Abstract

The combination of temperature programmed reaction spectroscopy, temperature programmed oxidation (TPO) and N2O reactive frontal chromatography (N2O-RFC) has shown that the adsorbate produced by dosing dimethylsuccinate on to a Cu/Al2O3 catalyst is a succinate species with 8 out of 10 surface Cu atoms having a succinate species adsorbed on them. The succinate species are bonded end-on and unidentate to the Cu atoms. This configuration constitutes a self-assembled monolayer. Temperature programming causes vicinal strands of the adsorbed succinate to interact, resulting in simultaneous dehydrogenation and decarboxylation, producing coincident evolution of H2 and CO2 in peaks at 668 and 793 K and leaving the C of the succinate chain on the Cu surface This C is removed by TPO, producing CO2 at a peak maximum temperature of 593 K. Prior to the oxidation of the C to CO2, TPO oxidises the Cu metal to CuO in the temperature range 323–493 K. Reduction of this CuO produces Cu metal whose metal surface area as measured by N2O-RFC is 9.8 m2 g−1, a value which is identical to that of the fresh Cu/Al2O3 catalyst. Therefore oxidation of the Cu metal to bulk CuO and re-reduction does not cause sintering of the Cu. However, the surface morphology of the Cu metal produced by reduction of the CuO has changed as evidenced by temperature programmed reduction (TPR) of the N2O surface oxidised Cu in H2/He (5 % H2 101 kPa). TPR of the N2O surface oxidised fresh Cu/Al2O3 has two peaks in H2 consumption at 395 and 410 K corresponding to Cu–O surface bond energies of 341 and 358 kJ mol−1. TPR of the N2O surface oxidised Cu metal, resulting from reduction of the CuO, has three peaks in the consumption of H2 at 410, 422 and 434 K corresponding to surface Cu–O bond energies of 379, 381 and 388 kJ mol−1. Hydrogen temperature programmed reduction of N2O surface oxidised Cu (and other metals) constitutes a particularly apt technique for the determination of surface Cu–O bond strengths and hence of the morphology of the Cu surface.

Graphical Abstract

Dosing dimethylsuccinate on to Cu/Al2O3 produces a self-assembled monolayer of succinate species bonded to 80 % of the Cu atoms. Temperature programming causes the individual strands of succinate to interact, producing CO2 and H2 coincidently at 668 and 793 K. Hydrogen temperature programmed reduction of N2O oxidised Cu determines the surface morphology of the Cu.

Similar content being viewed by others

1 Introduction

Temperature programmed desorption is a well-established technique for the determination of: (i) desorption activation energies, (ii) the order of desorption, and (iii) surface coverages of atoms and simple molecules on single crystal metal surfaces and polycrystalline metal surfaces which exist on metal oxide supported metal catalysts.

Redhead devised the method and used it to determine the desorption activation energy of CO from polycrystalline W wire [1, 2]. The method involves dosing the adsorbate on to the surface, removing the gas phase adsorbate either in a flow of inert gas or by evacuation, and raising the temperature, usually linearly, with time. The adsorbed species desorb at a given temperature which is determined by the strength of the bond which the adsorbate makes to the substrate. The mechanism of the desorption process is simply that of a unimolecular decomposition in which the adsorbed molecule and the surrounding adsorbent atoms constitute a large complex. The adsorbed molecule desorbs when a critical minimum energy is located in the adsorbate–surface oscillator, the probability of which is given by Ae−E/RT, where A is the vibrational frequency, normally taken to be 1013 s−1, but the value can vary by up to an order of magnitude depending on the structure of: (i) the adsorbent, (ii) the adsorbate and (iii) of the desorption transition state (vide infra), E is the adsorbate–surface bond energy (J mol−1), R is the gas constant (J mol−1 K−1) and T/K is the absolute temperature. Redhead devised an equation, commonly known as the Redhead equation, which allows the determination of the desorption activation energy of the adsorbate from the value of the desorption peak maximum temperature [1, 2].

Temperature programmed reaction spectroscopy (TPRS) is a variant of the technique of TPD. It is used to determine both the structure of adsorbed reaction intermediates and of their decomposition activation energy. Madix devised the technique and used it initially to determine the structure of adsorbed formate species on Cu single crystals [3, 4]. This was done by dosing CH3OH or HCO2H on to Cu single crystals which had been pre-dosed with O atoms to ¼ monolayer coverage. On temperature programming Madix observed the coincident desorption of H2 and CO2 at 440 K in a stoichiometry H:CO2 [3, 4], corresponding to a formate species. It is important to note that the desorption peak maximum temperature for the formate species was much higher than that of the individual components of the formate: H2 (Tm 300 K) and CO2 (Tm 244 K, 288 K). While no mechanism for the coincident evolution of H2 and CO2 at 440 K during TPRS of formate species adsorbed on Cu exists in the literature, the unwritten consensus is that the rate determining step is C–H bond scission.

Scanning tunnelling microscopy (STM) has shown that formates are adsorbed on Cu(110) in a bidentate mode through the two O atoms of the formate in an aligned bridge structure with their molecular axis perpendicular to the uppermost Cu row [5]. Bowker has proposed that the mechanism for the coincident evolution of H2 and CO2 at 440 K observed by TPRS for these formates adsorbed on Cu(110) is for the formate to bend its molecular axis from 90° to parallel to the surface where the terminal H atom of the formate interacts with a free Cu atom at which point the terminal H atom is abstracted by the bare Cu atom. The abstracted H atom then migrates on the surface and reacts with a second H atom to form a H2 molecule which immediately desorbs [6]. The residual CO2 molecule is weakly held on Cu [7, 8] and so it desorbs immediately the H atom is abstracted. This is an entirely feasible mechanism at low coverage where there are vacant Cu sites.

At high coverages, however, STM shows that the formate species form an ordered c(2 × 2) overlayer in which there are no vacant Cu sites [5]. This ordered overlayer to some extent constitutes a self assembled monolayer. Heating this ordered overlayer can cause the individual strands of the formate to interact with each other on bending. The terminal H atoms can react with other terminal H atoms to form H2 as has been observed in the study of self assembled monolayers [9–11]. We have observed coincident H2 and CO2 evolution at 440 K from an overlayer of formate species at 80 % of saturation [12], suggesting that the self assembled monolayer mechanism could operate under these conditions.

Nitrous oxide reaction frontal chromatography (N2O RFC) is a technique which was devised initially to measure the copper metal area of supported copper catalysts [13]. It was calibrated against the area of unsupported Cu [13]. It was an adaptation of the N2O dosing technique which Ertl and co-workers had used to determine the structure of oxygen atom over-layers on single crystal copper surfaces [14]. Ertl found that the structure of the O atoms on Cu(110) was a (2 × 1)-O overlayer. This corresponds to a maximum coverage of 50 % of a monolayer. Waugh et al. [13] found that the N2 evolution produced by dosing N2O (5 % N2O in He, 50 cm3 min−1) at 333 K on to polycrystalline Cu terminated at 50 % coverage of the polycrystalline Cu [13].

These techniques, TPD, TPRS and N2O RFC have been used previously in combination to determine the detailed kinetics and mechanisms of the synthesis of methanol from CO/CO2/H2 feeds over supported metal oxide Cu catalysts (Cu/SiO2, Cu/ZnO, Cu/Al2O3 and Cu/ZnO/Al2O3 [15]). Here we report on their application in the determination of the structure of a succinate species produced by dosing dimethylsuccinate (DMS) on to Cu. In addition they are also used to determine the mechanism of the coincident CO2 and H2 evolution at 668 and 793 K from this succinate species where the results clearly negate the 90° bending argument. It is suggested that the mechanism proposed here for the succinate could be a model for the coincident evolution of H2 and CO2 at 440 K during TPRS of a formate species adsorbed on Cu.

2 Experimental

2.1 Apparatus

2.1.1 Mini-Plant Adsorption/Reactor System

The adsorption of DMS was conducted in a mini-plant adsorption/reactor system operated at 6 MPa and an inlet temperature of 456 K. Figure 1 shows a photograph of the mini plant system. The DMS was produced by hydrogenation of dimethylmaleate (DMM) in situ in the adsorption/reactor system.

2.1.2 The Liquid Feed System

The liquid feed system is shown on the right hand side of the photograph. The liquid DMM was monitored using a level indicator controller and was pumped through the equipment using a speed controller; a speed controller is a positive displacement pump. The liquid DMM is pumped through trace heated lines to the vaporiser. The vaporiser system is the 16–20 cm external diameter silver tubular system located immediately to the left of the liquid feed system.

2.1.3 The Vaporiser

The vaporiser itself is a 1.4 m long 1½ inch bore (3.81 cm) 316 stainless steel tube. It is packed with a stainless steel mesh (Sulzer DX). The liquid feed enters the vaporiser exactly half way up while the gas feed enters from the bottom. The vaporiser operates at the same temperature as the reactor inlet (456 K). It is heated by trace heating elements and thermally insulated by Rockwool insulation.

2.1.4 The Adsorption/Reactor System

The adsorption/reactor is located in the 30 cm diameter silver tube shown in the top left of the photograph in Fig. 1. The adsorber/reactor is a 1.4 m long 316 stainless steel tube of 1 inch bore (2.54 cm id). It was packed with three different types of supported Cu catalysts. The catalysts are loaded as pellets which are cylinders 0.3 cm long and 0.3 cm diameter. A photograph of typical catalyst pellets is shown in Fig. 2.

The adsorber/reactor is heated electrically using trace heating and is internally insulated in the 30 cm silver tube using Rockwell insulation. The top 63 cm length of the reactor is packed with glass balls (0.6 cm diameter, 530 g). The first charge of catalyst (Cu/Cr2O3) commences at this point (10 cm long, 50 cm3, 67.5 g). The second length (20 cm long, 73–93 cm from the top) is packed with a Cu/Al2O3 catalyst (146.7 g). The third length (20 cm long, 93–113 cm from the top) is packed with another Cu/Al2O3 catalyst (139.3 g) of slightly different composition to that in the second length. The next 10.5 cm length is packed with glass balls (0.6 cm diameter, 88.4 g) and the final packed length (64 cm) contains woven stainless steel support. The reactor exit is located 129 cm from the top.

The catalyst which underwent detailed pre- and post-reaction investigation was the Cu/Al2O3 catalyst was located just before the reactor exit at the bottom end of the adsorber/reactor. It was a commercially provided catalyst, produced by Na2CO3 precipitation from a mixed Cu/Al nitrate solution. It was reduced in situ prior to reaction in a highly controlled manner so as to attain both complete reduction of the copper and the maximum copper metal area.

At the outset, the reduction was carried out in a H2/N2 flow (0.2 mol% H2, 350 kPa, 1250 Nl/h) by raising the temperature from ambient to 373 K in 1 h, at which point the temperature was raised to 393 K at a heating rate of 20 K/h. Having reached 393 K the heating rate was decreased to 10 K/h and the temperature was raised to 433 K where it was held for 1 h. The inlet composition of H2 was then increased to 0.3 mol% and the catalyst was held under that flow at 433 K for 1 h after which the inlet H2 composition was increased to 0.4 mol% and the catalyst was held for a further 1 h under that composition at 433 K after which the H2 inlet composition was increased to 0.5 mol% and the catalyst was held under that flow at 433 K until no reaction of the H2 was detected. The temperature of the catalyst was then increased to 443 K at 10 K/h under the 0.5 mol% H2 flow and the catalyst was held at that temperature under that flow until no further reaction of the H2 was detected.

2.1.5 Off-Line Characterisation of the Catalyst

The catalyst was characterised before and after adsorption using a multi-purpose micro-reactor which has been described in detail previously [16]. It is a stainless steel tubular reactor (20 cm long, 0.4 cm id) which is connected via a heated capillary to an on-line mass spectrometer (Hiden Analytical, Warrington, UK). The mass spectrometer was capable of following 16 masses continuously as the temperature was increased.

The reactor was housed in a stainless steel block which could be cooled to 77 K by pumping liquid nitrogen through it for total area measurements. The metal block could also be heated at various linear heating rates from 77 to 1100 K using a Newtronics controller to control the cartridge heaters housed in the block. The thermocouple used to provide the catalyst temperature to the Newtronics controller is housed in the centre of the catalyst bed.

The reduced fresh and used catalyst pellets are first passivated (surface oxidised) before discharge from the mini-plant adsorber/reactor. This is done by cooling the catalyst to room temperature under the H2 flow. Once cooled, the flow is changed to an air/N2 mixture (20 % air in N2, 101 kPa), the air component of the mixture gradually being increased to 100 %. This controlled passivation is necessary since the reduced catalyst would spontaneously combust were they to be exposed in that form to air.

The passivated catalyst was then ground in a pestle and mortar, retaining the 200–300 µm particle size material for loading into the micro-reactor. Usually 0.5 g of this material was used.

The reduced catalyst was characterised in this equipment by measuring:

-

a)

The total area by N2 up-take at 77 K using frontal up-take [16] or by linearising the N2 isotherm using the BET equation [16].

-

b)

The Cu metal area of the catalyst using N2O reactive frontal chromatography [13].

-

c)

The stoichiometry of the adsorbate was determined by temperature programmed decomposition followed by temperature programmed oxidation.

-

d)

The morphology of the Cu of the fresh and used catalyst is determined by H2 temperature programmed reduction of the N2O surface oxidised Cu.

3 Results and Discussion

3.1 The Adsorption of DMS on the Cu/Al2O3 Catalyst

The DMM was vapourised in a hydrogen flow (230 mol h−1, 6 MPa) at 456 K. This produced a flow of 0.68 mol h−1 of DMM in the H2. The DMM was quantitatively converted to DMS in the initial section of the adsorber/reactor system by reaction over the Cu/Cr2O3 catalyst. The DMS/H2 mixture so produced was passed over the Cu/Al2O3 catalyst overnight at 456 K.

3.2 Characterisation of the Fresh Cu/Al2O3 Catalyst

3.2.1 Measurement of the Cu Metal Area

Figure 3 is the N2O reactive frontal chromatogram of the reduced fresh Cu/Al2O3 catalyst. The metal area of the Cu component of the catalyst obtained from the integral of the N2 evolved from the decomposition of the N2O is 9.8 m2 g−1. (The total surface area of the Cu/Al2O3 catalyst obtained by the up-take of N2 (10 % in He) at 77 K was 43 m2 g−1).

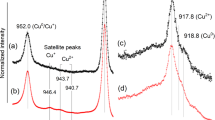

3.2.2 Temperature Programmed Reaction of H2 with the N2O Surface Oxidised Cu

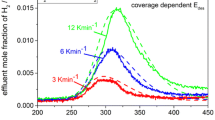

Figure 4 is the H2 temperature programmed reaction profile of the N2O surface oxidised Cu/Al2O3 catalyst. It was obtained by passing a H2/He (5 % H2, 101 kPa, 25 cm3 mn−1) over the N2O surface oxidised Cu while temperature programming at 3 K min−1.

The H2 up-take curve resulting from its reaction with the surface O atoms shows a peak minimum temperature of 395 K and a shoulder at 410 K. The H2O peak produced by the reaction is less well defined than the H2 up-take curve, probably because the H2O is “sticky” and adheres to the piping leading from the reactor to the mass spectrometer.

The activation energy for the reaction of gas phase H2 with surface oxidised Cu (Eq. 1) can be obtained without any assumptions about the value of the pre-exponential term by lineshape analysis of the leading edge of the H2 up-take curve up to a maximum of 10 % of the conversion of the H2

The activation energy so obtained is between 373 and 386 K is 92 kJ mol−1.

An estimate of the activation energy for the reaction of H2 with the adsorbed O atoms which produces the 410 K shoulder in the H2 up-take curve cannot be obtained by deconvoluting the 410 K shoulder from the 395 K peak and analysing its lineshape since this deconvolution makes assumptions about the order, and hence the kinetics, of the reaction. However, if a “realistic” value of the pre-exponential term, A, can be found, an estimate activation of the reaction producing this shoulder can be obtained from the peak maximum temperature of 410 K by solution of the Redhead equation (Eq. 2)

where E/J mol−1 is the activation energy, R/8.314 J mol K−1 is the gas constant, Tm/K is the peak maximum temperature, A/s−1 is the pre-exponential term, and β/Ks−1 is the heating rate

This “realistic” value can be obtained by the following procedure:

-

a)

A value of the pre-exponential term of the 395 K peak can be obtained by substitution of the value of 92 kJ mol−1 for the activation energy for Reaction 1 into the Redhead equation (Eq. 2) and solving that equation for a value of the A-factor. The value so obtained is 5.2 × 1011 s−1.

-

b)

Since the reaction giving rise to the peaks at 395 and 410 K is that of a stretched Cu–H surface bond reacting with a stretched Cu–O bond, the transition states giving rise to both peaks are likely to be highly similar, if not the same.

-

c)

When this value of 5.2 × 1011 s−1 is substituted into the Redhead equation and the equation is solved for the activation energy, E, for a peak maximum temperature of 410 K, the activation energy so obtained is 109 kJ mol−1.

These values of the activation energies for the reaction of gas-phase H2 with surface oxidised Cu can be used to calculate the Cu–O bond strength giving rise to these activation energies.

3.3 Calculation of the Cu–O Bond Strengths on the Fresh Cu/Al2O3 Catalyst

Calculation of the Cu–O bond strengths corresponding to the 395 and 410 K peaks requires knowledge of the heat of adsorption of H2O on Cu and of the activation energy for the decomposition of the adsorbed H2O to H2 and Cu2O.

The heat of adsorption of H2O on unsupported polycrystalline Cu has been found to be 45 kJ mol−1 [17]. The activation energy for the decomposition of the adsorbed H2O on polycrystalline Cu has been found to be 38 kJ mol−1 [17]. The heat of formation of H2O is −241.8 kJ mol−1 and so the state of H2O adsorbed on polycrystalline Cu is at −287 kJ mol−1. The transition state for the decomposition of adsorbed H2O is therefore at −287 + 38 = −249 kJ mol−1. When this is combined with the activation energy of 92 kJ mol−1 for the reaction of H2 with surface oxidised Cu, the potential energy diagram shown in Fig. 5 can be obtained. This shows state CuOa + H2 is at −249−92 = −341 kJ mol−1.

Applying the same arguments to the 410 K peak for which the value of 109 KJ mol−1 for the activation energy for the reaction of H2 with surface oxidised Cu has been determined, produces the result that the Cu–O bond strength giving rise to this peak is −358 kJ mol−1.

These two surface Cu–O bond strengths derive from the morphology of the Cu surface. The majority Cu–O bond (the −341 kJ mol−1 bond) occupies 87 % of the surface while the higher energy Cu–O bond (the −358 kJ mol−1 bond) occupies 13 % of the surface. It is probable that the majority of the surface is Cu(111). We had previously shown that the heat of adsorption of CO on the unsupported polycrystalline Cu was 50 kJ mol−1, a value which is identical to that found for CO adsorption of Cu(111) [16, 18]. The surface giving rise to the higher Cu–O bond is probably Cu(110). The latter suggestion is consistent with the observation that CO2 decomposes on only 10 % of the total area of polycrystalline Cu and that this is the Cu(110) face [19]. It is also worthy of comment that the value of −358 kJ mol−1 for the Cu–O bond strength is considerably greater than the difference in the heats of formation of CO(∆Hf = −105 kJ mol−1) and CO2(∆Hf = −393.5 kJ mol−1) which is a basic requirement for the decomposition of CO2 on Cu (Reaction 3) not to be endothermic.

3.4 Characterisation of the Used Cu/Al2O3 Catalyst Subtending the Adsorbate

Figure 6 is the N2O reactive frontal chromatogram of the reduced Cu/Al2O3 catalyst on to which the DMS had been dosed. The Cu metal area calculated from the amount of N2 produced is 1.8 m2 g−1. This is only 18 % of the Cu metal area of the fresh catalyst. This loss of Cu metal area could results from either sintering of the Cu as a result of repeated adsorption and desorption, or from a significant coverage of the surface of the Cu by the adsorbate.

The following set of experiments will show that the loss of Cu metal area is not caused by sintering of the Cu but is caused by the catalyst being covered to 80 % by the adsorbate. This adsorbate can be quantitatively removed by a combination of temperature programmed dehydrogenation/decarboxylation followed by temperature programmed oxidation. The combination of these two techniques allows determination of the mechanism of the coincident dehydrogenation and decarboxylation and of the structure of the adsorbate and of the adsorbed over-layer.

3.5 Structure of the Adsorbate

3.5.1 Temperature Programmed Dehydrogenation/Decarboxylation of the Adsorbate

Figure 7 is the spectrum produced by submitting the used CuAl2O3 catalyst to temperature programming in He (25 cm3 min−1, 101 kPa) at a heating rate of 5 K min−1. Previous studies on the desorption of H2 and CO2 from Cu have shown that H2 desorbs at a peak maximum temperature of 300 K [20] and CO2, while heteroenergetically adsorbed, has a highest peak maximum desorption temperature of 445 K [21]. Therefore the H2 and CO2 which desorb coincidently at 668 and 793 K cannot be bound, individually and separately, directly to the Cu.

By the tenets of temperature programmed reaction spectroscopy (TPRS), the coincident desorption of two molecules at temperatures above which they desorb individually occurs because of the decomposition of a common intermediate [3, 12]. Thus, for example, a formate species adsorbed on Cu has been characterised by TPRS by the coincident desorption of H2 and CO2 at 440 K in the stoichiometry of ½H2:CO2 [3, 12]. Obviously then the adsorbate giving rise to the coincident desorption of H2 and CO2 at 668 and 793 K cannot be a formate since the H:CO2 ratios are ~10:1 for the 668 K peak and ~4:1 for the 793 K peak.

Two pieces of additional information have allowed elucidation of the stoichiometry of the adsorbate and ultimately of the structure of the overlayer. The N2O reactive frontal chromatogram of the Cu/Al2O3 catalyst from which the CO2 and H2 had been desorbed showed that the Cu metal area was still only 18 % of that of the fresh Cu/Al2O3 catalyst. Since the H and CO2 are not directly adsorbed on the Cu, some adsorbate to which the H and CO2 must be bound must be adsorbed on the Cu. Expecting this adsorbate to be carbon, the catalyst was therefore subjected to temperature programmed oxidation in an O2/He (5 % O2, 101 kPa, 25 cm3 min−1) at a heating rate of 5 K min−1.

3.5.2 Temperature Programmed Oxidation of Residue Left After Temperature Programmed Dehydrogenation/Decarboxylation of the Adsorbate

Figure 8 is the temperature programmed oxidation spectrum of the Cu/Al2O3 catalyst which contained the surface residue produced after desorbing the CO2 and H2-. Only CO2 was evolved. No water was observed and so the residue was simply carbon. Re-reduction of this oxidised Cu/Al2O3 catalyst was followed by N2O reactive frontal chromatography to measure its Cu metal area. Figure 9 shows the N2O reactive frontal chromatograms of the fresh (red trace) and oxidised/re-reduced (black trace) Cu/Al2O3 catalysts. They superimpose exactly, showing that the original Cu metal area had been restored. The adsorbate which had been produced by hydrogenation of DMM therefore covers 80 % of the Cu area and has the composition: carbon, hydrogen and carboxy (CH2CO2).

Temperature programmed oxidation of the carbon residue produced following Fig. 7

The stoichiometry of the adsorbate can be determined by integration of the amounts of H2 and CO2 produced by TPRS in the 668 and 793 K peaks in Fig. 7 and the amount of CO2 produced by TPO in the 523 K and 593 K peaks shown in Fig. 8. These amounts are listed in Table 1.

From the amounts listed in Table 1 the stoichiometry of the adsorbate is:

Since Cu does not affect C–C bond scission and since the reactant is dimethyl succinate, the stoichiometry of the adsorbate is:

It is an adsorbed succinate. The amount of succinate adsorbed is 0.85 × 1020 species g−1.

3.6 Structure of the Succinate Overlayer

The structure of the succinate overlayer can be determined by: (i) knowledge of the Cu metal area per gram, (ii) the average Cu atom density on the surface, (iii) the number of Cu sites covered by the succinate and (iv) the number of succinate species. These are:

The succinate species has two possible modes of bonding to the Cu—the bi-succinate and the mono-succinate [22]. These are shown in Fig. 10. The maximum coverage by a bi-succinate species would be only 0.25 monolayers since it occupies 4 Cu atoms, while that of a monosuccinate would be 0.5 monolayers since it occupies 2 Cu atoms.

At a coverage of 80 % of a monolayer, the adsorbed succinate overlayer must be end-on bonded mono-succinate and must be uni-dentate as shown in Fig. 11. At 80 % of a monolayer, the end-on uni-dentate succinate species are close-packed and constitute a self-assembled monolayer. This concept of a self-assembled monolayer of succinate species provides an indication about the mechanism for the coincident evolution of H2 and CO2 at 668 and 793 K.

It is obvious by inspection of Fig. 11 that the crowding of the succinate species on the Cu surface precludes their decomposing by bending and interacting with the Cu surface. Any accentuated bending vibrations, brought about by heating, will cause the succinate species interact with each other on the surface. It is well known in the theory and practice of self-assembled monolayers that individual strands of the monolayer can interact together forming a new overlayer (9–11). Thus, for example, if the H atoms at the C3 position of the succinate interact together forming H2, the CO2 end group is likely to be destabilised and desorb. Hence, H2 and CO2 evolve coincidently at 668 K, leaving the C3C2H2C1O2 species bonded to the Cu. The coincident evolution of H2 and CO2 at 793 K occurs by similar lateral interactions of the residual C3C2H2C1O2 groups, the higher temperature arising from the C1O2 group being bonded to the Cu.

3.7 Calculation of the Cu–O Bond Strength on the Oxidised/Reduced Used Cu/Al2O3 Catalyst

Figure 12 (black curve) is the H2 temperature programmed reduction spectrum of the N2O surface oxidised regenerated Cu/Al2O3 catalyst. It shows three peaks in H2 consumption at 407, 422 and 434 K. This is completely different from the H2 temperature programmed reduction profile obtained from N2O surface oxidised fresh Cu/Al2O catalyst shown in Fig. 4 and in the red curve here. The 395 K peak (Cu(111) surface) has gone. The 406 K peak (Cu(110) surface) remains and there are new states at 422 and 434 K corresponding to higher Cu–O bond strengths. These probably derive from more stepped Cu faces. The new surface is now Cu(110) which is 60 % of the surface, 422 K (33 % of the surface), and 434 K (7 % of the surface). This compares with the original morphology which is Cu(111) (80 %) and Cu(110) (20 %).

Close examination of the oxygen up-take curve shown in the upper blue line of Fig. 8 provides considerable detail of the oxidation process. The shoulder in the O2 up-take curve at 423 K corresponds to oxidation of the surface Cu. The total amount of oxygen which reacts from 423 to 493 K corresponds to the complete oxidation of the total Cu content of the Cu/Al2O3 catalyst to CuO.

Onset of oxidation of the carbon on the surface of the Cu only occurs after the Cu has been oxidised to CuO. The dynamics of the oxidation process are that the O2 is dissociatively adsorbed on the surface of the Cu to O atoms. Once adsorbed, the O atoms are rapidly incorporated into the Cu and are therefore not available to react with the adsorbed C atoms. The oxidation of the adsorbed C occurs essentially through a Mars and van Krevelen mechanism. Reduction of this CuO by H2 results in a Cu metal with a surface morphology which is completely different from that of the original material. This probably results from the bulk morphology of the CuO produced by oxidation of Cu metal being different from that produced in the synthesis of the catalyst by calcination of a hydroxyl copper carbonate.

Lineshape analysis of the 407 K peak in Fig. 12 gives an activation energy for reaction of 130 kJ mol−1. (This has to be compared with the value of 109 kJ mol−1 obtained by assuming a value of 5.2 × 1011 s−1 for the pre-exponential obtained from Fig. 4).

The activation energies for reaction producing the 420 and 434 K peaks are obtained by calculating the value of the pre-exponential term for 406 K peak associated with the 130 kJ mol−1 activation energy from the Redhead equation (Eq. 3) (4.2 × 1014s−1) and assuming that this value applies to the 420 and 434 K peaks. The activation energies obtained by solving the Redhead equation at peak maximum temperatures of 420 and 434 K using the value of the pre-exponential of 4.2 × 1014 s−1 are 135 and 139 kJ mol−1 respectively. The Cu–O bond strengths of the fresh and regenerated Cu/Al2O3 catalysts together with their activation energies for reaction with H2 are listed in Table 2.

4 Conclusions

-

(1)

Dosing dimethylsuccinate (DMS) on to a Cu/Al2O3 catalyst at 456 K results in the adsorption of a succinate species on the Cu component of the catalyst.

-

(2)

This succinate species is bonded monodentate and end-on on to the Cu component of the catalyst. As such it constitutes a self-assembled monolayer of the succinate species on the Cu.

-

(3)

Temperature programming does not cause the succinate species to desorb intact. Rather the individual strands of the succinate species interact with neighbouring succinate species, resulting in simultaneous decarboxylation and dehydrogenation at 668 and 793 K which produces CO2 and H2 coincidently in the gas phase and leaves carbon on the surface of the Cu.

-

(4)

This residual carbon can be removed quantitatively from the Cu surface by temperature programmed oxidation (TPO), producing CO2 at a peak maximum temperature of 593 K. The Cu component of the Cu/Al2O3 catalyst is oxidised to CuO between 323 and 518 K prior to the oxidation of the carbon.

-

(5)

Temperature programmed reduction of the CuO, obtained by TPO, produces Cu metal, having the same Cu metal area as the fresh Cu/Al2O3 catalyst, as measured by N2O reactive frontal chromatography.

-

(6)

Temperature programmed reduction of the N2O surface oxidised Cu of the fresh Cu/Al2O3 catalyst, results in two peaks in H2 consumption at 395 and 410 K, deriving from the reduction of surface CuO, having surface Cu–O bond strengths of 341 and 388 kJ mol−1. Temperature programmed reduction of the N2O surface oxidised Cu of the used and reduced, bulk oxidised Cu, results in three peaks the consumption of H2 at 410, 422 and 434 K, deriving from the reduction of surface CuO having Cu–O surface bond strengths of 379, 381 and 388 kJ mol−1. These increased Cu–O surface bond strengths result from a change in the surface morphology of the Cu metal. It is evident then that the bulk CuO produced by thermal decomposition of a Cu oxycarbonate produced by precipitation during catalyst preparation has a different bulk morphology from that produced by bulk oxidation of Cu metal. This gives rise to the different surface morphologies of the Cu metal produced by reduction of these two different bulk Cu oxides.

-

(7)

The method of temperature programmed reduction in H2 of N2O surface oxidised Cu is particularly useful for the determination of the morphology of the Cu metal.

References

Redhead PA (1961) Trans Faraday Soc 57:641

Redhead PA (1962) Vacuum 12:203

Wachs IE, Madix RJ (1978) J Catal 53:208

Ying DHS, Madix RJ (1980) J Catal 61:48

Poulston S, Bennett RA, Jones AH, Bowker M (1997) Phys Rev B 55:12888

Bowker M Private Communication

Ernst K-H, Schlatterbeck D, Christmann K (1999) Phys Chem Chem Phys 1:4105

Elliott AJ, Hadden RA, Tabatabaei J, Waugh KC, Zemicael FW (1995) J Catal 157:153

Cooper E, Leggett JG (1998) Langmuir 14:4795

Cooper E, Leggett GJ (1999) Langmuir 15:1024

Wong IS, Janusz SJ, Sun S, Leggett GJ, Micklefield J (2010) Chem Eur J 16:12234

Bowker M, Hadden RA, Houghton H, Hyland JNK, Waugh KC (1988) J Catal 109:263

Chinchen GC, Hay CM, Vandervell HD, Waugh KC (1987) J Catal 103:79

Ertl G (1967) Surf Sci 6:208

Waugh KC (2012) Catal Lett 142:1153

Waugh KC (1988) Appl Catal 42:315

Colbourn EA, Hadden RA, Vandervell HD, Waugh KC, Webb G (1991) J Catal 130:514

Horn K, Hussain M, Pritchard J (1977) Surf Sci 63:244

Hadden RA, Vandervell HD, Waugh KC, Webb G (1988) Catal Lett 1:27

Tabatabaei J, Sakakini BH, Watson MJ, Waugh KC (1999) Catal Lett 59:143

Chinchen GC, Spencer MS, Waugh KC, Whan DA (1987) J Chem Soc Faraday Trans 1(83):2193

Humblot V, Lorenzo MO, Baddeley JC, Haq S, Raval R (2004) J Am Chem Soc 126:6460

Acknowledgments

The author would like to thank Davy Process Technology (Princeton Drive, Stockton-on-Tees TS17 6PY, UK) for the use of their high pressure mini-plant and for the use of their multi-purpose microreactor. He is indebted to Dr J. Tabatabaei for conducting the experiments and to Dr B. Parnham for the computer graphics.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Waugh, K.C. Postulate of a Mechanism for Temperature Programmed Reaction Spectroscopy (TPRS) Which Accounts for the Coincident Evolution of H2 and CO2 in the TPRS of Succinates and Formates Adsorbed on Cu: Description of a Novel Method for the Identification of the Surface Morphology of Cu on Supported Cu Catalysts. Catal Lett 146, 269–278 (2016). https://doi.org/10.1007/s10562-015-1645-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-015-1645-x