Abstract

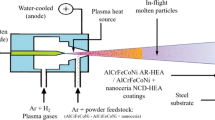

The primary focus of the study is to explore the influence of annealing on the various properties like phase formation, microstructure evolution and wear analysis of equiatomic AlCoCrFeNiTi high entropy alloy (HEA) coatings developed by atmospheric plasma spray technique. Post deposition, annealing was performed at three different temperatures of 700 °C, 900 °C and 1200 °C, respectively, for a time period of 180 min. X-ray diffraction (XRD) studies revealed that AlCoCrFeNiTi HEA coating comprises two BCC solid solution phases. The deposited samples were characterized using scanning electron microscopy (FESEM), surface profilometer, chemical analysis using x-ray photoelectron spectroscopy (XPS) and Fourier transform infra-red spectroscopy (FTIR). The dilution level study revealed the strong metallurgical bonding between coating and substrate. Microhardness of the AlCrCoFeNiTi was found to be marginally decreased by increasing the annealing temperature due to coarsening of grains and the deposited coating microhardness was found to be 768.48 ± 16 HV0.2. Wear test analysis performed using the ball-on disc test revealed that, there is a significant decrease in wear resistance after heat treatment at 1200 °C. Beyond 900 °C, annealing decreased the microhardness and wear resistance due to coarsening of grains. The wear volume rate of the unannealed as-deposited coating was found to be 2.8 × 10–7 mm3 N−1 m−1 and the coating annealed at 700 °C, 900 °C, and 1200 °C had a wear volume rate of about 2.89 × 10–7 mm3 N−1 m−1, 2.87 × 10–7 mm3 N−1 m−1, 7.29 × 10–7 mm3 N−1 m−1, respectively.

Graphical Abstract

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

B. Cantor, Entropy 16, 4749 (2014)

B.S. Murty, J.-W. Yeh, S. Ranganathan, P.P. Bhattacharjee, High-Entropy Alloys, 2nd edn. (Elsevier, Amsterdam, 2019), pp. 37–56

R. Feng, P.K. Liaw, M.C. Gao, M. Widom, npj Comput. Mater. 3, 50 (2017)

S. Guo, C.T. Liu, Prog. Nat. Sci. 21, 433 (2011)

J.-K. Xiao, T.-T. Li, Y.-Q. Wu, J. Chen, C. Zhang, J. Therm. Spray Tech. 30, 926 (2021)

D. Wang, J. Tan, C.J. Li, X.M. Qin, S.F. Guo, J. Alloy. Compd. 885, 161038 (2021)

A. Meghwal, A. Anupam, V. Luzin, C. Schulz, C. Hall, B.S. Murty, R.S. Kottada, C.C. Berndt, A.S.M. Ang, J. Alloy. Compd. 854, 157140 (2021)

J. Lu, L. Li, H. Zhang, Y. Chen, L. Luo, X. Zhao, F. Guo, P. Xiao, Corros. Sci. 181, 109257 (2021)

A. Anupam, R.S. Kottada, S. Kashyap, A. Meghwal, B.S. Murty, C.C. Berndt, A.S.M. Ang, Appl. Surf. Sci. 505, 144117 (2020)

V. Soni, B. Gwalani, O.N. Senkov, B. Viswanathan, T. Alam, D.B. Miracle, R. Banerjee, J. Mater. Res. 33, 3235 (2018)

L.-H. Tian, W. Xiong, C. Liu, S. Lu, M. Fu, J. Mater. Eng. Perform. 25, 5513 (2016)

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, S. Praveen, R.S. Kottada, B.S. Murt, Metall. Mater. Trans. A 46, 791 (2015)

L. Wei, X. Liu, Y. Gao, X. Peng, N. Hu, M. Chen, Intermetallics 138, 107310 (2021)

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, Z.Q. Hu, Mater. Sci. Eng. A 527, 7210 (2010)

H. Liu, S. Sun, T. Zhang, G. Zhang, H. Yang, J. Hao, Surf. Coat. Tech. 405, 126522 (2021)

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, Z.Q. Hu, Mater. Sci. Eng. A 527, 6975 (2010)

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, Z.Q. Hu, J. Alloy. Compd. 509, 3476 (2011)

Q. Chen, Y. Dong, J. Zhang, Y. Lu, Rare Metal Mat. Eng. 46, 651 (2017)

G.F. Ma, H. Ye, H.L. Zhang, C.L. He, H.F. Zhang, Mater. Chem. Phys. 199, 1 (2017)

H. Duan, Wu. Yong, M. Hua, C. Yuan, D. Wang, Tu. Jiesong, H. Kou, J. Li, Wear 297, 1045 (2013)

S.G. Ma, Y. Zhang, Mater. Sci. Eng. A 532, 480 (2012)

Y. Dong, K. Zhou, Y. Lu, X. Gao, T. Wang, T. Li, Mater. Design 57, 67 (2014)

J. Chen, P. Niu, Y. Liu, Y. Lu, X. Wang, Y. Peng, J. Liu, Mater. Design 94, 39 (2016)

G.-S. Ham, Y.-K. Kim, Y.S. Na, K.-A. Lee, Met. Mater. Int. 27, 156 (2021)

Y. Yu, J. Wang, J. Li, H. Kou, W. Liu, Mater. Lett. 138, 78 (2015)

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada, A.S.M. Ang, J. Therm. Spray Tech. 29, 857 (2020)

S. Zhu, Z. Zhang, B. Zhang, Y. Yu, Z. Wang, X. Zhang, B. Lu, J. Therm. Spray Tech. 30, 772 (2021)

H. Zhang, Y. Pan, Y. He, J. Therm. Spray Tech. 20, 1049 (2011)

M. Sha, L. Zhang, J. Zhang, N. Li, T. Li, N. Wang, Rare Metal Mat. Eng. 46, 1237 (2017)

R.K. Mishra, R.R. Shahi, J. Magn. Magn. Mater. 465, 169 (2018)

H. Liu, J. Liu, Xi. Li, P. Chen, H. Yang, J. Hao, Surf. Coat. Tech. 392, 125758 (2020)

P. Patel, S.A. Alidokht, N. Sharifi, A. Roy, K. Harrington, P. Stoyanov, R.R. Chromik, C. Moreau, J. Therm. Spray Tech. 31, 1285 (2022)

J.-T. Liang, K.-C. Cheng, S.-H. Chen, J. Alloy. Compd. 803, 484 (2019)

A. Munitz, S. Salhov, S. Hayun, N. Frage, J. Alloy. Compd. 683, 221 (2016)

P. Wüst, A. Edelmann, R. Hellmann, Materials 13, 418 (2020)

M. Kazemnejadi, Z. Sharafi, B. Mahmoudi, A. Zeinali, M.A. Nasseri, J. Iran Chem. Soc. 17, 777 (2020)

Y. Zhang, W. Li, L.J. France, Z. Chen, Q. Zeng, D. Guo, X. Li, ACS Omega 4, 8681 (2019)

S. Kumar, S. Baruah, A. Puzari, Polym. Bull. 77, 441 (2020)

R.W. Gray, M.B. Welch, R.O. Ragsdale, Inorg. Chim. Acta 3, 17 (1969)

A.N. Mansour, Surf. Sci. Spectra 3, 247 (1994)

I. Pollini, Phys. Rev. B 50, 2095 (1994)

G.A. Carson, M.H. Nassir, M.A. Langell, J. Vac. Sci. Technol. A 14, 1637 (1996)

Y. Yamamoto, M. Mori, H. Konno, Bull. Chem. Soc. Jpn. 54, 1995 (1981)

M.C. Biesinger, B.P. Payne, A.P. Grosvenor, L.W.M. Lau, A.R. Gerson, R.S.C. Smart, Appl. Surf. Sci. 257, 2717 (2011)

Z. Song, J. Hrbek, R. Osgood, Nano Lett. 5, 1327 (2005)

J.A. Rotole, P.M.A. Sherwood, Surf. Sci. Spectra 5, 4 (1998)

I.N. Shabanova, V.A. Trapeznikov, J. Electron. Spectrosc. Relat. Phenom. 6, 297 (1975)

R.H. Temperton, A. Gibson, J.N. O’Shea, Phys. Chem. Chem. Phys. 21, 1393 (2019)

J.F. Moulder, W.F. Stickle, P.E. Sobol, K.D. Bomben, Handbook of X-Ray Photoelectron Spectroscopy (Perkin-Elmer Corporation, Eden Prairie, 1992), pp 82–83

H.A.E. Hagelin-Weaver, G.B. Hoflund, D.M. Minahan, G.N. Salaita, Appl. Surf. Sci. 235, 420 (2004)

A. Kadari, T. Schemme, D. Kadri, J. Wollschläger, Results Phys. 7, 3124 (2017)

S. Srivastava, S. Badrinarayanan, A.J. Mukhedkar, Polyhedron 4, 409 (1985)

G.A. Bhaduri, L. Šiller, Catal Sci. Technol. 3, 1234 (2013)

D. Gonbeau, C. Guimon, G. Pfister-Guillouzo, A. Levasseur, G. Meunier, R. Dormoy, Surf. Sci. 254, 81 (1991)

R. Sanjinés, H. Tang, H. Berger, F. Gozzo, G. Margaritondo, F. Lévy, J. Appl. Phys. 75, 2945 (1994)

H. Lv, G. Ji, W. Liu, H. Zhang, Y. Du, J. Mater. Chem. C 3, 10232 (2015)

P. Ghods, O. Burkan Isgor, F. Bensebaa, D. Kingston, Corros. Sci. 58, 159 (2012)

S. Holfmann, Auger- and X-Ray Photoelectron Spectroscopy in Materials Science (Springer, Berlin, 2013), pp. 487–504

M.G. Fontana, Corrosion Engineering, 3rd edn. (McGraw-Hill, Singapore, 1987), pp. 42–43

S. Sarkar, S. Mukherjee, C.S. Kumar, A.K. Nath, J. Manuf. Process. 50, 279 (2020)

H. Li, J. Li, C. Yan, X. Zhang, D. Xiong, J. Mater. Eng. Perform. 29, 1640 (2020)

M.A.G. Soler, F. Qu, in Raman Spectroscopy for Nanomaterials Characterization, ed. by C.S.S.R. Kumar (Springer Berlin, Heidelberg, 2012), pp. 379–416

Y. Liu, B. Cheng, K.-K. Wang, G.-P. Ling, J. Cai, C.-L. Song, G.-R. Han, Solid State Commun. 178, 16 (2014)

Acknowledgements

This research work is financially supported by the Indian Space Research Organization (ISRO) under project no. (ISRO/RES/3/844/19-20). The authors like to express their gratitude to ISRO for funding this project. The authors extend their gratitude to central instrumentation facility (CIF) at the Indian Institute of Technology Jammu (IIT Jammu) for providing essential characterization facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, H., Bhaduri, G.A., Manikandan, S.G.K. et al. Influence of Annealing on Microstructure and Tribological Properties of AlCoCrFeNiTi High Entropy Alloy Based Coating. Met. Mater. Int. 29, 645–658 (2023). https://doi.org/10.1007/s12540-022-01264-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01264-y