Abstract

The aim of this experiment was to impregnate thermally modified wood using an easy and cost-effective method. Industrially processed thermally modified European aspen (Populus tremula L.) and birch (Betula pubescens Ehrh.) were collected and secondarily treated at the laboratory scale with the preservatives tung oil, pine tar and Elit Träskydd (Beckers) using a simple and effective method. Preservative uptake and distribution in sample boards were evaluated using computed tomography (CT) and scanning electron microscopy (SEM) techniques. Preservative uptake and treatability in terms of void volume filled were found the highest in Beckers and the lowest in tung oil-treated samples. Thermally modified samples had lower treatability than their counterpart control samples. More structural changes after thermal modification, especially in birch, significantly reduced the preservative uptake and distribution. The differences of preservatives uptake near the end grain were high and then decreased near the mid position of the samples length as compared with similar type of wood sample. Non-destructive evaluation by CT scanning provided a very useful method to locate the preservative gradients throughout the sample length. SEM analysis enabled the visualization of the preservative deposits in wood cells at the microstructural level.

Similar content being viewed by others

Introduction

Biodeterioration of wood occurs if the wood serves as a suitable living environment for biological organisms. Under certain conditions of exposure, particularly when wood becomes wet or when there is sufficient moisture and oxygen, wood may rapidly become susceptible to fungi and, to some extent, bacteria [1]. To ensure a long, useful and extended service life, timber needs protection from the hazards of fungal decay and weathering. Thus, wood must be treated with preservatives, modified chemically or modified thermally. During the last decade, wood modification with heat has been widely investigated as a method to reduce its equilibrium moisture content (EMC) and water absorption and to increase its dimensional stability, although the durability of thermally modified wood in outdoor applications remains questionable [2, 3]. The extent of changes in wood properties during heat treatment depends on the method used for thermal modification, the wood species, the initial moisture content (MC) of the wood, the surrounding atmosphere and, most important, the treatment time and temperature [4]. Of these factors, temperature has the strongest effect on the thermally modified wood properties [5, 6]. The available –OH groups present in hemicelluloses have the most significant effect on the physical properties of wood, and heat treatment decreases the number of available –OH groups and inhibits water adsorption, resulting in higher dimensional stability [7].

Wood preservation with either oil-borne or water-borne preservatives can eliminate biological attack by fungi, insects and termites and can increase mechanical strength [8]. However, no single preservative is available that can provide all the desired kinds of protection. Though the natural durability of wood offers a certain degree of resistance to wood degrading agents, there is evidently no ideal wood species that can be used universally in any application without eventual break-down [9]. As a result, a wide range of techniques and methods have been developed for wood preservation [10–13]. Preservation is an important part of wood technology, encompassing every process of chemical or physical treatment that is undertaken to extend the service life of wood by optimizing its resistance to biological attack, fire, shrinkage and swelling due to changes in MC. One of the greatest advantages of wood treatment is that it reduces the ability of wood to absorb moisture and thus improves its dimensional stability. Water repelling characteristics have been shown to increase after the impregnation of Scots pine (Pinus sylvestris L.) sapwood with linseed oil [14], coconut oil and various tall oils [15]. Even though the decreased hygroscopicity in heat-treated wood is reported to increase decay resistance [16–18], thermally modified wood is not found to be suitable for ground contact outdoor applications [3, 19]. The decay resistance depends on several factors, such as wood species, treatment method and exposure conditions. For example, a noticeably lower mass loss due to fungal attack is observed for oil–heat-treated wood compared with air–heat-treated wood [20]. Nevertheless, heat-treated wood is found to be susceptible to termites as well as marine borers [21, 22]. No single method has been shown to protect wood from all types of biodegradation. Thus, heat treatment in combination with oil can provide more effective protection than single treatment methods alone [13, 20].

The studies cited above emphasize the susceptibility of thermally modified wood to different biodegrading agents and the performance improvements that can be obtained by combining heat treatment with a secondary treatment, such as oil treatment. For example, water uptake by borate-treated wood can be slowed down by treating wood with secondary water repellent substances [23]. To the authors’ knowledge, however, the published literature on the secondary treatment of thermally modified wood with a preservative to improve the durability of wood in outdoor conditions is still lacking. Additionally, it is important to know the distribution pattern of a chemical preservative in wood, because deep and uniform penetration of the preservative in the wood is crucial for achieving good retention and performance [9, 24]. We conducted this study to provide insight into the uptake and distribution of different oil-borne wood preservatives in thermally modified European aspen and birch boards. Durability testing in outdoor conditions involves many parameters, the complexities of which are outside the scope of this article. However, the preservative distribution in thermally modified boards was assessed using high-value techniques such as computed tomography (CT) and scanning electron microscopy (SEM).

Materials and methods

Industrial materials and thermal modification

Commercial thermally modified European aspen (Populus tremula L.) (ca. 27 × 165 × 4000 mm) and birch (Betula pubescens Ehrh.) boards (ca. 27 × 92 × 4000 mm) were purchased from Thermoplus (Arvidsjaur, Sweden). There, green boards were kiln-dried to 18 % MC prior to thermal modification at 170 °C for 2.5 h. Saturated steam at approximately 8 bar was used during drying and thermal treatment as a protective vapor to prevent the wood from burning. More about this thermal modification process, which was introduced by the Danish company Wood Treatment Technology (WTT), can be found in Dagbro et al. [5]. Treated boards were brought to the laboratory for subsequent preservative impregnation. Additional green samples from aspen and birch were also collected before thermal modification to serve as control samples after attaining the EMC at room conditions.

Secondary treatment

Preservatives used

Three different oil-borne preservatives were used. The first was a water-miscible commercial product, Elit Träskydd (Beckers, Stockholm, Sweden). This preservative contains additives such as propiconazole (0.6 %) and 3-iodo-2-propynyl butylcarbamate (IPBC, 0.3 %), with modified linseed oil as a binder and water as a solvent. The second preservative was a commercially produced pine tar mixed in boiled linseed oil with turpentine (Claessons Trätjära AB, Göteborg, Sweden) for thinning the oil-based preservatives at a ratio of 1:4:2, respectively. The third preservative was commercial 100 % tung oil (Pelard AB, Stockholm, Sweden). This oil, pressed from nuts of tung tree (Aleurites fordii Hemsl.), is reported to confer fungal resistance to treated wood [25]. All preservative solutions were stirred properly before use. Elit Träskydd and pine tar are referred to as Beckers and tar, respectively, in the following sections.

Test samples and preservative treatment

Three commercially treated boards from each species were planed, and three end-matched samples from each thermally modified board and control board were prepared. The sample dimensions were 25 × 90 × 300 mm. The samples were free of knots, cracks and other visible defects, and they were numbered consecutively. Three matched thermally modified and control samples from each species (aspen and birch) for each of the three treatments (tung oil, tar and Beckers) were used for preservative uptake, for a total of 36 samples tested. Samples were impregnated with preservatives following a simple and easy method described by Ahmed and Morén [26]. The ultimate goal is to implement oil impregnation in commercial plants during the cooling phase of the thermal modification process. The tests described here are part of a series of experiments to evaluate the efficacy of secondary treatment at a laboratory scale. Here, additional heating at 170 °C for 1 h in a dry oven was performed to reach the sample target temperature (170 °C), as is performed in commercial plants during the heat treatment phase. Then, the still-hot samples were quickly submerged in preservatives for simultaneous impregnation and cooling for 2 h. We defined this process as the secondary treatment of thermally modified wood. No external vacuum or pressure was applied before or during the preservative impregnation.

Measurement of preservative solution uptake and treatability of wood

After 2 h of soaking, additional preservative liquid was wiped off gently from the surfaces with a paper towel, and the sample mass was recorded using a balance accurate to the nearest 0.01 g. The amount of preservative absorbed by the sample was calculated as follows: uptake (kg m−3) = 1000G/V, where G is the grams of preservative solution absorbed by the sample (the mass difference between preservative-treated and oven-dried samples) and V is the volume of the sample in cm3.

Preservative retention is often used as an indication of the treatment level. Maximum retention is always influenced by the permeability and wood density. Thus, retention is not the best descriptor for treatability, since it is influenced by density. Treatability in this study is so expressed as the ratio of preservative uptake to the potential volume that could be occupied if the samples were completely filled. Void volume filled (VVF) will, therefore, be a direct measure of treatability, as long as none of the samples are fully treated.

In this equation, M t is the mass of the treated sample (g), M u is the mass of untreated sample (g), V is the untreated sample volume (cm3), and P is the porosity as void volume of wood, P = [{1 − (oven-dry density/1.50)} × 100] considering the average density of the solid wood substance 1.50 g cm−3 [9]. This calculation represents the amount of space available in each sample and provides an estimate of the maximum volume of preservative that could potentially be absorbed by the wood.

CT scanning and image processing

A Siemens CT scanner (SOMATOM Emotion Duo, Munich, Germany) located at Luleå University of Technology, Campus Skellefteå, Sweden, was used for the non-destructive density measurements. The density accuracy in a CT scanner is ±2 kg m−3 for dry wood and ±6 kg m−3 for wet wood, with moisture content ranging from 6 to 100 % in a 2 × 2 × 1.5 mm sample, and larger measuring volumes give more accurate density measurements [27]. The 512 × 512 pixel CT images were obtained using scan settings of 110 kV, 260 mAs, 1.5 s scan time and 3.0 s delay time. The intensity value of each pixel corresponds to the measured density in that measuring volume. The volume of each voxel was 0.98 × 0.98 mm through the cross-section and 5 mm in the grain direction. Thirty scans at 5 mm intervals were performed, covering half of the sample length and producing a total of 2160 scan images before and after impregnation. Scanning on the other half was not performed, but the other half was assumed to have the same distribution of density values. To ensure measurement at the same position of each sample, reference marks were used. Preservative uptake was calculated by taking the density values obtained after preservative treatment and subtracting the values obtained for the oven-dried wood before treatment. The subtraction was performed using the image analysis software, ImageJ 1.46i [28]. Averaged data from the triplicate samples were used to plot the density graphs. To calculate preservative distribution profiles, the UnwarpJ plugin in ImageJ was used to correct slight swelling effects in the treated sample images so that they would more closely resemble the untreated sample images in terms of their physical dimensions.

Scanning electron microscopy

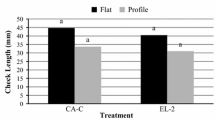

SEM specimens were prepared after sawing wood cubes measuring ca. 5 (radial, R) × 5 (tangential, T) × 5 (longitudinal, L) mm from thermally modified and control samples. Thermally modified wood became brittle [29] and thus required embedding in order to preserve microscopic structures. Artifacts due to the embedding and microtoming are expected to be minimized as PEG 1500 is not reported to penetrate cell wall [30]. Samples were immersed overnight in melted polyethylene glycol (PEG 1500, Sigma-Aldrich Chemie GmbH, Schnelldorf, Germany) at 60 °C. The transverse surfaces of embedded specimens were finished with a sliding microtome (Reichert, Vienna, Austria). Specimens were washed with several changes of warm distilled water to remove the PEG embedding matrix, and they were subsequently air dried. Samples were then observed under SEM following the technique mentioned elsewhere [31]. Without embedding, radial and tangential surfaces of the thermally modified samples impregnated with preservatives were split along a tangential or a radial plane with a razor blade and were examined to observe the preservatives deposition. Three sample blocks from each control samples were examined and captured SEM images were analyzed by ImageJ 1.46i for the following quantified details: aperture diameter of vessel–ray pits in R–L sections, number of uni-, bi- or tri-seriate rays per mm2 in T–L section (considering all complete plus incomplete rays crossing one vertical and one horizontal side of the square and ignoring all incomplete rays crossing the other vertical and horizontal sides) and rays contacted with vessel in T–L section measured by total counted rays divided by the ray in contact with vessel in 1 mm2 area.

Data analysis

Uptake and treatability data were analyzed using the statistical software package IBM SPSS Statistics, Version 20 (IBM Corporation, New York, USA). An analysis of variance (ANOVA) was carried out, and a 5 % level of significance was used to detect differences. A one-way ANOVA was applied to determine whether tung oil, pine tar and Beckers uptake were significantly different between wood samples. A similar test was performed to assess the effect of preservative on the treatability (VVF%) of wood. When significant differences were found, Duncan’s multiple-range test was performed, and significant differences were marked by different letters.

Results and discussion

Wood microstructure

Microscopic analysis of aspen and birch wood before and after thermal modification is presented in Fig. 1. Microscopic observation indicates that vessels, fibers, parenchyma and rays are still obvious, though wood anatomy was slightly affected and some shrinkage occurred after thermal modification. A similar observation was also reported by Mburu et al. [18]. Moreover, intrawall and transwall fractures were observed after thermal modification (Fig. 1c, f). There were no observed artifacts on control sample due to PEG 1500 embedding and microtoming. And thus fractures on thermally modified wood were supposedly the effect of heat treatment. These fractures appear to be the result of stress caused by differential shrinkage due to heat treatment. Compared to birch, aspen wood showed fewer structural changes due to thermal modification (Fig. 1) and developed smaller cracks in the cell walls and small changes in the shape of vessels, i.e., less vessel wall buckling. In contrast, birch samples showed substantial shrinkage of vessels leading to vessel wall buckling (Fig. 1e). While birch showed structural changes such as the disintegration of ray parenchyma resulting from cell wall thinning and vessel wall buckling could reduce the preservative uptake and alter the distribution of preservative (Table 1). Further observation indicated that both types of thermally modified samples were more brittle than their untreated counterparts.

Scanning electron micrographs of aspen and birch on transverse sections. Aspen before (a) and after (b and c) thermal modification. Birch before (d) and after (e and f) thermal modification. White and black arrowheads indicate intrawall and transwall fracture on thermally modified samples, respectively. V vessel, F fiber, Rp ray parenchyma. Scale bars (a, b, d and e) 100 μm, (c and f) 10 μm

Treatability to preservative liquids

The mechanism of oil impregnation is as follows: as wood is preheated prior to secondary treatment, whatever air that is contained within the cell cavities and voids becomes hot and expands. Immersing the hot wood in a room temperature preservative solution causes the rapid contraction of the air within the cell cavities and voids, resulting in the solution being drawn into the wood void structures. It is believed that the performance of treated wood is closely connected with the oil properties, the amount of absorption and the extent of oil leaching during use. Although we did not investigate leaching in this study, more details on that phenomenon can be found in Ahmed and Morén [26].

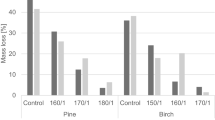

Table 2 shows the average preservative uptake in different wood samples. For both species, thermally modified samples had lower preservative uptake than their corresponding control samples. In particular, thermally modified birch had the lowest preservative uptake, and that difference was found to be statistically significant. In Table 2, it is also evident that Beckers had the highest penetration in both types of wood samples. However, previous results from Ahmed and Morén [26] and Ahmed et al. [32]. indicate that Beckers has lower penetration in Scots pine (Pinus sylvestris L.) and Norway spruce (Picea abies [L.] Karst.). This discrepancy could be attributable to the tert-butylhydroquinone that is added to the commercial formulation. The previous studies also suggested that a separation of the solute (e.g., tert-butylhydroquinone) from the solvent could cause reduced penetration [32]. In this experiment, however, we used only commercial Beckers solution, which contains both non-polar and polar substances (see “Preservatives used” in “Materials and methods”). It is well known that non-polar liquids penetrate by bulk flow, mainly through the cell lumens and pits, whereas polar liquids penetrate by both bulk flow and diffusion through the wood cell wall [33, 34]. Thus, uptake differences may exist among tung oil, tar and Beckers.

Birch and aspen vary in wood density. The average oven-dry densities for control aspen and birch samples were 452 and 577 kg m−3, respectively, as measured by the CT scanner. This density parameter is an important factor influencing the theoretical maximum amount of preservative liquid that can be absorbed in a given block volume. The gross pore space or porosity (void volume) of each sample was calculated as an estimate of the maximum volume of preservative that could be absorbed by the wood. Table 3 shows the variation in treatability expressed as VVF in different samples. Because Beckers showed greater penetration than tung oil and tar, the highest treatability was obtained for Beckers-treated samples, especially in aspen. Birch had lower preservative uptake, and we observed no significant differences in treatability between tung oil, tar and Beckers.

Assessment of preservative distribution

CT scanner

Non-destructive quantitative analysis of preservative uptake using CT scanning was performed for samples comprising the part of the board from the non-sealed end grain to the middle (Fig. 2). Near the end grain (0–5 mm), the preservative uptake was the highest, and the uptake gradually decreased through the length of the sample, in agreement with Banks [35] and Johansson et al. [2]. The effect of the non-sealed end grain was quite prominent in Beckers-treated samples, which showed greater preservative uptake up to 125 mm deep into the sample boards. This high uptake could be caused by the higher permeability of Beckers in wood. For tung oil and tar, the end grain effect was limited to 35 mm, and the preservative uptake gradually declined and became steady near the middle of the samples (Fig. 2). Lateral penetration was mainly responsible for distributing the preservative along the length of the sample. Interestingly, regardless of preservative type, the preservative uptake in a particular kind of wood sample was similar in the middle position, indicating the effectiveness of the secondary treatment process. Boards longer than the experimental samples considered here could also be effectively impregnated. Of the three types of wood preservatives, Beckers certainly showed the highest treatability, and tung oil showed the lowest (Table 3). The likely reason for the greater treatability with tar rather than tung oil is that turpentine is used as a thinner for oil-based media. Turpentine actually reduces the viscosity of tar, and it has been reported that an even distribution was observed when the preservative viscosity was kept low [34].

Structural changes due to thermal modification, such as cracks in the cell wall and delamination of the middle lamella, should increase the treatability of wood. However, as mentioned above, the treatability of thermally modified wood was low for aspen and birch compared to their corresponding control samples. These results suggest that it may be the chemical changes in wood cell material that affect preservative treatability, rather than the structural changes caused by thermal modification alone. Chemical changes during thermal modification such as degradation of hemicellulose, ramification of lignin, crystallization of cellulose, formation of furfural or 5-(hydroxymethyl) furfural take place depending on the treatment condition [7, 36]. Chemical decomposition of birch is reported to be more affected than aspen [7]. This could be the reason why the thermally modified wood has lower especially the birch sample had the lowest preservative uptake.

Visualization of preservative penetration at different points along the sample length is shown in Fig. 3. Greater amounts of preservative were impregnated both in control and thermally modified aspen, and preservatives were found to be evenly distributed. In contrast, birch had lower amounts of impregnated preservative, especially in the thermally modified samples. Anatomical differences between the two species are thought to be responsible for these distribution differences. Properties such as a greater number of vessels or larger vessel–ray pit aperture in aspen could make it more permeable than birch. The movement of liquid through wood occurs primarily along the grain. It is also evident that rays play an important role in liquid penetration and distribution [37]. A subsequent SEM examinations revealed that aspen has exclusively uniseriate rays and that birch has additional bi- and tri-seriate rays. Aspen has a higher percentage of vessels with ray contact than birch (Table 1). Moreover, the larger vessel–ray pits in aspen could affect the preservative distribution. In addition, the cells of the uniseriate rays of aspen have more direct contact with the vessels and other longitudinal elements than the bulk of the cells in the bi- or tri-seriate rays, so uniseriate rays are expected to be more permeable. These results explain the better treatability and distribution of preservatives in aspen (Fig. 3). In contrast, approximately 71 % of rays in birch were bi- or tri-seriate, and those rays seemed to be discontinued or collapsed (Table 1) after thermal treatment. This discontinuation probably was responsible for the poor preservative uptake and distribution in birch.

Scanning electron microscopy

SEM analyses visualized the penetration path of preservatives in wood cells through different pit membranes and the pattern of preservative deposition in cell lumen. SEM observations show that the intervessel pit membranes in hardwood are permeable despite the lack of margo-like structures, which are present in softwood (Fig. 4b, e). The observed preservative deposition in different pit membrane of thermally modified samples indicates their permeability. Apparently, hardwood pit membranes acts like filters in which the fluid flows circuitously in the membrane. Thus, uptake may be higher due to better access to the remaining axial pathway and better ‘bridging’ of flow pathways that may occur between the ray cells and axial elements, especially vessels and fibers. SEM observation showed that pit membranes in vessel–ray pits, intervessel pits and fiber pits were permeable (Fig. 4a–c, e). It is impossible for preservative to move great distances along the vessel only [34]. Thus, transverse movement is important to achieve an even distribution of preservative throughout the sample board. In this case, ray parenchyma facilitated radial penetration (Fig. 4d). Moreover, vessels connected by intervessel pits, especially on the tangential walls of aspen and birch, also allow the transverse flow of preservative liquids. Regardless, the highest uptake and most prominent deposition were not observed under SEM for the Beckers, and hence, those micrographs are excluded. As water is used as a solvent in Beckers formulation, it could be absorbed by the cell wall materials leaving no visible traces.

Scanning electron micrographs of thermally modified aspen and birch after tar (a–c) and tung oil (d and e) impregnation, respectively. a Vessel–ray pits in aspen. b Intervessel pits in aspen. c Fiber pits in aspen. d Ray parenchyma in birch. e Intervessel pits in birch with coalescent apertures. Arrow head indicating preservative deposition in the pit membrane. V vessel, F fiber, Rp ray parenchyma, L longitudinal, R radial, T tangential. Scale bars 10 μm

Despite the nature of the deposition observed in wood cells, it can be concluded that preservative uptake and distribution depend on the wood structure and the nature of the preservative used. Wood species with little or no commercial value can be thermally modified and subjected to secondary treatment with preservative, and in this way, a new use can be found for those species. The durability of thermally modified wood after secondary treatment in outdoor conditions remains an important area for future investigations.

Conclusions

After thermal modification, a greater number of anatomical changes in birch led to reduced preservative uptake and treatability (as measured by VVF%) compared to counterpart control samples, whereas this deviation was found to be quite low in aspen. A non-destructive analysis of the preservative distribution by CT scanning revealed great differences in preservative uptake at the end grain, but quite small differences near the middle of the wood samples. SEM analysis showed that preservatives especially tar and tung oil deposited in the cell lumen by passing through different pit membranes. Beckers was found to be absorbed by cell wall materials. The preservative treatability of all types of wood followed the order Beckers > tar > tung oil, and the preservative distribution was found to be more even in the aspen samples.

References

Sell J, Leukens U (1971) Investigations of weathered wood surfaces: part II. Weathering phenomena of unprotected wood species. Holz Roh Werkst 29:23–31

Johansson D, Sehlstedt-Persson M, Morén T (2006) Effect of heat treatment on capillary water absorption of heat-treated pine, spruce and birch. In: Kurjatko S, Cown D, Kúdela J (eds) Proceedings of the 5th IUFRO Symposium wood structure and properties ′06, Sliač–Sielnica, Slovakia, pp 251–255

Welzbacher CR, Rapp AO (2007) Durability of thermally modified timber from industrial-scale processes in different use classes: results from laboratory and field tests. Wood Mater Sci Eng 2:4–14

Korkut S, Bektaş Î (2008) The effects of heat treatment on physical properties of Uludağ fir (Abies bornmuelleriana Mattf.) and Scots pine (Pinus sylvestris L.) wood. Forest Prod J 58:95–99

Dagbro O, Torniainen P, Karlsson O, Morén T (2010) Colour responses from wood, thermally modified in superheated steam and pressurized steam atmospheres. Wood Mater Sci Eng 5:211–219

Mitchell PH (1988) Irreversible property changes of small loblolly pine specimens heated in air, nitrogen, or oxygen. Wood Fiber Sci 20:320–355

Kocaefe D, Poncsak S, Boluk Y (2008) Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 3:517–537

Goodman JR, Stewart AH (1990) Wood pole management-utilities case study. IEEE Trans Power Del 5:422–426

Kollmann FFP, Côté WA (1984) Principles of wood science and technology. Volume I solid wood. Springer, Berlin

Esteves BM, Pereira HM (2009) Wood modification by heat treatment: a review. BioResources 4:370–404

Kumar S (1994) Chemical modification of wood. Wood Fiber Sci 26:270–280

Militz H, Schaffert S, Peters BC, Fitzgerald CJ (2011) Termite resistance of DMDHEU-treated wood. Wood Sci Technol 45:547–557

Wang JY, Cooper PA (2005) Effect of oil type, temperature and time on moisture properties of hot oil-treated wood. Holz Roh Werkst 63:417–422

Schneider MH (1980) Hygroscopicity of wood impregnated with linseed oil. Wood Sci Technol 14:107–114

van Eckeveld A, Homan WJ, Militz H (2001) Increasing the water repellency of Scots pine sapwood by impregnation with undiluted linseed oil, wood oil, coccos oil and tall oil. Holzforsch Holzverwert 53:113–115

Calonego FW, Severo ETD, Furtado EL (2010) Decay resistance of thermally-modified Eucalyptus grandis wood at 140 °C, 160 °C, 180 °C, 200 °C and 220 °C. Bioresour Technol 101:9391–9394

Hakkou M, Pétrissans M, Gérardin P, Zoulalian A (2006) Investigations of the reasons for fungal durability of heat-treated beech wood. Polym Degrad Stab 91:393–397

Mburu F, Dumarçay S, Huber F, Petrissans M, Gérardin P (2007) Evaluation of thermally modified Grevillea robusta heartwood as an alternative to shortage of wood resource in Kenya: characterisation of physicochemical properties and improvement of bio-resistance. Bioresour Technol 98:3478–3486

Schultz TP, Nicholas DD, Preston AF (2007) A brief review of the past, present and future of wood preservation. Pest Manag Sci 63:784–788

Rapp AO, Sailer M (2001) Oil heat treatment of wood in Germany- state of the art. In: Rapp AO (ed) Review on heat treatments of wood. Cost Action E22. Proceedings of Special Seminar, Antibes, France, pp 45–62

Doi S, Kurimoto Y, Ohmura W, Ohara S, Aoyama M, Yoshimura T (1999) Effects of heat treatment of wood on the feeding behavior of two subterranean termites. Holzforschung 53:225–229

Westin M, Rapp A, Nilsson T (2006) Field test of resistance of modified wood to marine borers. Wood Mater Sci Eng 1:34–38

Baysal E, Sonmez A, Colak M, Toker H (2006) Amount of leachant and water absorption levels of wood treated with borates and water repellents. Bioresour Technol 97:2271–2279

De Groot RC (1994) Comparison of laboratory and field methods to evaluate durability of preservative-treated shakes. Wood Fiber Sci 26:306–314

Karlsson O, Sidorova E, Morén T (2011) Influence of heat transferring media on durability of thermally modified wood. BioResources 6:356–372

Ahmed SA, Morén T (2012) Moisture properties of heat-treated Scots pine and Norway spruce sapwood impregnated with wood preservatives. Wood Fiber Sci 44:85–93

Lindgren O (1992) Medical CT-scanners for non-destructive wood density and moisture content measurements. Doctoral Thesis, Luleå University of Technology, Division of Wood Technology, Skellefteå, Sweden. Thesis No. 1992:111D. ISSN 0348-8373

Abramoff MD, Magalhaes PJ, Ram SJ (2004) Image processing with ImageJ. Biophotonics Int 11:36–42

Phuong LX, Shida S, Saito Y (2007) Effects of heat treatment on brittleness of Styrax tonkinensis wood. J Wood Sci 53:181–186

Wallström L, Lindberg KAH (1995) Wood surface stabilization with polyethyleneglycol, PEG. Wood Sci Technol 29:109–119

Ahmed SA, Sehlstedt-Persson M, Karlsson O, Morén T (2012) Uneven distribution of preservative in kiln-dried sapwood lumber of Scots pine: impact of wood structure and resin allocation. Holzforschung 66:251–258

Ahmed SA, Hansson L, Morén T (2012) Distribution of preservatives in thermally modified Scots pine and Norway spruce sapwood. Wood Sci Technol. doi:10.1007/s00226-012-0509-4

Bailey PJ, Preston RD (1970) Some aspects of softwood permeability. II. Flow of polar and non-polar liquids through sapwood and heartwood of Douglas fir. Holzforschung 24:37–45

Rudman P (1965) Studies in wood preservation. Pt. I The penetration of liquids into Eucalypt sapwoods. Holzforschung 19:5–13

Banks WB (1981) Addressing the problem of non-steady state liquid flow in wood. Wood Sci Technol 15:171–177

Karlsson O, Torniainen P, Dagbro O, Granlund K, Morén T (2012) Presence of water-soluble compounds in thermally modified wood: carbohydrates and furfurals. BioResources 7:3679–3689

Wheeler EA, Thomas RJ (1981) Ultrastructural characteristics of mature wood of southern red oak (Quercus falcata Michx.) and white oak (Quercus alba L.). Wood Fiber 13:169–181

Acknowledgments

Financial support from the European Union and the European Regional Development Fund, the County Administration of Västerbotten, the municipality of Skellefteå and TräCentrum Norr is highly appreciated and acknowledged.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ahmed, S.A., Sehlstedt-Persson, M., Hansson, L. et al. Evaluation of preservative distribution in thermally modified European aspen and birch boards using computed tomography and scanning electron microscopy. J Wood Sci 59, 57–66 (2013). https://doi.org/10.1007/s10086-012-1299-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-012-1299-x