Abstract

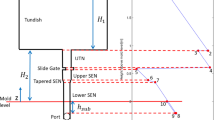

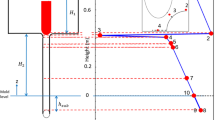

The inter-related effects of nozzle clogging, argon injection, tundish bath depth, slide-gate opening position, and nozzle-bore diameter on the steel flow rate and pressure in continuous-casting slide-gate nozzles are quantified using computational models of three-dimensional (3-D) multiphase turbulent flow. The results are validated with measurements on operating steel continuous slab-casting machines and are presented for practical conditions with the aid of an inverse model. Predictions show that initial clogging may enhance the steel flow rate due to a potential streamlining effect before it becomes great enough to restrict the flow channel. The clogging condition can be detected by comparing the measured steel flow rate to the expected flow rate for those conditions, based on the predictions of the inverse model presented here. Increasing argon injection may help to reduce air aspiration by increasing the minimum pressure, which is found just below the slide gate. More argon is needed to avoid a partial-vacuum effect at intermediate casting speeds and in deeper tundishes. Argon flow should be reduced during shallow tundish and low casting speed conditions (such as those encountered during a ladle transition) in order to avoid detrimental effects on flow pattern. Argon should also be reduced at high casting speed, when the slide gate is open wider and the potential for air aspiration is less. The optimal argon flow rate depends on the casting speed, tundish level, and nozzle-bore diameter and is quantified in this work for a typical nozzle and range of bore diameters and operating conditions.

Similar content being viewed by others

Abbreviations

- a i, bi, ci :

-

curve fitting constants

- D N :

-

diameter of nozzle bore (mm)

- F A :

-

slide-gate opening (area fraction)

- F L :

-

slide-gate opening, linear fraction

- F P :

-

slide-gate opening (plant definition, Eq. [3])

- f g :

-

gas volume fraction (“hot” argon in steel)

- g :

-

gravitational acceleration (9.81 m/s2)

- H T :

-

tundish bath depth (m)

- H SEN :

-

SEN submerged depth (m)

- P L :

-

lowest pressure in nozzle (kPa)

- Q G :

-

“cold” argon gas flow rate, measured at standard conditions (STP of 25 °C and 1 atmosphere pressure) (SLPM)

- Q Fe :

-

steel throughput (tonne/min)

- U B :

-

average velocity at the top inlet of the nozzle (m/s)

- U C :

-

average jet velocity at the nozzle port (m/s)

- V C :

-

casting speed based on 0.203×1.321 m slab (m/min)

References

K.G. Rackers and B.G. Thomas: 78th Steelmaking Conf., Nashville, TN, Apr. 2–5, 1995, ISS, Warrendale, PA, 1995, vol. 78, pp. 723–34.

F.L. Kemeny: McLean Symp. Proc., Toronto, Mar. 22–25, 1998, IS Warrendale, PA, 1998, pp. 103–10.

B.G. Thomas and H. Bai: Steelmaking. Conf. Proc., 18th PTD Conf., Baltimore, MD, Mar. 25–28, 2001, ISS, Warrendale, PA, 2001, pp. 895–912.

W. Lai, M. Milone, and I.V. Samarasekera: 83rd Steelmaking Conf. Proc., Pittsburgh, PA, Mar. 26–29, 2000, ISS, Warrendale, PA, 2000, vol. 83, pp. 461–76.

J. Knoepke and M. Hubbard: 77th Steelmaking Conf. Proc., Chicago, IL, Mar. 20–23, 1994, ISS, Warrendale, PA, 1994, vol. 77, pp. 381–88.

I. Sasaka, T. Harada, H. Shikano, and I. Tanaka: 74th ISS Steelmaking Conf., Washington, DC, Apr. 14–17, 1991, ISS, Warrendale, PA, 1991, vol. 74, pp. 349–56.

B.G. Thomas, A. Dennisov, and H. Bai: 80th ISS Steelmaking Conf. Proc., Chicago, IL, Apr. 13–16, 1977, ISS, Warrendale, PA, 1997, vol. 80, pp. 375–84.

H. Buhr and J. Pirdzun: Continuous Casting of Steel, Biarritz, France, 1976.

E.S. Szekeres: 4th Int. Conf. on Clean Steel, Balatonszeplak, Hungary, 1992.

H.H. Ozeki, T. Yamaguchi, T. Takasu, and T. Auki: 2nd Int. Conf. on Refractories, Tech Association of Refractories, Osaka, Japan, 1987, pp. 398–410.

N.A. McPherson and S.L. McIntosh: 70th Steelmaking Conf. Proc., ISS, Warrendale, PA, 1987, vol. 70, pp. 17–25.

W.H. Emling, T.A. Waugaman, S.L. Feldbauer, and A.W. Cramb: Steelmaking Conf. Proc., Chicago, IL, Apr. 13–16, 1997, ISS, Warrendale, PA, 1994, vol. 77, pp. 371–79.

S.M. Dawson: 73rd Steelmaking Conf. Proc., Detroit, MI, Mar. 25–28, 1990, ISS, Warrendale, PA, 1990, vol. 73, pp. 15–31.

H.T. Tsai: “Water Modeling on Pressure Profile in the Tundish Shroud at Flo-Con”, Report. ISPAT-Inland Steel, East Chicago, IN, 1986.

L. Wang, H.-G. Lee, and P. Hayes: Steel Res., 1995, vol. 66 (7), pp. 279–86.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253–67.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 269–84.

U. S00123ost00123om, M. Burty, A. Gaggioli, and J. Radot: 81st Steelmaking Conf. Proc., Toronto, Mar. 22–25, 1998, ISS, Warrendale, PA, 1998, vol. 81, pp. 63–71.

CFX 4.2 Users Manual, AEA Technology, Pittsburgh, PA, 1998.

M.T. Heath: Scientific Computing, An Introductory Survey, McGraw-Hill, New York, 1997.

H. Bai: Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, 2000.

R. Gass: Inland Steel, East Chicago, Indiana, private communication, 1998.

F.M. Najjar, B.G. Thomas, and D. Hershey: Metall. Trans. B, 1995, vol. 26B, pp. 749–66.

Y.H. Wang: 10th Process Technology Conf. Proc., Toronto, Apr. 5–8, 1992, ISS, Warrendale, PA, 1992, vol. 10, pp. 271–78.

M.B. Assar: LTV Steel Research, Independence, OH, private communication, 1998.

B.G. Thomas, X. Huang, and R.C. Sussman: Metall. Mater. Trans. B, 1994, vol. 25B, pp. 527–47.

M. Burty, M. Larrecq, C. Pusse, and Y. Zbaczyniak: 13th PTD Conf. Proc., Nashville, TN, Apr. 2–5, 1995, ISS, Warrendale, PA, 1995, vol. 13, pp. 287–92.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, in press.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bai, H., Thomas, B.G. Effects of clogging, argon injection, and continuous casting conditions on flow and air aspiration in submerged entry nozzles. Metall Mater Trans B 32, 707–722 (2001). https://doi.org/10.1007/s11663-001-0125-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0125-4