Abstract

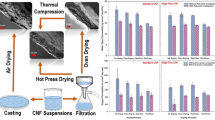

All cellulose composites made of 100% cellulose nanofibrils (CNFs) were produced without the use of solvent, binders, chemicals and/or dissolution process. Specimens were produced by thermo-compression and compared with materials made with cellulosic fibers. Different compression conditions such as temperature, time and pressure were tested and their impacts were quantified regarding the mechanical properties of the obtained materials. After determining the optimal compressing conditions, different grades of CNFs were tested and characterized using several characterization methods such as bending properties, Charpy impact strength, water absorption or degree of polymerization. Specimens made of 100% CNFs present improved bending properties, lower Charpy impact strength and lower water sensitivity than samples made with cellulose fibers. CNFs with their smaller size and increased number of possible H-bonds, create samples of lower porosity and allow establishing a solid H-bonding network. However, the particle size of the dry CNF powder influences strongly the self-bonding of the CNFs and the mechanical resistance of the thermo-compressed objects. Objects made of 100% CNFs can now be produced using an environmentally friendly process.

Graphic abstract

Schematic illustration of the study: production of 100% CNF objects by thermo-compression.

Similar content being viewed by others

Abbreviations

- CNF:

-

Cellulose nanofibrils

- TSE:

-

Twin-screw extrusion

- CNF–Enz–TSE 7p:

-

Cellulose nanofibrils produced via a combination of enzymatic pretreatment and 7 passes through the TSE

- CNF–Enz–Homogenizer:

-

Cellulose nanofibrils produced via a combination of enzymatic pretreatment and a homogenizer

- CNF–TEMPO–Grinder:

-

Cellulose nanofibrils produced via a combination of TEMPO oxidation and a grinder

- CNF–P–Grinder:

-

Cellulose nanofibrils produced via a combination of phosphorylation and a grinder

- DP:

-

Degree of polymerization

References

Ando M, Sato M (2009) Manufacture of plywood bonded with kenaf core powder. J Wood Sci 55:283–288. https://doi.org/10.1007/s10086-009-1022-8

Ando M, Sato M (2010) Evaluation of the self-bonding ability of sugi and application of sugi powder as a binder for plywood. J Wood Sci 56:194–200. https://doi.org/10.1007/s10086-009-1096-3

Anglès MN, Reguant J, Montané D et al (1999) Binderless composites from pretreated residual softwood. J Appl Polym Sci 73:2485–2491. https://doi.org/10.1002/(SICI)1097-4628(19990919)73:12%3c2485:AID-APP17%3e3.0.CO;2-G

Anglès MN, Ferrando F, Farriol X, Salvadó J (2001) Suitability of steam exploded residual softwood for the production of binderless panels. Effect of the pre-treatment severity and lignin addition. Biomass Bioenergy 21:211–224. https://doi.org/10.1016/S0961-9534(01)00031-9

Arévalo R, Peijs T (2016) Binderless all-cellulose fibreboard from microfibrillated lignocellulosic natural fibres. Compos Part A Appl Sci Manuf 83:38–46. https://doi.org/10.1016/j.compositesa.2015.11.027

Baati R, Magnin A, Boufi S (2017) High solid content production of nanofibrillar cellulose via continuous extrusion. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.6b02673

Bhatnagar A, Sain M (2005) Processing of cellulose nanofiber-reinforced composites. J Reinf Plast Compos 24:1259–1268. https://doi.org/10.1177/0731684405049864

Boon JG, Hashim R, Sulaiman O et al (2013) Influence of processing parameters on some properties of oil palm trunk binderless particleboard. Eur J Wood Wood Prod 71:583–589. https://doi.org/10.1007/s00107-013-0712-5

Desmaisons J, Boutonnet E, Rueff M et al (2017) A new quality index for benchmarking of different cellulose nanofibrils. Carbohydr Polym 174:318–329. https://doi.org/10.1016/j.carbpol.2017.06.032

Desmaisons J, Gustafsson E, Dufresne A, Bras J (2018) Hybrid nanopaper of cellulose nanofibrils and PET microfibers with high tear and crumpling resistance. Cellulose. https://doi.org/10.1007/s10570-018-2044-4

Duchemin BJC, Mathew AP, Oksman K (2009) All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride. Compos Part A Appl Sci Manuf 40:2031–2037. https://doi.org/10.1016/j.compositesa.2009.09.013

Duchemin B, Le Corre D, Leray N et al (2016) All-cellulose composites based on microfibrillated cellulose and filter paper via a NaOH-urea solvent system. Cellulose 23:593–609. https://doi.org/10.1007/s10570-015-0835-4

Fu S, Tian C, Lucia LA (2017) Water sorption and barrier properties of cellulose nanocomposites. In: Kargarzadeh H, Ahmad I, Thomas S, Dufresne A (eds) Handbook of nanocellulose and cellulose nanocomposites. Wiley, Hoboken, pp 649–681

Gao Z, Wang X-M, Wan H, Brunette G (2011) Binderless panels made with black spruce bark. BioResources 6:3960–3972. https://doi.org/10.15376/biores.6.4.3960-3972

Ghanadpour M, Carosio F, Larsson PT, Wågberg L (2015) phosphorylated cellulose nanofibrils: a renewable nanomaterial for the preparation of intrinsically flame-retardant materials. Biomacromol 16:3399–3410. https://doi.org/10.1021/acs.biomac.5b01117

González I, Alcalà M, Chinga-Carrasco G et al (2014) From paper to nanopaper: evolution of mechanical and physical properties. Cellulose 21:2599–2609. https://doi.org/10.1007/s10570-014-0341-0

Hashim R, Saari N, Sulaiman O et al (2010) Effect of particle geometry on the properties of binderless particleboard manufactured from oil palm trunk. Mater Des 31:4251–4257. https://doi.org/10.1016/j.matdes.2010.04.012

Hashim R, Said N, Lamaming J et al (2011) Influence of press temperature on the properties of binderless particleboard made from oil palm trunk. Mater Des 32:2520–2525. https://doi.org/10.1016/j.matdes.2011.01.053

Henriksson M, Berglund LA (2007) Structure and properties of cellulose nanocomposite films containing melamine formaldehyde. J Appl Polym Sci 106:2817–2824. https://doi.org/10.1002/app.26946

Ho TTT, Abe K, Zimmermann T, Yano H (2014) Nanofibrillation of pulp fibers by twin-screw extrusion. Cellulose 22:421–433. https://doi.org/10.1007/s10570-014-0518-6

Hubbe MA, Ferrer A, Tyagi P et al (2017) Nanocellulose in thin films, coatings, and plies for packaging applications: a review. BioResources 12:2143–2233. https://doi.org/10.15376/biores.12.1.2143-2233

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/C0NR00583E

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89:461–466. https://doi.org/10.1007/s00339-007-4175-6

Kondo T, Kose R, Naito H, Kasai W (2014) Aqueous counter collision using paired water jets as a novel means of preparing bio-nanofibers. Carbohydr Polym 112:284–290. https://doi.org/10.1016/j.carbpol.2014.05.064

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Lavoine N, Bras J, Desloges I (2014a) Mechanical and barrier properties of cardboard and 3D packaging coated with microfibrillated cellulose. J Appl Polym Sci. https://doi.org/10.1002/app.40106

Lavoine N, Desloges I, Khelifi B, Bras J (2014b) Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J Mater Sci 49:2879–2893. https://doi.org/10.1007/s10853-013-7995-0

Lichtenstein K, Lavoine N (2017) Toward a deeper understanding of the thermal degradation mechanism of nanocellulose. Polym Degrad Stab 146:53–60. https://doi.org/10.1016/j.polymdegradstab.2017.09.018

Liimatainen H, Visanko M, Sirviö J et al (2013) Sulfonated cellulose nanofibrils obtained from wood pulp through regioselective oxidative bisulfite pre-treatment. Cellulose 20:741–749. https://doi.org/10.1007/s10570-013-9865-y

Miki T, Takeuchi K, Sugimoto H, Kanayama K (2007) Performance study of compact wood powder material processing for improved impact characteristics aiming at substitute for plastics. J Mater Process Technol 192–193:422–427. https://doi.org/10.1016/j.jmatprotec.2007.04.078

Mobarak F, Fahmy Y, Augustin H (1982) Binderless lignocellulose composite from bagasse and mechanism of self-bonding. Holzforsch Int J Biol Chem Phys Technol Wood 36:131–136. https://doi.org/10.1515/hfsg.1982.36.3.131

Nadhari WNAW, Hashim R, Sulaiman O et al (2013) Utilization of oil palm trunk waste for manufacturing of binderless particleboard: optimization study. BioResources 8:1675–1696. https://doi.org/10.15376/biores.8.2.1675-1696

Nair SS, Zhu JY, Deng Y, Ragauskas AJ (2014) Characterization of cellulose nanofibrillation by micro grinding. J Nanoparticle Res 16:2349. https://doi.org/10.1007/s11051-014-2349-7

Nechyporchuk O, Pignon F, Belgacem MN (2015) Morphological properties of nanofibrillated cellulose produced using wet grinding as an ultimate fibrillation process. J Mater Sci 50:531–541. https://doi.org/10.1007/s10853-014-8609-1

Newman RH (2004) Carbon-13 NMR evidence for cocrystallization of cellulose as a mechanism for hornification of bleached kraft pulp. Cellulose 11:45–52. https://doi.org/10.1023/B:CELL.0000014768.28924.0c

Nilsson H, Galland S, Larsson PT et al (2010) A non-solvent approach for high-stiffness all-cellulose biocomposites based on pure wood cellulose. Compos Sci Technol 70:1704–1712. https://doi.org/10.1016/j.compscitech.2010.06.016

Nishino T, Arimoto N (2007) All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromol 8:2712–2716. https://doi.org/10.1021/bm0703416

Nonaka S, Umemura K, Kawai S (2013) Characterization of bagasse binderless particleboard manufactured in high-temperature range. J Wood Sci 59:50–56. https://doi.org/10.1007/s10086-012-1302-6

Okuda N, Sato M (2004) Manufacture and mechanical properties of binderless boards from kenaf core. J Wood Sci 50:53–61. https://doi.org/10.1007/s10086-003-0528-8

Okuda N, Sato M (2006) Water resistance properties of kenaf core binderless boards. J Wood Sci 52:422–428. https://doi.org/10.1007/s10086-005-0785-9

Okuda N, Hori K, Sato M (2006) Chemical changes of kenaf core binderless boards during hot pressing (II): effects on the binderless board properties. J Wood Sci 52:249–254. https://doi.org/10.1007/s10086-005-0744-5

Olszewska A, Eronen P, Johansson L-S et al (2011) The behaviour of cationic nanofibrillar cellulose in aqueous media. Cellulose 18:1213–1226. https://doi.org/10.1007/s10570-011-9577-0

Orelma H, Korpela A, Kunnari V et al (2017) Improving the mechanical properties of CNF films by NMMO partial dissolution with hot calender activation. Cellulose 24:1691–1704. https://doi.org/10.1007/s10570-017-1229-6

Pei A, Butchosa N, Berglund LA, Zhou Q (2013) Surface quaternized cellulose nanofibrils with high water absorbency and adsorption capacity for anionic dyes. Soft Matter 9:2047. https://doi.org/10.1039/c2sm27344f

Piltonen P, Hildebrandt NC, Westerlind B et al (2016) Green and efficient method for preparing all-cellulose composites with NaOH/urea solvent. Compos Sci Technol 135:153–158. https://doi.org/10.1016/j.compscitech.2016.09.022

Pintiaux T (2015) Etude d’un procédé de mise en forme de matières naturelles lignocellulosiques par thermocompression uniaxiale haute pression. Université de Toulouse

Pintiaux T, Viet D, Vandenbossche V et al (2013) High pressure compression-molding of α-cellulose and effects of operating conditions. Materials 6:2240–2261. https://doi.org/10.3390/ma6062240

Pintiaux T, Viet D, Vandenbossche V et al (2015) Binderless materials obtained by thermo-compressive processing of lignocellulosic fibers: a comprehensive review. BioResources 10:1915–1963

Pintiaux T, Heuls M, Vandenbossche V et al (2019) Cellulose consolidation under high-pressure and high-temperature uniaxial compression. Cellulose. https://doi.org/10.1007/s10570-019-02273-8

Rampinelli G, Di Landro L, Fujii T (2010) Characterization of biomaterials based on microfibrillated cellulose with different modifications. J Reinf Plast Compos 29:1793–1803. https://doi.org/10.1177/0731684409335453

Rol F, Karakashov B, Nechyporchuk O et al (2017) Pilot-scale twin screw extrusion and chemical pretreatment as an energy-efficient method for the production of nanofibrillated cellulose at high solid content. ACS Sustain Chem Eng 5:6524–6531. https://doi.org/10.1021/acssuschemeng.7b00630

Rol F, Belgacem MN, Gandini A, Bras J (2018) Recent advances in surface-modified cellulose nanofibrils. Prog Polym Sci. https://doi.org/10.1016/j.progpolymsci.2018.09.002

Saadaoui N, Rouilly A, Fares K, Rigal L (2013) Characterization of date palm lignocellulosic by-products and self-bonded composite materials obtained thereof. Mater Des 50:302–308. https://doi.org/10.1016/j.matdes.2013.03.011

Saini S, Yücel Falco Ç, Belgacem MN, Bras J (2016) Surface cationized cellulose nanofibrils for the production of contact active antimicrobial surfaces. Carbohydr Polym 135:239–247. https://doi.org/10.1016/j.carbpol.2015.09.002

Saito T, Isogai A (2006) Introduction of aldehyde groups on surfaces of native cellulose fibers by TEMPO-mediated oxidation. Colloids Surf Physicochem Eng Asp 289:219–225. https://doi.org/10.1016/j.colsurfa.2006.04.038

Sirviö JA, Visanko M, Liimatainen H (2015) Deep eutectic solvent system based on choline chloride-urea as a pre-treatment for nanofibrillation of wood cellulose. Green Chem 17:3401–3406. https://doi.org/10.1039/C5GC00398A

Smyth M, Fournier C, Driemeier C et al (2017) Tunable structural and mechanical properties of cellulose nanofiber substrates in aqueous conditions for stem cell culture. Biomacromol 18:2034–2044. https://doi.org/10.1021/acs.biomac.7b00209

Smyth M, M’Bengue M-S, Terrien M et al (2018) The effect of hydration on the material and mechanical properties of cellulose nanocrystal-alginate composites. Carbohydr Polym 179:186–195. https://doi.org/10.1016/j.carbpol.2017.09.002

Taipale T, Österberg M, Nykänen A et al (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020. https://doi.org/10.1007/s10570-010-9431-9

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47:291–294. https://doi.org/10.1002/(SICI)1097-0126(199811)47:3%3c291:AID-PI11%3e3.0.CO;2-1

Turbak AF, Snyder F, Sandberg K (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp USA 37:815–827

Vaca-Medina G, Jallabert B, Viet D et al (2013) Effect of temperature on high pressure cellulose compression. Cellulose 20:2311–2319. https://doi.org/10.1007/s10570-013-9999-y

van Dam JEG, van den Oever MJA, Teunissen W et al (2004) Process for production of high density/high performance binderless boards from whole coconut husk: Part 1: Lignin as intrinsic thermosetting binder resin. Ind Crops Prod 19:207–216. https://doi.org/10.1016/j.indcrop.2003.10.003

Velásquez JA, Ferrando F, Farriol X, Salvadó J (2003) Binderless fiberboard from steam exploded Miscanthus sinensis. Wood Sci Technol 37:269–278. https://doi.org/10.1007/s00226-003-0182-8

Yano H, Nakahara S (2004) Bio-composites produced from plant microfiber bundles with a nanometer unit web-like network. J Mater Sci 39:1635–1638. https://doi.org/10.1023/B:JMSC.0000016162.43897.0a

Yano H, Sugiyama J, Nakagaito AN et al (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17:153–155. https://doi.org/10.1002/adma.200400597

Zhang X, Wu X, Gao D, Xia K (2012) Bulk cellulose plastic materials from processing cellulose powder using back pressure-equal channel angular pressing. Carbohydr Polym 87:2470–2476. https://doi.org/10.1016/j.carbpol.2011.11.019

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6:754–761. https://doi.org/10.1002/adem.200400097

Acknowledgments

This research was supported by Institut Carnot Polynat (Grant Agreement No ANR-16-CARN-0025-01), Centre Technique du Papier (Grenoble, France) and LabEx Tec 21 (Grant Agreement No ANR-11-LABX-0030). LGP2 is part of the LabEx Tec 21 (Investissements d’Avenir) and PolyNat Carnot Institutes. The authors want to thank Denis Delnevo for its help in the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rol, F., Rouilly, A. & Bras, J. Thermo-compression of cellulose nanofibrils. Cellulose 27, 25–40 (2020). https://doi.org/10.1007/s10570-019-02720-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02720-6