Abstract

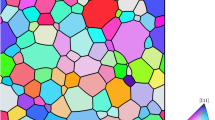

Grain boundaries strongly affect many materials properties in polycrystalline materials. However, very few structure–property models exist for grain boundaries, due in large part to the complicated and poorly understood way in which the properties of grain boundaries vary with their crystallographic structure. In the present work, we infer grain boundary structure–property correlations from measurements of the effective properties of a polycrystal. We refer to this approach as grain boundary properties localization. We apply this technique to a simple model system of grain boundary diffusivity in a two-dimensional microstructure, and infer the properties of low- and high-angle grain boundaries from the effective diffusivity of the grain boundary network. The generalization and use of these methods could greatly reduce the computational and experimental effort required to establish structure–property correlations for grain boundaries. More broadly, the technique of properties localization could be used to infer the properties of many microstructural constituents in complex microstructures.

Similar content being viewed by others

Notes

There are two distinct concepts of effective diffusivity (or conductivity) in the literature. One is the diffusivity of the actual heterogeneous network as a whole, and the other is the diffusivity of a single boundary in a hypothetical homogeneous sample whose network diffusivity matches that of the real sample. The two notions are related and we take the former interpretation, which is the reason that Eq. 4 differs from the form appearing in [35, 58, 59].

The percent error for \(\log \!\left( D_2\right) \) is strictly greater than or equal to that of \(\omega _{\text{t}}\). However, since \(\log \!\left( D_1\right) =0\) the concept of percent error is not well defined for this parameter. Alternatively, considering the percent error in \(D_1\) instead of its logarithm would be inconsistent with the rest of our analysis. While the absolute error of \(\log \!\left( D_1\right) \) is very large for \(N=3\), it is zero (or at least smaller than the resolution of \(\Lambda \)) for all other values of N that were tested, and consequently its %error can be reasonably considered to be zero as well. Therefore, using the percent error of \(\log \!\left( D_2\right) \) as a bound is strictly only valid for \(N \ge 5\).

References

Seita M, Hanson JP, Gradeˇcak S, Demkowicz MJ (2015a) The dual role of coherent twin boundaries in hydrogen embrittlement. Nat Commun 6:6164. doi:10.1038/ncomms7164

Lehockey EM, Limoges D, Palumbo G, et al. (1999) On improving the corrosion and growth resistance of positive Pb-acid battery grids by grain boundary engineering. J Power Sour 78(1–2):79–83. doi:10.1016/S0378-7753(99)00015-4

Lehockey EM, Palumbo G (1997) On the creep behaviour of grain boundary engineered nickel. Mater Sci Eng A 237(2):168–172. doi:10.1016/S0921-5093(97)00126-3

Lehockey EM, Palumbo G, Lin P (1998) Improving the weldability and service performance of nickel-and iron-based superalloys by grain boundary engineering. Metall Mater Trans A 29(12):3069–3079. doi:10.1007/s11661-998-0214-y

Norton DP, Goyal A, Budai JD, et al. (1996) Epitaxial YBa2Cu3O7 on biaxially textured Nickel (001): an approach to superconducting tapes with high critical current density. Science 274(5288):755–757. doi:10.1126/science.274.5288.755

Sutton AP, Balluffi RW (2007) Interfaces in crystalline materials. Monographs on the physics and chemistry of materials (Book 51), 3rd edn. New York: Oxford University Press

Demkowicz MJ, Wang J, Hoagland RG (2008) Interfaces between dissimilar crystalline solids, chap. 83. In: Hirth JP (ed) Dislocations in solids, vol. 14. New York: Elsevier, pp 141–205. doi:10.1016/S1572-4859(07)00003-4

Vitek V, Minonishi Y, Wang GJ (1985) Multiplicity of grain boundary structures: vacancies in boundaries and transformations of the boundary structure. J Phys Colloq 46(C4):C4-171–C4-183. doi:10.1051/jphyscol:1985420

Vitek V, Sutton A, Wang GJ, Schwartz D (1983) On the multiplicity of structures and grain boundaries. Scripta Metall 17:183–189. doi:10.1016/0036-9748(83)90096-0

Chin GY (1959) Studies of growth and fatigue in bicrystals of Aluminum. Cambridge: Bachelor of Science, Massacusetts Institute of Technology

Schwarz S, Houge E, Giannuzzi L, King A (2001) Bicrystal growth and characterization of copper twist grain boundaries. J Cryst Growth 222(1–2):392–398. doi:10.1016/S0022-0248(00)00918-0

Fleischer RL, Davis RS (1959) Controlling grain boundary position in growth from the melt. Trans Metall Soc AIME 215:665–666

Schober T, Balluffi RW (1969) Dislocation sub-boundary arrays in oriented thin-film bicrystals of gold. Philos Mag 20(165):511–518. doi:10.1080/14786436908228723

Amiri-Hezaveh A, Balluffi RW (1993) Apparatus for producing ultraclean bicrystals by the molecular beam epitaxy growth and ultrahigh vacuum bonding of thin films. Rev Sci Instrum 64(10):2983. doi:10.1063/1.1144344

Heinemann S, Wirth R, Dresen G (2001) Synthesis of feldspar bicrystals by direct bonding. Phys Chem Miner 28(10):685–692. doi:10.1007/s002690000142

Marquardt K, Petrishcheva E, Gard´es E, et al. (2011) Grain boundary and volume diffusion experiments in yttrium aluminium garnet bicrystals at 1,723 K: a miniaturized study. Contrib Mineral Petrol 162(4):739–749. doi:10.1007/s00410-011-0622-7

Pl¨oßl A, Kr¨auter G (1999) Wafer direct bonding: tailoring adhesion between brittle materials. Mater Sci Eng R 25(1–2):1–88. doi:10.1016/S0927-796X(98)00017-5

Holm EA, Olmsted DL, Foiles SM (2010) Comparing grain boundary energies in face-centered cubic metals: Al, Au, Cu and Ni. Scr Mater 63(9):905–908. doi:10.1016/j.scriptamat.2010.06.040

Olmsted DL, Foiles SM, Holm EA (2009a) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater 57(13):3694–3703. doi:10.1016/j.actamat.2009.04.007

Olmsted DL, Holm EA, Foiles SM (2009b) Survey of computed grain boundary properties in face-centered cubic metals II: grain boundary mobility. Acta Mater 57(13):3704–3713. doi:10.1016/j.actamat.2009.04.015

Seita M, Volpi M, Patala S, McCue I, Diamanti MV, Schuh CA, Demkowicz MJ. A hybrid non-destructive technique to characterize grain boundary crystallography (in preparation)

Sorensen C, Basinger JA, Nowell MM, Fullwood DT (2014) Five-parameter grain boundary inclination recovery with ebsd and interaction volume models. Metall Mater Trans A 45:4165–4172. doi:10.1007/s11661-014-2345-7

Suter RM, Hennessy D, Xiao C, Lienert U (2006) Forward modelling method for microstructure reconstruction using x-ray diffraction microscopy: Single-crystal verification. Rev Sci Instrum 77(12):123905. doi:10.1063/1.2400017

Binci M, Fullwood DT, Kalidindi SR (2008) A new spectral framework for establishing localization relationships for elastic behavior of composites and their calibration to finite-element models. Acta Mater 56(10):2272–2282. doi:10.1016/j.actamat.2008.01.017

Duvvuru HK, Wu X, Kalidindi SR (2007) Calibration of elastic localization tensors to finite element models: application to cubic polycrystals. Comput Mater Sci 41(2):138–144. doi:10.1016/j.commatsci.2007.03.008

Fast T, Kalidindi SR (2011) Formulation and calibration of higher-order elastic localization relationships using the MKS approach. Acta Mater 59(11):4595–4605. doi:10.1016/j.actamat.2011.04.005

Fullwood DT, Kalidindi SR, Adams BL (2009a) Second-order microstructure sensitive design using 2-point spatial correlations, chap. 13. In: Schwartz AJ, Kumar M, Adams BL, Field DP (eds) Electron backscatter diffraction in materials science; , 2nd edn. New York: Springer, pp 177–188. doi:10.1007/978-0-387-88136-2

Fullwood DT, Kalidindi SR, Adams BL, Ahmadi S (2009b) A discrete Fourier transform framework for localization relations. Comput Mater Contin 9(1):25–40. doi:10.3970/cmc.2009.009.025

Fullwood DT, Niezgoda SR, Adams BL, Kalidindi SR (2010) Microstructure sensitive design for performance optimization. Prog Mater Sci 55(6):477–562. doi:10.1016/j.pmatsci.2009.08.002

Kalidindi SR, Landi G, Fullwood DT (2008) Spectral representation of higher-order localization relationships for elastic behavior of polycrystalline cubic materials. Acta Mater 56(15):3843–3853. doi:10.1016/j.actamat.2008.01.058

Landi G, Kalidindi SR (2010) Thermo-elastic localization relationships for multi-phase composites. Comput Mater Contin 16(3):273–294. doi:10.3970/cmc.2010.016.273

Li D, Szpunar J (1992) Determination of single crystals’ elastic constants from the measurement of ultrasonic velocity in the polycrystalline material. Acta Metall Mater 40(12):3277–3283. doi:10.1016/0956-7151(92)90041-C

Howard CJ, Kisi EH (1999) Measurement of single-crystal elastic constants by neutron diffraction from polycrystals. J Appl Crystallogr 32(4):624–633. doi:10.1107/S0021889899002393

Hayakawa M, Imai S, Oka M (1985) Determination of single-crystal elastic constants from a cubic polycrystalline aggregate. J Appl Crystallogr 18(6):513–518. doi:10.1107/S0021889885010809

Chen Y, Schuh CA (2006) Diffusion on grain boundary networks: percolation theory and effective medium approximations. Acta Mater 54(18):4709–4720. doi:10.1016/j.actamat.2006.06.011

Rohrer GS (2011) Grain boundary energy anisotropy: a review. J Mater Sci 46(18):5881–5895. doi:10.1007/s10853-011-5677-3

Hwang JCM, Balluffi RW (1979) Measurement of grain-boundary diffusion at low temperatures by the surface accumulation method. I. Method and analysis. J Appl Phys 50(3):1339. doi:10.1063/1.326168

Ma Q, Balluffi RW (1993) Diffusion along [001] tilt boundaries in the Au/Ag system I. Experimental results. Acta Metall Mater 41(1):133–141. doi:10.1016/0956-7151(93)90345-S

Johnson OK, Schuh CA (2013) The uncorrelated triple junction distribution function: towards grain boundary network design. Acta Mater 61(8):2863–2873. doi:10.1016/j.actamat.2013.01.025

Gertsman VY, Tangri K (1995) Computer simulation study of grain boundary and triple junction distributions in microstructures formed by multiple twinning. Acta Metall Mater 43(6):2317–2324. doi:10.1016/0956-7151(94)00422-6

Fortier P (1997) Triple junction and grain boundary character distributions in metallic materials. Acta Mater 45(8):3459–3467. doi:10.1016/S1359-6454(97)00004-9

Kumar M, King WE, Schwartz AJ (2000) Modifications to the microstructural topology in f.c.c. materials through thermomechanical processing. Acta Mater 48(9):2081–2091. doi:10.1016/S1359-6454(00)00045-8

Davies P, Randle V, Watkins G, Davies H (2002) Triple junction distribution profiles as assessed by electron backscatter diffraction. J Mater Sci 37(19):4203–4209. doi:10.1023/A:1020052306493

Schuh CA, Kumar M, King WE (2003) Analysis of grain boundary networks and their evolution during grain boundary engineering. Acta Mater 51(3):687–700. doi:10.1016/S1359-6454(02)00447-0

Yi Y, Kim J (2004) Characterization methods of grain boundary and triple junction distributions. Scr Mater 50(6):855–859. doi:10.1016/j.scriptamat.2003.12.010

Frary ME, Schuh CA (2005a) Connectivity and percolation behaviour of grain boundary networks in three dimensions. Philos Mag 85(11):1123–1143. doi:10.1080/14786430412331323564

Mason JK, Schuh CA (2007) Correlated grain-boundary distributions in two-dimensional networks. Acta Crystallogr Sect A 63(Pt 4):315–328. doi:10.1107/S0108767307021782

Wall MA, Schwartz AJ, Nguyen L (2001) A high-resolution serial sectioning specimen preparation technique for application to electron backscatter diffraction. Ultramicroscopy 88(2):73–83. doi:10.1016/S0304-3991(01)00071-7

Rowenhorst D, Gupta A, Feng C, Spanos G (2006) 3D Crystallographic and morphological analysis of coarse martensite: combining EBSD and serial sectioning. Scr Mater 55(1):11–16. doi:10.1016/j.scriptamat.2005.12.061

Mulders J, Day A (2005) Three-dimensional texture analysis. Mater Sci Forum 495–497:237–244. doi:10.4028/www.scientific.net/MSF.495-497.237

Poulsen HF, Nielsen SF, Lauridsen EM, et al. (2001) Three-dimensional maps of grain boundaries and the stress state of individual grains in polycrystals and powders. J Appl Crystallogr 34(6):751–756. doi:10.1107/S0021889801014273

Ludwig W, Reischig P, King A, et al. (2009) Three-dimensional grain mapping by x-ray diffraction contrast tomography and the use of Friedel pairs in diffraction data analysis. Rev Sci Instrum 80(3):033905. doi:10.1063/1.3100200

King A, Herbig M, Ludwig W, et al. (2010) Non-destructive analysis of micro texture and grain boundary character from X-ray diffraction contrast tomography. Nucl Instrum Methods Phys Res Sect B 268(3–4):291–296. doi:10.1016/j.nimb.2009.07.020

Li SF, Suter RM (2013) Adaptive reconstruction method for three-dimensional orientation imaging. J Appl Crystallogr 46(2):512–524. doi:10.1107/S0021889813005268

Kirkpatrick S (1973) Percolation and conduction. Rev Mod Phys 45(4):574–588

Reed BW, Schuh CA (2009) Grain boundary networks, chap. 15. In: Schwartz AJ, Kumar M, Adams BL, Field DP (eds) Electron backscatter diffraction in materials science, 2nd edn. New York: Springer, pp 201–214. doi:10.1007/978-0-387-88136-2

Kaur I, Gust W (1989) Handbook of grain and interphase boundary diffusion data, vol. 1, 1st edn. Stuttgart: Ziegler Press

McLachlan DS (1987) An equation for the conductivity of binary mixtures with anisotropic grain structures. J Phys C 20(7):865–877. doi:10.1088/0022-3719/20/7/004

McLachlan DS (2003) The correct modelling of the second order terms of the complex AC conductivity results for continuum percolation media, using a single phenomenological equation. Phys B 338(1–4):256–260. doi:10.1016/j.physb.2003.08.002

Stauffer D, Aharony A (1994) Introduction to percolation theory, 2nd edn. Philadelphia: Taylor & Francis

Frary ME, Schuh CA (2005b) Grain boundary networks: scaling laws, preferred cluster structure, and their implications for grain boundary engineering. Acta Mater 53(16):4323–4335. doi:10.1016/j.actamat.2005.05.030

Frary ME, Schuh CA (2007) Correlation-space description of the percolation transition in composite microstructures. Phys Rev E 76(4):42–45. doi:10.1103/PhysRevE.76.041108

Bulatov VV, Reed BW, Kumar M (2013) Grain boundary energy function for fcc metals. Acta Mater 65:161–175. doi:10.1016/j.actamat.2013.10.057

K D (2015) Number of samples required for an event to occur with a given confidence level. Math Stack Exch. http://math.stackexchange.com/q/1209320

Acknowledgements

This work was supported by the US Department of Energy (DOE), Office of Basic Energy Sciences under Award No. DE-SC0008926. Oliver K. Johnson acknowledges support from the Department of Defense (DoD) through the National Defense Science & Engineering Graduate Fellowship (NDSEG) Program.

Author information

Authors and Affiliations

Corresponding author

Appendix: Error scaling for bicrystal experiments

Appendix: Error scaling for bicrystal experiments

In attempting to infer the parameters of the constitutive equation (Eq. 2) via bicrystal experiements, the parameter \(D_1\) will be recovered exactly if at least one bicrystal that we test has a misorientation \(\omega \le \omega _{\text{t}}\), assuming that there is no uncertainty in the value of \(D_1\) that we measure. Likewise, \(D_2\) will be recovered exactly with at least one bicrystal having \(\omega > \omega _{\text{t}}\). To recover the final parameter, \(\omega _{\text{t}}\), to within some specified accuracy (\(\%ERR\)), there must be at least one bicrystal with misorientation falling in the range \(\left[ \omega _{\text{t}}-\delta ,\omega _{\text{t}}\right] \) and another bicrystal with misorientation falling in the range \(\left[ \omega _{\text{t}},\omega _{\text{t}}+\delta \right] \), where \(\%ERR=\delta /\omega _{\text{t}}\). For small \(\delta \), the error in \(\omega _{\text{t}}\) will be larger than that of both \(D_1\) and \(D_2\). Specifically, this will be the case for \(\delta < \omega _{\text{t}}\). We wish to identify the number of bicrystal experiments, N, required to recover \(\omega _{\text{t}}\) to within \(\delta \) of its true value at a 95 % confidence level.

Consider a set of N bicrystals with respective misorientations, \(\left\{ \omega _1,\omega _2,\dots ,\omega _N\right\} \), which are sampled from \(\Omega \sim U\!\left( 0,\omega _{\text{max}}\right) \), where \(\omega _{\text{max}} = {180}^{\circ}\) for the crystal system considered in this study . LetFootnote 4 A be the event that at least one of these bicrystals falls in the interval \(\left[ \omega _{\text{t}}-\delta ,\omega _{\text{t}}\right] \), and let B be the event that at least one of these bicrystals falls in the interval \(\left[ \omega _{\text{t}},\omega _{\text{t}}+\delta \right] \). We are interested in finding N such that

Thus, we seek an expression for the joint probability \(\mathbb {P}\!\left( A \cap B\right) \). This may be accomplished by considering the complement:

The probability that none of the N samples fall within \(\left[ \omega _{\text{t}}-\delta ,\omega _{\text{t}}\right] \) is given by

Likewise, for the interval \(\left[ \omega _{\text{t}},\omega _{\text{t}}+\delta \right] \) we have

The probability that none of the samples fall in the interval \(\left[ \omega _{\text{t}}-\delta ,\omega _{\text{t}}+\delta \right] \) is given by

Substituting these results into Eq. 16 we find

Substituting \(\delta = \omega _{\text{t}} \left( \%\text {ERR}\right) \), setting Eq. 20 equal to 0.95, and solving for N numerically for 100 values of \(\%\text {ERR} \in \left\{ 0.001,0.002,\ldots ,0.100\right\}, \) we observe the \(N\!\left( \%\text {ERR}\right) \) dependence shown in Fig. 9.

Solutions of Eq. 15 for various values of \(\%\text {ERR} \in \left\{ 0.001,0.002,\ldots ,0.100\right\} \)

These results suggest a power-law dependence, and a fit to the data results in the following:

with a coefficient of determination equal to \(R^2 = 1.0000\) and an RMS error of 1.0407. The 95 % confidence intervals for the parameters in Eq. 21 are \(\left[ 44.0216,44.0459\right] \) and \(\left[ -1.0002,-1.0003\right] \), respectively. For comparison with the error scaling of the localization method (See Eq. 11), we can rearrange Eq. 21 to get the error scaling law for a bicrystal approach:

Rights and permissions

About this article

Cite this article

Johnson, O.K., Li, L., Demkowicz, M.J. et al. Inferring grain boundary structure–property relations from effective property measurements. J Mater Sci 50, 6907–6919 (2015). https://doi.org/10.1007/s10853-015-9241-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9241-4