Abstract

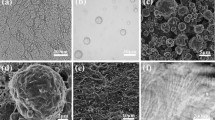

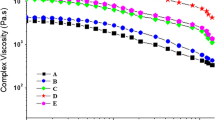

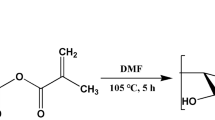

Cellulose nanowhiskers (CNWs) prepared via TEMPO mediated oxidation are used as biodegradable filler in an epoxy matrix. Since CNWs are hydrophilic and epoxy is hydrophobic, amphiphilic block copolymer surfactants are employed to improve the interactions between the filler and the matrix. The surfactants used are Pluronics, a family of triblock copolymers containing two poly(ethylene oxide) blocks and one poly(propylene oxide) block. In this study, Pluronic L61 and L121 with molecular weight of 2000 and 4400 g/mol and hydrophilic to lipophilic balance of 3 and 1 respectively, are used and their effect on the dispersion of CNWs in epoxy is discussed. The hydrophilic tails of Pluronics interact with the hydroxyl and carboxylic groups on the CNW surface and then these surfactant-treated CNWs are directly incorporated into epoxy by high speed mixing. The dispersion state of the surfactant-treated CNWs in epoxy is assessed by rheological measurements and the mechanical properties of the resulting composites are characterized by tensile test and dynamic mechanical thermal analysis. The Pluronic L61 treated CNW/epoxy composites show the highest storage modulus at high temperatures (about 77 % increases) indicative of improved interfacial interactions between the CNWs and the epoxy matrix. Also, an increase of around 10 °C in the glass–rubbery transition temperature of the L61 treated CNW/epoxy composite leads to potential application at higher service temperatures.

Similar content being viewed by others

References

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8:3276–3278

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues: wheat straw and soy hulls. Bioresour Technol 99:1664–1671. doi:10.1016/j.biortech.2007.04.029

Alexandridis P, Hatton TA (1995) Poly(ethylene oxide)–poly(propylene oxide)–poly(ethylene oxide) block copolymer surfactants in aqueous solutions and at interfaces: thermodynamics, structure, dynamic, and modeling. Colloids Surf A Physicochem Eng Asp 96:1–46

Aspler J, Bouchard J, Hamad W et al (2013) Review of nanocellulosic products and their applications, 1st edn. Wiley, Hoboken

Batrakova EV, Li S, Alakhov VY et al (2003) Optimal structure requirements for pluronic block copolymers in modifying P-glycoprotein drug efflux transporter activity in bovine brain microvessel endothelial cells. J Pharmacol Exp Ther 304:845–854. doi:10.1124/jpet.102.043307

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules 6:1048–1054. doi:10.1021/bm049300p

Bercea M, Navard P (2000) Shear dynamics of aqueous suspensions of cellulose whiskers. Macromolecules 33:6011–6016. doi:10.1021/ma000417p

Bledzki AK, Reihmane S, Gassan J (1996) Properties and modification methods for vegetable fibers for natural fiber composites. J Appl Polym Sci 59:1329–1336. doi:10.1002/(SICI)1097-4628(19960222)59:8<1329:AID-APP17>3.3.CO;2-5

Bondeson D, Oksman K (2007) Dispersion and characteristics of surfactant modified cellulose whiskers nanocomposites. Compos Interfaces 14:617–630. doi:10.1163/156855407782106519

Cao X, Ding B, Yu J, Al-Deyab SS (2012) Cellulose nanowhiskers extracted from TEMPO-oxidized jute fibers. Carbohydr Polym 90:1075–1080. doi:10.1016/j.carbpol.2012.06.046

Capadona JR, Shanmuganathan K, Trittschuh S et al (2009) Polymer nanocomposites with nanowhiskers isolated from microcrystalline cellulose. Biomacromolecules 10:712–716. doi:10.1021/bm8010903

Chen W, Yu H, Liu Y et al (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83:1804–1811. doi:10.1016/j.carbpol.2010.10.040

Cross L, Schueneman G, Mintz E et al (2013) Nanocellulose reinforced epoxy elastomer. In: Proceeding of the annual meeting of the adhesion, pp 25–27

Dong H, Strawhecker KE, Snyder JF et al (2012) Cellulose nanocrystals as a reinforcing material for electrospun poly(methyl methacrylate) fibers: formation, properties and nanomechanical characterization. Carbohydr Polym 87:2488–2495. doi:10.1016/j.carbpol.2011.11.015

Eberle APR, Baird DG, Wapperom P (2008) Rheology of non-Newtonian fluids containing glass fibers: a review of experimental literature. Ind Eng Chem Res 47:3470–3488. doi:10.1021/ie070800j

Eichhorn SJ, Dufresne A, Aranguren M et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33. doi:10.1007/s10853-009-3874-0

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J-L et al (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9:57–65. doi:10.1021/bm700769p

Evers R, Kool M, Smith AJ et al (2000) Inhibitory effect of the reversal agents V-104, and MRP2-mediated transport. Br J Cancer 83:366–374

Fan Z, Advani SG (2007) Rheology of multiwall carbon nanotube suspensions. J Rheol (N Y N Y) 51:585. doi:10.1122/1.2736424

Fan J, Li Y (2012) Maximizing the yield of nanocrystalline cellulose from cotton pulp fiber. Carbohydr Polym 88:1184–1188. doi:10.1016/j.carbpol.2012.01.081

Favier V, Chanzy H, Cavaille J (1995) Polymer nanocomposites reinforced by cellulose whiskers. Macromolecules 28:6365–6367

Ghorabi S, Rajabi L, Madaeni SS et al (2012) Effects of three surfactant types of anionic, cationic and non-ionic on tensile properties and fracture surface morphology of epoxy/MWCNT nanocomposites. Iran Polym J 21:121–130. doi:10.1007/s13726-011-0013-y

Grant LDR, Adam RD, da Silva LFM (2009) Effect of the temperature on the strength of adhesively-bonded single lab an T joints for the automotive industry. Int J Adhes Adhes 29:535–542

Grunert M, Winter WT (2002) Nanocomposites of cellulose acetate butyrate reinforced with cellulose nanocrystals. J Polym Environ 10:27–30

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. doi:10.1021/cr900339w

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. doi:10.1039/c0nr00583e

Kalia S, Dufresne A, Cherian BM et al (2011) Cellulose-based bio- and nanocomposites: a review. Int J Polym Sci 2011:1–35. doi:10.1155/2011/837875

Kim J, Montero G, Habibi Y et al (2009) Dispersion of cellulose crystallites by nonionic surfactants in a hydrophobic polymer matrix. Polym Eng Sci. doi:10.1002/pen

Li Y-Q, Fu S-Y, Mai Y-W (2006) Preparation and characterization of transparent ZnO/epoxy nanocomposites with high-UV shielding efficiency. Polymer (Guildf) 47:2127–2132. doi:10.1016/j.polymer.2006.01.071

Li R, Fei J, Cai Y et al (2009) Cellulose whiskers extracted from mulberry: a novel biomass production. Carbohydr Polym 76:94–99. doi:10.1016/j.carbpol.2008.09.034

Li Y, Liu H, Song J et al (2011) Adsorption and association of a symmetric PEO–PPO–PEO triblock copolymer on polypropylene, polyethylene, and cellulose surfaces. ACS Appl Mater Interfaces 3:2349–2357

Lin N, Bruzzese C, Dufresne A (2012) TEMPO-oxidized nanocellulose participating as crosslinking aid for alginate-based sponges. ACS Appl Mater Interfaces 4:4948–4959. doi:10.1021/am301325r

Ljungberg N, Bonini C, Bortolussi F et al (2005) New nanocomposite materials reinforced with cellulose whiskers in atactic polypropylene: effect of surface and dispersion characteristics. Biomacromolecules 6:2732–2739. doi:10.1021/bm050222v

Loos MR, Manas-Zloczower I (2013) Micromechanical models for carbon nanotube and cellulose nanowhisker reinforced composites. Polym Eng Sci. doi:10.1002/pen

Loos MR, Yang J, Feke DL, Manas-Zloczower I (2012) Effect of block-copolymer dispersants on properties of carbon nanotube/epoxy systems. Compos Sci Technol 72:482–488. doi:10.1016/j.compscitech.2011.11.034

Martin-Gallego M, Verdejo R, Gestos A et al (2015) Morphology and mechanical properties of nanostructured thermoset/block copolymer blends with carbon nanoparticles. Compos Part A 71:136–143

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159. doi:10.1007/s10570-007-9145-9

Oh KT, Bronich TK, Kabanov AV (2004) Micellar formulations for drug delivery based on mixtures of hydrophobic and hydrophilic Pluronic® block copolymers. J Control Release 94:411–422. doi:10.1016/j.jconrel.2003.10.018

Petersson L, Oksman K (2006) Biopolymer based nanocomposites: comparing layered silicates and microcrystalline cellulose as nanoreinforcement. Compos Sci Technol 66:2187–2196. doi:10.1016/j.compscitech.2005.12.010

Pircheraghi G, Foudazi R, Manas-Zloczower I (2015) Characterization of carbon nanotube dispersion and filler network formation in melted polyol for nanocomposite materials. Power Technol 276:222–231

Qin Z-Y, Tong G-L, Chin YCF, Zhou J-C (2011) Preparation of ultrasonic-assisted high carboxylate content cellulose nanocrystals by tempo oxidation. BioResource 6:1136–1146

Reis JML, Amorim FC, da Silva AHMFT, da Costa Mattos HS (2015) Influence of temperature on the behavior of DGEBA (bisphenol A diglycidyl ether) epoxy adhesive. Int J Adhes Adhes 58:88–92. doi:10.1016/j.ijadhadh.2015.01.013

Ruiz-Pérez L, Royston GJ, Fairclough JPA, Ryan AJ (2008) Toughening by nanostructure. Polymer (Guildf) 49:4475–4488. doi:10.1016/j.polymer.2008.07.048

Sacui IA, Nieuwendaal RC, Burnett DJ et al (2014) Comparison of the properties of cellulose nanocrystals and cellulose nanofibrils isolated from bacteria, tunicate, and wood processed using acid, enzymatic, mechanical, and oxidative methods. ACS Appl Mater Interfaces 6:6127–6138. doi:10.1021/am500359f

Sadeghifar H, Filpponen I, Clarke SP et al (2011) Production of cellulose nanocrystals using hydrobromic acid and click reactions on their surface. J Mater Sci 46:7344–7355. doi:10.1007/s10853-011-5696-0

Saito T, Isogai A (2008) TEMPO-mediated oxidation of native cellulose. The effect of oxidation conditions on chemical and crystal structures of the water-insoluble fractions. Biomacromolecules 5:1983–1989

Saito T, Okita Y, Nge TT et al (2006) TEMPO-mediated oxidation of native cellulose: microscopic analysis of fibrous fractions in the oxidized products. Carbohydr Polym 65:435–440. doi:10.1016/j.carbpol.2006.01.034

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491. doi:10.1021/bm0703970

Satyamurthy P, Jain P, Balasubramanya RH, Vigneshwaran N (2011) Preparation and characterization of cellulose nanowhiskers from cotton fibres by controlled microbial hydrolysis. Carbohydr Polym 83:122–129. doi:10.1016/j.carbpol.2010.07.029

Semsarzadeh M, Lotfali A, Mirzadeh H (1984) Jute reinforced polyester structures. Polym Compos 5:141–142

Silva MDBLEM, Campilho RDSG (2012) Effect of temperature on tensile strength and mode I fracture toughness of a high temperature epoxy adhesive. J Adhes Sci Technol 26:939–953

Singh V, Khullar P, Dave PN, Kaur N (2013) Micelles, mixed micelles, and applications of polyoxypropylene (PPO)-polyoxyethylene (PEO)-polyoxypropylene (PPO) triblock polymers. Int J Ind Chem 4:12. doi:10.1186/2228-5547-4-12

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: a review of preparation, properties and applications. Polymers (Basel) 2:728–765. doi:10.3390/polym2040728

Souza JPB, Reis JML (2013) Thermal behavior of DGEBA (Diglycidyl Ether of Bisphenol A) adhesives and its influence on the strength of joints. Appl Adhes Sci 1:1–10

Sun C (2005) True density of microcrystalline cellulose. J Pharm Sci 94:2132–2134. doi:10.1002/jps.20459

Tang L, Weder C (2010) Cellulose whisker/epoxy resin nanocomposites. ACS Appl Mater Interfaces 2:1073–1080. doi:10.1021/am900830h

Tang L, Whalen J, Schutte G, Weder C (2009) Stimuli-responsive epoxy coatings. ACS Appl Mater Interfaces 1:688–696. doi:10.1021/am800199u

Tercjak A, Gutierrez J, Barud HS et al (2015) Nano- and macroscale structural and mechanical properties of in situ synthesized bacterial cellulose/PEO-b-PPO-b-PEO biocomposites. ACS Appl Mater Interfaces 7:4142–4150. doi:10.1021/am508273x

Wang P, Liu J, Li R (1994) Physical modification of polyacrylonitrile precursor fiber: its effect on mechanical properties. J Appl Polym Sci 52:1667–1674

Xu X, Liu F, Jiang L et al (2013) Cellulose nanocrystals vs. cellulose nano fibrils: a comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces 5:2999–3009

Yang J, Zhao J, Xu F, Sun R (2013) Revealing strong nanocomposite hydrogels reinforced by cellulose nanocrystals: insight into morphologies and interactions. ACS Appl Mater Interfaces 5:12960–12967

Acknowledgments

We acknowledge the National Science Foundation for the financial support of our research through Grant PIRE-1243313.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Emami, Z., Meng, Q., Pircheraghi, G. et al. Use of surfactants in cellulose nanowhisker/epoxy nanocomposites: effect on filler dispersion and system properties. Cellulose 22, 3161–3176 (2015). https://doi.org/10.1007/s10570-015-0728-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0728-6