Abstract

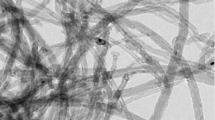

A ceramic/ceramic nanocomposite powder of WC/MgO has been fabricated by high-energy ball milling a mixture of elemental Mg and powders of C with WO3 under an argon gas atmosphere at room temperature. During the early stage of milling (at 1.8 ks), the WO3 and C powders are embedded into the soft matrix of Mg (the reducing agent) particles to form coarse composite powders of the reactant materials. Increasing the milling time (to 22 ks) leads to the formation of fresh active surfaces of Mg, which have a high reducing potential and react with the WO3 in a typical oxidation/reduction reaction. At the end of this stage (at 43 ks), the Mg powders are oxidized to MgO, whereas the WO3 is reduced completely to metallic W. During the last stage of milling (86 to 173 ks), a solid-state reaction takes place between W and the unreacted C powders to yield nanocomposite WC/MgO particles. This end-product was consolidated in vacuum at 1963 K with a pressure of 19.6 to 38.2 MPa for 0.3 ks, using a plasma-activated sintering (PAS) method. The sintered sample is fully dense (above 99.5 pct of the theoretical density) and contains nanocrystalline grains of less than 50 nm in diameter. This fine grain structure offers an opportunity for the composite material to combine high values of two opposite properties, i.e., hardness and fracture toughness (K c ), of 15 GPa and 14 MPa √m, respectively. Here, we propose this nanocomposite material for a wide range of industrial applications, including tips for cutting tools and tips for oil drilling equipment.

Similar content being viewed by others

References

J.S. Benjamin: Metall. Trans., 1970, vol. 1, pp. 2943–51.

L.G. Wright and A. Wilox: Metall. Trans., 1974, vol. 5, pp. 957–60.

G.H. Gessinger: Metall. Trans. A, 1976, vol. 7A, pp. 1203–09.

C.C. Koch, O.B. Cavin, C.G. MacKamey, and J.O. Scarbourgh: Appl. Phys. Lett., 1983, vol. 43, pp. 1017–19.

R. Schwarz and C.C. Koch: Appl. Phys. Lett., 1986, vol. 49, pp. 146–49.

M. Sherif El-Eskandarany: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3267–78.

M. Sherif El-Eskandarany, K. Aoki, K. Sumiyama, and K. Suzuki: Appl. Phys. Lett., 1997, vol. 70, pp. 1679–81.

M. Sherif El-Eskandarany, M. Omori, T.J. Konno, K. Sumiyama, T. Hirai, and K. Suzuki: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1973–81.

M. Sherif El-Eskandarany, H.A. Ahmed, K. Sumiyama, and K. Suzuki: J. Alloys Compounds, 1995, vol. 218 (1), pp. 36–43.

M. Sherif El-Eskandarany: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2374–82.

M. Sherif El-Eskandarany: J. Alloys Compounds, 1998, vol. 279, pp. 263–71.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki: J. Less-Common Met., 1990, vol. 167, pp. 113–18.

M. Sherif El-Eskandarany: Mater. Trans. JIM, 1995, vol. 36, pp. 182–87

M. Sherif El-Eskandarany, M. Omori, M. Ishikuro, T.J. Konno, K. Takada, K. Sumiyama, T. Hirai, and K. Suzuki: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 4210–13.

Stephen W.H. Yih and Chun T. Wang: Tungsten, Plenum Press, New York, NY, 1979, p. 392.

S. Mi and T.H. Courtney: Scripta Metall., 1997, vol. 38, pp. 171–76.

M. Ishiyama: Proc. Powder Metallurgy World Congr., Japan Society of Powder and Powder Metallurgy, JSPM, Kyoto, 1993, pp. 931–34.

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall: J. Am. Ceram. Soc., 1981, vol. 64 (9), pp. 533–38.

Fracture Mechanics Applied to Brittle Materials, S.W. Freiman, ASTM Special Technical Publication No. 678, S.W. Freiman, ed., ASTM, Philadelphia, PA, 1979.

F.R. Boer, R. Boom, W.C. Mattens, A.R. Miedema, and A.K. Nissen: Cohesion in Metals—Transition Metal Alloys, 1 st ed., North-Holland, Amsterdam, 1988, vol. 1, pp. 751 and 754.

M. Sherif El-Eskandarany: J. Jpn. Soc. Powder and Powder Metallurgy (JSPM), 1997, vol. 44, pp. 1131–41.

W.D. Schubert, H. Neumeister, G. Kinger, and B. Lux: Int. J. Refr. Met. Hard Mater., 1998, vol. 16 (2) pp. 133–42.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

El-Eskandarany, M.S., Omori, M., Hirai, T. et al. Synthesizing of nanocomposite WC/MgO powders by mechanical solid-state reduction and subsequent plasma-activated sintering. Metall Mater Trans A 32, 157–164 (2001). https://doi.org/10.1007/s11661-001-0111-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0111-0