–3 mN/m or less, while C12HSB and C14HSB can only reduce the IFT to 10−2–10−1 mN/m. C16HSB and C18HSB are more effective implying that surfactants with stronger hydrophobicity are more suitable to Shengli crude oil. As the hydrophobic interaction becomes stronger with increasing alkyl chain length, the molecular arrangement is more orderly and closer at the interface, resulting in optimal interfacial activity. However, the solubility decreases dramatically for zwitterionic surfactants with chain length over C18. Therefore, in this study, only C16HSB and C18HSB were selected for the subsequent evaluation.

IFT after adsorption

The interaction between surfactant and rock might affect the activity of surfactant. The ability to maintain high interfacial activity after interacting with the reservoir sand is very important for oil displacement.

The dynamic IFTs before and after adsorption are shown in Fig. 3. It can be seen that IFT increased but still reached ultra-low after adsorption, indicating that the interaction of C16HSB and C18HSB with sand has no impact on its activity.

Compatibility with polymer

HPAM is the representative polymer used in chemical flooding. The compatibility between C n HSB and HPAM was examined in terms of viscosity and IFT. The viscosity (η) and IFT results are shown in Table 2 and Fig. 4, respectively. Compared with single surfactant system, IFT of binary system increased but still remained in the ultra-low range which is demanded by surfactant EOR. Normally, surfactant as salt can promote polymer hydrolysis that leads to viscosity loss. In contrast, the viscosity of the compound system increased slightly. It might be a result of weak associative interaction between –OH of C n HSB and –CONH– of HPAM through hydrogen bonding. In this respect, C16HSB and C18HSB are favorable for SP flood application.

Thermal stability

The heat aging experiment was performed to evaluate the heat-resistant capability of C n HSB under reservoir conditions. As shown in Fig. 5, 0.3 wt% C16HSB and C18HSB can lower the IFTs to ultra-low after heat aging for 45 days, implying that C16HSB and C18HSB are heat resistant and applicable for high-temperature and high-salinity reservoirs.

Physical simulation

Physical simulation experiment was performed to evaluate the oil displacing capability. Displacement results of different chemical systems are shown in Table 3. For conventional water flooding, the recovery efficiency was only 48.6 %, quite low because of the fingering of injected water. For polymer flooding (0.15 wt% HPAM), the recovery efficiency was 55.7 %. The oil recovery increment is not high (7.1 % over water flooding), indicating that the improvement of sweep efficiency by viscous polymer solution is limited under high-temperature and high-salinity conditions (80 °C, 17435 mg/L). In comparison, the oil recovery of SP flooding (0.3 wt% C18HSB + 0.15 wt% HPAM) reached 67.2 %, increased by 18.6 % for over water flooding and 10.5 % over polymer flooding. The high recovery efficiency is the synergistic result of swept efficiency improvement by polymer and good displacement efficiency by zwitterionic surfactant. Our results indicate that C18HSB is the most favorable surfactant for oil displacement.

Conclusion

A series of novel alkyl-hydroxyl-sulfobetaine zwitterionic surfactants was synthesized and its applicability for chemical EOR in Shengli oilfield was studied. The results showed that C16HSB and C18HSB have excellent interfacial activity over a wide range of reservoir conditions. The interfacial activity was also maintained high after interacting with sand. The compatibility with HPAM is acceptable in terms of viscosity and IFT. Core flooding experiment showed that the oil recovery of SP (0.3 wt% C18HSB + 0.15 wt% HPAM) can be improved by 18.6 % over water flooding. Our study suggests that C18HSB has the potential as new opportunity for high-temperature and high-salinity reservoirs.

References

Austan T (1995) Chemical flooding of oil reservoirs 3. Dissociative surfactant-polymer interaction with a positive effect on oil recovery. Colloids Surf A 103:83–90

Danov KD, Kralchevska SD, Kralchevsky PA, Ananthapadmanabhan KP, Lips A (2004) Mixed solutions of anionic and zwitterionic surfactant (betaine): surface tension isotherms, adsorption and relaxation kinetics. Langmuir 20:5445–5453

El-Aila HJ (2005) Effect of urea and salt on micelle formation of zwitterionic surfactants. J Surfactants Deterg 8:165–168

Harrison D, Szule R, Fisch MR (1998) Solution behavior of the zwitterionic surfactant octadecyldimethylbetaine. J Phys Chem B 102:6487–6492

Sun H, Li Z, Cao X (2007) Surfactant/polymer technology. Science and Technology Publishing House, Beijing

Wang H, Cao X, Zhang J, Zhang A (2009) Development and application of dilute surfactant-polymer flooding system for Shengli oilfield. J Pet Sci Eng 65:45–50

Acknowledgments

The authors thank financial support from the National Science & Technology Major Project of China (2011ZX05011-004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Guo, S., Wang, H., Shi, J. et al. Synthesis and properties of a novel alkyl-hydroxyl-sulfobetaine zwitterionic surfactant for enhanced oil recovery. J Petrol Explor Prod Technol 5, 321–326 (2015). https://doi.org/10.1007/s13202-014-0141-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-014-0141-y