Abstract

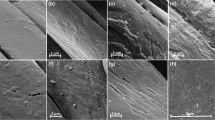

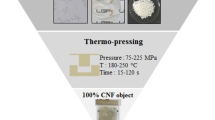

Fourteen cotton samples of various strength, maturity and fineness were compressed in the same conditions at elevated pressure (2.0 GPa) and temperature (120 °C) in a home-made Bridgman anvil press designed to process samples of about 20 mm diameter. The influence of cotton properties to the abilities to be compacted into a solid 3D object was studied by mechanical measurements (nano-indentation and DMA) and scanning electron morphology observations. No influence of maturity ratio was observed. But strength and fineness were important parameters. It was shown that the lower are the mechanical properties of the cotton fibres (low strength or large fineness value), the easier it is to compact them. By observing the morphology of compacted samples, it was shown that compaction is linked to the destructuration of fibres under pressure down to the nanofibrillar level.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polymr 87(2):963–979

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8(10):3276–3278

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99(6):1664–1671

Basra AS (1999) Cotton fibers: developmental biology, quality improvement and textile processing. Food Products Press, New York

Bassett DC, Block S, Piermarini GJ (1974) A high-pressure phase of polyethylene and chain-extended growth. J Appl Phys 45(10):4146–4150

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24(2):221–274

Ellis J (1995) Scouring, enzymes and softeners. In: Carr CM (ed) Chemistry of the textile industry, Blackie Academic and Professional. London, pp 249–275

Gawrysiak G, Lassus S, Gourlot J-P, Gozé E (2008) Calibration, measurements stability and replacement of standard cottons for an FMT3. In: World cotton research conference 4: Lubbock, United States, September 10–14, Omnipress, Madison

Graupner N, Endres H-J, Müssig J (2008) Influence of fiber fineness, fiber maturity, and nep content on the properties of natural fiber reinforced cotton-epoxy composites. J Nat Fibers 5(4):289–315

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci Appl Polym Symp 37:797–813

Hsieh Y-L (1997) University of California, Davis at 1997 Cotton beltwide conference, Strength and structure of cotton fiber during development, cotton quality measurements conference (3):505–507

Hsieh Y-L, Hu XP, Nguyen A (1997) Strength and crystalline structure of developing Acala cotton. Text Res J 67(7):529–536

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromolecules 9(3):1022–1026

Klemm D, Philipp B, Heinze T, Heinze U, Wagenknecht W (1998) Comprehensive cellulose chemistry, vol 1. Wiley, Weinheim

Krässig HA (1993) Cellulose—structure, accessibility and reactivity. In: Huglin MB (ed) Polymer monographs 11. Gordon and Breach Science Publishers, Amsterdam

Liu J, Yang H, Hsieh Y-L (2005) Distribution of single fibre tensile properties of four cotton genotypes. Text Res J 75(2):117–122

Long RL, Bange MP (2011) Consequences of immature fiber on the processing performance of upland cotton. Field Crop Res 121(3):401–407

Montalvo JG Jr, Von Hoven TM (2005) Relationships between micronaire, fineness, and maturity, part I and II. J Cotton Sci 9:81–88–89–96

Montalvo JG Jr, Faught SE, Buco SM (2002) Sensitivity of the Shirley Developments Ltd. Micromat tester to operators and sample preparations. J Cotton Sci 6:133–142

Mukherjee PS, Satyanarayana KG (1986) Structure and properties of some vegetable fibers—part 2: pineapple fiber. J Mater Sci 21(1):51–56

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941

Privas E, Felder E, Navard P (2013) Destructuration of cotton under elevated pressure. Cellulose( to appear)

Rogovina SZ, Zhorin VA, Enikolopian NS (1995) Modification of cellulose in conditions of plastic flow under pressure. J Appl Polym Sci 57(4):439–447

Uetani K, Yano H (2011) Nanofibrillation of wood pulp using a high-speed blender. Biomacromolecules 12(2):348–353

Yasuniwa M, Nakafuku C (1987) High pressure crystallisation of ultra-high molecular weight polyethylene. Polym J 19(7):805–813

Zhao H-P, Feng X-G, Gao H (2007) Ultrasonic technique for extracting nanofibers from nature materials. Appl Phys Lett 90(073112)

Zhorin VA, Kiselev MR, Zelenetskii AN, Rudakova TA (2010) Calorimetric investigation of some polysaccharides subjected to high-pressure plastic deformation. Polym Sci Ser A 52(4):398–406

Acknowledgments

The work was performed in the frame of the Industrial Chair in Bioplastics supported by Arkema, l’Oréal, Nestlé, PSA Peugeot-Citroën and Schneider Electric. The authors also thank researchers and technicians at the CIRAD cotton laboratory LTC for FMT and Uster HVI® 1000/700 measurements and other contributions to this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Disclaimer: Mention of a trademark, warranty, proprietary product or vendor does not constitute a guarantee by CIRAD and does not imply approval or recommendation of the product to the exclusion of others that may be suitable

CEMEF is a Member of the European Polysaccharide Network of Excellence (www.epnoe.eu).

Rights and permissions

About this article

Cite this article

Privas, E., Gawrysiak, G., Lapeyre, ME. et al. Influence of cotton variety on compression and destructuration abilities under elevated pressure. Cellulose 20, 1013–1022 (2013). https://doi.org/10.1007/s10570-013-9928-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9928-0