Abstract

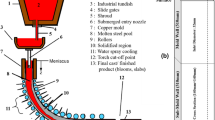

Measurements of clog deposit thickness on the interior surfaces of a commercial continuous casting nozzle are compared with computational fluid dynamics (CFD) predictions of melt flow patterns and particle–wall interactions to identify the mechanisms of nozzle clogging. A submerged entry nozzle received from industry was encased in epoxy and carefully sectioned to allow measurement of the deposit thickness on the internal surfaces of the nozzle. CFD simulations of melt flow patterns and particle behavior inside the nozzle were performed by combining the Eulerian-Lagrangian approach and detached eddy simulation turbulent model, matching the geometry and operating conditions of the industrial test. The CFD results indicated that convergent areas of the interior cross section of the nozzle increased the velocity and turbulence of the flowing steel inside the nozzle and decreased the clog deposit thickness locally in these areas. CFD simulations also predicted a higher rate of attachment of particles in the divergent area between two convergent sections of the nozzle, which matched the observations made in the industrial nozzle measurements.

Similar content being viewed by others

References

SK Choudhary and AJ Khan: Steel Times Int., 2000, vol. 24, p. 21.

KG Rackers and BG Thomas: Urbana, 1995, vol. 51, p. 61801.

H. Schuster S. Rödl, S. Ekerot, G. Xia,N. Veneri, F. Ferro, S. Baragiola, P. Rossi, S. Fera, V. Colla, G. Bioli, M. Krings, L.-F. Sancho, A. Diaz, M. Andersson and N. Kojola, Research Fund for Coal and Steel Unit 2008.

A Theodorakakos and G Bergeles: Metall. Mater. Trans. B, 1998, vol. 29, pp. 1321-1327.

GA Panaras, A Theodorakakos, and G Berggeles: Metall. Mater. Trans. B, 1998, vol. 29, pp. 1117-1126.

J Anagnostopoulos and G Bergeles: Metall. Mater. Trans. B, 1999, vol. 30, pp. 1095-1105.

Noriko Kubo, Toshio Ishii, Jun Kubota, and Norichika Aramaki: ISIJ Int., 2002, vol. 42, pp. 1251-1258.

Yeong-Ho Ho, Chi-Hung Chen, and Weng-Sing Hwang: ISIJ Int., 1994, vol. 34, pp. 255-264.

M. Mohammadi-Ghaleni, M. Zivdar, and M. Reza Nemati: in 6th International Conference on Advanced Computational and Experimenting, 2012, Istanbul, Turkey.

Hua Bai and Brian G Thomas: Metall. Mater. Trans. B, 2001, vol. 32, pp. 707-722.

Lifeng Zhang, Yufeng Wang, and Xiangjun Zuo: Metall. Mater. Trans. B, 2008, vol. 39, pp. 534-550.

C Pfeiler, M Wu, and A Ludwig: Mater. Sci. Eng. A, 2005, vol. 413, pp. 115-120.

Quan Yuan, Brian G Thomas, and SP Vanka: Metall. Mater. Trans. B, 2004, vol. 35, pp. 685-702.

Quan Yuan, Brian G Thomas, and SP Vanka: Metall. Mater. Trans. B, 2004, vol. 35, pp. 703-714.

B.G. Thomas and H. Bai: in Steelmaking Conference Proceedings, 2001.

R Sambasivam: Ironmak. Steelmak., 2006, vol. 33, pp. 439-453.

Lifeng Zhang, Brian G Thomas (2006) J. Univ. Sci. Technol. Beijing Min. Metall. Mater., 13: 293-300.

Fangming Yuan, Xinghua Wang, Jiongming Zhang, and Li Zhang: J. Univ. Sci. Technol. Beijing Miner. Metall. Mater., 2008, vol. 15, pp. 227-235.

Hong Lei, Dian-Qiao Geng, and Ji-Cheng He: ISIJ Int., 2009, vol. 49, pp. 1575-1582.

Mujun Long, Xiangjun Zuo, Lifeng Zhang, and Dengfu Chen: ISIJ Int., 2010, vol. 50, pp. 712-720.

Mahdi Mohammadi-Ghaleni, Mohsen Asle Zaeem, Jeffrey D Smith, and Ronald O’Malley: Metall. Mater. Trans. B, 2016. doi:10.1007/s11663-016-0729-3

ANSYS CFX 14.0 User Manual. Ansys Inc., Canonsburg

Peiyuan Ni, Lage Tord Ingemar Jonsson, Mikael Ersson, and Pär Göran Jönsson: Int. J. Multiph. Flow, 2014, vol. 62, pp. 152-160.

Acknowledgment

The authors would like to acknowledge the Kent D. Peaslee Steel Manufacturing Research Center (PSMRC) at Missouri University of Science and Technology (Missouri S&T) for funding support of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 26, 2016.

Rights and permissions

About this article

Cite this article

Mohammadi-Ghaleni, M., Asle Zaeem, M., Smith, J.D. et al. Comparison of CFD Simulations with Experimental Measurements of Nozzle Clogging in Continuous Casting of Steels. Metall Mater Trans B 47, 3384–3393 (2016). https://doi.org/10.1007/s11663-016-0798-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0798-3