Abstract

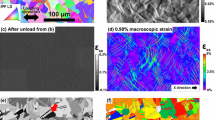

Mechanical failure of polycrystalline metals is often difficult to predict, in part because of the wide range of conditions under which individual elements of the material’s microstructure fail. We describe an efficient method for posing, assessing, and optimizing failure criteria for individual microstructural elements, such as grains, grain boundaries, precipitates, or precipitate–matrix interfaces. Such criteria may lead to improved failure predictions for polycrystalline metals. Our method constructs a failure probability function from a database of individual failure events obtained from experiments on polycrystalline samples. It then uses the Kullback–Leibler (K–L) divergence to compare it to probability densities corresponding to specific hypothesized failure mechanisms. The likeliest failure mechanism is the one that minimizes the K–L divergence with respect to a suitably chosen null hypothesis. As a demonstration, we apply this approach to hydrogen-assisted crack initiation at coherent twin boundaries in Ni-based alloy 725 and deduce a best-fit failure criterion for them.

Similar content being viewed by others

Abbreviations

- \( D_{{{\text{K}} - {\text{L}}}} \), \( D_{{{\text{K}} - {\text{L}}}}^{i} \) :

-

Kullback–Leibler (K–L) divergence, K–L divergence for failure model \( i \)

- \( p \) :

-

Experimentally determined failure probability distribution

- \( \bar{p} \), \( \bar{p}_{i} \).:

-

Hypothesized failure probability distribution, indexed by \( i \) when there is more than one

- \( \bar{p}_{i}^{e} \) :

-

Hypothesized failure probability distribution with exponential form

- \( \bar{p}_{i}^{F - D} \) :

-

Hypothesized failure probability distribution with Fermi-Dirac form

- \( \varOmega \) :

-

The domain over which both experimentally determined and hypothesized failure probability distributions are defined

- \( \left\{ {Q_{j} } \right\} \) :

-

Physical parameters upon which failure of the microstructural element of interest depends

- \( \left\{ {x_{k} } \right\} \) :

-

Model parameters upon which hypothesized failure probability distributions depend

- \( \tilde{D}_{K - L}^{i} \) :

-

K–L divergence optimized with respect to the model parameters, \( \left\{ {x_{k} } \right\} \)

- \( \left\{ {\tilde{x}_{k} } \right\} \) :

-

Values of the model parameters, \( \left\{ {x_{k} } \right\} \), at which the K-L divergence is optimized

- \( f \) :

-

Frequency with which the microstructural element of interest is observed to fail in a mechanical test

- \( g \) :

-

Probability of encountering the microstructural parameter of interest in a specific sample or set of samples

- \( \sigma_{a} \;\sigma_{ab} \) :

-

Variance describing all sources of uncertainty in experimental measurements on the ath microstructural element of interest, indexed by \( b \) whenever a class \( b \) of measured parameters has a different uncertainty from other classes

- \( \left\{ {Q_{j} } \right\}_{a} \) :

-

Physical parameters describing the ath microstructural element

- \( m \) :

-

Number of instances of failure of the microstructural element of interest

- \( n \) :

-

Number of instances of the microstructural element of interest—whether failed or not—in the microstructure as a whole

- \( P \), \( P_{b} \) :

-

Any probability distribution peaked at zero, indexed by \( b \) whenever a class \( b \) of measured parameters has a different probability distribution from other classes

- \( d \), \( d_{b} \) :

-

Metric that quantifies the distance between the \( \left\{ {Q_{j} } \right\} \) values where \( f \) or \( g \) are evaluated and the \( \left\{ {Q_{j} } \right\}_{a} \) values corresponding to each of the experimentally determined data points, indexed by \( b \) whenever a class \( b \) of measured parameters has a different metric from other classes

- \( \bar{p}_{0} \) :

-

Hypothesized model representing the null hypothesis

- \( C_{\text{norm}} \) :

-

Factor whose value is to be determined by normalizing the distribution to unity over its domain

- \( \hat{n} \) :

-

Unit vector pointing normal to the coherent twin boundary plane

- α:

-

Angle between \( \hat{n} \) and the tensile axis

- β:

-

Smallest angle between a 〈110〉-type direction in the coherent twin boundary plane and the steepest direction along the coherent twin boundary plane

- \( p_{vM} \) :

-

Un-normalized von Mises distribution with a mean of zero

- \( \kappa \) :

-

Measure of spread in \( p_{vM} \)

- \( u \) :

-

Angular uncertainty in the orientation of the EBSD data with respect to the tensile axis

- \( \sigma \) :

-

Uniaxial tensile stress

- \( \sigma_{n} \), \( \bar{\sigma }_{n} \).:

-

Normal traction perpendicular to the coherent twin boundary plane, normalized by \( \sigma \)

- \( \tau_{ \hbox{max} } \), \( \bar{\tau }_{\max} \).:

-

Maximum shear traction along the coherent twin boundary plane, normalized by \( \sigma \)

- \( {\tau }_{\text{rss}},\; \bar{\tau }_{\text{rss}}\) :

-

Shear stress along the 〈110〉-type crystallographic direction within the coherent twin boundary plane that forms the smallest angle with \( \hat{n} \), normalized by \( \sigma \)

- \( \bar{\sigma } \) :

-

Weighted sum of \( \bar{\sigma }_{n} \), \( \bar{\tau }_{ \hbox{max} } \), and \( \bar{\tau }_{\text{rss}} \) used to predict failure

- \( A \), \( B \) :

-

Weights used in the definition of \( \bar{\sigma } \)

- \( \bar{\sigma }^{c} \) :

-

Critical value of \( \bar{\sigma } \) for failure

- \( \bar{\sigma }_{n}^{c} \) :

-

Critical value of \( \bar{\sigma } \) for failure when \( \bar{\sigma } \) depends solely on \( \bar{\sigma }_{n} \)

- \( \Delta \bar{\sigma } \) :

-

Difference between \( \bar{\sigma }^{c} \) and \( \bar{\sigma } \)

- \( s \) :

-

Prefactor by which \( \Delta \bar{\sigma } \) is multiplied when formulating failure models, \( \bar{p}_{i} \)

References

Seita M, Hanson JP, Gradecak S, Demkowicz MJ (2015) The dual role of coherent twin boundaries in hydrogen embrittlement. Nat Commun 6:6164. doi:10.1038/ncomms7164

Hanson JP, Seita M, Jones E, Gradecak S, Demkowicz MJ (2015) Corrosion 2015Nace International. Dallas, Texas

Jothi S, Merzlikin SV, Croft TN, Andersson J, Brown SGR (2016) An investigation of micro-mechanisms in hydrogen induced cracking in nickel-based superalloy 718. J Alloy Compd 664:664–681. doi:10.1016/j.jallcom.2016.01.033

Bridier F, Villechaise P, Mendez J (2008) Slip and fatigue crack formation processes in an alpha/beta titanium alloy in relation to crystallographic texture on different scales. Acta Mater 56:3951–3962. doi:10.1016/j.actamat.2008.04.036

Uta E, Gey N, Bocher P, Humbert M, Gilgert J (2009) Texture heterogeneities in alpha(p)/alpha(s) titanium forging analysed by EBSD-relation to fatigue crack propagation. J Microsc-Oxford 233:451–459. doi:10.1111/j.1365-2818.2009.03141.x

Simkin BA, Crimp MA, Bieler TR (2003) A factor to predict microcrack nucleation at gamma-gamma grain boundaries in TiAl. Scr Mater 49:149–154. doi:10.1016/s1359-6462(03)00216-1

Kumar D, Bieler TR, Eisenlohr P et al (2008) On predicting nucleation of microcracks due to slip-twin interactions at grain boundaries in duplex Near gamma-TiAl. J Eng Mater Technol 130:021012

Bieler TR, Eisenlohr P, Roters F et al (2009) The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int J Plast 25:1655. doi:10.1016/j.ijplas.2008.09.002

Johnson OK, Li L, Demkowicz MJ, Schuh CA (2015) Inferring grain boundary structure-property relations from effective property measurements. J Mater Sci 50:6907. doi:10.1007/s10853-015-9241-4

Sutton AP, Balluffi RW (1995) Interfaces in crystalline materials. Clarendon Press, Oxford

Jun TS, Zhang Z, Sernicola G, Dunne FPE, Britton TB (2016) Local strain rate sensitivity of single alpha phase within a dual-phase Ti alloy. Acta Mater 107:298–309. doi:10.1016/j.actamat.2016.01.057

Imrich PJ, Kirchlechner C, Motz C, Dehm G (2014) Differences in deformation behavior of bicrystalline Cu micropillars containing a twin boundary or a large-angle grain boundary. Acta Mater 73:240–250. doi:10.1016/j.actamat.2014.04.022

Robertson IM (2001) The effect of hydrogen on dislocation dynamics. Eng Fract Mech 68:671–692

Legros M (2014) In situ mechanical TEM: seeing and measuring under stress with electrons. CR Phys 15:224–240. doi:10.1016/j.crhy.2014.02.002

LE Shoemaker (2005) Alloys 625 and 725: trends in properties and applications. Superalloys 718, 625, 706 and Derivatives, Proceedings: 409

Watanabe T (1994) The impact of grain-boundary-character-distribution on fracture in polycrystals. Mater Sci Eng A 176:39–49

Palumbo G, Aust KT (1995) Solute effects in grain-boundary engineering. Can Metall Quart 34:165. doi:10.1016/0008-4433(95)00014-O

Bechtle S, Kumar M, Somerday BP, Launey ME, Ritchie RO (2009) Grain-boundary engineering markedly reduces susceptibility to intergranular hydrogen embrittlement in metallic materials. Acta Mater 57:4148. doi:10.1016/j.actamat.2009.05.012

Kullback S, Leibler RA (1951) On information and sufficiency. Ann Math Stat 22:79. doi:10.1214/aoms/1177729694

Eguchi S, Copas J (2006) Interpreting Kullback–Leibler divergence with the Neyman–Pearson lemma. J Multivar Anal 97:2034. doi:10.1016/j.jmva.2006.03.007

Duda RO, Hart PE, Stork DG (2001) Pattern classification. Wiley, New York

Huffman DA (1952) A method for the construction of minimum-redundancy codes. Proc Inst Radio Eng 40:1098–1101. doi:10.1109/jrproc.1952.273898

Bachmann F, Hielscher R, Schaeben H (2010) Texture analysis with MTEX—free and open source software toolbox. Sol St Phen 160:63–68. doi:10.4028/http://www.scientific.net/SSP.160.63

Grimmer H, Bollmann W, Warringt Dh (1974) Coincidence-site lattices and complete pattern-shift lattices in cubic-crystals. Acta Crystallogr Sect A 30:197–207. doi:10.1107/S056773947400043x

Saylor DM, Morawiec A, Rohrer GS (2003) Distribution of grain boundaries in magnesia as a function of five macroscopic parameters. Acta Mater 51:3663–3674. doi:10.1016/s1359-6454(03)00181-2

Saylor DM, El-Dasher BS, Adams BL, Rohrer GS (2004) Measuring the five-parameter grain-boundary distribution from observations of planar sections. Metall Mater Trans A 35A:1981–1989. doi:10.1007/s11661-004-0147-z

Randle V, Davies H (2002) A comparison between three-dimensional and two-dimensional grain boundary plane analysis. Ultramicroscopy 90:153–162. doi:10.1016/S0304-3991(01)00137-1

Davies H, Randle V (2002) Single-section plane assessment in grain boundary engineered brass. J Microsc-Oxf 205:253–258. doi:10.1046/j.1365-2818.2002.00989.x

Rohrer GS (2011) Grain boundary energy anisotropy: a review. J Mater Sci 46:5881–5895. doi:10.1007/s10853-011-5677-3

Tschopp MA, McDowell DL (2007) Structures and energies of Sigma 3 asymmetric tilt grain boundaries in copper and aluminium. Philos Mag 87:3147–3173. doi:10.1080/14786430701255895

Wang J, Zhang X (2016) Twinning effects on strength and plasticity of metallic materials. MRS Bull 41:274–281

Jin SB, Zhang K, Bjorge R et al (2015) Formation of incoherent deformation twin boundaries in a coarse-grained Al-7 Mg alloy. Appl Phys Lett 107:091901. doi:10.1063/1.4929683

Hirth JP, Lothe J (1982) Theory of dislocations. Wiley, New York

Osovski S, Srivastava A, Williams JC, Needleman A (2015) Grain boundary crack growth in metastable titanium beta alloys. Acta Mater 82:167–178. doi:10.1016/j.actamat.2014.08.062

Adams BL, Kalidindi S, Fullwood DT (2013) Microstructure-sensitive design for performance optimization. Butterworth–Heinemann, Waltham

Fullwood DT, Niezgoda SR, Adams BL, Kalidindi SR (2010) Microstructure sensitive design for performance optimization. Prog Mater Sci 55:477–562. doi:10.1016/j.pmatsci.2009.08.002

Seita M, Nimerfroh MM, Demkowicz MJ (2017) Acquisition of partial grain orientation information using optical microscopy. Acta Mater 123:70–81

Seita M, Volpi M, Patala S et al (2016) A high-throughput technique for determining grain boundary character non-destructively in microstructures with through-thickness grains. Nat Comput Mater 2:16016

Sheather SJ (2009) A modern approach to regression with R. Springer, New York

Di Stefano D, Mrovec M, Elsasser C (2015) First-principles investigation of hydrogen trapping and diffusion at grain boundaries in nickel. Acta Mater 98:306–312. doi:10.1016/j.actamat.2015.07.031

Ritchie RO, Knott JF, Rice JR (1973) Relationship between critical tensile stress and fracture toughness in mild-steel. J Mech Phys Solids 21:395–410. doi:10.1016/0022-5096(73)90008-2

Chen X, Dejoie C, Jiang T, Ku C-S, Tamura N (2016) Quantitative microstructural imaging by scanning Laue x-ray micro- and nanodiffraction. MRS bull 41:445–453

Acknowledgements

This work was supported by the US Department of Energy, Office of Basic Energy Sciences under Award No DE-SC0008926, with the exception of experiments on CTBs in alloy 725 (the “Assembly of an experimental database of failure events for hydrogen-assisted crack initiation in Ni-based alloy 725” section), which were supported by the BP-MIT Materials and Corrosion Center. Access to shared experimental facilities was provided by the MIT Center for Materials Science Engineering, supported in part by the MRSEC Program of the National Science Foundation under award number DMR—0213282. J.P.H. Acknowledges the Department of Energy Office of Science Graduate Fellowship Program (DOE SCGF), made possible in part by the American Recovery and Reinvestment Act of 2009, administered by ORISE-ORAU under contract no. DE-AC05-06OR23100. M.J.D. Acknowledges stimulating discussions with A. Srivastava.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seita, M., Hanson, J.P., Gradečak, S. et al. Probabilistic failure criteria for individual microstructural elements: an application to hydrogen-assisted crack initiation in alloy 725. J Mater Sci 52, 2763–2779 (2017). https://doi.org/10.1007/s10853-016-0568-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0568-2