Abstract

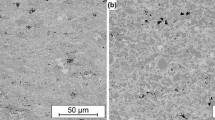

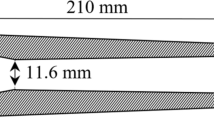

This work is aimed at developing a new type of Cr7C3-(Ni,Cr)3(Al,Cr) coating for parts used in heavy-duty diesel engines. The feedstock, in which the stripe-shaped Cr7C3 was in situ formed, was firstly prepared by vacuum melting and gas atomization and then subjected by high-velocity oxy-fuel spraying to form the coatings. The carbon content, microstructure and phase constitution of the powders, as well as the sprayed coatings, were analyzed by chemical analysis, SEM and XRD. The hardness and sliding wear performance of the sprayed coatings were also tested and compared to a commercial Cr3C2-NiCr coating used on piston rings. The results showed that the content of carbon in feedstock was almost the same as designed, and that the volume content of in situ formed Cr7C3 was increased with carbon and chromium added. The major phases of the powders and sprayed coatings are Cr7C3 and Cr-alloyed Ni3Al. Only a small amount of carbon lost during the spraying process. As Cr7C3 content increased in the coatings, the microhardness at room temperature was firstly increased to about 1000Hv0.3. The microhardness of the coatings stayed almost constant, while the testing temperature was raised up to 700 °C for 0.5 h, which illustrates the potential application of the investigated coatings under high temperature conditions. The coatings containing 70 and 77 vol.% Cr7C3 showed the most promising wear resistance, lower friction coefficient and better tribological compatibility to gray cast iron counterpart than other tested Cr7C3-(Ni,Cr)3(Al,Cr) coatings and the reference Cr3C2-NiCr coating.

Similar content being viewed by others

References

D.C. Herbst, Thermal Spray Solutions For Diesel Engine Piston Rings, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., ASM International, Orlando, 2003, p 120-138

H. Fukutome, H. Shimizu, N. Yamashita, and Y. Shimizu, The Application of Cermet Coating on Piston Ring by HVOF, Thermal Spraying: Current Status and Future Trends, Akira Ohmori, Ed., High Temperature Society of Japan, Kobe, 1995, p 21-26

D. C. Herbst, Thermally Applied Coating of Mechanically Alloyed Powders for Piston Rings, U.S. Patent 6,887,585, 3 May 2005

J.A. Picas, A. Forna, and G. Matthaus, HVOF Coatings as An Alternative to Hard Chrome for Pistons and Valves, Surf. Coat. Technol., 2006, 261(5–6), p 477-484

F. Rastegar and D.E. Richardson, Alternative to Chrome: HVOF Cermet Coatings for High Horse Power Diesel Engines, Surf. Coat. Technol., 1997, 90(1), p 156-163

L.M. Berger, Hardmetals as Thermal Spray Coatings, Powder Metal., 2007, 50(3), p 205-214

S. Matthews, Development of High Carbide Dissolution/Low Carbon Loss Cr3C2-NiCr Coatings by Shrouded Plasma Spraying, Surf. Coat. Technol., 2014, 258, p 886-900

W. Mayr, W. Lengauer, P. Ettmayer, D. Rafaja, J. Baue, and M. Bohr, Phase Equilibria and Multiphase Reaction Diffusion in the Cr-C and Cr-N Systems, J. Phase Equilib., 1999, 20(1), p 35-44

M. Small and E. Ryba, Calculation and Evaluation of the Gibbs Energies of Formation of Cr3C2, Cr7C3, and Cr23C6, Metall. Trans. A, 1981, 12(8), p 1389-1396

R.A. Varin, Intermetallics: Crystal Structures, Encyclopedia of Materials: Science and Technology, 1st ed., K.H.J. Buschow, Ed., Elsevier, Amsterdam, 2001, p 9913 ISBN 0-08-0431526

N. Cinca, C.R.C. Lima, and J.M. Guilemany, An Overview of Intermetallics Research and Application: Status of Thermal Spray Coatings, J. Mater. Res. Technol., 2013, 2(1), p 75-86

P. Jozwik, W. Polkowski, and Z. Bojar, Applications of Ni3Al Based Intermetallic Alloys—Current Stage and Potential Perceptivities, Mater., 2015, 8(5), p 2537-2568

P.J. Blau and C.E. Devore, Sliding Behavior of Alumina/Nickel and Alumina/Nickel Aluminide Couples at Room and Elevated Temperature, J. Tribol., 1988, 110(4), p 646-652

M. Johnson, D.E. Mikkola, P.A. March, and R.N. Wright, The Resistance of Nickel and Iron Aluminides to Cavitation Erosion and Abrasive Wear, Wear, 1990, 140(2), p 279-289

P.V.M. Rao, K.S. Murthy, S.V. Suryanarayana, and S.V.N. Naidu, High Temperature Thermal Expansion Characteristics of Ni3Al Alloys, J. Alloys Compd., 1993, 190(2), p 33-35

Z. Pędzich, K. Haberko, J. Babiarz, and M. Faryna, The TZP–Chromium Oxide and Chromium Carbide Composites, J. Eur. Ceram. Soc., 1998, 18(13), p 1939-1943

K. Gong, H. Luo, D. Feng, and C. Li, Wear of Ni3Al-Based Materials and Its Chromium-Carbide Reinforced Composites, Wear, 2008, 265(11), p 1751-1755

P. La, Q. Xue, and W. Liu, Effects of Boron Doping on Tribological Properties of Ni3Al-Cr7C3 Coatings Under Dry Sliding, Wear, 2001, 249(1–2), p 93-99

C.T. Liu, C.L. White, and E.H. Lee, Effect of test environment on ductility and fracture behavior of boron-doped Ni3Al at 600 °C, Scripta Mater., 1985, 20(10), p 1247-1250

H. Okamoto, Al-Ni (aluminum-nickel), J. Phase Equilib., 1993, 14(14), p 257-259

T.N. Tiegs, K.B. Alexander, K.P. Plucknett, P.A. Menchhofer, P.F. Becher, and S.B. Waters, Ceramic Composites with a Ductile Ni3Al Binder Phase, Mater. Sci. Eng. A, 1996, 209(s1–2), p 243-247

X. Wu, J. Xing, H. Fu, and X. Zhi, Effect of Titanium on the Morphology of Primary M7C3 Carbides in Hypereutectic High Chromium White Iron, Mater. Sci. Eng. A, 2007, 457(1), p 180-185

T.Y. Velikanova, A.A. Bondar, and A.V. Grytsiv, The Chromium-Nickel-Carbon (Cr-Ni-C) Phase Diagram, J. Phase Equilib., 1999, 20(2), p 125-147

S.C. Deevi and V.K. Sikka, Nickel and Iron Aluminides: An Overview on Properties, Processing, and Applications, Intermetallics, 1996, 4(5), p 357-375

H.B. Zhu, H. Li, and Z.X. Li, Plasma Sprayed TiB2-Ni Cermet Coatings: Effect of Feedstock Characteristics on the Microstructure and Tribological Performance, Surf. Coat. Technol., 2013, 235(22), p 620-627

T.L. Stewart and K.P. Plucknett, The Sliding Wear of TiC and Ti(C, N) Cermets Prepared with a Stoichiometric Ni3Al Binder, Wear, 2014, 318(1), p 153-167

M.G. Gee, A. Gant, and B. Roebuck, Wear Mechanisms in Abrasion and Erosion of WC/Co and Related Hardmetals, Wear, 2007, 263(19), p 137-148

J. Vleugels, K.C.H. Kumar, R.G. Vitchev, O. van der Biest, and B. Basu, Unlubricated Fretting Wear of TiB2-containing Composites Against Bearing Steel, Metall. Mater. Trans. A, 2002, 33(12), p 3847-3859

Acknowledgments

The authors are grateful for the financial support by National Natural Science Foundation of China (51541107, 51101017) and International Science & Technology Cooperation Program of China (2015DFA50970).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, HB., Shen, J., Gao, F. et al. Microstructure and Sliding Wear Performance of Cr7C3-(Ni,Cr)3(Al,Cr) Coating Deposited from Cr7C3 In Situ Formed Atomized Powder. J Therm Spray Tech 26, 254–264 (2017). https://doi.org/10.1007/s11666-016-0498-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0498-1