Abstract

In this paper a purely phenomenological formulation and finite element numerical implementation for quasi-incompressible transversely isotropic and orthotropic materials is presented. The stored energy is composed of distinct anisotropic equilibrated and non-equilibrated parts. The nonequilibrated strains are obtained from the multiplicative decomposition of the deformation gradient. The procedure can be considered as an extension of the Reese and Govindjee framework to anisotropic materials and reduces to such formulation for isotropic materials. The stress-point algorithmic implementation is based on an elastic-predictor viscous-corrector algorithm similar to that employed in plasticity. The consistent tangent moduli for the general anisotropic case are also derived. Numerical examples explain the procedure to obtain the material parameters, show the quadratic convergence of the algorithm and usefulness in multiaxial loading. One example also highlights the importance of prescribing a complete set of stress-strain curves in orthotropic materials.

Similar content being viewed by others

References

Cristensen RM (2003) Theory of viscoelasticity. Elsevier, Dover

Shaw MT, MacKnight WJ (2005) Introduction to polymer viscoelasticity. Wiley-Blackwell, New York

Argon AS (2013) The physics of deformation and fracture of polymers. Cambridge University Press, Cambridge

Schapery RA, Sun CT (eds) (2000) Time dependent and nonlinear effects in polymers and composites. American Society for Testing and Materials (ASTM), West Conshohocken

Gennisson JL, Deffieux T, Macé E, Montaldo G, Fink M, Tanter M (2010) Viscoelastic and anisotropic mechanical properties of in vivo muscle tissue assessed by supersonic shear imaging. Ultrasound Med Biol 36(5):789–801

Schapery RA (2000) Nonlinear viscoelastic solids. Int J Solids Struct 37(1):359–366

Truesdell C, Noll W (2004) The non-linear field theories of mechanics. Springer, Berlin

Rivlin RS (1965) Nonlinear viscoelastic solids. SIAM Rev 7(3):323–340

Fung YC (1993) A first course in continuum mechanics. Prentice-Hall, Upper Saddle River

Fung YC (1972) Stress–strain-history relations of soft tissues in simple elongation. Biomechanics 7:181–208

Sauren AAHJ, Rousseau EPM (1983) A concise sensitivity analysis of the quasi-linear viscoelastic model proposed by Fung. J Biomech Eng 105(1):92–95

Rebouah M, Chagnon G (2014) Extension of classical viscoelastic models in large deformation to anisotropy and stress softening. Int J Non-Linear Mech 61:54–64

Poon H, Ahmad MF (1998) A material point time integration procedure for anisotropic, thermo rheologically simple, viscoelastic solids. Comput Mech 21(3):236–242

Drapaca CS, Sivaloganathan S, Tenti G (2007) Nonlinear constitutive laws in viscoelasticity. Math Mech Solids 12(5):475–501

Simo JC, Hughes TJR (1998) Computational inelasticity. Springer, New York

Holzapfel GA (2000) Nonlinear solid mechanics. A continuum approach for engineering. Wiley, Chichester

Peña JA, Martínez MA, Peña E (2011) A formulation to model the nonlinear viscoelastic properties of the vascular tissue. Acta Mech 217(1–2):63–74

Peña E, Peña JA, Doblaré M (2008) On modelling nonlinear viscoelastic effects in ligaments. J Biomech 41(12):2659–2666

Holzapfel GA (1996) On large strain viscoelasticity: continuum formulation and finite element applications to elastomeric structures. Int J Numer Methods Engrg 39(22):3903–3926

Liefeith D, Kolling S (2007) An Anisotropic Material Model for Finite Rubber Viscoelasticity. LS-Dyna Anwenderforum, Frankenthal

Haupt P (2002) Continuum mechanics and theory of materials, 2nd edn. Springer, Berlin

Bergström JS, Boyce MC (1998) Constitutive modeling of the large strain time-dependent behavior of elastomers. J Mech Phys Solids 46(5):931–954

Le Tallec P, Rahier C, Kaiss A (1993) Three-dimensional incompressible viscoelasticity in large strains: formulation and numerical approximation. Comput Methods Appl Mech Eng 109:233–258

Haupt P, Sedlan K (2001) Viscoplasticity of elastomeric materials: experimental facts and constitutive modelling. Arch Appl Mech 71:89–109

Lion A (1996) A constitutive model for carbon black filled rubber: experimental investigations and mathematical representation. Contin Mech Thermodyn 8(3):153–169

Lion A (1998) Thixotropic behaviour of rubber under dynamic loading histories: experiments and theory. J Mech Phys Solids 46(5):895–930

Simo JC (1987) On a fully three-dimensional finite-strain viscoelastic damage model: formulation and computational aspects. Comput Methods Appl Mech Eng 60(2):153–173

Craiem D, Rojo FJ, Atienza JM, Armentano RL, Guinea GV (2008) Fractional-order viscoelasticity applied to describe uniaxial stress relaxation of human arteries. Phys Med Biol 53:4543–4554

Kaliske M, Rothert H (1997) Formulation and implementation of three-dimensional viscoelasticity at small and finite strains. Comput Mech 19(3):228–239

Gasser TC, Forsell C (2011) The numerical implementation of invariant-based viscoelastic formulations at finite strains. An anisotropic model for the passive myocardium. Comput Methods Appl Mech Eng 200(49):3637–3645

Reese S, Govindjee S (1998) A theory of finite viscoelasticity and numerical aspects. Int J Solids Struct 35(26):3455–3482

Lubliner J (1985) A model of rubber viscoelasticity. Mech Res Commun 12(2):93–99

Sidoroff F (1974) Un modèle viscoélastique non linéaire avec configuration intermédiaire. J Mécanique 13(4):679–713

Lee EH (1969) Elastic-plastic deformation at finite strains. J Appl Mech 36(1):1–6

Bilby BA, Bullough R, Smith E (1955) Continuous distributions of dislocations: a new application of the methods of non-Riemannian geometry. Proc R Soc Lond Ser A 231(1185):263–273

Herrmann LR, Peterson FE (1968) A numerical procedure for viscoelastic stress analysis. In: Seventh meeting of ICRPG mechanical behavior working group, Orlando, FL, CPIA Publication, vol 177, pp 60–69

Taylor RL, Pister KS, Goudreau Gl et al (1970) Thermomechanical analysis of viscoelastic solids. Int J Numer Methods Eng 2(1):45–59

Hartmann S (2002) Computation in finite-strain viscoelasticity: finite elements based on the interpretation as differential-algebraic equations. Comput Methods Appl Mech Eng 191(13–14):1439–1470

Eidel B, Kuhn C (2011) Order reduction in computational inelasticity: why it happens and how to overcome it–The ODE-case of viscoelasticity. Int J Numer Methods Eng 87(11):1046–1073

Haslach HW Jr (2005) Nonlinear viscoelastic, thermodynamically consistent, models for biological soft tissue. Biomech Model Mechanobiol 3(3):172–189

Pioletti DP, Rakotomanana LR, Benvenuti JF, Leyvraz PF (1998) Viscoelastic constitutive law in large deformations: application to human knee ligaments and tendons. J Biomech 31(8):753–757

Merodio J, Goicolea JM (2007) On thermodynamically consistent constitutive equations for fiber-reinforced nonlinearly viscoelastic solids with application to biomechanics. Mech Res Commun 34(7):561–571

Bonet J (2001) Large strain viscoelastic constitutive models. Int J Solids Struct 38(17):2953–2968

Peric D, Dettmer W (2003) A computational model for generalized inelastic materials at finite strains combining elastic, viscoelastic and plastic material behaviour. Eng Comput 20(5/6):768–787

Nedjar B (2002) Frameworks for finite strain viscoelastic-plasticity based on multiplicative decompositions. Part I: continuum formulations. Comput Methods Appl Mech Eng 191(15):1541–1562

Latorre M, Montáns FJ (2014) On the interpretation of the logarithmic strain tensor in an arbitrary system of representation. Int J Solids Struct 51(7):1507–1515

Eterovic AL, Bathe KJ (1990) A hyperelastic-based large strain elasto-plastic constitutive formulation with combined isotropic-kinematic hardening using the logarithmic stress and strain measures. Int J Numer Methods Eng 30(6):1099–1114

Simo JC (1992) Algorithms for static and dynamic multiplicative plasticity that preserve the classical return mapping schemes of the infinitesimal theory. Comput Methods Appl Mech Eng 99(1):61–112

Caminero MA, Montáns FJ, Bathe KJ (2011) Modeling large strain anisotropic elasto-plasticity with logarithmic strain and stress measures. Comput Struct 89(11):826–843

Montáns FJ, Benítez JM, Caminero MA (2012) A large strain anisotropic elastoplastic continuum theory for nonlinear kinematic hardening and texture evolution. Mech Res Commun 43:50–56

Papadopoulos P, Lu J (2001) On the formulation and numerical solution of problems in anisotropic finite plasticity. Comput Meth Appl Mech Eng 190(37):4889–4910

Miehe C, Apel N, Lambrecht M (2002) Anisotropic additive plasticity in the logarithmic strain space: modular kinematic formulation and implementation based on incremental minimization principles for standard materials. Comput Meth Appl Mech Eng 191(47):5383–5425

Vogel F, Göktepe S, Steinmann P, Kuhl E (2014) Modeling and simulation of viscous electro-active polymers. Eur J Mech 48:112–128

Holmes DW, Loughran JG (2010) Numerical aspects associated with the implementation of a finite strain, elasto-viscoelastic-viscoplastic constitutive theory in principal stretches. Int J Numer Methods Eng 83(3):366–402

Holzapfel GA, Gasser TC, Stadler M (2002) A structural model for the viscoelastic behavior of arterial walls: continuum formulation and finite element analysis. Eur J Mech 21(3):441–463

Nguyen TD, Jones RE, Boyce BL (2007) Modeling the anisotropic finite-deformation viscoelastic behavior of soft fiber-reinforced composites. Int J Solids Struct 44(25):8366–8389

Nedjar B (2007) An anisotropic viscoelastic fibre-matrix model at finite strains: continuum formulation and computational aspects. Comput Methods Appl Mech Eng 196(9):1745–1756

Latorre M, Montáns FJ (2013) Extension of the Sussman-Bathe spline-based hyperelastic model to incompressible transversely isotropic materials. Comput Struct 122:13–26

Latorre M, Montáns FJ (2014) What-you-prescribe-is-what-you-get orthotropic hyperelasticity. Comput Mech 53(6):1279–1298

Latorre M, Montáns FJ (2015) Material-symmetries congruency in transversely isotropic and orthotropic hyperelastic materials. Eur J Mech 53:99–106

Miñano M, Montáns FJ (2015) A new approach to modeling isotropic damage for Mullins effect in hyperelastic materials. Int J Solids Struct 67–68:272–282

Montáns FJ, Bathe KJ (2005) Computational issues in large strain elasto-plasticity: an algorithm for mixed hardening and plastic spin. Int J Numer Methods Eng 63(2):159–196

Montáns FJ, Bathe KJ (2007) Towards a model for large strain anisotropic elasto-plasticity. Computational plasticity. Springer, New York, pp 13–36

Bathe KJ (2014) Finite element procedures, 2nd edn. Klaus-Jurgen Bathe, Berlin

Weber G, Anand L (1990) Finite deformation constitutive equations and a time integration procedure for isotropic, hyperelastic-viscoplastic solids. Comput Methods Appl Mech Eng 79(2):173–202

Hartmann S, Quint KJ, Arnold M (2008) On plastic incompressibility within time-adaptive finite elements combined with projection techniques. Comput Methods Appl Mech Eng 198:178–193

Simo JC, Miehe C (1992) Associative coupled thermoplasticity at finite strains: formulation, numerical analysis and implementation. Comput Methods Appl Mech Eng 98(1):41–104

Sansour C, Bocko J (2003) On the numerical implications of multiplicative inelasticity with an anisotropic elastic constitutive law. Int J Numer Methods Eng 58(14):2131–2160

Bischoff JE, Arruda EM, Grosh K (2004) A rheological network model for the continuum anisotropic and viscoelastic behavior of soft tissue. Biomech Model Mechanobiol 3(1):56–65

Sussman T, Bathe KJ (2009) A model of incompressible isotropic hyperelastic material behavior using spline interpolations of tension-compression test data. Commun Numer Methods Eng 25:53–63

Sussman T, Bathe KJ (1987) A finite element formulation for nonlinear incompressible elastic and inelastic analysis. Comput Struct 26:357–409

Ogden RW (1997) Nonlinear elastic deformations. Dover, New York

Kim DN, Montáns FJ, Bathe KJ (2009) Insight into a model for large strain anisotropic elasto-plasticity. Comput Mech 44(5):651–668

Acknowledgments

Partial financial support for this work has been given by grant DPI2011-26635 from the Dirección General de Proyectos de Investigación of the Ministerio de Economía y Competitividad of Spain.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Proof of Eqs. (114) and (115)

The stress tensor \(\varvec{S}_{neq}^{|d}\) defined in Eq. (97) is “traceless” in the sense that

where the results \(\varvec{\tau }_{neq}^{|d}=\varvec{X}^{d}\varvec{S} _{neq}^{|d}\varvec{X}^{dT}=\varvec{X}^{e}\varvec{S}_{neq}^{|e}\varvec{X} ^{eT}=\varvec{\tau }_{neq}^{|e}\), \(tr(\varvec{\tau }_{neq}^{|e})=tr(\varvec{T}_{neq}^{|e})\) (see Ref. [59]) and Eq. (66) have been used. Therefore, the expression of the second Piola–Kirchhoff stress tensor \(\varvec{S}_{neq}\) that derives from the purely deviatoric strain energy function \(\mathcal {W}_{neq}\), as given in Eq. (97), reduces to Eq. (114)

where \(d\varvec{A}^{d}/d\varvec{A}=d\varvec{C}^{d}/d\varvec{C}\) has been obtained differentiating the expression \(\varvec{C}^{d}=J^{-2/3}\varvec{C}\), with \(J^2=det(\varvec{C})\), with respect to \(\varvec{C}\).

Differentiating Eq. (157) with respect to \(\varvec{C}^{d}\)

Using the major symmetries of \(\mathbb {C}_{neq}^{|d}\), cf. Eqs. (102) and (113), we arrive at the following relation

After some algebraic manipulations, we identify this last result in the expression of the deviatoric constitutive tensor that derives from \(\varvec{S}_{neq}\), which finally simplifies to Eq. (115)

Appendix 2: General expressions for \(\varvec{T}_{neq}^{|tr}\) and \(d\varvec{T}_{neq}^{|tr}/d\,^{tr}\varvec{E}_{e}\)

If the approximation of Eq. (108) is not considered adequate, we can compute the mapping tensor \(\partial \varvec{E}_{e} /\partial \,^{tr}\varvec{E}_{e}\) with the viscous flow frozen, needed for the computation of the stresses in Eq. (106), and its gradient with respect to \(\,^{tr}\varvec{E}_{e}\), needed for the computation of the consistent tangent moduli.

From the relation \(\,^{tr}\varvec{X}_{e}=\varvec{X}^d\,^{tr}\varvec{X}_{v}^{-1}\), with \(\,^{tr}\varvec{X}_v\) fixed by definition, see Fig. 3, we obtain

which represents the spatial counterpart, in rate-form, of the change of variable given in Eq. (99). Accordingly, the independent variables of the isochoric counterpart of Eq. (40) may be changed to give

or

with \(\left. \mathbb {M}_{\,^{tr}d_{e}}^{d_{e}}\right| _{\varvec{l}_v = \varvec{0}\varvec{}} =\mathbb {I}^{S}\). Hence we obtain —recall Eq. (54)

with

Although \(\varvec{\tau }_{neq}^{|e}=\varvec{\tau }_{neq}^{|tr}=\varvec{\tau }_{neq}^{|d}\) represent all them the same Kirchhoff stress tensor operating in the current isochoric configuration, we use different superscripts to emphasize the fact that this stress tensor may be obtained from different Lagrangian stress tensors defined in different configurations. In terms of Generalized Kirchhoff stresses, Eq. (166) reads

where, for example, \(\mathbb {M}_{d_{e}}^{\dot{E}_{e}}\) is the fourth-order tensor that maps, on the one hand, the elastic deformation rate tensor \(\varvec{d}_{e}\) to the material rate tensor \({\dot{\varvec{E}}}_{e}\) and, on the other hand, the stresses \(\varvec{T}_{neq}^{|e}\) to the stresses \(\varvec{\tau }_{neq}^{|e}\), compare to Eqs. (45) and (49). Hence

Taking into consideration that \(\left. \mathbb {M}_{\,^{tr}d_{e}}^{d_{e} }\right| _{\varvec{l}_v = \varvec{0}\varvec{}}=\mathbb {I}^{S}\) we arrive at

where we have defined the rotated deformation rate tensors

and we have used the fact that \(\,^{tr}\varvec{R}_{e}=\varvec{R}_{e}\), so \(\mathbb {M}_{d_{e}}^{\bar{d}_{e}}:\mathbb {M}_{\,^{tr}\bar{d}_{e}} ^{\,^{tr}d_{e}}=\mathbb {I}^{S}\). Thus, the general expression for Eq. (106) reads

which defines the mapping between the stress tensors \(\varvec{T}_{neq}^{|e}\), defined in the updated intermediate configuration, and \(\varvec{T}_{neq}^{|tr}\), defined in the trial (fixed) intermediate configuration. The reader is referred to Ref. [59], Eq. (35), to see the specific spectral form of the mapping tensors present in Eq. (172), where the Lagrangian basis and the stretches are to be adapted to each case. Note that if the deformation occurs about the preferred material directions, then the shear terms of these mapping tensors do not take place in the relation between \(\varvec{T}_{neq}^{|tr}\) and \(\varvec{T}_{neq}^{|e}\) (because they are coaxial), so from the spectral forms of \(\mathbb {M}_{\bar{d}_{e}}^{\dot{E}_{e}}\) and \(\mathbb {M} _{\,^{tr}\dot{E}_{e}}^{\,^{tr}\bar{d}_{e}}\) we obtain \(\varvec{T}_{neq}^{|tr} =\varvec{T}_{neq}^{|e}\); recall Identity (107)\(_{2}\). Furthermore, the approximation of Identity (108)\(_{2}\) is also based on the specific spectral forms of \(\mathbb {M}_{\bar{d}_{e}}^{\dot{E}_{e}}\) and \(\mathbb {M}_{\,^{tr}\dot{E}_{e}}^{\,^{tr}\bar{d}_{e}}\) and on the fact that the eigenvectors of \(\varvec{E}_{e}\) and \(\,^{tr}\varvec{E}_{e}\) are almost coincident for \(\Delta t/\tau \ll 1\), as one may deduce from Eq. (81).

For the computation of the consistent tangent moduli \(d\varvec{T}_{neq}^{|tr}/d\,^{tr}\varvec{E}_{e}\), to be used in Eq. (104), we must take into consideration that the trial logarithmic strains \(\,^{tr}\varvec{E}_{e}\) and the updated logarithmic strains \(\,_{\qquad 0}^{t+\Delta t}\varvec{E}_{e}\) are related in the algorithm through Eq. (81), so their increments relate through Eq. (111), see also Eq. (112). Then, taking derivatives in Eq. (172) —note that \(\mathbb {M}_{\bar{d}_{e}}^{\dot{E}_{e}}\) and \(\mathbb {M}_{\,^{tr}\dot{E}_{e}}^{\,^{tr}\bar{d}_{e}}\) have major and minor symmetries

or, equivalently

where the result obtained from taking derivatives with respect to \(\varvec{E}_{e}\) in the identity \(\mathbb {M}_{\bar{d}_{e}}^{\dot{E}_{e} }:\mathbb {M}_{\dot{E}_{e}}^{\bar{d}_{e}}=\mathbb {I}^{S}\) has been used and \(\varvec{\bar{\tau }}_{neq}^{|e}\) stands for the Kirchhoff stress tensor \(\varvec{\tau }_{neq}^{|e}\) rotated by \(\varvec{R}_{e}^{T}\), i.e. \(\varvec{\bar{\tau }}_{neq}^{|e}=\varvec{T}_{neq}^{|e}:\mathbb {M} _{\bar{d}_{e}}^{\dot{E}_{e}}\). Following customary arguments, the sixth-order tensors of the type \(d\mathbb {M}_{\dot{E}}^{\bar{d}}/d \varvec{E}\) present in this last equation may be obtained from the comparison of the spectral decompositions of the material rate of \(\mathbb {M}_{\dot{E} }^{\bar{d}}\) and the material rate of \(\varvec{E}\), i.e.

see Refs. [49, 59, 72] for similar derivations and further details.

Appendix 3: Interpretation of off-axis shearing effects

From the third example above we infer that two different orthotropic materials subjected to the same off-axis finite deformation and with the same orientation of the preferred material axes may undergo angular distortions of opposite sign. Based on the fact that finite logarithmic strains extend the small strains meaning to the large strains setting [46] and on the fact that in that example we are using strain energy functions based on the same invariants used in infinitesimal orthotropic elasticity, we can explain these different mechanical responses from the infinitesimal theory and then extend the results to the case of Example 3.

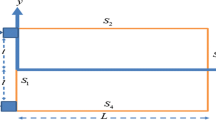

Consider as an example the uniaxial test of Fig. 14 performed over a perfectly incompressible orthotropic material with the preferred material direction 1 oriented at \(\alpha =30 {{}^o} \) with respect to the test axis x. We consider a plane strain state, so the out-of-plane strains vanish, i.e. \(\varepsilon _{31}=\varepsilon _{32} =\varepsilon _{33}=0\). The in-plane contribution of the (deviatoric) strain energy function is expressed in terms of the components of the infinitesimal strain tensor \(\varvec{\varepsilon }\) in the preferred material axes as

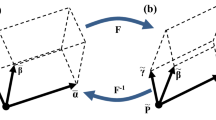

The stresses in principal material directions are

where the incompressibility constraint \(\varepsilon _{22}=-\varepsilon _{11}\) has been used and p is the initially unknown hydrostatic pressure. Since \(\sigma _{12}<0\), Eq. (179) yields \(\varepsilon _{12}<0\). From the Mohr’s circle of in-plane stresses shown in Fig. 15 we get the relation \(\sigma _{11}=3\sigma _{22}\) (note that the axes \(\{x,y\}\) are the principal directions of stresses because \(\sigma _{xy}=0\)). Combining Eq. (177), Identity (178)\(_{2}\) and the relation \(\sigma _{11}=3\sigma _{22}\) we arrive at

The sign of the angular distortion \(\gamma _{xy}=2\varepsilon _{xy}\) undergone by the specimen may be obtained by direct comparison of the Mohr’s representations of stresses and strains, see Fig. 15. On the one hand, in the Mohr’s circle of stresses we have \(-\sigma _{12}/\left( \sigma _{11}/3\right) =\tan \left( 2\times 30 {{}^o} \right) =\tan \left( 60 {{}^o} \right) \). On the other hand, from the Mohr’s circle in the strain space we obtain \(-\varepsilon _{12}/\varepsilon _{11}=\tan \left( 2\theta \right) \). These angles are related by Eqs. (179) and (180 ), i.e.

Hence we distinguish three different possibilities

which, note, satisfactorily explain the different behaviors obtained for the instantaneous (equilibrated plus non-equilibrated) and equilibrated responses in the Example 3 above. Finally, we remark that the condition \(2\mu _{12} =\mu _{11}+\mu _{22}\) does not imply isotropic behavior in the plane 12 (although \(\gamma _{xy}=0\)). Evidently, if the material is isotropic in the plane 12, then \(\mu _{11} =\mu _{22}=\mu _{12}\) and the condition \(2\mu _{12}=\mu _{11}+\mu _{22}\) is also satisfied, as one would expect.

Mohr’s circles for stresses (left) and strains (right) associated to the uniaxial test under plane strain of Figure 14 with \(\alpha =30{{}^o}\). In the Mohr’s circle of stresses we use \(\sigma _{xy} =\sigma _{yy}=0\) (boundary conditions). In the Mohr’s circle of strains we use \(\varepsilon _{yy}=-\varepsilon _{xx}\) (incompressibility). Subscript n means “normal” and subscript t means “tangential”

Interestingly, the strain components \(\varepsilon _{xx}\) and \(\varepsilon _{xy}\) obtained for the orientations of \(\alpha =30 {{}^o} \) and \(\alpha =60 {{}^o} \) for the same uniaxial stress \(\sigma _{xx}\) relate through

which, again, let us explain the symmetric responses in the finite deformation context shown in Figures 8 and 9 of Ref. [59] (compare the cases \(\alpha =30 {{}^o} \) and \(\alpha =60 {{}^o} \) of each figure). Note that the reference configurations for \(\alpha =30 {{}^o} \) and \(\alpha =60 {{}^o} \) are different (i.e. they are not a reflection from each other). The symmetric responses are just a consequence of the plane strain condition, the incompressible behavior and the symmetry of the strain energy terms \(\omega _{ij}(E_{ij})=\omega _{ij}(-E_{ij})\) considered in that paper (as in the small strains case).

Another interesting view of this phenomenon may be obtained through the skew part of the Mandel stress tensor, used in Refs. [50, 63, 73] in the context of plasticity to account for the update of the principal material directions. This tensor, work-conjugate to spins and which may be interpreted as fictitious angular moments per unit volume (couple-stress), accounts for the lack of commutativity due to elastic anisotropy and is obtained from the elastic strains and stored energy function as

For this particular case, using Eq. (176) and small strains

where

Note that there is a change of sign if either \(\mu _{11}+\mu _{22}-2\mu _{12}\) (material dependent) changes sign or if \(\varepsilon _{11}\varepsilon _{12}\) (load dependent) changes sign. Furthermore, for in-axis (axial) loading \(\varepsilon _{12}=0\) or pure shear loading \(\varepsilon _{11}=\varepsilon _{22}=0\), the tensor \(\varvec{\sigma }_{w}\) vanishes. Obviously for the isotropic case all \(\mu _{ij}\) are coincident and \(\varvec{\sigma }_{w}\) also vanishes.

Rights and permissions

About this article

Cite this article

Latorre, M., Montáns, F.J. Anisotropic finite strain viscoelasticity based on the Sidoroff multiplicative decomposition and logarithmic strains. Comput Mech 56, 503–531 (2015). https://doi.org/10.1007/s00466-015-1184-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1184-8