Abstract

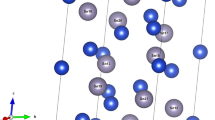

Due to the miniaturization of the solder joints in micro/nanoelectronic devices, the volume ratio of intermetallic (IMCs) materials has substantially increased. This increased ratio could affect the reliability of solder joints depending on the regime and the rate of the loading. Cu6Sn5 is the primary IMC layer in the solder joint, and the primary crack initiation is observed in Cu6Sn5 site in the literature. As the size of the joints becomes closer to the grain size, joints may only contain a few numbers of grains of Cu6Sn5. This manifests itself in statistical grain size effects, as well as anisotropy. Modeling these joints using bulk properties of Cu6Sn5 does not capture the actual behavior of these joints especially when plastic deformation is involved. Plastic deformation, starting at yield point, happens to be associated with the activation of slip systems. Deformation of a slip system of single crystal largely rests on the slip parameters such as critical resolved shear stress (CRSS), initial hardening modulus, and saturation stress (Stage I stress when large plastic flow occurs). However, no efforts have been made to capture the slip parameters of Cu6Sn5 experimentally or analytically because of the difficulties of using conventional mechanical tests to measure the slip parameters of HCP single crystals. Due to wide range of CRSS values, it becomes difficult to isolate a specific slip system in testing without activating the other slip systems. The crystal plasticity finite-element (CPFE) method takes into account the effect of anisotropy and slip system behavior in modeling materials. This work uses a combined strategy based upon experiments, modeling, and a comparative analysis to obtain slip system parameters that could predict the slip process of Cu6Sn5. Nanoindentation tests were performed on Cu6Sn5 single crystal to extract the load–displacement curves, and a CPFE nanoindentation model analysis along with custom user material was utilized to obtain set of crystal plasticity material parameters which can represent the plastic behavior of Cu6Sn5 IMC. These parameters were then used to predict shear yield strength and shear modulus of Cu6Sn5, and the findings were compared with the previously published values in the literature.

Similar content being viewed by others

References

F. Ochoa, J.J. Williams, and N. Chawla: J. Electron. Mater., 2003, vol. 32, pp. 1414–20.

H. Zou, Q. Zhu, and Z. Zhang: J. Alloys Compd., 2008, vol. 461, pp. 410–17.

I. Panchenko, J. Grafe, M. Mueller, and K.-J. Wolter: IEEE 15th Electron. Packag. Technol. Conf. (EPTC 2013), 2013, vol. 318, pp. 318–23.

M.N. Islam, A. Sharif, and Y.C. Chan: J. Electron. Mater., 2005, vol. 34, pp. 143–49.

J.-M. Song, B.-R. Huang, C.-Y. Liu, Y.-S. Lai, Y.-T. Chiu, and T.-W. Huang: Mater. Sci. Eng. A, 2012, vol. 534, pp. 53–59.

T. Laurila, V. Vuorinen, and J.K. Kivilahti: Mater. Sci. Eng. R Rep., 2005, vol. 49, pp. 1–60.

S.F. Choudhury and L. Ladani: in ASME 2013 Int. Tech. Conf. Exhib. Packag. Integr. Electron. Photonic Microsystems (ASME), 2013.

L. Jiang, H. Jiang, and N. Chawla: J. Electron. Mater., 2012, vol. 41, pp. 2083–88.

J.W. Christian and S. Mahajan: Prog. Mater Sci., 1995, vol. 39, pp. 1–157.

M.H. Yoo: Metall. Trans. A, 1981, vol. 12A, pp. 409–18.

G. Timár and J.Q. da Fonseca: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5883–90.

H. Wang, P.D. Wu, J. Wang, and C.N. Tomé: Int. J. Plast., 2013, vol. 49, pp. 36–52.

B. Eidel: Acta Mater., 2011, vol. 59, pp. 1761–71.

Y.S. Choi, M.A. Groeber, P.A. Shade, T.J. Turner, J.C. Schuren, D.M. Dimiduk, M.D. Uchic, and A.D. Rollett: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 6352–59.

M.G. Lee, H. Lim, B.L. Adams, J.P. Hirth, and R.H. Wagoner: Int. J. Plast., 2010, vol. 26, pp. 925–38.

D. Esqué-de los Ojos, J. Očenášek, and J. Alcalá: Comput. Mater. Sci., 2014, vol. 86, pp. 186–92.

O. Casals and S. Forest: Comput. Mater. Sci., 2009, vol. 45, pp. 774–82.

P. Darbandi, T.R. Bieler, F. Pourboghrat, and T. Lee: J. Electron. Mater., 2012, vol. 42, pp. 201–14.

R.J. Asaro and A. Needleman: Acta Metall., 1985, vol. 33, pp. 923–53.

E. W. Schmid and W. Boas: 1950.

R. Hill and J. R. Rice, J. Mech. Phys. Solids 20, pp. 401–13 (1972).

J. R. Rice, J. Mech. Phys. Solids 19, pp. 433–55 (1971).

Y. Huang: A User-material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program, Mech Report 178, Harvard University, Cambridge, MA, 1991. http://scholar.google.com/scholar?hl=en&q=huang+umat&btnG=&as_sdt=1%2C7&as_sdtp=

E. H. Lee, J. Appl. Mech. 36, pp. 1–6 (1969).

J. Pan and J. R. Rice, Int. J. Solids Struct. 19, 973–87 (1983).

D. Peirce, R. J. Asaro, and A. Needleman, Acta Metall. 30, 1087–1119 (1982).

U.F. Kocks: Metall. Trans., 1970, vol. 1, p. 1121–43.

A. Zamiri, T. R. Bieler, and F. Pourboghrat, J. Electron. Mater. 38: 231–40 (2008).

P. Kratochvíl, P. Lukáč, and B. Sprušil, Czechoslov. J. Phys. 23, 621–26 (1973).

H. E. Friedrich and B. L. Mordike, Magnesium Technology: Metallurgy, Design Data, Applications (Springer, 2006), p. 699.

Y. Yang, L. Wang, C. Zambaldi, P. Eisenlohr, R. Barabash, W. Liu, M.R. Stoudt, M.A. Crimp, and T.R. Bieler: JOM, 2011, vol. 63, pp. 66–73.

P. A. Sabnis, S. Forest, N. K. Arakere, and V. A. Yastrebov, Int. J. Plast. 51, 200–217 (2013).

L. Li, L. Shen, G. Proust, C. K. S. Moy, and G. Ranzi, Mater. Sci. Eng. A 579, 41–49 (2013).

S. F. Choudhury and L. Ladani, J. Electron. Mater. 43, 996–1004 (2014).

C. Zambaldi, Y. Yang, T. R. Bieler, and D. Raabe, J. Mater. Res. 27, 356–67 (2011).

J. Gong and A. J. Wilkinson, Acta Mater. 57, pp. 5693–5705 (2009).

M. H. Yoo, S. R. Agnew, J. R. Morris, and K. M. Ho, Mater. Sci. Eng. A 321, pp. 87–92 (2001).

K. Ito and V. Vitek, Philos. Mag. A 81, 1387–1407 (2001).

X.-L. Nan, H.-Y. Wang, L. Zhang, J.-B. Li, and Q.-C. Jiang: Scripta Mater. 67, 443–46 (2012).

A. Chapuis and J. H. Driver, Acta Mater. 59, 1986–94 (2011).

Y. B. Chun and C. H. J. Davies, Mater. Sci. Eng. A 528, 3489–95 (2011).

Y. N. Wang and J. C. Huang, Acta Mater. 55, 897–905 (2007).

A. Gangulee, G. C. Das, and M. B. Bever, Metall. Trans. 4, 2063–66 (1973).

M. Dao, N. Chollacoop, K. J. Van Vliet, T. a. Venkatesh, and S. Suresh, Acta Mater. 49, 3899–3918 (2001).

A. K. Bhattacharya and W. D. Nix, Int. J. Solids Struct. 24, 881–91 (1988).

N. T. S. Lee, V. B. C. Tan, and K. M. Lim, Appl. Phys. Lett. 88, 031913 (2006).

U. Borg and J. W. Kysar, Int. J. Solids Struct. 44, 6382–97 (2007).

F. Roters, P. Eisenlohr, L. Hantcherli, D. D. Tjahjanto, T. R. Bieler, and D. Raabe, Acta Mater. 58, 1152–1211. (2010).

J.-M. Song, Y.-L. Shen, C.-W. Su, Y.-S. Lai, and Y.-T. Chiu, Mater. Trans. 50, 1231–34 (2009).

M. Liu, C. Lu, and K. A. Tieu: in TMS 2014 Ann. Meet. Suppl. Proc., 2014, vol. 317, pp. 317–37

O. Casals, J. Ocenasek, and J. Alcala, Acta Mater. 55, 55–68 (2007).

G. M. Pharr and A. Bolshakov, J. Mater. Res. 17, 2660–71 (2011).

K. L. Johnson and K. L. Johnson, Contact Mechanics (Cambridge University Press, 1987), pp. 1–452.

Y. Liu, S. Varghese, J. Ma, M. Yoshino, H. Lu, and R. Komanduri, Int. J. Plast. 24, 1990–2015 (2008).

W. G. Mao, Y. G. Shen, and C. Lu, J. Eur. Ceram. Soc. 31, 1865–71 (2011).

G. Ghosh and M. Asta, J. Mater. Res. 20, 3102–17 (2005).

Q. K. Zhang, J. Tan, and Z. F. Zhang, J. Appl. Phys. 110, 014502 (2011).

Acknowledgments

This paper is based upon work supported by the National Science Foundation under CMMI Grant No. 1242141, 1415165, 1416682, and 0927319. The authors greatly appreciate the support from NSF. The authors would like to acknowledge the central Analytical Facility which is supported by The University of Alabama, for providing the SEM and EBSD facility. The UA MINT center is acknowledged for the use of nanoindentation equipment.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 22, 2014.

Rights and permissions

About this article

Cite this article

Choudhury, S.F., Ladani, L. Single Crystal Plasticity Finite Element Analysis of Cu6Sn5 Intermetallic. Metall Mater Trans A 46, 1108–1118 (2015). https://doi.org/10.1007/s11661-014-2696-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2696-0