Abstract

The huge consumption of conventional light crude and the continuous depletion of its reserves in addition to rising oil price have shifted attention to heavy oil reserves as an alternative substitute for our world which is largely dependent on petroleum-based fuels energy resource. To exploit heavy oil reserves economically with less environmental impact, the toe-to-heel air injection and its add-on CAtalytic upgrading PRocess In-situ (THAI–CAPRI™) process was developed for its recovery and upgrading in situ in the reservoir. This technology was propelled by several factors: producing oil of commercial value in situ that meets refinery feedstock specifications, the rising global demands for energy, the declining of conventional light oil reservoirs, increasing price of light crude alongside fluctuating supply, and most importantly the abundant deposits of heavy oil and bitumen energy resources worldwide that is waiting exploitation. With estimated 8 trillions of heavy oil and bitumen reserves, it shows their capacity to boost global energy source for decades. The THAI–CAPRI™ process was developed in 1998, and its main objective was to convert heavy oil into light oil in situ without resort to further surface upgrading, in contrast to other thermal technologies like steam flooding, SAGD, CSS, conventional in situ combustion, etc. Throughout this paper the primary focus will be on THAI–CAPRI™ process, a brief overview of the thermal methods commonly applied by the petroleum industry for heavy oil and bitumen recovery will also be presented, so as to enable comparison between the techniques, in view that the findings would shape further research and applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The conventional crude oil is declining continuously in the face of its rising price alongside the increasing energy demand globally. In the light of this, attention of petroleum industries have been turned towards vast deposits of heavy crude oil resource to eliminate energy crisis as light oil approaches its peak production. Although, heavy crude oil resource is encountered in many countries, with over 8 trillion barrels of heavy crude oil and tar sands in place worldwide, major reserves are, however, found in Canada (3 trillion barrels), Venezuela (2 trillion barrels), USA (100–180 billion barrels), Russia (1.1 trillion barrels), Middle East, etc. (Farouq-Ali 2003; OECD/IEA 2005). This discovery minimises exploration risk and stimulates the petroleum industries into looking for means of recovering and upgrading these resources economically, to add more viability and make it easily refinable. This huge deposit of heavy oil is an enormous energy resource that is largely untapped and has the capacity to boost our energy needs this 21st century for the next four decades, while the search and development of alternative energy sources other than petroleum continues.

Geologically, crude oil becomes heavy via biological, chemical and physical degradation processes during migration and after entrapment inside the pore space of the rocky reservoir. So, heavy oil and bitumen is formed from the residue of formerly light oil whose light molecular weight hydrocarbons components have been lost through microbial degradation, water washing and evaporation (Meyer and Attanasi 2003). The US geological survey (USGS) energy resource program has classified crude oil depending on their API (i.e. American Petroleum Institute) gravity [i.e. (141.5/sp.g at 60 °F)––131.5] and viscosity (i.e. the resistance flow) of the oil as follows (Meyer and Attanasi 2003):

-

Light oil (or conventional oil) has API gravity greater than 22° API and a viscosity <100 cP (see Fig. 1).

-

Heavy oils are dense and viscous oil characterised by its asphaltenes content, low API gravity (<22° API) and a viscosity of more than 100 cP (see Fig. 1).

-

Extra-heavy oils are heavy crude oil with API gravity <10° API.

-

Natural bitumen (or Tar sands) is denser, poor mobility, and their extremely high viscosity more than 10,000 cP and API gravity <10° API.

In this paper, heavy and extra-heavy oils are collectively called heavy oil. As there is no clear distinction between heavy crude oils, as they are generally characterised by their poor fluidity due to their high viscosity at reservoir temperatures and low API gravity. Therefore, owing to their high viscosity and extremely low mobility, the recovery factor of heavy oil by primary recovery method which depends on the pressure within the oil reservoir to be greater than hydrostatic pressure to drive the fluids to the production well is low, about 5 % original oil in place (OOIP) is recoverable. Also, secondary recovery methods such water flooding to maintain pressure and push the oil forward can achieve 10–20 % OOIP. In the view of this, tertiary oil recovery (i.e. enhanced oil recovery, EOR) techniques are required to improve production from the early phase. The low recovery factor of primary and secondary methods arises from their low sweep efficiency at the macroscopic level as the viscosity of the heavy oil is far greater than the viscosity of water (i.e. viscous fingering) and the low displacement efficiency at the pores matrix due to capillary forces that trap the oil (Bartel et al. 2007). In such situation, the effective and economical means of recovering heavy oil is by significant viscosity reduction via solvent dilution or heating.

Presently, 12 % of the total global oil supply comes from heavy oil production (Silverman et al. 2011). This is because the exploitation of heavy crude oil deposit is hampered by the recovery challenges such as the cost involved in its production, the cost of pre-processing before refining, its low market value, and the pace of getting the heavy oil out of the reservoir as fast as the production of conventional light crude oil. It presents difficulties at all stages of recovery and processing, mainly due to their low fluidity as a result of the extreme high viscosity (due to the presence of high molecular weight compounds such as asphaltenes and resins) of the oil at reservoir conditions of temperature and pressure. This affects the reservoir productivity index (PI). Additionally, it is difficult to transport heavy oil and bitumen via pipeline to refineries without the addition of diluents or pipeline heating which incurs additional cost. Other problems of processing and refining these resources include the presence of impurities like sulphur, nitrogen, heavy metals (V, Ni), asphaltenes, resins, etc., that drastically deactivate downstream catalyst and process equipment (Nares et al. 2007). These challenges have lowered their price at the world market even though on the same volume basis, heavy oil contains more energy than conventional light crude oils. Therefore, upgrading heavy crude oil to almost light oil in situ will add more value to it.

Nevertheless, because of the extremely high viscosity of heavy oil (i.e. 50–50,000 mPas and bitumen viscosity of about 1,000,000 mPas), cold production can recover <20 % of OOIP (Xia and Greaves 2001a, b). In that case, once cold production has reached its economic limit, the main means of enhancing the production of heavy crude oils from the reservoir is through the reduction of viscosity, and that is best achieved by heating (i.e. thermal methods of EOR). This is because it favours the heavy oil reservoir as the increased temperature of the oil-bearing matrix greatly reduces the oil viscosity by several orders of magnitudes (Xia et al. 2003). This can be achieved, through the injection of hot water or steam, or generation of heat in situ in the oil reservoir by burning a fraction of the crude oil; this is called in situ combustion (Bagci et al. 1998). The application microbial enhanced oil recovery (MEOR) still at developmental stages and also the microbes could not withstand the reservoir conditions. Subsequently, other EOR technologies such as chemical and solvent displacement have been proposed, but they are much slower processes and less effective because they rely on dissolution of solvent into the heavy oil by molecular diffusion and convective dispersion for the recovery of heavy crude oils. In view of this, thermal EOR processes are the most widely used for heavy oil recovery, which includes: steam flooding, steam assisted gravity drainage (SAGD), cyclic steam simulation (CSS), conventional in situ combustion (ISC) and additionally the new novel ‘toe-to-heel’ air injection (THAI™) and its add-on catalytic upgrading process in situ (CAPRI™), collectively called THAI–CAPRI™. These processes rely on the reduction of heavy crude oil viscosity by heat to improve its flow from the oil reservoir to the producer well (Nares et al. 2007). Steam injection is the most commonly used and proven of all the thermal-enhanced oil recovery processes, whose primary recovery mechanism is steam distillation. Field trial of hot water flooding has achieved limited success because of poor transfer heat energy.

Furthermore, conventional surface upgrading technologies in the petroleum industries to convert the heavy residue to light hydrocarbons include coking, thermal and/or catalytic cracking, visbreaking, and hydroconversion processes. These processes can be achieved in a single THAI–CAPRI process, which combines in situ combustion, catalytic upgrading and horizontal wellbore technology for down-hole or in situ recovery and upgrading of heavy oil and bitumen to improve fluidity and subsequently add commercial value to the produced oil. This simply implies taking the process to the oil reservoir, as the reservoir formation acts as the reactor. The idea offers the advantage of minimising impurities such as heavy metals (V, Ni), asphaltenes, and sulphur content found in the produced oil, as most of these contaminants in the heavy crude oil are left in the oil reservoir. This reduces their impact on the environment as well as on downstream processes (Weissman 1997). While the oil recovered from other thermal methods such as SAGD, CSS, steam flooding, and ISC still requires further expensive surface upgrading process prior to refinery. However, the concept of down-hole catalytic upgrading of heavy crude oil in situ was first proposed by Weissman et al. (1996) and Moore et al. (1999). They outlined the requirements for successful in situ upgrading project which include; (1) placement of a down-hole catalyst bed in the oil-bearing geologic matrix, (2) mobilisation of the heavy oil and co-reactants such as hydrogen, water, or carbon monoxide, over the catalyst layer, (3) creating appropriate reaction conditions of temperature and pressure for upgrading at the catalyst layer, and (4) production of the upgraded oil. Subsequently, down-hole in situ upgrading of heavy crude offers several advantages over conventional surface upgrading processes such as less capital investment on demanding downstream processing, improve the ease of pipeline transportation, can be implemented on a well by well basis, and there is no need building an expensive large processing pressure vessel as in surface upgrading, rather the oil reservoir formation act as the reactor (Weissman et al. 1996). Nevertheless, the presence of brine and creating the optimum condition down-hole environment for catalytic activity in the oil reservoir present some challenges not encountered in conventional surface upgrading process.

In addition, electrical down-hole heaters have been proposed, which involve the provision electrical current to generate heat to the vicinity of the wellbore, increase temperature, lower oil viscosity and improve oil production rate (Rodriguez et al. 2008). The technique eliminates the injection of heat carrying fluids into the well; however, the distribution of heat through the entire oil-bearing geologic formation remains one of the major drawbacks of the technique (Weissman et al. 1996). On the other hand, the CAPRI™ process has the ability to further upgrade the thermally cracked heavy crude oil by THAI™ process to almost light crude, as it flows across the catalyst liner along the ‘toe-to-heel’ horizontal production wellbore of the CAPRI. Therefore, in this paper, the potential of the newly proposed novel THAI–CAPRI™ process for heavy oil recovery and upgrading in situ would be reviewed in comparison to other thermal EOR technologies, with the hope that findings will help direct future research and experiment towards providing practical solutions to the challenges presently encountered in heavy oil and bitumen exploitation.

THAI–CAPRI process

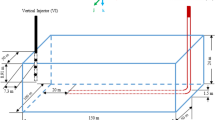

Commonly used thermal EOR processes for the recovery of heavy oil such as steam flooding, CSS, conventional ISC, etc., uses vertical injection and vertical production (VIVP) wells, which operations are long-distance displacement, as the mobilised oil pathway to the production well is hundreds of metres. However, the advent of horizontal well technology leads to the development of short-distance oil displacement processes such as SAGD, vapour extraction (VAPEX), toe-to-heel steam flooding (THSF), and THAI. However, the concept of the THAI process was developed in the 1990s by the Improved Oil Recovery group at the University of Bath (Greaves et al. 2001), and was first field tested early 2005 by Petrobank Energy and Resource Ltd., at Christina Lake, Athabasca tar sands, Alberta, Canada (Greaves 2004). THAI—“toe-to-heel” air injection integrates in situ combustion and horizontal production well concept, as illustrated in Fig. 2 (Greaves and Turta 1997).

The process commences by burning a small fraction of the oil in the reservoir, thereby releasing high temperature oxidation (HTO) energy from the combustion reaction between the injected enriched air and hydrocarbons. The continuous air injection propagates the combustion front from the toe-position to the heel of the horizontal producer well, as illustrated in Fig. 2 (Greaves and Xia 2004). As shown in Fig. 2, the mobilised oil ahead of the combustion front flow short-distance downstream by gravity into the horizontal producer well.

To bypass expansive surface upgrading process, further upgrading of the heavy oil to almost light oil in situ in addition to thermal upgrading can be achieved by the catalytic layer incorporated to horizontal well section. This objective was accomplished in 1998, by the Petroleum Recovery Institute (PRI), Calgary, Canada, in collaboration with the University of Bath Improved Oil Recovery group. The CAPRI process involves incorporating an active catalyst layer between the concentric slotted liners of the horizontal production well(s), as illustrated in Figs. 2 and 3 below (Xia and Greaves 2001a, b; Greaves and Rigby 2008).

Furthermore, few laboratory-scale experiments have been conducted to demonstrate the ability of the THAI–CAPRI process for heavy recovery and upgrading, such as Xia and Greaves (2001a, b) investigation of Wolf Lake heavy oil using Ni-Mo and Co-Mo hydrodesulphurization (HDS) catalysts, and a 3D physical model of THAI–CAPRI at temperatures ranging from 500 to 600 °C and water–air ratio of 1.1 m3/1,000 sm3. The feedstock was Athabasca tar sand bitumen with density of 1007.7 kg/m3 and viscosity 1,000,000 mPas measured at 20 °C. During the experiment, the produced gas was constantly monitored by a three Servomex gas analyser (O2, CO, and CO2). The result shows that THAI process alone achieves nearly ten points increase in the API gravity of the produced oil by pyrolysis, which was further increased in the range of 4–7 points API gravity by the incorporation of catalytic upgrading process in situ (CAPRI), with the produced oil having low viscosity of 10 mPas at 20 °C and 80 % recovery of OOIP. Subsequently, Xia et al. (2002) demonstrated the THAI–CAPRI process potential with a series 3D combustion cell experiments, using Lloydminster heavy crude oil with API gravity of 11.9° API and Co-Mo (HDS) catalyst at a temperature of 500–550 °C. It was found that oil recovery was 79 % OOIP and upgraded oil API gravity of 23° API with low viscosity of 20–30 mPas. The effluent gas compositions include light hydrocarbons (C1–C5, H2, CO, CO2, H2S, etc.). Based on the results from literatures, it shows that THAI–CAPRI process has the potential to convert heavy crude oil to almost light crude oil in a single step, without further surface upgrade required. The oxidation reaction between hydrocarbons and oxygen generates heat and flue gas in situ to drive the thermal as well as catalytic upgrading reactions. The temperature of the in situ combustion can be controlled by controlling the air injection rate. However, high temperature oxidation (HTO) is desired over low temperature oxidation (LTO).

The THAI–CAPRI process can be applied to shallow reservoirs as well as high pressure ones (>20 bar) achieving operating temperatures of about 400–600 °C favourable to drive the catalytic upgrading process in CAPRI (Xia and Greaves 2001a, b). As the combustion front moves forward from the toe position of the horizontal producer well to the heel, coke lay-down occurs, with the deposited coke being subsequently burnt to sustain the combustion process. The resulting heat causes oil ahead of the coke zone to flow towards the horizontal well in a region known as the mobile oil zone (MOZ) where thermal cracking is believed to take place. The following combustion reactions generate gases as illustrated by three Eqs. 1, 2, 3. These dominant chemical reactions are similar to those of conventional ISC (Xia and Greaves 2001a, b):

-

(a)

Thermal cracking (or pyrolysis):

(1) -

(b)

Oxidation of coke (high temperature oxidation, HTO):

(2) -

(c)

Oxidation of heavy residue:

(3)

Heavy oil upgrading is accomplished through two main chemical reaction routes: hydrogen addition and carbon rejection (Weissman 1997). The thermally cracked oil produced in THAI process is due to carbon rejection reactions, as shown in Eq. 4, which depend on the temperature and pressure in the reservoir.

-

(d)

Carbon rejection:

(4)

Consequently, further upgrading is obtained in the presence of a hydrotreating (HDT) catalyst in CAPRI via catalytic hydrogenation in addition to the pyrolysis of heavy oil as follows:

-

(e)

Hydrogen addition:

(5)

Hydrogen species is released from gasification of hydrocarbon and/or water–gas shift reaction over the catalyst (Hajdo et al. 1985), basically due to the high temperature in situ combustion as shown:

-

(f)

Gasification of hydrocarbon:

(6)

-

(g)

Water–gas shift:

(9)

Notwithstanding, heavy oil is a complex mixture consisting of paraffins, cycloparaffins (naphthenes) and large aromatic compounds. The catalytic upgrading reactions proceed through carbonium ion intermediate and β-scission (Jian-hong et al. 2008). This mechanism is similar to the chain reaction mechanism. It involves three basic stages: initiation step, chain propagation, and termination. The initiation step begins with formation of carbenium ions by protonation of acids sites of the catalysts, due to the direct attack of the Brǿnsted acid sites on C–C and C–H bonds. Additionally, the other routes through which carbenium ions may be generated include: (1) protolytic cracking, (2) hydride abstraction of paraffins, or (3) protonation of olefins by Brǿnsted acid sites (Lee et al. 2011).

Thereafter, series of hydride ion transfer from the oil molecules to carbocations takes place in the chain propagation stage, yielding carbenium ions steadily. In some cases, the generated carbenium ions undergo isomerisation to stable secondary or tertiary carbenium ion through hydride shift or alkyl shift (Lee et al. 2011). However, the produced carbenium ions subsequently split to various smaller hydrocarbons through β-scission, hydride transfer, isomerisation, cracking, alkylation/dealkylation, protonation/deprotonation, ring opening (i.e. naphthenic), cyclisation, etc. On the other hand, in the termination stage the carbonium ions are depronated from the catalyst, collapse to give light hydrocarbons and/or hydrogen, and tri-coordinated carbenium ions (Jian-hong et al. 2008). The key classes of upgrading reactions with general formulae for reactant and products are presented in Table 1 and aromatic cracking mechanism is presented in Fig. 4.

Aromatic cracking mechanism (Lee et al. 2011)

Hydroprocessing (e.g. hydrotreating) catalyst such as oxides of Mo, Co, Ni, and W, which includes Ni-Mo, Co-Mo on a support of alumina, silica or silica–alumina are commonly used catalyst for heavy oil upgrading, this is basically because of their ability to induce hydrocracking, hydrodesulphurisation (HDS), hydrodenitrogenation (HDN), hydrodemetallisation (HDM) and Conradson Carbon Removal (HDCCR), and asphaltenes conversion in the presence of hydrogen and high pressure of about 400 psi (Weissman 1997; Liu et al. 2009). These catalysts are expected to have properties such as mesopore sizes to enhance accessibility to large molecules to the active sites and moderate acidity to reduce deactivation by coke. However, the thermal cracking (i.e. Eq. 1), carbon rejection (i.e. Eq. 4) and the polymerisation and condensation reactions deposit coke on the catalyst which accumulates and plug the pores and voids of the catalyst, leading to fouling and rapid deactivation of the catalyst within a short period. In addition, the clogging of the inter-particle voids by coke gives rise to pressure drop in the CAPRI section which would greatly impact on the process economy. Additionally, the presence of heavy metals (V, Ni, As, Hg, etc.), sulphur and other contaminants in the oil entering the catalyst layer poisons and deactivates the performance and activity of the catalyst. The performance of catalyst used in catalytic upgrading process in situ down-hole is dependent on numerous parameters: feedstock composition, contact time between oil and catalyst, catalyst properties, and operating conditions as shown in Fig. 5.

Furthermore, Gray et al. (2000) proposed chemistry of coke formation on the catalyst surface which causes deactivation during catalytic upgrading reactions as illustrated schematically in Fig. 6. They proposed the following stages of coke formation; first is the adsorption of asphaltenic and resinic components onto the surface of the catalyst because of their polar properties characterised in the order of 30–60 min of operation. Subsequently, the adsorbed component undergoes dehydrogenation resulting in poly-aromatic material with strong adherence to the catalyst surface. Finally, the poly-aromatic materials undergo gradual condensation and polymerisation reactions on the catalyst surface to coke as hydrogen is continuously abstracted from the macromolecule. Finally, the gradual deposition of heavy metals leads to the complete deactivation of the catalyst.

Schematic of coke formation on catalyst surface in CAPRI process (Gray et al. 2000)

The THAI–CAPRI process had been successfully proven at the laboratory scale from literatures; the challenges of the process have been extending the catalyst lifespan to allow sufficient time to process the propagating reaction front as well as in situ regeneration of the deactivated catalyst. In such case, the use of catalysts with larger pores and voids can be useful and more effective for heavier feeds, as it acts as filter, slow to fouling due to deposition of coke and metals, and reduces pressure drop build-up. To demonstrate the further upgrading ability of CAPRI process after the thermal upgrading by THAI as obtained in the laboratory, the Petrobank Energy and Resource Ltd. successfully implemented a pilot field trial of the THAI–CAPRI™ process at Whitesands near Conklin, Alberta, Canada (Petrobank 2010a, b). The P-3B well as it was called has been on continuous production up to 400 barrels per day. They found that the incorporation of CAPRI (i.e. catalytic upgrading process) effectively increased the produced oil API gravity by about 2–5° API, the viscosity further reduced by 10–25 % and the impurities reduced as well compared to that obtained when THAI process was used alone. This result was in line with the laboratory-scale investigation reported by Xia et al. (2002). This significant reduction of viscosity will increase the fluidity of the oil, thereby enhancing recovery and pipeline transportation. A surface upgrading facility, on the other hand may cost $100s million to achieve similar conversion (Xia et al. 2002).

THAI–CAPRI comparison with other thermal EOR processes

The conventional in situ combustion (ISC) offers advantages by generating the heat energy in situ in the reservoir by burning a small of the oil, which includes high heat energy utilisation, efficient displacement drive mechanism and less environmental impact (Moore et al. 1997), but despite the extensive laboratory and field studies, the conventional ISC process has not gained wide acceptance because of the problems associated with the vertical–vertical well pattern (see Fig. 7) such as gas overriding due to density difference between oil and gas, channelling as a result of rock heterogeneity, unfavourable gas/oil mobility ratio and poor process control (Greaves et al. 2000). Details of conventional ISC method is reported by Castanier and Brigham (2003), Greaves et al. (2000) and Xia et al. (2003). In contrast, the THAI–CAPRI process uses a horizontal producer well instead of vertical well as in conventional ISC, this configuration controls the effect of gas overriding, creates a narrow mobile oil zone ahead of the combustion front allows the process to operate efficiently and safely, the cold oil region provides a seal along the horizontal well preventing gas bypassing, and also the effect of reservoir heterogeneity is reduced and thermally and catalytically upgraded oil in situ is preserved, as the upgraded and mobilised oil is drawn down into the horizontal production well in line drive, while for conventional ISC process the mobilised oil flows through the cold high viscous region to the distanced vertical production well (see Fig. 7). In THAI–CAPRI process, the thermally cracked heavy oil aids oil recovery along side catalytic cracking to almost light oil reduces downstream processing prior to refining (Xia et al. 2002).

Similarly, the THAI–CAPRI, steam assisted gravity drainage (SAGD) (see Fig. 8), vapour extraction (VAPEX), and toe-to-heel steam flooding (THSF) are classified as a ‘short-distance displacement’ as the distance travelled by the mobilised oil to the producer well is few metres, compared to hundreds of metres in long-distance displacement like conventional ISC process (see Fig. 7). However, in SAGD and VAPEX (i.e. the solvent equivalent of SAGD), two parallel horizontal wells about 2–10 m apart are used as illustrated in Fig. 8. Steam is injected via the upper well to heat and mobilise the oil, which remains hot as its drains downward by gravity into the lower horizontal production well.

Nonetheless, SAGD has been field tested since 1984, with more than 20 field pilots (Komery et al. 1998) and recovery factor in the range of 20–60 % OOIP. Its applicability, however, requires high reservoir permeability, large formation thickness, labour intensive, the efficiency at later stage of the process decreases due to heat losses, the counter-current flow in the drainage area limits the utilisation of the gravity drive and reservoir energy (natural drive) (Greaves et al. 2000). In addition, steam EOR processes (i.e. CSS, SAGD, THSF, and Steam flooding) are faced with the problems of heat losses to the adjacent formations, which lower the thermal efficiency as the process progresses and also the use of large amount of gas and water for energy and steam generation makes them expensive and uneconomical. On the other hand, the gravity drive and the forced flow drive in THAI–CAPRI process make it more efficient, the continuous air flux stabilises the performances, creates ideal condition for an in situ upgrading with high oil recovery factor of range 79–85 %, eliminates the need for blending with costly diluents to aid transportation, addresses the downstream challenges associated with heavy oil processing as the impact contaminants are minimised, and the finally produced oil has high API gravity and lower viscosity, sulphur, heavy metals and nitrogen content compared to the original heavy oil. Nevertheless, THAI–CAPRI process is faced with problem of rapid catalyst deactivation due to asphaltenes and coke deposition, possible plugging of the catalyst bed leading to high pressure drop as well as early shutdown of the process.

Usually, extracted heavy oil is blended with costly diluents to reduce viscosity to aid its pipeline transportation, but the THAI–CAPRI process can eliminate the need for costly diluents, as commercially valued product is obtained prior to the produced oil getting to the surface. The produced oil in steam flooding, SAGD, CSS, conventional ISC processes, etc., requires additional surface upgrading prior to refining with most of the impurities still present in the oil. Whilst in THAI–CAPRI process the produced oil characteristics are almost equivalent to light oil with low impurities and low viscosity to ease transportation via pipeline. The CSS process in particular is an alternating cyclic process which involves three stages namely: steam injection, soak phase and production, therefore, does not ensure continuous oil production, production decreases as number of repeated cycle increases and the oil recovery factor tends to be low ranges from 10 to 40 % of oil in the drainage area assigned to the production/injection well (Thomas 2007). In depth details of CSS can be found in Denbina et al. (1991). Consequently, for steam system of thermal EOR external gas is the fuel source for steam generation, but for conventional in situ combustion and THAI–CAPRI processes the reservoir oil itself is the fuel source, thereby reducing operational cost. Temperatures of 400–650 °C is achievable in THAI–CAPRI and conventional ISC, allowing heat to penetrate potential barriers in the oil reservoir, as compared to 200–300 °C obtainable in steam technologies. However, unlike steam-based recovery methods, THAI–CAPRI is less affected by the reservoir geologic variables.

The economy of steam-based thermal recovery methods are tenuous and the energy consumed is almost equivalent of the 25 % total energy present in the produced volume of the heavy oil (Silverman et al. 2011). The vital factor that determines the volume (barrels) of oil produced per unit volume of injected steam is the oil–steam ratio, which depends on various factors and varies with time. The project cost forecast for some steam-based method such as SAGD cost in the range of ~$20,000–$42,000 per bbl/day, cyclic steam CSS in the range ~$15,000–$25,000 per bbl/day, while THAI–CAPRI process has lower capital and operational cost because of minimal natural gas consumption, steam and water, and the used catalyst is relatively cheap (Dunn 2010; Petrobank 2010a, b). Additionally, steam-based thermal methods are highly sensitive to oil price and steam–oil ratio. An increase in steam–oil ratio causes a corresponding increase in the amount of water required to produce the same amount of oil. Furthermore, the issues of treatment, disposal and handling the large quantity of water produced at steam-based EOR methods are challenging as well as the amount of emission are large used. However, for THAI–CAPRI process the environmental impact is much lesser. A good evaluation of the various methods of heavy oil recovery and upgrading should be based on energy consumption, economics, environmental impact and oil recovery factor.

Concluding remarks

Presently conventional light oil reserves are diminishing globally in the face of rising global energy demand, with large estimated reserve of heavy crude oil and tar sands worldwide, the petroleum industries are turning to heavy oil as an alternative potential of energy source. The economic production alongside the low market value and the pre-processing cost of heavy oil prior to refining due to the presence of high molecular weight hydrocarbon and heavy metals hampers its exploitation. Also, the environmental and economic challenges associated with the need for natural gas and large amount of water to generate steam in steam flooding, CSS, SAGD, THSF, etc., techniques for heavy oil recovery make them less effective. These realities lead to the development of the THAI–CAPRI technology. The THAI–CAPRI process, therefore, is an emerging technology to enhance the recovery and upgrading of heavy oil to light oil in situ, thereby bypassing expensive surface upgrading process. Offering several advantages over the commonly used thermal EOR technologies as it has high recovery factor, reduces environmental impact of notable pollutants in heavy oil and from the process, produced valuable product and does not involve the use of large quantity of gas and water as in steam technology. However, short catalyst lifetime due to rapid deactivation and possibility of catalyst bed plugging are issues that need to be addressed.

Abbreviations

- EOR:

-

Enhanced oil recovery

- CSS:

-

Cyclic steam simulation

- VIVP:

-

Vertical injection and vertical production

- SAGD:

-

Steam assisted gravity drainage

- ISC:

-

In situ combustion

- VAPEX:

-

Vapour extraction

- THAI:

-

Toe-to-heel air injection

- THSF:

-

Toe-to-heel steam flooding

- HTO:

-

High temperature oxidation

- LTO:

-

Low temperature oxidation

- CAPRI:

-

Catalytic upgrading process in situ

- MOZ:

-

Mobile oil zone

- WHSV:

-

Weight hourly space velocity

References

Bagci S, Turna EP, Altmis U (1998) Steamflooding of medium and light oils in limestone using 3-D laboratory model. Trans IChemE 76(Part A):604–611

Bartel S, Max J, Rudiger M (2007) A firrite element method for the miscible displacement problem. http://www.maths.sussex.ac.uk/seminars/document/seminar-slides-07-007.pdf. Accessed 14 May 2011

Castanier LM, Brigham WE (2003) Upgrading of crude oil via in situ combustion. J Petrol Sci Eng 39:125–136

Denbina ES, Boberg TC, Rotter MB (1991) Evaluation of key reservoir drive mechanisms in the early cycles of steam stimulation at Cold Lake, SPE Reservoir Engineering, pp 207–211

Farouq-Ali SM (2003) Heavy oil-evermore mobile. J Petrol Sci Eng 37:5–9

Gray MR, Zhao Y, McKnight CM (2000) Coke and mineral removal from bitumen hydroconversion catalysts. Fuel 79:285–294

Greaves M (2004) Air injection-improved oil recovery strategy for the UK continental shelf. Bus Br: Explor Prod: Oil Gas Rev, pp 118–121

Greaves M, Rigby SP (2008) In-situ catalytic upgrading of heavy crude and bitumen: optimisation of novel CAPRI reactor. http://www.environmentalresearch.info/search/searchDetails.aspx?ID=406701. Accessed 26 Apr 2011

Greaves M, Turta AT (1997) Oilfield in situ combustion process. US Patent 5,626,191 6 May 1997

Greaves M, Xia TX (2004) Downhole upgrading of Wolf Lake oil using THAI-CAPRI processes-tracer tests. Prep Pap Am Chem Soc Div Fuel Chem 49(1):69–72

Greaves M, Xia TX, Turta AT, Ayasse C (2000) Recent laboratory results of THAI and its comparison with other IOR process, SPE 59334. In:SPE/DOE improved oil recovery symposium held in Tulsa, Oklahoma, 3–5 April 2000

Greaves M, Saghr AM, Xia TX, Turta AT, Ayasse C (2001) THAI-new air injection technology for heavy oil recovery and in situ upgrading. J Can Pet Technol 40(3):38–47

Hajdo LE, Hallam RJ, Vorndran LDL (1985) Hydrogen generation during in situ combustion. In: SPE paper No. 13661 presented at the SPE California Regional Meeting, Bakersfield, California, 27–29 March 1985

Jian-hong G, Long J, Xu Y-H (2008) Protolytic cracking in daqing VGO catalytic cracking process. J Fuel Chem Technol 36(6):691–695

Komery DP, Luhning RW, Pearce JV, Good WK (1998) Pilot testing of post-steam bitumen recovery from mature SAGD well in Canada. In: Petroleum Society of CIM, 49th annual technical conference, Calgary, 10–12 June 1998

Lee Ho J, Sookil K, Young K, Sunwon P (2011) New approach for kinetic modelling of catalytic cracking of paraffinic naphtha. Ind Eng Chem Res 50:4264–4279

Liu Y, Liang G, Langyou W, Baoning Z (2009) Recent advances in heavy oil hydroprocessing technologies. Recent Pat Chem Eng 2:22–36

Meyer RF, Attanasi ED (2003) Heavy oil and natural bitumen-strategic petroleum resources, USGS Fact Sheet 70-03, August. http://pubs.usgs.gov/fs/fs070-03/fs070-03.html. Accessed 26 Apr 2011

Dunn P. Michael (2010) SAGD economics, FirstEnergy Capital. www.firstenergy.com. Accessed 15 May 2011

Moore RG, Laureshen CJ, Belgrave DM, Ursenbach MG, Mehta SA (1997) In-situ combustion heavy-oil reservoirs: problems and perspectives. In Situ 21(1):1–26

Moore RG, Laureshen CJ, Mehta SA, Ursenbach MG, Belgrave JDM, Weissman JG, Kessler RV (1999) A downhole catalytic upgrading process for heavy oil using in situ combustion. J Can Petrol Technol 38(13):72–96

Nares HR, Schacht-Hernandez P, Ramirez-garnica MA, Cabrera-Reyes MC (2007) Heavy-crude-oil upgrading with transition metals. In: SPE 107837 presented at 2007 SPE Latin American and Caribbean petroleum engineering conference, Buenos Aires, 15–18 April 2007, pp 49–50

OECD/IEA (2005) Resources to reserve-oil and gas technologies for the energy markets of the future, internal energy agency. http://www.iea.org. Accessed 20 Apr 2011

Petrobank Energy and Resource Ltd (2010a) Announces first THAI™–CAPRI™ production. http://www.petrobank.com. Accessed 23 Apr 2011

Petrobank Energy and Resource Ltd (2010b) THAI® process. http://www.petrobank.com. Accessed 15 May 2011

Rodriguez R, Bashbush JL, Rincon A (2008) Feasibility of using electrical downhole heaters in Faja heavy oil reservoirs. Presented SPE/PS/CHOA international thermal operations and heavy oil symposium, Calgary, Alberta, 20–23 October 2008

Silverman MA, Pavel SK, Hillerman MD (2011) HTL heavy oil upgrading; A key solution for heavy oil upstream and midstream operations, World Heavy Oil Congress [WHOC11]. Edmonton, Alberta, pp 1–7

Thomas S (2007) Enhanced oil recovery––overview. oil Gas Sci Technol Rev IFP. doi:10.2516/ogst:2007060

Weissman Jeffrey G (1997) Review of processes for downhole catalytic upgrading of heavy crude oil. Fuel Process Technol 50:199–213

Weissman JG, Kessler RV, Sawick RA, Belgrave JDM, Laureshen CJ, Mehta SA, Moore RG, Ursenbach MG (1996) Down-hole catalytic upgrading of heavy crude oil. Energy Fuel 10:883–889

Xia TX, Greaves M (2001a) Downhole upgrading Athabasca tar sand bitumen using THAI-SARA analysis. In: SPE 69693 presented at the 2001 SPE international thermal operations and heavy oil symposium held in Porlamar, Margarita Island, Venezuela, 12 March 2001

Xia TX, Greaves M (2001b) 3-D physical model studies of downhole catalytic upgrading of Wolf Lake heavy oil using THAI. In: CIPC paper 2001-017 presented at the petroleum society’s Canadian internal petroleum conference, Calgary, Alberta, 12–14 June 2001

Xia TX, Greaves M, Werfilli WS, Rathbone RR (2002) Downhole conversion of Lloydminster heavy oil using THAI-CAPRI process. In: SPE/Petroleum Society of CIM/CHOA 78998 presented at international horizontal well technology conference, Calgary, Alberta, 4–7 November 2002

Xia TX, Greaves M, Turta AT, Ayasse C (2003) THAI––a ‘short-distance displacment’ in-situ combustion process for the recovery and upgrading of heavy oil. Trans IChemE 81(Part A):295–304

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Hart, A. The novel THAI–CAPRI technology and its comparison to other thermal methods for heavy oil recovery and upgrading. J Petrol Explor Prod Technol 4, 427–437 (2014). https://doi.org/10.1007/s13202-013-0096-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-013-0096-4