Abstract

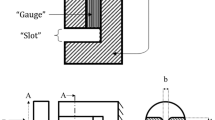

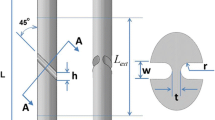

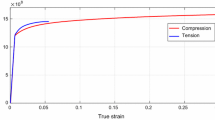

A modified shear-compression specimen (SCS), for large strain testing over a wide range of strain rates is presented. The original SCS design includes two rectangular slots that are machined at 45° with respect to the longitudinal axis. The modification consists of creating two diametrically opposed semi-circular slots. The new “circular” specimen is first thoroughly investigated numerically under quasi-static and dynamic loading using an elasto-plastic material model. The results of the comparison between the two-slot designs confirm the feasibility of the new specimen for larger strain testing and indicates its advantages over the rectangular slot design: larger strain range characterization, failure and fracture within the gauge, and constant Lode parameter during plastic deformation. Both types of SCS as well as cylindrical specimens are used to characterize the flow behavior of steel 1020, in the quasi-static and dynamic regimes using a split Hopkinson pressure bar. Dog-bone specimens are also tested quasi-statically in tension. A very good agreement is achieved for the results of all specimens in both the quasi-static and dynamic regimes. The numerical validation procedure shows that the flow stress of 1020 steel obtained with the new SCS is ~3 % lower in the quasi-static regime, and 8 % lower in the dynamic regime with respect to the flow stress of the rectangular SCS. This difference is attributed to effect of the third invariant of the stress deviator (i.e., Lode parameter), which is considerably lower in the new SCS design.

Similar content being viewed by others

References

Rittel D, Lee S, Ravichandran G (2002) A shear compression specimen for large strain testing. Exp Mech 42:58–64

Dorogoy A, Rittel D (2005) Numerical validation of the Shear Compression Specimen (SCS). Part I: Quasi-static large strain testing. Exp Mech 45:167–177

Dorogoy A, Rittel D (2005) Numerical validation of the Shear Compression Specimen (SCS). Part II: Dynamic large strain testing. Exp Mech 45:178–185

Dorogoy A, Rittel D (2006) A numerical study of the applicability of the Shear Compression Specimen to parabolic hardening materials. Exp Mech 46:355–366

Rittel D, Lee S, Ravichandran (2002) Large strain constitutive behavior of OFHC copper over a wide range of strain-rates using the shear compression specimen. Mech Mater 34:627–642

Vural M, Rittel D, Ravichandran G (2003) Large strain mechanical behavior of 1018 cold-rolled steel over a wide range of strain rates. Metall Mater Trans A 34:2873–2885

Rittel D, Levin R, Dorogoy A (2004) On the isotropy of the dynamic mechanical and failure properties of swaged tungsten heavy alloys. Metall Mater Trans A 35:3787–3795

Bhattacharyya A, Rittel D, Ravichandran G (2005) Effect of strain rate on deformation texture of OFHC copper. Scr Mater 52:657–661

Rittel D, Wang ZG, Merzer M (2006) Adiabatic shear failure and dynamic stored energy of cold work. Phys Rev Lett 96(075502–1):075502–075504

Rittel D, Wang ZG, Dorogoy A (2008) Geometrical imperfection and adiabatic shear banding. Int J Impact Eng 35:1280–1292

Rittel D, Wang Z (2008) Thermo-mechanical aspects of adiabatic shear failure of AM60 and Ti6Al4V alloys. Mech Mater 40:629–635

Ames M, Grewer M, Braun C, Birringer R (2012) Nanocrystalline metals go ductile under shear deformation Mater. Sci Eng A 546:248–257

Zhao J, Knauss WG, Ravichandran G (2009) A new shear-compression-specimen for determining quasistatic and dynamic polymer properties. Exp Mech 49:427–436

Alkhader M, Knauss WG, Ravichandran G (2011) The influence of pressure on the large deformation shear response of a Polyurea. Conf Proc Soc Exp Mech Ser 3:287–295

Vural M, Molinari A, Bhattacharyya N (2011) Analysis of slot orientation in shear-compression specimen (SCS). Exp Mech 51:263–273

Osovski S, Rittel D, Landau P, Venkert A (2012) Microstructural effects on adiabatic shear band formation. Scr Mater 66:9–12

Dolinski M, Rittel D, Dorogoy A (2010) Modeling adiabatic shear failure from energy considerations. J Mech Phys Solids 58:1759–1775

Abaqus, 2012. Finite element package, v6.12–2, Dassault Systemes, Simulia Corp., Providence, RI

Barsoum I, Faleskog J (2007) Rupture mechanisms in combined tension and shear -Experiments. Int J Solids Struct 44:1768–1786

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and Lode dependence. Int J Plast 24:1071–1096

Barsoum I, Faleskog J (2007) Rupture mechanisms in combined tension and shear - Micromechanics. Int J Solids Struct 44:5481–5498

Gao X, Zhang T, Hayden M, Roe C (2009) Effects of the stress state on plasticity and ductile failure of an aluminum 5083 alloy. Int J Plast 25:2366–2382

Keshavarz A, Ghajar R, Mirone G (2014) A new experimental failure model based on triaxiality factor and Lode angle for X-100 pipe line steel. Int J Mech Sci 80:175–182

Pivonka P, Willam K (2003) The effect of the third invariant in computational plasticity. Eng Comput 20:741–753

MATLAB R (2013b) The MathWorks Inc., Natick, MA 01760–2098, USA

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc Phys Soc London 62-B:676–700

Abaqus/CAE version 6.12-2 (2009). Abaqus documentation Abaqus analysis user’s manual. Dassault systemes. Springer, New York, Chapter 24: Progressive Damage and Failure

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dorogoy, A., Rittel, D. & Godinger, A. Modification of the Shear-Compression Specimen for Large Strain Testing. Exp Mech 55, 1627–1639 (2015). https://doi.org/10.1007/s11340-015-0057-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0057-6