Abstract

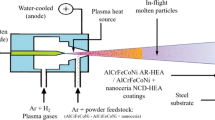

Due to the advantages such as high strength, high hardness and good wear resistance, high-entropy alloys (HEAs) attracted more and more attentions in recent decades. However, most reports on HEAs were limited to bulk materials. Although a few of studies on atmospheric plasma-sprayed (APS) HEA coatings were carried out, the wear behavior, especially the high-temperature wear behavior of those coatings has not been investigated till now. Therefore, in this study, APS was employed to deposit AlCoCrFeNiTi high-entropy alloy coating using mechanically alloyed AlCoCrFeNiTi powder as the feedstock. The phase structure of the initial powder, the feedstock powder and the as-sprayed coating was examined by an x-ray diffractometer. The surface morphology of the feedstock powder and the microstructure of the as-sprayed coating were analyzed by field emission scanning electron microscopy and energy-dispersive spectroscopy. The bonding strength and the microhardness of the as-sprayed coating were tested. The wear behavior of the coating at 25, 500, 700 and 900 °C was investigated by analysis of the wear surface morphology and measurements of the volume wear rate and the coefficient of friction.

Similar content being viewed by others

References

M. Vaidya, S. Armugam, S. Kashyap, and B.S. Murty, Amorphization in Equiatomic High Entropy Alloys, J. Non-Cryst. Solids, 2015, 413, p 8–14

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299–303

C.J. Tong, Y.L. Chen, J.W. Yeh, S.J. Lin, S.K. Chen, T.T. Shun, C.H. Tsau, and S.Y. Chang, Microstructure Characterization of AlxCoCrCuFeNi High-Entropy with Multiprincipal Elements, Metall. Mater. Trans. A, 2005, 36, p 881–893

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, and D.B. Miracle, Oxidation Behavior of a Refractory NbCrMo0.5Ta0.5TiZr Alloy, J. Mater. Sci., 2012, 47, p 6522–6534

S. Varalakshmi, R.A. Rao, M. Kamaraj, and B.S. Murty, Hot Consolidation and Mechanical Properties of Nanocrystalline Aquiatomic AlFeTiCrZnCu High Entropy Alloy After Mechanical Alloying, J. Mater. Sci., 2010, 45, p 5158–5163

C.P. Lee, C.C. Chang, Y.Y. Chen, J.W. Yeh, and H.C. Shih, Effect of the Aluminum Content of AlxCrFe1.5MnNi0.5 High-Entropy Alloys on the Corrosion Behaviour in Aqueous Environments, Corros. Sci., 2008, 50, p 2053–2060

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid Solution and Phase Formation Rules for Multi-Component Alloys, Adv. Eng. Mater., 2008, 10, p 534–538

H.R. Sistla, J.W. Newkirk, and E.F. Liou, Effect of Al/Ni Ratio, Heat Treatment on Phase Transformations and Microstructure of AlxFeCoCrNi2−x (x = 0.3, 1) High Entropy Alloys, Mater. Des., 2015, 81, p 113–121

W. Wu, L. Jiang, H. Jiang, X.M. Pan, Z.Q. Cao, D.W. Deng, T.M. Wang, and T.J. Li, Phase Evolution and Properties of Al2CrFeNiMox High-Entropy Alloys Coating by Laser Cladding, J. Therm. Spray Technol., 2015, 24, p 1333–1340

I. Kunce, M. Polanski, K. Karczewski, T. Plocinski, and K.J. Kurzydlowski, Microstructural Characterization of High-Entropy Alloy AlCoCrFeNi Fabricated by Laser Engineered Net Shaping, J. Alloys Compd., 2015, 648, p 751–758

L. Liu, J.B. Zhu, C. Hou, J.C. Li, and Q. Jiang, Dense and Smooth Amorphous Films of Multicomponent FeCoNiCuVZrAl High-Entropy Alloy Deposited by Direct Current Magnetron Sputtering, Mater. Des., 2013, 46, p 675–679

L.M. Wang, C.C. Chen, J.W. Yeh, and S.T. Ke, The Microstructure and Strengthening Mechanism of Thermal Spray Coating NixCo0.6Fe0.2CrySizAlTi0.2 High-Entropy Alloys, Mater. Chem. Phys., 2011, 126, p 880–885

T.M. Yue, H. Xie, X. Lin, H. Yang, and G. Meng, Microstructure of Laser Re-melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying, Entropy, 2013, 15, p 2833–2845

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, S. Praveen, R.S. Kottada, and B.S. Murty, Plasma-Sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi, Metall. Mater. Trans. A, 2015, 46, p 791–800

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, H. Wang, Y.C. Wang, Q.J. Zhang, and J. Shi, Microstructure and Mechanical Properties of CoCrFeNiTiAlx High-Entropy Alloys, Mater. Sci. Eng. A, 2009, 508, p 214–219

Y.F. Wang, S.G. Ma, X.H. Chen, J.Y. Shi, Y. Zhang, and J.W. Qiao, Optimizing Mechanical Properties of AlCoCrFeNiTix High-Entropy Alloys by Tailoring Microstructures, Acta Metall. Sin. (Engl. Lett.), 2013, 26, p 277–284

Y.F. Wang, The Study of Microstructures and Mechanical Properties of AlCoCrFeNiTi x High-Entropy Alloys. Master Thesis, Taiyuan University of Technology, 2013

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, S.W. Lee, and K. Niihara, Characterization of Nanocrystalline CoCrFeNiTiAl High-Entropy Solid Solution Processed by Mechanical Alloying, J. Alloys Compd., 2010, 495, p 33–38

S. Varalakshmi, M. Kamaraj, and B.S. Murty, Synthesis and Characterization of Nanocrystalline AlFeTiCrZnCu High Entropy Solid Solution by Mechanical Alloying, J. Alloys Compd., 2008, 460, p 253–257

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, J. Shi, W.M. Wang, H. Wang, Y.C. Wang, and Q.J. Zhang, Nanocrystalline CoCrFeNiCuAl High-Entropy Solid Solution Synthesized by Mechanical Alloying, J. Alloys Compd., 2009, 485, p L31–L34

S. Liu and W.G. Huang, Microstructure and Mechanical Performance of AlCoCrNiSix High-Entropy Alloys, J. Mater. Eng., 2012, 1, p 222–227

C.C. Tung, J.W. Yeh, T.T. Shun, S.K. Chen, Y.S. Huang, and H.C. Chen, On the Elemental Effect of AlCoCrCuFeNi High-Entropy Alloy System, Mater. Lett., 2007, 61, p 1–5

C.W. Lin, M.H. Tsai, C.W. Tsai, J.W. Yeh, and S.K. Chen, Microstructure and Aging Behaviour of Al5Cr32Fe35Ni22Ti6 High Entropy Alloy, Mater. Sci. Technol., 2015, 31, p 1165–1170

Y. Yu, W.M. Liu, T.B. Zhang, J.S. Li, J. Wang, H.C. Kou, and J. Li, Microstructure and Tribological Properties of AlCoCrFeNiTi0.5 High-Entropy Alloy in Hydrogen Peroxide Solution, Metall. Mater. Trans. A, 2014, 45A, p 201–207

K. Voleník, P. Ctibor, J. Dubský, P. Chráska, and J. Horák, Oxidation of Nickel During Plasma Spraying and Some Properties of Nickel Oxide, Czechoslov. J. Phys., 2004, 54, p C889–C896

J.F. Li and C.X. Ding, Study on Vickers Hardness of Plasma Sprayed Cr3C2-NiCr Coating, J. Chin. Ceram. Soc., 2000, 28, p 223–228

C.F. Lee and T.T. Shun, Age Hardening of the Al0.5CoCrNiTi0.5 High-Entropy Alloy, Metall. Mater. Trans. A, 2014, 45A, p 191–195

G. Bolelli, A. Candeli, L. Lusvarghi, A. Ravaux, K. Cazes, A. Valette, C. Chazelas, E. Meillot, and L. Bianchi, Tribology of NiCrAlY+Al2O3 Composite Coatings by Plasma Spraying with Hybrid Feeding of Dry Powder + Suspension, Wear, 2015, 344-345, p 69–85

A. Ohmori and C.J. Li, Quantitative Characterization of the Structure of Plasma Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, 1991, 201, p 241–252

L.H. Tian, Study on the Preparation and the Properties of FeAl/TiC Composite Coatings by Shrouded Plasma Spraying. PhD Dissertation, Xi’an Jiaotong University, 2012

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys, Acta Mater., 2011, 59, p 6308–6317

Q. Luo, Temperature Dependent Friction and Wear of Magnetron Sputtered Coating TiAlN/VN, Wear, 2011, 271, p 2058–2066

Š. Houdková, E. Smazalová, M. Vostřák, and J. Schubert, Properties of NiCrBSi Coating, As Sprayed and Remelted by Different Technologies, Surf. Coat. Technol., 2014, 253, p 14–26

C. Guo, J. Zhou, J. Chen, J. Zhao, Y. Yu, and H. Zhou, High Temperature Wear Resistance of Laser Cladding NiCrBSi and NiCrBSi/WC-Ni Composite Coatings, Wear, 2011, 270, p 492–498

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Number 51401091); and a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions. The authors also appreciate the Institute of Nuclear Energy Safety Technology of Chinese Academy of Sciences in providing the field emission scanning electron microscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, LH., Xiong, W., Liu, C. et al. Microstructure and Wear Behavior of Atmospheric Plasma-Sprayed AlCoCrFeNiTi High-Entropy Alloy Coating. J. of Materi Eng and Perform 25, 5513–5521 (2016). https://doi.org/10.1007/s11665-016-2396-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2396-6