Abstract

Researchers on metallic iron (Fe0) for environmental remediation and water treatment are walking in a valley of confusion for 25 years. This valley is characterized by the propagation of different beliefs that have resulted from a partial analysis of the Fe0/H2O system as (1) a reductive chemical reaction was considered an electrochemical one and (2) the mass balance of iron has not been really addressed. The partial analysis in turn has been undermining the scientific method while discouraging any real critical argumentation. This communication re-establishes the complex nature of the Fe0/H2O system while recalling that, finally, proper system analysis and chemical thermodynamics are the most confident ways to solve any conflicting situation in Fe0 environmental remediation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Preliminary remarks

Metallic iron (Fe0) is increasingly used for water treatment and environmental remediation (Fe0/H2O system) (Madaffari, 2015; Chen et al. 2017; Gatcha-Bandjun et al. 2017: Mwakabona et al. 2017; Song et al. 2017, Yang et al. 2017). There are many recent review articles concerning investigations on the Fe0/H2O system, including Fe0 composites and nano-Fe0. Recently raised critical comments on advances in research on the Fe0/H2O system (Noubactep 2015) have not been properly considered (Li et al. 2015; Guo et al. 2016; Raman and Kanmani 2016; Sleiman et al. 2016; Kumar and Sinha 2017). Typically, Noubactep (2015) and references criticized therein are cited in the same set of available review articles, without any further specification. This suggests that more explanation is needed to convince active researchers to move environmental research on the Fe0/H2O system to the mainstream science. The present article is regarded as an extension of Noubactep (2015) and provides some directions to be reconsidered in this field. Only a proper consideration of hints given herein would enable an open collaborative research aiming at: (1) providing more insightful evidence on the structure/activity relationship within the Fe0/H2O system, (2) characterizing the thermodynamic and kinetic of the Fe0/H2O system as influenced by relevant operational conditions, and (3) facilitating the design and operation of pilot scale tests to prepare more efficient (affordable) and sustainable Fe0-based systems for water treatment and environmental remediation (Mwakabona et al. 2017; Naseri et al. 2017).

Introduction

The last two decades have witnessed the establishment of metallic iron (Fe0) as an excellent filling material for filtration systems in environmental remediation and water treatment (O´Hannesin and Gillham 1998; Scherer et al. 2000; Richardson and Nicklow 2002; Henderson and Demond, 2007; Cundy et al. 2008; Thiruvenkatachari et al. 2008; Comba et al. 2011; Gheju 2011; Naidu 2013; Fu et al. 2014; Obiri-Nyarko et al. 2014; Guan et al. 2015; Naidu and Birke 2015; Noubactep 2015; Guo et al. 2016; Karottu-Ansaf et al. 2016; Zou et al. 2016). In this context, Fe0 is currently regarded as (1) a reductant for some species, (2) an adsorbent for other species, (3) a coagulant for various anionic species (Richardson and Nicklow 2002; Noubactep 2010a; Shrimpton et al. 2015; Lu et al. 2016; Sun et al. 2016; Xu et al. 2016) and (4) a long-term supplier of Fe2+ for activation of oxidation processes (Liang and Guo 2010; Segura et al. 2015; Lee et al. 2014; Lin et al. 2016). The properties making Fe0 suitable for environmental remediation include: (1) its readily availability and (2) its environmental friendliness implying the generation of non-toxic hydroxides and oxides. Contaminants that have been successfully removed from aqueous solutions in the presence of Fe0 include arsenic, bacteria, bromate, chromate, dyes, halogenated organics, mercury, nitrate, nitroaromatics, pesticides, phenolic compounds, phosphates, selenium, uranium, viruses and zinc (Richardson and Nicklow 2002; Henderson and Demond 2007; Guan et al. 2015; Naidu and Birke 2015; Zou et al. 2016).

The literature on using metallic iron (Fe0) for environmental remediation and water treatment (e.g., the Fe0/H2O system) is a richly confused one (Ghauch 2015; Nkundimana et al. 2015; Noubactep 2015; Gheju et al. 2016; Noubactep 2016a). The ancient use of Fe0 for safe drinking water provision both at household (Bischof 1877, 1878; Baker 1934) and large scale (Devonshire 1890; Baker 1934; Van Craenenbroeck 1998) levels has been widely overseen (Mwakabona et al. 2017). The redox complex geochemistry of iron (Table 1) probably constitutes the main reason why the Fe0/H2O system has received such varied attention. In fact, Fe0 is oxidized by water to form FeII species (Eq. 8) that are further transformed to FeIII species and mixed FeII/FeIII species including hydroxides and oxides (Eq. 10) (Liu and Millero 1999; Nesic 2007; Antia 2010; Noubactep 2010a, b, c; Luo et al. 2013; Noubactep 2016b, c, d, e; van Genuchten et al. 2016). The difference in the crystal structure of Fe0 and generated corrosion products (Table 2) implies that the oxide scale is not primarily a protective one (Lazzari 2008; Noubactep 2010c).

Generated FeIII species can be transformed back to FeII species. The whole process is sustained by micro-organisms and in situ generated nascent mineral surfaces (Matheson and Tratnyek, 1994; Pokhrel et al. 2005; Pokhrel and Viraraghavan 2008; Pokhrel et al. 2009; Pokhrel and Viraraghavan 2009). Fe0 oxidation by water also generates H2 (Eq. 8) (Lackovic et al. 2000; Han et al. 2016; Noubactep 2016a, d, e). As summarized, the Fe0/H2O system contains (1) oxidizing agents (e.g., FeIII species), (2) reducing agents (e.g., H2, FeII, Fe3O4) and (3) adsorbing agents (e.g., hydroxides and oxides) acting in synergy. Fe0 can also be specifically used to generate FeII/FeIII (Khan et al. 2000; Noubactep 2016d; Gottinger et al. 2013), H2 (Reardon 1995, 2005), or hydroxides and oxides (Karschunke et al. 2000; Khan et al. 2000). In another phrase, in an Fe0/H2O system a contaminant can be adsorbed, oxidized or/and reduced depending on its affinities to available mineral phases and its chemical reactivity with other species. It is also understood that the surface of Fe minerals possesses catalytic properties for relevant reactions (Furukawa et al. 2002; Richardson and Nicklow 2002; Jia et al. 2007; Jiao et al. 2009; Noubactep 2009a; Ghauch et al. 2010; Ghauch et al. 2011; Gheju and Balcu 2011; Ghauch, 2015; Gheju et al. 2016). However, at concentration levels relevant for natural waters, contaminants are removed from the aqueous phase by (1) adsorption, (2) co-precipitation and (3) size-exclusion (Pokhrel and Viraraghavan 2008; Noubactep 2011b; Luo et al. 2013; Ndé-Tchoupé et al. 2015; Tepong-Tsindé et al. 2015a; b; Noubactep 2016a) (Table 3).

Hundreds of students enrolled in research on the Fe0/H2O system try to exploit (e.g., critically review) the abundant Fe0 literature (Tratnyek 2002) in order to identify knowledge gaps to be filled by own contributions. This review process often involves struggles with confusion, which certainly has an adverse effect on the own research idea, leading to more confusing papers in the scientific literature (Ghauch 2015; Noubactep 2015, 2016a). A survey of the Fe0 literature reveals that confusion is the rule and not the exception (“Common confusions regarding the Fe0/H2O system”) (Sarr 2001; Henderson and Demond 2007; Lee et al. 2004; Comba et al. 2011; Gheju 2011; Fu et al. 2014; Obiri-Nyarko et al. 2014; Ghauch 2015; Naidu and Birke 2015; Noubactep 2015, 2016a, b; Zou et al. 2016). It is obvious that the more confusion the researchers are exposed to, the lower the quality of their results. Accordingly, the resolution of confusion helps mitigate this effect and improve the scientific quality of resulting publications. Herein, the most common confusions of the Fe0 literature are explored for the sake of more clarity within the Fe0 research community.

Common confusions regarding the Fe0/H2O system

A profound understanding of interactions in Fe0/H2O systems yielding water treatment is essential for enhancing the design of Fe0 filters (Sarr 2001; Lee et al. 2004; Li et al. 2006; Henderson and Demond 2011; Ulsamer 2011; Caré et al. 2013; Rahman et al. 2013; Guan et al. 2015). Information regarding Fe0 reactivity and interactions in Fe0/H2O system is highly conflicting (Furukawa et al. 2002. Bartzas and Komnitsas 2010; Li and Benson 2010; Domga et al. 2015; Guan et al. 2015; Noubactep 2015). A recent critical review on 20 years research on ‘applying Fe0 in contaminant removal’ (Guan et al. 2015) was proven confusing as many factors conventionally discussed as limitations of the technology are its true strengths (Ghauch 2015; Noubactep 2015, 2016a, b). The first of these factors is the presence of an oxide scale on Fe0 which is usually presented as the cause of reactivity loss (Mackenzie et al. 1999; Henderson and Demond, 2007; Guan et al. 2015). Together with permeability loss, reactivity loss is the major concern on the sustainability of Fe0 filters (Henderson and Demond 2007; Guan et al. 2015; Moraci et al. 2016). However, if the presence of an oxide scale on Fe0 was such a huge problem, Fe0 would never be used for any decontamination system at pH values of natural waters (pH > 4.5). This pH range corresponds to the lowest solubility of iron (both FeII and FeIII) in water (Liu and Millero 1999; Ghauch 2015). Thus, iron precipitation cannot be avoided. Moreover, if the oxide scale on Fe0 was a problem, Fe0 filters would not have worked for more than 10 years (Phillips et al. 2010; Wilkin et al. 2014; Naidu and Birke 2015).

The present work will not replicate the related discussion extensively presented in the peer-reviewed literature since 2007 (Noubactep 2007, 2008, 2010c, d, 2012a, b, 2013a, b, c, 2014a, b; Ghauch 2015) and summarized in Noubactep (2015). Rather, the focus is on the key points that had led to the most significant confusions. Clearly, it is not discussed herein why discrepant data have been presented but rather mainly where discrepancies come from. It is understood that the origin of controversial reports is that falsehoods were introduced into the information stream of iron corrosion science as Fe0 was considered an own reducing agent under environmental conditions (Noubactep 2007, 2008). The current stand is that misconceptions are so widely propagated that the path back to mainstream science could be regarded as moving ‘against the tide’ (Noubactep 2015, 2016b).

The most important discrepancies regard (1) the mechanism of contaminant removal in Fe0/H2O systems, (2) the use of nano-scale materials, (3) the sustainability of hybrid systems and (4) the design of Fe0 filters. These main issues are interrelated and can be subdivided into several aspects. The next section gives a short comment on twelve selected aspects by identifying their origin and suggest ways out of the valley of confusion.

Fixing confusions in Fe0/H2O systems

Contaminant removal mechanisms in Fe0/H2O systems

The Fe0 technology for water treatment was introduced with the view that Fe0 oxidative dissolution is mediated by contaminant reduction (Matheson and Tratnyek 1994; Weber 1996; Gheju and Balcu 2011; Han et al. 2016). This view supposes that contaminant reduction is the cathodic reaction simultaneous to Fe0 oxidation (Eq. 11) (Ghauch 2015; Noubactep 2016a, b). RCl stands for a chlorinated hydrocarbon.

This view obviously degrades Fe0 corrosion by water (Eq. 8) to a side reaction although water is the solvent ([H2O] = 55.5 mol L−1) and has been documented a stand-alone corrosive agent both in the open corrosion literature (Stratmann and Müller 1994; Nesic 2007; Alamilla et al. 2009) and in the Fe0 remediation literature (Reardon 1995; Khan et al. 2000; Furukawa et al. 2002). Moreover, Fe0 oxidation by Eq. 8 produces iron oxides and hydroxides (Eq. 10) which form a multi-layered oxide scale on Fe0 or in its vicinity (Sun et al. 2016). As a rule, the oxide scale is electronic non-conductive, rendering (quantitative) contaminant reduction after Eq. 11 simply impossible (Ghauch 2015; Noubactep 2015). It should be recalled that all models rationalizing the occurrence of Eq. 11 despite the presence of the oxide scale were proven faulty (Odziemkowski 2009; Noubactep 2016a). It is, therefore, surprising that contaminant reduction at the surface of Fe0 has survived until the present day (Fu et al. 2014; Guan et al. 2015; Naidu and Birke 2015; Statham et al. 2016; Zou et al. 2016). The consideration of the kinetics of Eq. 8 and Eq. 11 excellently demonstrates the fallacy of the ‘reducing Fe0’ theory (Noubactep 2015, 2016a).

Kinetics of contaminant removal in Fe0/H2O systems

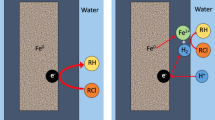

It is established that (1) the interactions between Fe0 and the oxide scale are not galvanic ones and (2) contaminant reduction in Fe0/H2O systems is a chemical reaction (Ghauch 2015; Noubactep 2015; Gheju et al. 2016; Sun et al. 2016). Galvanic interactions occur when electrically conducting phases (e.g., Fe0 and Cu0 or Fe0 and Fe3O4) are in contact and are present in an electrolyte. In an Fe0/H2O system, H2O reduction is the sole cathodic reaction that is likely to be quantitative under environmental conditions (Fig. 1) (Ghauch 2015; Noubactep 2015; Sun et al. 2016). The inherent existence of an Fe0/oxide interface implies time-dependant changes of the rates of Fe0 oxidative dissolution and H2O reduction (Dutrizac and MacDonald 1973; Mehta and Murr 1983; Holmes and Crundwell 1995; Sarr 2001; Ndé-Tchoupé et al. 2015; Tepong-Tsindé et al. 2015a). To fully describe the process of contaminant removal in Fe0/H2O systems, the kinetics of the electrode processes must be considered (Holmes and Crundwell 1995). In other words, the law of FeII generation should be established. This approximatively corresponds to the rate of aqueous iron corrosion that has been traditionally expressed as the mass loss (per unit of surface area) per unit of time (Nesic 2007 and refs. cited therein). An alternative expression is the decrease in Fe0 thickness or the increase of the thickness of the oxide scale per unit of time (Noubactep 2016a). In the remediation research, however, the initial formation and the further transformation of the oxide scale have to be considered as well.

The Fe0/H2O system labeling key features relevant for contaminant (e.g., Cu2+, O2 and RCl) removal. Corrosion begins at a location where Fe2+ is generated (anode). Fe2+ goes into the aqueous solution and two electrons, left behind migrate to another location (cathode) where they are taken up by H+ from water dissociation. The resulting hydroxide ions (OH−) react with the Fe2+ to initially form hydrous iron oxides that precipitate as Fe(OH)2. Depending on the environmental conditions Fe(OH)2 is oxidized and transformed to various FeII/FeIII oxides that form the oxide scale. The oxide scale impairs quantitative contaminant transfer to the Fe0 surface. Reproduced with permission of Atlas of Science

The kinetics of sustained Fe0 oxidative dissolution involve a series of stages comprising: (1) the H2O adsorption onto the Fe0 surface; (2) the formation of an oxide nucleus and (3) the increase in the thickness of the oxide scale. Once the oxide scale has formed over the whole surface, its growth occurs through solid-state diffusion processes within the scale (Griffin 1984; Gan and Orazem 1987; Sikora and Macdonald 2000; Nesic 2007; Lazzari 2008). The oxide scale on Fe0 is non-protective in essence; it detaches due to the compressive stresses which originate from differences in the crystal structures of metallic iron and its oxides (Noubactep 2010c; Lazzari 2008). As a consequence, the Fe0 surface is continually exposed to water and the oxidation rate can be considered constant. Thus, the oxide scale growth is linear and the generation of FeII species can be given by an equation of the following type:

where t is the time and k iron (Noubactep 2016c) is a constant of the used metal (apparent rate constant of iron corrosion).

Giving the kinetics of iron corrosion by relations similar to Eq. 12 is certainly an oversimplification. A similar reasoning may yield the concentration of generated H2 (Eq. 8). For example, while considering the H2 entrapment rate by the iron granules (Sievert’s law), the apparent corrosion rate of Fe0 materials could be characterized by monitoring H2 evolution (VH2) in sealed cells (Reardon 1995, 2005). These results recall the importance of kinetic considerations and point out the following. Although Fe0 is a class of material from a thermodynamic view (E 0 = −0.44 V), it should be considered that each Fe0 material is subject to its own unique corrosion process (intrinsic reactivity). Composite iron matrix, iron nails, iron fillings, steel wool and sponge iron and other materials have been widely tested and used in Fe0 filtration systems (Li et al. 2011; Allred 2012; Neumann et al. 2013 Xu et al. 2013; Allred and Racharaks 2014; Allred and Tost 2014; Ju et al. 2015a, b, c). Each tested material has its own benefits but there is still nothing like a characteristic material class, e.g., cast iron fillings perform better than iron nails for a given application. The material selected for each application needs to have the necessary chemical (and mechanical) properties to fulfill the intended function of the installation.

The typical relationship giving the kinetics of contaminant (X) reduction by FeII species is well known to geoscientist (e.g., pyrite oxidation) (Schwertmann 1991; Eggleston et al. 1996; Cornell and Schwertmann 2003; Duckworth and Martin 2004) and is given by Eq. 13. Herein, m and n are constants with ‘n + m’ being the order or reaction (reduction by Fe2+).

Until now, k iron has not been determined or was determined independently from contaminant reduction (Reardon 1995, 2005; Ruhl et al. 2012a). However, [Fe2+] in Eq. 13 (given by Eq. 12) is produced from Eq. 8 but is difficult to quantify because of the low solubility of Fe in the neutral pH range. The main sources of electrons for any contaminant in an Fe0/H2O system are H2 and FeII species (indirect reduction) (Jiao et al. 2009; Ghauch et al. 2010, 2011; Gheju and Balcu 2011; Gheju et al. 2016). Accordingly, properly modeling the kinetic of any reductive transformation in Fe0/H2O systems depends on the accurate characterization of the kinetics of the production of Fe2+ and H+ or the determination of the kinetics of Fe0 corrosion by water (Eq. 8) (Noubactep 2016a, b).

Iron mass balance

Scientists have been also driven deeply into confusion because of the lack of mass balance for iron. The mass balance of contaminants has been done while considering that non-recovered original species is chemically reduced (Lee et al. 2004; Noubactep 2007; Ghauch 2015). In this manner, the amount of contaminant certainly enmeshed in the matrix of the oxide scale (co-precipitation) is considered chemically reduced (Noubactep 2007, 2008). Considering the mass balance of iron would have evidenced the importance of adsorption and co-precipitation that are still mostly just considered as other reaction paths beside reductive transformations (degradation or precipitation) (Chen et al. 2013; Obiri-Nyarko et al. 2014; Guan et al. 2015).

Contaminants are removed in Fe0/H2O systems by a synergy between adsorption, co-precipitation and size-exclusion. Contaminant chemical transformation (if applicable) is mediated by iron corrosion products (e.g., FeII, FeIII, Fe3O4 and/or H2) but even reduced species (e.g., reaction products) must be removed to a level below the maximum contaminant level (MCL) allowed. In another phrase, the mechanisms of contaminant removal in Fe0/H2O systems are known. The extent of individual mechanisms varies with operational parameters (e.g., amount of Fe0, Fe0 intrinsic reactivity, residence time, age of the Fe0 filters). Despite this evidence, the number of even recent publications investigating the mechanism of contaminant removal in Fe0/H2O systems is large (Guan et al. 2015 and ref. cited therein) and Fe0 is still cited as an environmental reducing agent (Zou et al. 2016).

The suitability of nano-scale Fe0 materials

The relationship between the particle diameter (d) and the specific surface area (SSA) helps to understand the suitability of nano Fe0. Per definition, the SSA is the surface divided by the mass. Assuming a spherical geometry, the surface is π × d 2 and the mass is ρ/6 × ρ × d 3 (ρ = density). Thus,

For two different particle sizes d 1 and d 2, d 2 = n × d 1, SSA1/SSA2 = d 2/d 1 = n × d 1/d 1 = n. If d 2 = 2 × d 1, SSA1/SSA2 = 2. This means that halving the particle size doubles the surface area. In other words, using smaller particles increases the area available for contaminant accumulation (adsorption) and subsequent reduction (if applicable). However, decreasing the particle size is coupled with rapid production of corrosion products and, thus, short service life for the Fe0 materials (Gillham 2003; Crane and Scott 2012; Noubactep et al. 2012a). Moreover, because small particles react very rapidly, particle cementation is observed within a relative short time (Crane and Scott 2012; Noubactep et al. 2012a). Although there are other explanations for particle agglomeration, expansive iron corrosion is the first one and implies that dispersion of nano Fe0 is a pre-requisite for its application (Crane and Scott 2012; Noubactep et al. 2012a). Coming back to μm and mm sized particles, the slowness of involved processes has delayed the universal acceptance of the evidence that admixing Fe0 and non-expansive aggregate (e.g., gravel, pumice, sand) are equally a pre-requisite for sustainability (Miyajima 2012; Miyajima and Noubactep 2012; Caré et al. 2013; Noubactep 2013d). It is understood that gelatinous iron hydroxides also cement particles of added aggregates, particularly under oxic conditions. This evidence makes porous materials (composite iron matrix, sponge iron) potential better materials for sustainable Fe0 filters (Rahman et al. 2013; Li et al. 2011; Neumann et al. 2013; Xu et al. 2013).

Adsorption capacity of Fe0

The Fe0 literature is full of partly tabulated values of the adsorption/reduction/removal capacity (e.g., mg g−1) of Fe0 for individual contaminants (Johnson et al. 1996; Richardson and Nicklow 2002; McGeough et al. 2007; Sleiman et al. 2016). However, this parameter is non-appropriate because the used Fe0 mass says nothing about the amount of in situ generated (1) reducing agents (FeII, H2) and/or (2) contaminant collectors (iron oxides) during the experiment/application. The removal capacity (sometimes termed as ‘saturation’) is a parameter borrowed from adsorption literature (adsorptive removal). However, in the adsorption context, the adsorptive surface (SSA) is available at the start of the experiment (t 0 = 0) and the experiments are stopped at equilibrium (t ∞ = t equilibrium). Depending on the size and the porosity of the adsorbent, the equilibrium can be achieved within some hours. In the context of Fe0 remediation, an initial phase of increased contaminant removal is related to several processes including (1) Fe0 oxidative dissolution and (ii) precipitation of iron oxides upon local sursaturation. In particular, a slower removal kinetic following an initial rapid uptake is likely due to changes in the kinetic of Fe0 dissolution (Alamilla et al. 2009; Noubactep 2016a). This stage is at best a pseudo-equilibrium and is only indirectly coupled to an adsorption process as co-precipitation also occur and is more difficult to quantify (Crawford et al. 1993a, b).

Designing Fe0 filters from laboratory data

Efforts to develop comprehensive, cost-effective and rapid approaches for selecting media for water treatment in packed-bed filters use (1) batch laboratory tests, (2) lab-scale continuous flow column tests and (3) pilot-scale tests (Crittenden et al. 1986, 1987, 1991; Johnson et al. 1996; Richardson and Nicklow 2002; Westerhoff et al. 2005, 2006; Moraci and Calabrò 2010; Ndé-Tchoupé et al. 2015; Tepong-Tsindé et al. 2015a, b; Moraci et al. 2016). Such tests have been widely used to evaluate removal efficiency, robustness, operational benefits and cost effectiveness of inert adsorbents and Fe0 materials as well (Morrison et al. 2002; Westerhoff and James 2003; Morrison et al. 2006). As a rule, batch tests provided limited benefit when compared against continuous flow rapid small-scale column tests (RSSCTs) to evaluate contaminant removal capability by tested media (Westerhoff et al. 2006). Moreover, for inert adsorbents, breakthrough curves corresponded well between lab-scale RSSCT and field-based pilot scale, suggesting that RSSCTs offer a time-saving approach for adsorptive media selection (Crittenden et al. 1991; Westerhoff et al. 2005, 2006).

The disadvantages of pilot testing (PT) are summarized by Westerhoff et al. (2006) as follows: it is time consuming (6–8 months) and costly to construct and operate. The advantages of RSSCTs are: (1) short operation time (i.e., few weeks), limited amount of materials (i.e., some grams versus kilograms in PT) and limited amount of water (i.e., few liters versus hundreds of liters for PT). The RSSCTs approach, if reliable, would be an excellent approach to test/verify the suitability of Fe0 material for site-specific application. Unfortunately, Fe0 corrodes with a different kinetics in the time scale in question (weeks vs. years) (Alamilla et al. 2009; Noubactep 2016a). This reason alone disqualifies testing Fe0 materials by RSSCTs. Another fundamental reason against RSSCTs is that they use smaller particle sizes (μm Fe0) of the materials. Because generated iron hydoxides and oxides occupy the same space in PT and RSSCT (Domga et al. 2015), RSSCT would clog very soon and this clogging behavior is not transferable to field situations (mm Fe0). The last fundamental flaw mediated by RSSCTs is the typically used accelerated water flow velocities. This operation increases the contaminant flux in the filter but does not (significantly) impact the kinetics of iron corrosion and, thus, the rate of production of contaminant collectors.

As summarized, there is actually no established intelligent tool to shorten the experimental duration of Fe0 testing while still obtaining reliable results. On the contrary, available discrepancies in the literature have been widely explained after purposefully lengthening the duration of batch experiments from some hours to some weeks (up to 16 weeks or 120 days) while working under quiescent conditions (Noubactep et al. 2003, 2005a, 2006, 2009a). Moreover, inert (e.g., sand) and/or reactive additives (e.g., FeS2, MnO2) have been demonstrated to sustain the efficiency of the Fe0/H20 system primarily by avoiding material compaction and increasing the adsorptive surface by in situ coating of the surface of the additives (Noubactep et al. 2005a; Ghauch et al. 2010, 2011; Noubactep 2013d; Gheju et al. 2016).

Tools to gain reliable design results from column studies were recently presented (Li et al. 2011; Allred 2012; Btatkeu-K et al. 2013, 2014; Miyajima and Noubactep 2015; Phukan 2015; Phukan et al. 2015; Btatkeu-K. et al. 2016; Phukan et al. 2016). In this context, the differential adsorptive behavior of methylene blue onto sand and iron oxides (Mitchell et al. 1955; Saha et al. 2011) is used to follow the extent of in situ coating of sand in Fe0/sand filters. The shortest experiments lasted for 70 days.

The results from ‘long-term’ batch and column studies have recalled that one should first understand the behavior of Fe0 particles used in water treatment before start to develop simplified tests for the materials (Noubactep 2016a). Some simple tests have been presented (Reardon 1995, 2005; Noubactep et al. 2009a; Noubactep 2011a, 2012b; Li et al. 2016) whose adoption would accelerate the understanding of Fe0/H2O systems. However, properly modeling the behavior of Fe0 filters goes exclusively through the characterization of the long-term kinetics of relevant particles and field conditions (Lu et al. 2016; Sun et al. 2016).

Fe0 as external source of FeII

One of the first Fe0 applications for safe drinking water provision consisted in in situ producing FeII to enhance the natural FeII level of groundwater. This operation enabled arsenic removal by sand filtration (Khan et al. 2000; Noubactep et al. 2012b). The method generates Fe2+ by contacting groundwater with Fe0 (H2O oxidizes Fe0—Eq. 1). Generated Fe2+ species are reported to form hydrous ferric oxide (HFO) upon oxidation and As adsorbed on HFO is efficiently removed by a (subsequent) sand filtration (Gottinger et al. 2013; Kowalski and Søgaard, 2014; Wan et al. 2016). In other words, Fe0 is oxidized by water to certainly produce efficient As adsorbents (including HFO).

Quantitative oxidation of AsIII to AsV has been widely assumed to rationalize the process of As removal, since AsIII removal by HFO is not quantitative (Leupin and Hug 2005). This simplification ignores the evidence that HFO and other iron precipitates are formed in situ in the presence of As. Thus, AsIII co-precipitation is likely to be quantitative (Crawford et al. 1993a, 1993b; Noubactep 2007, 2008). The proof that As is not quantitatively removed after any oxidation reaction is given by the quantitative removal of selenium in Fe0/H2O systems (CH2 M Hill, 2010; Twidwell and McCloskey 2011). It is the oxidized Se species, selenate (SeVI) which is not quantitatively removed by HFO. HFO quantitatively removed selenite (SeIV). This means that quantitative Se removal in Fe0/H2O systems would have been rationalized by reduction of SeVI to SeIV. However, it would be absurd to consider that the Fe0/H2O system selectively removes certain contaminants upon oxidation (e.g., As) and others upon reduction (e.g., Se).

The reasoning in this section has shown that Fe0 has been successfully used as external source of FeII for decontamination: \({\text{Fe}}^{ 2+ }_{{({\text{groundwater}})}} + {\text{Fe}}^{ 2+ }_{{({\text{iron \, corrosion}})}}\) generates enough adsorbents for contaminant removal by adsorption and co-precipitation. This knowledge co-exists in the scientific literature with the view that adding external Fe2+ sustains contaminant reduction by Fe0 (Huang et al. 2012, 2013a, b). The fallacy of this view has been largely demonstrated in previous sections. On the other hand, using Fe0 as external source of FeII recalls that Fe0 oxidation by water (Eq. 8) is quantitative.

External source of FeII sustains Fe0 efficiency

Equation 8 can be re-written as a chemical equilibrium.

According to LeChatelier’s Principle, if Fe2+ is added to an Fe0/H2O system (external FeII), the equilibrium will be shifted to the left, meaning that less Fe0 is corroded. Therefore, the argument that external FeII sustains contaminant reduction by Fe0 is not acceptable. Since increased contaminant removal upon addition of external FeII has been largely documented (Huang et al. 2012, 2013a, b), this observation needs a scientific explanation.

An Fe0/H2O system is the home state of iron oxides (oxide scale) with adsorptive affinities to FeII species and contaminants (Mitchell et al. 1955; Miyajima 2012; Btatkeu-K et al. 2014; Phukan 2015; Phukan et al. 2015; Btatkeu-K. et al. 2016; Phukan et al. 2016). Adsorbed FeII (termed as structural FeII) is a more powerful reducing agent than dissolved FeII (Table 1) (White and Peterson 1996; Liger et al. 1999). Accordingly, increased contaminant reduction in Fe0/H2O systems upon addition of external FeII is thermodynamically funded. On the other hand, external FeII increases the concentration of iron and the probability of precipitation (by exceeding the solubility limit). Contaminants are adsorbed onto Fe precipitates and/or co-precipitated with the same. This process is responsible for the better efficiency of (Fe0 + external FeII) systems relative to Fe0 systems.

This section has recalled that Fe0 is quantitatively oxidized by water (Eq. 1) and that the increased efficiency of Fe0/H2O systems upon addition of external FeII is a proof that primary (FeII, H2) and secondary (hydroxides/oxides) corrosion products are responsible for decontamination: chemical transformation and removal from the aqueous phase. In other words, Fe0 is the generator of contaminant collectors (Yao et al. 1971). This knowledge was established prior to the introduction of the Fe0 remediation technology (Tseng et al. 1984; James et al. 1992). For example, Tseng et al. (1984) used steel wool (an Fe0 material) to in situ produce iron oxides as adsorbents for the concentration 60Co from sea water. In another phrase, the fact that so many publications are still discussing the mechanism of contaminant removal in Fe0/H2O systems is highly confusing. Remember that for the range of concentrations of natural waters, chemical reduction is rarely a stand-alone removal mechanism as (1) the initial concentrations are sometimes lower than the solubility limit of the oxidized species or (2) the maximum contamination level (MCL) is higher than the solubility limit of the reduced species (Ndé-Tchoupé et al. 2015). The former case means that the realized decontamination is due to meta-stability while the later demonstrates that additional efforts are needed to reach concentrations lower than the MCL. For properly designed Fe0/H2O systems, contaminants are removed by adsorption, co-precipitation and size-exclusion.

Fe0 ratio in a filter

The differential use of Fe0 as a reducing agent (Matheson and Tratnyek 1994; Weber 1996) or a generator of contaminant collectors (Khan et al. 2000; Gottinger et al. 2013; Chaudhari et al. 2014; Kowalski and Søgaard 2014) suggests that the amount (e.g., the mass in gram) of Fe0 to be used is case specific. For example, Berg et al. (2006) reported that an Fe/As ratio of 250 is required to achieve less than 10 μg/L arsenic concentration. Lower Fe/As ratios have been reported by other researches (Khan et al. 2000), but this issue is not discussed herein. While using Fe0 as a reducing agent, the Fe0 amount is deduced from the stoichiometry of the involved reaction (e.g., Eq. 11). The presentation above has recalled that using reactions similar to Eq. 11 is not acceptable. But the focus in this section is on the kinetics of iron corrosion or the question how long should the experiment last to produce the required amount of reducing agents or adsorbents (iron oxides)?

This question cannot be answered without knowledge of the rate constant of iron corrosion (k iron). k iron values relevant for the particle sizes used in Fe0 filters cannot be obtained from the open corrosion literature and are yet to be determined (Noubactep 2016a). In the absence of k iron values, no scientific discussion on the right Fe0 amount can be performed. This is arguably the main reason why published results are highly qualitative in nature. As an example, the community-scale Fe0 arsenic filter developed at the Indian Institute of Technology Bombay (IITB filter) uses commercial iron nails of unknown k iron values (Chaudhari et al. 2014). Each community filters used some 10 kg iron nails and should work for about 5 years. However, it is not certain that (1) various nail types will give comparable results or (2) the same iron nails at locations with very different water chemistry would work well.

Summarizing the Fe0 amount to be used cannot be addressed before a testing protocol for Fe0 materials is established. Such tests in long-term experiments (>1 year) would yield classes of k iron values which could be used for individual applications (e.g., household filter, HCO3-rich groundwater, chloride-rich wastewaters). k iron values will also determine the Fe0 ratio to be used in a filter (e.g., Fe0/sand). For example, 5% (v/v) of a highly reactive material can be sufficient where 20% of a less reactive material would be needed.

Sustainable Fe0 filters

Filters containing more than 52% Fe0 (v/v) will clog before Fe0 is depleted (material wastage) (Noubactep et al. 2010; Caré et al. 2013). Calculations have been made for spherical particles and a compaction of 64 or 36% porosity (Noubactep and Caré 2010a, b, 2011; Caré et al. 2013; Rahman et al. 2013; Domga et al. 2015). However, it is certain that the higher the Fe0 ratio, the shorter the service life. Further calculations have shown that the optimal hybrid system concealing long-term efficiency (high Fe0) and long-term permeability (less Fe0) is 25% Fe0 (v/v) (Miyajima 2012; Miyajima and Noubactep 2012; Btatkeu-K et al. 2014, 2016). However, as discussed above, using just 5% of an Fe0 material could correspond to 20% of another material depending on the k iron value.

Sand is the most abundant admixing agent for Fe0 filters. Fe0/sand filters should, therefore, be considered a reference system and other systems tested in comparison (Btatkeu-K et al. 2014, 2016). This approach has not been adopted and various aggregates (Fe3O4, gravel, pumice, zeolite) have been positively tested (Moraci and Calabrò 2010; Huang et al. 2012; Bilardi et al. 2013a, b; Huang et al. 2013a, b). In all the cases, it should be considered that the initial system (t 0 = 0) is made up of Fe0 and the used aggregate(s). With increasing operational duration (t > t 0), the aggregates are progressively coated with iron oxides (in situ coating). This is particularly valid for inert aggregates like sand or pumice. In other words, in many systems, the whole filter probably becomes an ionic selective system, preferentially adsorbing species with high affinities to iron oxides (Phukan 2015; Phukan et al. 2015, 2016).

A right wording

The terms ‘efficiency’ and ‘reactivity’ are confusingly used in the Fe0 literature. Miyajima and Noubactep (2015) complained that these terms are mostly randomly interchanged. However, reactivity is an intrinsic property of each material while the efficiency is the expression of the reactivity under specific operational conditions.

In essence, the reactivity of an Fe0 specimen cannot be measured but just indirectly assessed by index comparable to the iodine number or the molasse number for activated carbons (Attia et al. 2008). Such an index can be the H2 volume produced for a fixed duration by a fixed Fe0 mass under well-defined operational conditions (Reardon 1995). No simple protocol for the characterization of the Fe0 reactivity based on H2 production has been presented. An already tested index of the Fe0 reactivity is the kEDTA value introduced by Noubactep et al. (2005b) and validated by Btatkeu-K et al. (2013). The k EDTA is defined as the rate constant of the dissolution of 0.1 g of an Fe0 specimen in 50 mL of a 2 mM M EDTA solution for 96 h (4 days). Li et al. (2016) have recently presented a ‘facile method for determining’ the Fe0 reactivity.

The method of Li et al. (2016) is reported to be based on FeIII/Fe0 redox reaction (Eq. 7, Table 1) which is kinetically rapid, and has a simple stoichiometry, and easy-to-assay reaction products. The experimental protocol implied mixing Fe0 sample with concentrated FeIII solution (≤3.0 g L−1) for up to 4 h. The tested Fe0 specimen is characterized by both (1) the extent of iron dissolution (final total dissolved iron), and (2) the observed dissolution rate constants (intrinsic reactivity). The used experimental duration (just 4 h) can be regarded as too short to address the complexity of processes occurring in Fe0/H2O systems (Btatkeu-K et al. 2016; Noubactep 2016a). However, this very recent paper by Li et al. (2016) is recommended for the state-of-the-art knowledge on quality assurance and quality control for Fe0 materials used in water treatment. In particular, it recalls (1) the diversity of Fe0 materials (e.g., chemical composition, origin, size), (2) that the success of Fe0 in any application depends largely on the material quality, and (3) that reliable methods for Fe0 selection (quality assurance) are urgently needed (Richardson and Nicklow 2002; Btatkeu-K et al. 2016). Table 4 summarizes some uses of Fe0 materials implying aqueous iron corrosion. It is obvious from the diversity of applications that available expertise should be exploited for the Fe0 remediation technology.

The effects of co-solutes on the efficiency of Fe0/H2O systems

More than thirty variables have been experimentally shown to significantly affect the efficiency of Fe0/H2O systems for water treatment (Henderson and Demond 2007; Xie and Shang 2007; Noubactep et al. 2009a; Comba et al. 2011; Gheju 2011; Obiri-Nyarko et al. 2014; Guan et al. 2015; Sun et al. 2016; Naseri et al. 2017). Related experiments were performed under a variety of conditions (Noubactep et al. 2009a; Li et al. 2016; Sun et al. 2016). This makes comparisons and correlation of achieved results difficult. An analysis of the fundamental processes yielding decontamination, together with some recently achieved results (Btatkeu-K et al. 2016), brings out a number of important considerations which greatly simplify studies of the Fe0/H2O system. The effects of common operational parameters (e.g., Fe0 size, Fe0 type, Fe0 pre-treatment, nature and concentration of contaminants, pH value, presence of dissolved O2, reaction temperature, reaction time) can only be systematically investigated, on a case-by-case basis. On the contrary, the effects of environmental ligands (e.g., bicarbonate, chloride, humic substances, phosphate, sulfate) and other common ions (e.g., chlorate, fluoride, nitrate, nitrite) can be investigated in a way that more transferable results are achieved. This approach is necessary as some contaminants (mostly nitrate and phosphate) are co-solutes in many situations (Chirukuri and Atmakuru 2015).

If the concentration of all species was typically given in moles per litre (mol L−1), it would be practically easier to (1) correlate data obtained from different Fe0/H2O systems using the same Fe0 sample or (2) discuss data obtained from Fe0/H2O systems using different Fe0 samples. For instance, data for the impact of phosphate (\(\text{PO}_4^{3-}\)) could be grouped according to the tested PO4-concentration ranges (e.g., 0–50 μM, 50–100 μM, 100–250 μM…), whether \(\text{PO}_4^{3-}\) is a contaminant or a co-solute. This approach would enable a better discussion of the progress of iron corrosion as impacted by the available amount of phosphate (Noubactep et al. 2012a). If future investigations follow this approach, a database will soon be available to enable the identification of sets of conditions, within which comparable effects of individual co-solutes on the rate of corrosion are achieved. It can be emphasized that the failure to distinguish between these ranges within which different factors are controlling Fe0 dissolution is one of the fundamental reasons why controversial results have so frequently been drawn in characterizing the effects of operational parameters on the efficiency of Fe0/H2O systems (Noubactep 2015).

Discussion

Decontamination mechanism

Metallic iron (Fe0) is now established as a key material for environmental remediation, industrial wastewater treatment and safe drinking water provision (Hussam and Munir 2007; Comba et al. 2011; Gheju 2011; Gottinger et al. 2013; Noubactep 2013a, b; Kowalski and Søgaard 2014; Ghauch 2015; Guan et al. 2015; Naidu and Birke 2015; Noubactep 2015; Zou et al. 2016). Upon well design, Fe0 filters are able to eliminate and/or transform a wide array of biological and chemical species. Relevant species included chlorinated aliphatic hydrocarbons, azo-dyes, bacteria, carbon disulfides, chlorinated aromatics, heavy metals nitro-aromatics and radionuclides (Johnson et al. 1996; Richardson and Nicklow 2002; Henderson and Demond 2007; McGeough et al. 2007; Fu et al. 2014; Obiri-Nyarko et al. 2014; Guan et al. 2015). These species are neutral, negatively or positively charged, polar or not, small or large in size, redox reactive or not. They are collectively removed from the aqueous phase by three mechanisms: (1) adsorption, (2) co-precipitation and (3) size-exclusion. Chemical reductive (and/or oxidative) transformations may occur within the system but are not mediated by the uncorroded iron (Ghauch 2015; Noubactep 2015; Gheju et al. 2016). The abundant literature on Fe0 remediation has a qualitative character because no collective effort for systematic research has been made. The knowledge that the Fe0/H2O system is ion selective should support both the design of future experiments and their interpretation. If this path is followed by several research groups and the results are discussed with respect to charge/size of tested contaminants, a database would be soon available to boost the optimization of Fe0 filters.

Designing Fe0 filters

The evidence that Fe0 filters clog after a certain service life (Westerhoff and James 2003; Hussam and Munir 2007; Hussam 2009; Kowalski and Søgaard 2014) has been investigated independently from the knowledge that iron corrosion is a volumetric expansive process (Pilling and Bedworth 1923; Caré et al. 2008). Based on the assumption that Fe0 is a reducing agent, conventional Fe0 filters contain 100% iron in their reactive zone. Reactive zones with less Fe0 ratios were tested to investigate the extent of filter’s efficiency despite ‘Fe0 dilution’. Another reason for hybrid Fe0 filters (e.g., Fe0/sand) was to save Fe0 costs (Bi et al. 2009; Ulsamer, 2011).

The proper consideration of the volumetric expansive nature of iron corrosion has demonstrated that only hybrid Fe0 filters are sustainable (Noubactep and Caré 2010b; Noubactep et al. 2010; Noubactep and Caré 2011; Bilardi et al. 2013a, b; Caré et al. 2013; Noubactep 2013d; Rahman et al. 2013). The most investigated hybrid system to date is the Fe0/sand system; other additives include anthracite, Fe3O4, MnO2 and pumice (Moraci and Calabrò 2010; Bilardi et al. 2013a, b; Ruhl et al. 2012b; Btatkeu-K et al. 2014). Ideally each additive should be tested using the Fe0/sand system as reference. If this effort is not made, observations will be speculatively interpreted. It is sufficient to note that the Fe0/Fe3O4 system (Huang et al. 2012, a, b) initially combines the positively charged surface of Fe3O4 and in situ generation of FeII (and H/H2) species by corroding Fe0 to remove (and transform) contaminants. In an Fe0/sand system, the initially negatively charged sand surface is progressively coated by a positively charged oxide scale. This implies that investigation regarding the functionality of Fe0/H2O systems should last for several months. As discussed herein, tools to shorten the experimental duration would only make sense when a profound understanding of the system is achieved.

Characterization of Fe0 reactivity

Fe0 samples for water treatment and environmental remediation are conventionally characterized for their elemental composition using for example atomic adsorption spectroscopy (AAS), inductively coupled plasma mass spectrometry (ICP MS) or X-ray fluorescence (XRF). The samples are also characterized using BET-N2 adsorption, scanning electron microscope (SEM) and X-ray diffraction (XRD). The results have demonstrated that Fe0 materials used for environmental remediation widely varied in their elemental composition but no correlation with the efficiency of related systems could be established (Richardson and Nicklow 2002; Miehr et al. 2004; Noubactep et al. 2005a; Btatkeu-K et al. 2013; Birke et al. 2015; Li et al. 2016).

Fe0 materials also vary in shape, size, surface area, and are dissimilar in reactivity (Richardson and Nicklow 2002; Li et al. 2016). Fe0 materials are of various types (e.g., cast iron, direct reduced iron), alloyed to a large number of elements (e.g., C, Cr, Mn, Ni, S, Si or Ti) and are sometimes embedded in complex composites (e.g., with activated carbon, bentonite, clay, membrane and MnO2) (Ghauch et al. 2010; Zou, et al. 2010; Ghauch et al. 2011). These Fe0 materials necessarily depict disparities in their intrinsic reactivity but correlating the reactivity to any material characteristic properties, including the nature of alloyed elements, was proven an impossible task (Richardson and Nicklow 2002; Miehr et al. 2004; Noubactep et al. 2009a; Btatkeu-K et al. 2013; Birke et al. 2015; Li et al. 2016). Disparities in Fe0 reactivity were also documented as resulting from differences in synthetic routes (e.g., gas condensation, H2 reduction and sodium borohydride reduction) (Richardson and Nicklow 2002; Li et al. 2016).

The presentation above clearly demonstrates that characterizing the reactivity of Fe0 materials for water treatment is still a challenge to the scientific community. Past and current efforts have failed to properly consider the specificities of Fe0 materials, in particular their comparatively small size and the paucity of corrosion rate constants applicable to Fe0 filters (Richardson and Nicklow 2002; Noubactep 2010b, 2015; Li et al. 2016). This conclusion clearly shows that the ‘heart’ of the Fe0 technology has not been properly considered. It is, therefore, not surprising that a circular reasoning is established within the Fe0 research community. This circular reasoning is termed herein as a Valley of Confusion. It is now the time to collectively leave this valley.

Undermining the scientific method

Jarrard (2001) summarized some guidance for scientists in an online book on “the structure of science”, its methodologies and logic. Richard D. Jarrard argued that many scientists may agree on the following elements of successful scientific method: “Facts are collected by carefully controlled experiments. Based on these facts, verifiable hypotheses are proposed, objectively tested by further experiments, and thereby proven or discarded.” Herein, ‘facts’ and ‘observations’ can be randomly interchanged. This section recalls that the fundamental elements of the scientific method have been undermined in the Fe0 remediation research. The research started with the observation that chlorinated compounds were chemically reduced in a steel canister. This tangible observation (a fact) yielded to hypothesis that Fe0 was the reducing agent (an hypothesis) (Matheson and Tratnyek 1994). Unfortunately, the hypothesis by Matheson and Tratnyek (1994) was considered a fact by Weber (1996) and validated as such (Ebelle et al. 2016; Noubactep 2016d).

To understand what went wrong with research on Fe0 filters, the following text from Jarrard (2001) will be reproduced: “A law is an explanation in which we have the greatest confidence, based on a long track record of confirmations. A theory, for most scientists, denotes an explanation that has been confirmed sufficiently to be generally accepted, but which is less firmly established than a law. An axiom is a concept that is accepted without proof, perhaps because it is obvious or universally accepted (e.g., time, causality) or perhaps to investigate its implications. A hypothesis is an idea that is still in the process of active testing; it may or may not be correct. Models are mathematical or conceptual hypotheses that provide useful perspectives in spite of recognized oversimplification. Whereas laws and theories are relatively static, hypothesis formation, testing, and evaluation are the dynamic life of science.” It appears that the evidence that Fe0 is a reducing agent (E 0 = −0.44 V for the couple FeII/Fe0, Table 1) has been considered an axiom (accepted without proof) within the Fe0 environmental research community. This is a plausible explanation why, despite one decade of severe refutation (Noubactep 2006, 2007, 2008, 2009a, b, c, 2010a, 2011c, 2015, 2016a, c, d), the theory that Fe0 is an environmental reducing agent has survived (Richardson and Nicklow 2002; Fu et al. 2014; Guan et al. 2015; Zou et al. 2016). However, accepting this theory is refuting the law that under environmental conditions, the Fe0 surface is shielded by a non-conductive scale, making any quantitative electron transfer impossible. In other words, the scientific method has been falsified for the Fe0/H2O system by considering Fe0 an own reducing agent. This mistake is incorporated in the majority of available models and theories (Fu et al. 2014; Obiri-Nyarko et al. 2014; Guan et al. 2015; Moraci et al. 2016).

Actually, the major reason for undermined scientific method is identified but this is not sufficient to justify why a fallacy has survived for two decades. In particular, if observations were collected and reproduced under controlled conditions and the initial hypotheses verified, the validity of the theory that Fe0 is a reducing agent under environmental conditions would have been refuted. Unfortunately, attempts to independently reproduce experimental results are very scarce in the Fe0 literature (Noubactep 2015). This means that Fe0 was considered a class of material and results obtained with various Fe0 materials compared to each other (Richardson and Nicklow 2002; Miehr et al. 2004; Birke et al. 2015; Li et al. 2016). Such an approach always results in qualitative results. It is not surprising that despite two decades of intensive research, the Fe0 remediation technology is still in its infancy (Noubactep 2015, 2016a, c).

Finally, the scientific method has been undermined by a lack of critical evaluation of the available literature on the Fe0/H2O system at the introduction of the technology and during the past two decades. Three examples will be given for illustration.

Example 1 Cast iron pipes have been largely used for water distribution (Baylis 1926; Laskowski et al. 2015). It is established that iron corrosion in cast iron pipes: (1) causes increased turbidity, (2) impairs effectiveness of disinfectants due to their reaction with FeII (Kiéné et al. 1998; Zhang et al. 2008; Liu et al. 2014), and (3) causes increased roughness of the pipe’s interior as a result of a corrosion scale that grows at the Fe0 surface. Despite this evidence, the Fe0 remediation community has overseen that ‘increased turbidity’ and ‘scale growth’ are the main cause of porosity loss in their filters (Noubactep 2013d).

Example 2 The reduction of nitrobenzene in the presence of Fe0 corresponds to the synthesis of aniline as introduced in 1854 by Béchamp (Popat and Padhiyar 2013; and refs. cited therein). However, the Béchamp process is only quantitative in acidic solutions (e.g., HCl). The Béchamp process is the oldest commercial process for preparation of amines (Popat and Padhiyar 2013). The quality of obtained amines is sensitive to operational parameters such as physical state of iron, pH value, type of acid used and agitation speed (Popat and Padhiyar 2013; Hindle et al. 2006; Dong et al. 2010; Le et al. 2011). Despite this century old knowledge, the quantitative reduction of nitrobenzene by Fe0 has been independently discussed (Hung et al. 2000; Hindle et al. 2006; Huang and Zhang 2006). Unfortunately, this discussion has not addressed the reason why nitrobenzene reduction should be quantitative at neutral pH values.

Example 3 Warning of some scientists (Lipczynska-Kochany et al. 1994; Farrell et al. 2001; Lavine et al. 2001; Noubactep 2006; Jiao et al. 2009) about the stability of the theory that Fe0 is an environmental reducing agent has been collectively ignored (Richardson and Nicklow 2002; Fu et al. 2014; Guan et al. 2015; Zou et al. 2016). Moreover, the alternative theory that Fe0 is a generator of reducing agents and iron oxides (Noubactep 2006, 2007, 2008) was equally refuted (Kang and Choi 2009; Tratnyek and Salter 2010), incompletely considered (Chen et al. 2013; Guan et al. 2015) or simply ignored (Fu et al. 2014; Zou et al. 2016). Actually, the alternative theory has conciliated the Fe0 literature with mainstream science while using the scientific method as presented by Jarrard (2001).

The way forward

The presentation herein is a continuation of a systematic work that has been lasting for the last 10 years. The work started by the ascertainment that Fe0 should be a universal material for water treatment in deep bed filtration (Noubactep 2007, 2008, 2009a, 2010a, b, 2011a; Noubactep et al. 2009b). This ascertainment was based on, and supported by previous reports on the efficiency of Fe0 for the quantitative removal several classes of biological and chemical contaminants (Bojic et al. 2001; Richardson and Nicklow 2002; Bojic et al. 2004; You et al. 2005; Bojic et al. 2007; Henderson and Demond 2007; Thiruvenkatachari et al. 2008; Bojic et al. 2009). Subsequent works demonstrated that chemical reduction was not a relevant removal mechanism (Noubactep 2011c) and that observed reductive transformations were not the cathodic reaction coupled to anodic iron dissolution (Ghauch 2015; Noubactep 2015, 2016a).

The next step was the demonstration that the volumetric expansive nature of iron corrosion was the main cause of system clogging as Fe0 is corroded by water (Noubactep 2010a, 2013d; Noubactep and Caré 2010a; Noubactep et al. 2010; Noubactep and Caré 2011; Bilardi et al. 2013a). As a consequence, it was established that admixing non-expansive additive (MnO2, pumice, sand) to Fe0 is a pre-requisite for sustainable filters. It was also demonstrated that for spherical particles the Fe0 ratio should not exceed 52% (v/v). While this threshold value is only valid for spherical particles, it is certain that 100% Fe0 filters are not sustainable and that the least possible Fe0 ratio should be used (Noubactep and Caré 2010a; Noubactep et al. 2010; Noubactep and Caré, 2011; Miyajima and Noubactep 2012; Btatkeu-K et al. 2014).

The last important result is that the Fe0/H2O system is an ion-selective one (Phukan 2015, Phukan et al. 2015, 2016). The selectivity of the Fe0/H2O system is governed by the positively charged surface of iron oxides at neutral pH values. This makes Fe0/H2O systems better adsorbents for negatively charged species. However, also positively species are removed by co-precipitation and size exclusion. This conclusion validates the starting hypothesis that Fe0 filters are universal devices for water treatment (Noubactep et al. 2009b).

The next generation Fe0 filters should be based on the state-of-the-art recalled herein as common basis for future investigations. In essence, the next work consists in building a database for the rate constant of Fe0 materials under field conditions. Some laboratory and field designs were recently published (Noubactep 2011d; Noubactep et al. 2012a; Caré et al. 2013; Bilardi et al. 2013a, 2013b; Ndé-Tchoupé et al. 2015; Tepong-Tsindé et al. 2015a; Li et al. 2016). Practical experiments could start with an Fe0/sand volumetric ratio of 25/75, a 20 cm high reactive zone, a water flow velocity of 150 mL day−1 and should last for at least 365 d (1 year). It is important to notice that parallel experiments should be performed with waters differing in their chemical compositions while using the same Fe0 material (Luo et al. 2013). Such experiments even without model contamination will help in characterizing the kinetics of iron corrosion under field conditions as well as the extent of permeability loss. Changes in the Fe0/H2O system should be characterized by systematically monitoring: (1) the aqueous Fe concentration, (2) the pH value, (3) the water flow velocity, and (4) the electric conductivity. Intermittently adding a contaminant, including an indicator like methylene blue (e.g., 250 mL every 2 months) and monitoring its behavior would help to discuss the efficiency of the investigated systems. At the end of the term, the success of the Fe0 technology depends largely on testing well-characterized materials under well-defined conditions and building a database describing the experimental results as function of all relevant operational parameters. It is understood that the intrinsic reactivity of each Fe0 material (the ‘heart’ of the system) should be properly characterized. Only upon such an initial systematic work could fast and reliable method for Fe0 selection be developed (Naseri et al. 2017). Moreover, the testing procedure should last for at least some months to uncover and go beyond the initial rapid corrosion stage of Fe0 (Alamilla et al. 2009; Ndé-Tchoupé et al. 2015; Noubactep 2015; Tepong-Tsindé et al. 2015b).

Philosophical aspect: leave the valley

A Tibetan saying states: “You must leave the valley of your origin” (to grow spiritually). Its meanings may be translated into the Fe0 literature as “leave the valley of conventional reasoning”. The valley of the origin of the Fe0 technology is the thinking system (e.g., Fe0 as reducing agent) that had accompanied its introduction and had never been seriously questioned or any seriously questioning was ignored (Noubactep 2009a, 2009b; Noubactep and Schöner 2009; Noubactep and Caré 2010a; Noubactep 2011a, a; Togue-Kamga et al. 2012; Gatcha-Bandjun and Noubactep 2013; Kobbe-Dama et al. 2013; Noubactep 2013c, 2014b; Nkundimana et al. 2015).

Leaving “the valley of your origin” is stepping outside of your comfortable homeland. By doing this, you are like a refugee, without a secured protecting home. As you have accepted to leave the comfort at home, you may have to see the difference between work and employment. It could be challenging to convince colleagues (including reviewers and editors) that papers that have been published for 20 years contain thinking mistakes (Noubactep 2015). If there is any pressure to publish (“publish or perish”), you may loose your job because of the novelty of your ideas. You will be working for science while being unemployed in your society. These risks have to be parts of your backpack and will help you in hard times. Remember that it was your choice to leave the Valley of Confusion and climb the mountains of knowledge. Also constantly keep in mind that the reward is not immediate (new grant/paper) but longer lasting (contribution to science).

The way out of the valley of confusion almost always goes through another valley which is a more or less long period, when almost nobody understands you (Thesis Whisperer 2012). If you don’t care, you may lose confidence and belief in yourself. But again, remember that you have decided to follow mainstream science and that the valley leads to a higher state of knowledge. Accordingly, even if the intermediate valley seems endless because you are fighting “against the tide”, be assured of the beauty of the coming landscape beyond, in the kingdom of mainstream science. The present communication understands itself as the flashlight helping the Fe0 research community out of the valley of confusion.

Conclusions

The intensive discussion on the suitability, the efficiency and the sustainability of Fe0-based filtration systems for water treatment and environmental remediation is a long-standing one. This discussion is too vast to be resolved by the fragmented approach that has prevailed for the last 25 years. The enormity and urgency of a common starting point for the Fe0 research community are highlighted herein. The primary focus should be on the aqueous iron corrosion (Fe0 oxidative dissolution) that is common to all evolved systems. This overdue, chemistry-based approach implies a holistic consideration of the problem and would federate efforts on key aspects influencing the design of sustainable systems.

As described herein, there is a strong consensus that Fe0 is a reducing agent for water treatment and environmental remediation. This oversimplification corresponds to a fallacy interchanging ‘reduction by Fe0’ and ‘reduction in the presence of Fe0’. The former implies that contaminant reduction is the cathodic reaction simultaneous to Fe0 oxidative dissolution (electrochemical reaction). The latter implies that, in aqueous systems, Fe0 generates reducing agents that are the actual contaminant reductants (indirect reduction–chemical reaction). The universality of the indirect reduction mechanism is obvious from the presentation herein. In other words, the Fe0 research community should univocally adopt the indirect reduction concept as the path out of the Valley of Confusion or an avenue to affordable, efficient and sustainable Fe0-based filters.

The holistic approach presented herein, whether perceived as an expansion of the toolkit or a paradigm shift, is attempting to meet the need for more reliable models for the design of efficient and sustainable Fe0 filters. This approach augments and completes available methods to address the limitations of conventional Fe0 filters. This science-based approach also counters the prevailing tendency to separately consider (balkanize) ‘contaminant’ and ‘Fe0/H2O interface’. The circular reasoning created within the Fe0 research community by evidence-based investigations (case-by-case) is proven a time and resources wasting approach. On the contrary, results achieved by the holistic approach during the past 5–7 years (from 2010 on) suggest that more success is expected from an open collaboration.

It should be pointed out that while considering established scientific rules that “no model is without limitations”, “no model is immune from criticism” and “all models are needed for further research”, it has been overseen that the ‘reducing Fe0 concept’ is a fallacy. The future of Fe0 filters relies on the ability of the Fe0 research community to adopt a truly interdisciplinary research implying several branches of basic science (e.g., Chemistry, Chemical Engineering, Electrochemistry, Geochemistry). This interdisciplinary approach will strengthen and speed the development of efficient Fe0 filters.

References

Alamilla JL, Espinosa-Medina MA, Sosa E (2009) Modelling steel corrosion damage in soil environment. Corros Sci 51:2628–2638

Allred BJ (2012) Laboratory evaluation of zero valent iron and sulfur-modified iron for agricultural drainage water treatment. Ground Water Monit Remediat 32:81–95

Allred BJ, Racharaks R (2014) Laboratory comparison of four iron-based filter materials for drainage water phosphate treatment. Water Environ Res 86:852–862

Allred BJ, Tost BC (2014) Laboratory comparison of four iron-based filter materials for water treatment of trace element contaminants. Water Environ Res 86:2221–2232

Antia DDJ (2010) Sustainable zero-valent metal (ZVM) water treatment associated with diffusion, infiltration, abstraction and recirculation. Sustainability 2:2988–3073

Attia AA, Girgis BS, Fathy NA (2008) Removal of methylene blue by carbons derived from peach stones by H3PO4 activation: batch and column studies. Dyes Pigment 76:282–289

Baker M (1934) Sketch of the history of water treatment. J Am Water Works Assoc 26:902–938

Bartzas G, Komnitsas K (2010) Solid phase studies and geochemical modelling of low-cost permeable reactive barriers. J Hazard Mater 183:301–308

Baylis JR (1926) Prevention of corrosion and “red water”. J Am Water Works Assoc 15:598–633

Berg M, Luzi S, Trang PTK, Viet PH, Giger W, Stuben D (2006) Arsenic removal from groundwater by household sand filters: comparative field study, model calculations, and health benefits. Environ Sci Technol 40:5567–5573

Bi E, Devlin JF, Huang B (2009) Effects of mixing granular iron with sand on the kinetics of trichloroethylene reduction. Ground Water Monit Remed 29:56–62

Bilardi S, Calabrò PS, Caré S, Moraci N, Noubactep C (2013a) Effect of pumice and sand on the sustainability of granular iron beds for the removal of CuII, NiII, and ZnII. Clean Soil Air Water 41:835–843

Bilardi S, Calabrò PS, Caré S, Moraci N, Noubactep C (2013b) Improving the sustainability of granular iron/pumice systems for water treatment. J Environ Manag 121:133–141

Birke V, Schuett C, Burmeier H, Friedrich H-J (2015) Impact of trace elements and impurities in technical zero-valent iron brands on reductive dechlorination of chlorinated ethenes in groundwater. In: Naidu R, Birke V (ed) Permeable reactive barrier sustainable groundwater remediation, CRC Press: Boca Raton, FL, USA, 2014; pp 87–98

Bischof G (1877) On putrescent organic matter in potable water. I. Proc R S Lond 26:179–184

Bischof G (1878) On putrescent organic matter in potable water. II. Proc R Soc Lond 27:258–261

Bitton GJLHG, Fox JL, Strickland HG (1975) Removal of algae from Florida lakes by magnetic filtration. Appl Microbiol 30:905–908

Bojic A, Purenovic M, Kocic B, Perovic J, Ursic-Jankovic J, Bojic D (2001) The inactivation of escherichia coli by microalloyed aluminium based composite. Facta Universitatis. Phys Chem Technol 2:115–124

Bojic A, Purenovic M, Bojic D (2004) Removal of chromium(VI) from water by micro-alloyed aluminium based composite in flow conditions. Water SA 30:353–359

Bojic A Lj, Purenovic M, Bojic D, Andjelkovic T (2007) Dehalogenation of trihalomethanes by a micro-alloyed aluminium composite under flow conditions. Water SA 33:297–304

Bojic A Lj, Bojic D, Andjelkovic T (2009) Removal of Cu2+ and Zn2+ from model wastewaters by spontaneous reduction-coagulation process in flow conditions. J Hazard Mater 168:813–819

Bolm C, Legros J, Le Paih J, Zani L (2004) Iron-catalyzed reactions in organic synthesis. Chem Rev 104:6217–6254

Branston S, Stanley E, Ward J, Keshavarz-Moore E (2011) Study of robustness of filamentous bacteriophages for industrial applications. Biotechnol Bioeng 108:1468–1472

Btatkeu-K BD, Miyajima K, Noubactep C, Caré C (2013) Testing the suitability of metallic iron for environmental remediation: discoloration of methylene blue in column studies. Chem Eng J 215:959–968

Btatkeu-K BD, Olvera-Vargas H, Tchatchueng JB, Noubactep C, Caré S (2014) Characterizing the impact of MnO2 on the efficiency of Fe0-based filtration systems. Chem Eng J 250:416–422

Btatkeu-K BD, Tchatchueng JB, Noubactep C, Caré S (2016) Designing metallic iron based water filters: Light from methylene blue discoloration. J Environ Manag 166:567–573

Caré S, Nguyen QT, L’Hostis V, Berthaud Y (2008) Mechanical properties of the rust layer induced by impressed current method in reinforced mortar. Cem Concr Res 38:1079–1091

Caré S, Crane R, Calabrò PS, Ghauch A, Temgoua E, Noubactep C (2013) Modeling the permeability loss of metallic iron water filtration systems. Clear Soil Air Water 41:275–282

CH2M Hill Inc. (CH2 M) (2010). Review of available technologies for the removal of selenium from water. Final report prepared for North American Metals Council, 233 p

Chaudhari S, Banerji T, Kumar PR (2014) Domestic- and community-scale arsenic removal technologies suitable for developing countries. In: Ahuja S (ed) Water reclamation and sustainability, Elsevier Inc., ISBN: 978-0-12-411645-0, 155–182 pp. http://dx.doi.org/10.1016/B978-0-12-411645-0.00007-9

Chen L, Jin S, Fallgren PH, Liu F, Colberg PJS (2013) Passivation of zero-valent iron by denitrifying bacteria and the impact on trichloroethene reduction in groundwater. Water Sci Technol 67:1254–1259

Chen A, Shang C, Shao J, Zhang J, Huang H (2017) The application of iron-based technologies in uranium remediation: a review. Sci Total Environ 575:1291–1306

Chirukuri R, Atmakuru R (2015) Sorption characteristics and persistence of herbicide bispyribac sodium in different global soils. Chemosphere 138:932–939

Comba S, Di Molfetta A, Sethi R (2011) A Comparison between field applications of nano-, micro-, and millimetric zero-valent iron for the remediation of contaminated aquifers. Water Air Soil Pollut 215:595–607

Cornell RM, Schwertmann U (2003) The iron oxides, 2nd edn. Wiley, Weinheim, p 664

Crane RA, Scott TB (2012) Nanoscale zero-valent iron: future prospects for an emerging water treatment technology. J Hazard Mater 211–212:112–125

Crawford RJ, Harding IH, Mainwaring DE (1993a) Adsorption and coprecipitation of single heavy metal ions onto the hydrated oxides of iron and chromium. Langmuir 9:3050–3056

Crawford RJ, Harding IH, Mainwaring DE (1993b) Adsorption and coprecipitation of multiple heavy metal ions onto the hydrated oxides of iron and chromium. Langmuir 9:3057–3062

Crittenden JC, Berrigan JK, Hand DW (1986) Design of rapid small-scale adsorption tests for a constant diffusivity. J Water Pollut Control Fed 58:312–319

Crittenden JC, Berrigan JK, Hand DW, Lykins B (1987) Design of rapid fixed-bed adsorption tests for nonconstant diffusivities. J Environ Eng ASCE 1987(113):243–259

Crittenden JC, Reddy PS, Arora H, Trynoski J, Hand DW, Perram DL, Summers RS (1991) Predicting GAC performance with rapid small-scale column tests. J Am Water Works Assoc 83:77–87

Cundy AB, Hopkinson L, Whitby RLD (2008) Use of iron-based technologies in contaminated land and groundwater remediation: a review. Sci Total Environ 400:42–51

Delatour C, Schmitz G, Maxwell E, Kelland D (1983) Designing HGMS matrix arrays for selective filtration. Magn IEEE Trans 19:2127–2129

Devonshire E (1890) The purification of water by means of metallic iron. J Frankl Inst 129:449–461

Domga R, Togue-Kamga F, Noubactep C, Tchatchueng JB (2015) Discussing porosity loss of Fe0 packed water filters at ground level. Chem Eng J 263:127–134

Dong J, Zhao Y, Zhao R, Zhou R (2010) Effects of pH and particle size on kinetics of nitrobenzene reduction by zero-valent iron. J Environ Sci 22:1741–1747

Duckworth OW, Martin S (2004) Role of molecular oxygen in the dissolution of siderite and rhodochrosite. Geochim Cosmochim Acta 68:607–621

Dutrizac JE, MacDonald RJC (1973) The effect of some impurities on the rate of chalcopyrite dissolution. Can Metall Q 12:409–420

Duveau J (1984) Solids separation and liquid clarification system. US Patent No. 4,427,551. 24 Jan. 1984

Ebelle TC, Makota S, Tepong-Tsindé R, Nassi A, Noubactep C (2016) Metallic iron and the dialogue of the deaf. Fresenius Environ Bull. http://www.prt-parlar.de/ (Accepted)

Eggleston CM, Ehrhardt J-J, Stumm W (1996) Surface structural controls on pyrite oxidation kinetics: an XPS-UPS, STM, and modeling study. Am Mineral 81:1036–1056

Farrell J, Wang J, O’Day P, Conklin M (2001) Electrochemical and spectroscopic study of arsenate removal from water using zero-valent iron media. Environ Sci Technol 35:2026–2032

Fu F, Dionysiou DD, Liu H (2014) The use of zero-valent iron for groundwater remediation and wastewater treatment: a review. J Hazard Mater 267:194–205

Furukawa Y, Kim J-W, Watkins J, Wilkin RT (2002) Formation of ferrihydrite and associated iron corrosion products in permeable reactive barriers of zero-valent iron. Environ Sci Technol 36:5469–5475

Gan EC, Orazem ME (1987) A mathematical model for the corrosion of iron in sulfuric acid. J Electrochem Soc 134:1357–1366

Gatcha-Bandjun N, Noubactep C (2013) Metallic iron for environmental remediation: missing the ‘valley of death’. Fresenius Environ Bull 22:2632–2639

Gatcha-Bandjun N, Noubactep C, Benguellah Loura B (2017) Mitigation of contamination in effluents by metallic iron: the role of iron corrosion products. Environ Technol Innov 8:71–83

Ghauch A (2015) Iron-based metallic systems: an excellent choice for sustainable water treatment. Freib Online Geosci 38: 60 pp

Ghauch A, Abou Assi H, Bdeir S (2010) Aqueous removal of diclofenac by plated elemental iron: bimetallic systems. J Hazard Mater 182:64–74

Ghauch A, Abou Assi H, Baydoun H, Tuqan AM, Bejjani A (2011) Fe0-based trimetallic systems for the removal of aqueous diclofenac: mechanism and kinetics. Chem Eng J 172:1033–1044

Gheju M (2011) Hexavalent chromium reduction with zero-valent iron (ZVI) in aquatic systems. Water Air Soil Pollut 222:103–148

Gheju M, Balcu I (2011) Removal of chromium from Cr(VI) polluted wastewaters by reduction with scrap iron and subsequent precipitation of resulted cations. J Hazard Mater 196:131–138

Gheju M, Balcu I, Vancea C (2016) An investigation of Cr(VI) removal with metallic iron in the co-presence of sand and/or MnO2. J Environ Manag 170:145–151

Gillham RW (2003) Discussion of Papers/Discussion of nano-scale iron for dehalogenation by Evan K. Nyer and David B. Vance (2001), Ground Water Monitoring and Remediation, v. 21, no. 2, pages 41-54. Ground Water Monit Remed 23:6–8

Gottinger AM, McMartin DW, Wild DJ, Moldovan B (2013) Integration of zero valent iron sand beds into biological treatment systems for uranium removal from drinking water wells in rural Canada. Can J Civ Eng 40:945–950

Gould JP (1982) The kinetics of hexavalent chromium reduction by metallic iron. Water Res 16:871–877

Griffin GL (1984) A simple phase transition model for metal passivation kinetics. J Electrochem Soc 131:18–21

Guan X, Sun Y, Qin H, Li J, Lo IMC, He D, Dong H (2015) The limitations of applying zero-valent iron technology in contaminants sequestration and the corresponding countermeasures: the development in zero-valent iron technology in the last two decades (1994–2014). Water Res 45:224–248

Guo X, Yang Z, Dong H, Guan X, Ren Q, Lv X, Jin X (2016) Simple combination of oxidants with zero-valent-iron (ZVI) achieved very rapid and highly efficient removal of heavy metals from water. Water Res 88:671–680

Han L, Yang L, Wang H, Hu X, Chen Z, Hu C (2016) Sustaining reactivity of Fe0 for nitrate reduction via electron transfer between dissolved Fe2+ and surface iron oxides. J Hazard Mater 308:208–221

Henderson AD, Demond AH (2007) Long-term performance of zero-valent iron permeable reactive barriers: a critical review. Environ Eng Sci 24:401–423

Henderson AD, Demond AH (2011) Impact of solids formation and gas production on the permeability of ZVI PRBs. J Environ Eng 137:689–696

Hindle KT, Jackson SD, Stirling D, Webb G (2006) The hydrogenation of para-toluidine over rhodium/silica; the effect of metal particle size and support texture. J Catal 241:417–425

Holmes PR, Crundwell FK (1995) Kinetic aspects of galvanic interactions between minerals during dissolution. Hydrometallurgy 39:353–375

Huang YH, Zhang TC (2006) Reduction of nitrobenzene and formation of corrosion coatings in zerovalent iron systems. Water Res 40:3075–3082

Huang YH, Tang CL, Zeng H (2012) Removing molybdate from water using a hybridized zero-valent iron/magnetite/Fe(II) treatment system. Chem Eng J 200:205–263

Huang YH, Peddi PK, Zeng H, Tang CL, Teng XJ (2013a) Pilot-scale demonstration of the hybrid zero-valent iron process for treating flue-gas-desulfurization wastewater: part I. Water Sci Technol 67:16–23

Huang YH, Peddi PK, Zeng H, Tang CL, Teng XJ (2013b) Pilot-scale demonstration of the hybrid zero-valent iron process for treating flue-gas-desulfurization wastewater: part II. Water Sci Technol 67:239–246

Hung H-M, Ling FH, Hoffmann MR (2000) Kinetics and mechanism of the enhanced reductive degradation of nitrobenzene by elemental iron in the presence of ultrasound. Environ Sci Technol 34:1758–1763

Hussam A (2009) Contending with a development disaster: SONO filters remove arsenic from well water in Bangladesh. Innovations 4:89–102