Abstract

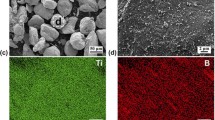

The additive manufacturing of bulk-form TiC/Ti nanocomposite parts was performed using Selective Laser Melting (SLM). Two categories of nanopowder, i.e., ball-milled TiC/Ti nanocomposite powder and directly mechanical mixed nano-TiC/Ti powder, were used for SLM. The influences of nanopowder characteristics and laser processing parameters on the densification behavior, microstructural features, and tribological properties of the SLM-processed TiC/Ti nanocomposite parts were studied. The study showed that the densification of TiC/Ti nanocomposite parts was affected by both laser energy density and powder categories. Using an insufficient laser energy density of 0.25 kJ/m lowered SLM densification rate, because of the occurrence of balling effect. An increase in the laser energy density above 0.33 kJ/m produced near fully dense SLM parts. The SLM densification levels of the ball-milled TiC/Ti nanocomposite powder were generally higher than that of the directly mixed nano-TiC/Ti powder. The TiC-reinforcing phase in SLM-processed TiC/Ti parts typically had a lamellar nanostructure with a nanoscale thickness, completely differing from the starting nanoparticle morphology before SLM. The lamellar nanostructure of the TiC reinforcement in SLM-processed ball-milled TiC/Ti nanocomposite parts could be maintained within a wide range of laser energy densities. However, the microstructures of the SLM-processed, directly mixed nano-TiC/Ti powder were sensitive to SLM parameters, and the TiC reinforcement experienced a successive change from the lamellar nanostructure to the relatively coarsened dendritic microstructure as laser energy density increased. A combination of the sufficiently high SLM densification rate and the formation of the nanostructured TiC reinforcement favored the improvement of the tribological property, leading to the considerably low coefficient of friction of 0.22 and wear rate of 2.8 × 10−16 m3 N−1 m−1. The coarsening and resultant disappearance of nanoscale TiC reinforcement in SLM-consolidated directly mixed nano-TiC/Ti powder at a high laser energy density lowered the tribological performance considerably.

Similar content being viewed by others

References

T. Vilaro, C. Colin, and J.D. Bartout: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3190–99.

J.P. Kruth, G. Levy, F. Klocke, and T.H.C. Childs: CIRP Ann. Manuf. Technol., 2007, vol. 56, pp. 730–59.

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe: Int. Mater. Rev., 2012, vol. 57, pp. 133–64.

P. Yu, M. Yan, G.B. Schaffer, and M. Qian: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2417–24.

B. Zheng, J.E. Smugeresky, Y. Zhou, D. Baker, and E.J. Lavernia: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1196–205.

B. Zheng, Y. Zhou, J.E. Smugeresky, J.M. Schoenung, and E.J. Lavernia: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2237–45.

V.D. Manvatkar, A.A. Gokhale, G. Jagan Reddy, A. Venkataramana, and A. De: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 4080–87.

W.P. Liu and J.N. DuPont: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1133–40.

R. Banerjee, A. Genç, P.C. Collins, and H.L. Fraser: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2143–52.

B.V. Krishna, S. Bose, and A. Bandyopadhyay: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1096–103.

I. Yadroitsev, L. Thivillon, Ph. Bertrand, and I. Smurov: Appl. Surf. Sci., vol. 254, pp. 980–83.

K.A. Mumtaz, P. Erasenthiran, and N. Hopkinson: J. Mater. Process Technol., 2008, vol. 195, pp. 77–87.

P. Fox, S. Pogson, C.J. Sutcliffe, and E. Jones: Surf. Coat Technol., 2008, vol. 202, pp. 5001–07.

C.Z. Yan, L. Hao, A. Hussein, and D. Raymont: Int. J. Mach. Tools Manuf., 2012, vol. 62, pp. 32–38.

D.D. Gu, Y.C. Hagedorn, W. Meiners, G.B. Meng, R.J.S. Batista, K. Wissenbach, and R. Poprawe: Acta Mater., 2012, vol. 60, pp. 3849–60.

M. Zhong and W. Liu: Proc. Inst. Mech. Eng. C. J. Mech. Eng. Sci., 2010, vol. 224, pp. 1041–60.

M. Das, V.K. Balla, D. Basu, S. Bose, and A. Bandyopadhyay: Scripta Mater., 2010, vol. 63, pp. 438–41.

B. Duan and M. Wang: MRS Bull., 2011, vol. 36, pp. 998–1005.

S.R. Athreya, K. Kalaitzidou, and S. Das: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2637–42.

S. Dadbakhsh and L. Hao: Adv. Eng. Mater., 2012, vol. 14, pp. 45–48.

S.S. Singh, D. Roy, R. Mitra, R.V. Subba Rao, R.K. Dayal, B. Raj, I. Manna: Mater. Sci. Eng. A, 2009, vol. 501, pp. 242–47.

V. Viswanathan, T. Laha, K. Balani, A. Agarwal, and S. Seal: Mater. Sci. Eng. R, 2006, vol. 54, pp.121–285.

A. Mortensen and J. Llorca: Annu. Rev. Mater. Res., 2010, vol. 40, pp. 243–70.

S.K. Kumar and R. Krishnamoorti: Annu. Rev. Chem. Biomol. Eng., 2010, vol. 1, pp. 37–58.

S.C. Tjong: Adv. Eng. Mater., 2007, vol. 9, pp. 639–52.

M. Sherif El-Eskandarany, M. Omori, T. Hirai, T.J. Konno, K. Sumiyama, and K. Suzuki: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 157–64.

I.V. Alexandrov, R.K. Islamgaliev, R.Z. Valiev, Y.T. Zhu, and T.C. Lowe: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2253–60.

P. Asadi, G. Faraji, A. Masoumi, and M.K. Besharati Givi: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 2820–32.

V. Udhayabanu, K.R. Ravi, K. Murugan, D. Sivaprahasam, and B.S. Murty: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 2085–93.

A.A.M. da Silva, J.F. dos Santos, and T.R. Strohaecker: Compos. Sci. Technol., 2005, vol. 65, pp. 1749–55.

L. Xiao, W. Lu, J. Qin, Y. Chen, D. Zhang, M. Wang, F. Zhu, B. Ji: Compos. Sci. Technol., 2009, vol. 69, pp. 1925–31.

D.D. Gu, G.B. Meng, C. Li, W. Meiners, and R. Poprawe: Scripta Mater., 2012, vol. 67, pp. 185–88.

D.D. Gu, Y.C. Hagedorn, W. Meiners, K. Wissenbach, and R. Poprawe: Compos. Sci. Technol., 2011, vol. 71, pp. 1612–20.

A. Simchi, F. Petzoldt, and H. Pohl: J. Mater. Process Technol., 2003, vol. 141, pp. 319–28.

D.D. Gu and Y.F. Shen: J. Alloys Compd., 2009, vol. 473, pp. 107–15.

M. Agarwala, D. Bourell, J. Beaman, H. Marcus, and J. Barlow: Rapid Prototyping J., 1995, vol. 1, pp. 26–36.

A. Simchi, F. Petzoldt, and H. Pohl: Int. J. Powder Metall., 2001, vol. 37, pp. 49–61.

N.K. Tolochko, S.E. Mozzharov, I.A. Yadroitsev, T. Laoui, L. Froyen, V.I. Titov, and M.B. Ignatiev: Rapid Prototyping J., 2004, vol. 10, pp. 78–87.

D.D. Gu and Y.F. Shen: Mater. Design, 2009, vol. 30, pp. 2903–10.

P.M. Ajayan, L.S. Schadler, and P.V. Braun: Nanocomposite Science and Technology, 1st ed., Wiley-VCH, Weinheim, Germany, 2003.

P. Fischer, V. Romano, H.P. Weber, N.P. Karapatis, E. Boillat, and R. Glardon: Acta Mater., 2003, vol. 51, pp. 1651–62.

I. Takamichi and I.L.G. Roderick: The Physical Properties of Liquid Metals, 1st ed., Clarendon Press, Oxford, UK, 1993.

Y.T. Chan and S.K. Choi: J. Appl. Phys., 1992, vol. 72, pp. 3741–49.

J. Tille and J.C. Kelly: Brit. J. Appl. Phys., 1963, vol. 14, pp. 717–19.

H.J. Niu and I.T.H. Chang: Scripta Mater., 1999, vol. 41, pp. 1229–34.

S. Das: Adv. Eng. Mater., 2003, vol. 5, pp. 701–711.

V.V. Semak, G.A. Knorovsky, D.O. MacCallum, and R. Allen Roach: J. Phys. D Appl. Phys., 2006, vol. 39, pp. 590–95.

L.R. Xu and S. Sengupta: J. Nanosci. Nanotechnol., 2005, vol. 5, pp. 620–26.

Acknowledgments

The authors gratefully appreciate the financial support from the National Natural Science Foundation of China (No. 51104090), the Outstanding Youth Foundation of Jiangsu Province of China (No. BK20130035), and the NUAA Fundamental Research Funds (No. NE2013103).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 26, 2012.

Rights and permissions

About this article

Cite this article

Gu, D., Wang, H. & Zhang, G. Selective Laser Melting Additive Manufacturing of Ti-Based Nanocomposites: The Role of Nanopowder. Metall Mater Trans A 45, 464–476 (2014). https://doi.org/10.1007/s11661-013-1968-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1968-4