Abstract

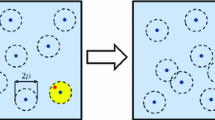

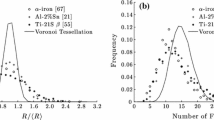

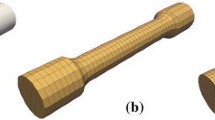

Simulation results from finite element models using two types of 3D polycrystal geometric representations, one with a voxel representation and stair-stepped grain boundaries and the other with smooth grain boundaries, are compared. Both models start with a periodic grain structure representation, which is in the form of a regular, rectangular 3D array of points, where each point is assigned an orientation. The voxel representation is obtained by simply sampling the array of grid points on a coarser regular grid with a prescribed resolution and forming a voxel centered at each grid point, which is assigned the grain orientation from the sampled grid point. The voxel representation may be meshed directly by decomposing each voxel into finite elements. In the second case, a method is presented that extracts geometric topology information for a grain structure with smooth, flat grain boundaries from the discrete grain structure representation. From the geometric topology information, a finite element mesh is created. The two representations are then subjected to large strain deformations, and the simulation results and efficiencies are compared. The macroscopic behavior, overall texture evolution, and statistical distribution of stress and slip are found to be nearly identical for both models. However, noticeable differences are observed in the misorientation distribution within grains and the smoothness of the stress field. The voxel representation is found to be more efficient because of the uniform finite element mesh.

Similar content being viewed by others

References

Taylor GI (1938) Plastic strains in metals. J Inst Metals 62(1): 307–324

Asaro RJ, Needleman A (1985) Texture development and strain hardening rate dependent polycrystals. Acta Metall 33: 923–953

Mathur KK, Dawson PR (1989) On modeling the development of crystallographic texture in bulk forming processes. Int J Plast 5: 67–94

Canova GR, Kocks UF, Jonas JJ (1984) Theory of torsion texture development. Acta Metall 32: 211–226

Mathur KK, Dawson PR, Kocks UF (1990) On modeling anisotropy in deformation processes involving textured polycrystals with distorted grain shape. Mech Mater 10: 183–202

Molinari A, Canova GR, Ahzi A (1987) A self consistent approach of the large deformation polycrystal viscoplasticity. Acta Metall 35: 2983–2994

Fleck N, Muller G, Ashby M, Hutchinson J (1994) Strain gradient plasticity: Theory and experiment. Acta Metall Mater 42: 475–487

Beaudoin AJ, Acharya A, Chen SR, Korzekwa DA, Stout MG (2000) Consideration of grain-size effect and kinetics in the plastic deformation of metal polycrystals. Acta Mater 48: 3409–3423

Janssen PJM, Hoefnagels JPM, de Keijsera TH, Geers MGD (2008) Processing induced size effects in plastic yielding upon miniaturisation. J Mech Phys Solids 56: 2687–2706

Beaudoin AJ, Mecking H, Kocks UF (1996) Development of localized orientation gradients in fcc polycrystals. Philos Mag A 73: 1503–1517

Sarma GB, Radhakrishnan B, Zacharia T (1998) Finite element simulations of cold deformation at the mesoscale. Comput Mater Sci 12: 105–122

Hochhalter JD, Littlewood DJ, Christ Jr RJ, Veilleux MG, Bozek JE, Ingraffea AR, Maniatty AM (2010) A geometric approach to modeling microstructurally small fatigue crack formation: II. Physically based modeling of microstructure-dependent slip localization and actuation of the crack nucleation mechanism in AA 7075-T651. Modell Simul Mater Sci Eng 18: 045004

Roters F, Eisenlohr P, Hantcherli L, Tjahjanto D, Bieler T, Raabe D (2010) Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater 58: 11521211

Van Houtte P, Delannay L, Kalidindi SR (2002) Comparison of two grain interaction models for polycrystal plasticity and deformation texture prediction. Int J Plast 18: 359–377

Anand L (2004) Single-crystal elasto-viscoplasticity: application to texture evolution in polycrystalline metals at large strains. Comput Methods Appl Mech Eng 193: 5359–5383

Li S, Kalidindi SR, Beyerlein IJ (2005) A crystal plasticity finite element analysis of texture evolution in equal channel angular extrusion. Mater Sci Eng A 410(411): 207–212

Buchheit TE, Wellman GW, Battaile CC (2005) Investigating the limits of polycrystal plasticity modeling. Int J Plast 21(2): 221–249

Fülöp T, Brekelmans WAM, Geers MGD (2006) Size effects from grain statistics in ultra-thin metal sheets. J Mater Process Technol 174: 233–238

Nakamachi E, Hiraiwa K, Morimoto H, Harimoto M (2000) Elastic/crystalline viscoplastic finite element analyses of single- and poly-crystal sheet deformations and their experimental verification. Int J Plast 16: 1419–1441

Ritz H, Dawson PR (2009) Sensitivity to grain discretization of the simulated crystal stress distributions in fcc polycrystals. Model Simul Mater Sci Eng 17:015001

Kanit T, Forest S, Galliet I, Mounoury V, Jeulin D (2003) Determination of the size of the representative volume element for random composites: Statistical and numerical approach. Int J Solids Struct 40: 3647–3679

Zhang KS, Wu MS, Feng R (2005) Simulation of microplasticity-induced deformation in uniaxially strained ceramics by 3-d voronoi polycrystal modeling. Int J Plast 21: 801–845

Zeghadi A, N’guyen F, Forest S, Gourgues AF, Bouaziz O (2007) Ensemble averaging stress–strain fields in polycrystalline aggregates with a constrained surface microstructure—part 1: anisotropic elastic behaviour. Philos Mag 87: 1401–1424

Zeghadi A, Forest S, Gourgues AF, Bouaziz O (2007) Ensemble averaging stress–strain fields in polycrystalline aggregates with a constrained surface microstructure—part 2: crystal plasticity. Philos Mag 87: 1425–1446

Anderson MP, Grest GS, Srolovitz DJ (1989) Computer simulation of normal grain growth in three dimensions. Philos Mag B 59: 293–329

Radhakrishnan B, Zacharia T (1995) Simulation of curvature-driven grain growth by using a modified Monte Carlo algorithm. Metall Mater Trans A 26: 167–180

Moelans N, Blanpain B, Wollants P (2005) A phase field model for the simulation of grain growth in materials containing finely dispersed incoherent second-phase particles. Acta Mater 53: 1771–1781

Marx V, Reher F, Gottstein G (1999) Simulation of primary recrystallization using a modified three-dimensional cellular automaton. Acta Mater 47: 1219–1230

Saylor DM, Fridy J, El-dasher BS, Jung KY, Rollett AD (2004) Statistically representative three-dimensional microstructures based on orthogonal observation sections. Metall and Mater Trans A 35: 1969–1979

St-Pierre L, Heripre E, Dexet M, Crepin J, Bertolino G, Bilger N (2008) 3d simulations of microstructure and comparison with experimental microstructure coming from OIM analysis. Int J Plast 24: 1515–1532

Claves SR, Bandar AR, Misiolek WZ, Michael JR (2004) Three-dimensional (3d) reconstruction of AlFeSi intermetallic particles in 6xxx aluminum alloys using the focused ion beam. Microsc Microanal 10: 1138–1139

Poulsen SO, Lauridsen EM, Lyckegaard A, Oddershede J, Gundlach C, Curfs C, Jensen DJ (2011) In situ measurements of growth rates and grain-averaged activation energies of individual grains during recrystallization of 50 % cold-rolled aluminium. Sci Mater 64: 1003–1006

Lorensen WE, Harvey EC (1987) Marching cubes: a high resolution 3d surface construction algorithm. In: Computer graphics. SIGGRAPH 87 conference proceedings. ACM, New York, pp 163–169

Amenta N, Bern M, Kamvysselis M (1998) A new Voronoi-based surface reconstruction algorithm. In: Computer graphics. SIGGRAPH 98 conference proceedings. ACM, New York, pp 415–421

Chernyaev EV (1995) Marching cubes 33: construction of topologically correct isosurfaces. Technical report CN/95-17. CERN, Geneva

Carneiro BP, Silva CT, Arie EK (1996) Tetra-cubes: an algorithm to generate 3d isosurfaces based upon tetrahedra. In: Anais do IX SIBGRAPI’96, Sociedade Brasileira de Computacao, pp 205–210. SBC, Brasil

Tarini M, M Callieri CM, Rocchini C (2002) Marching intersections: an efficient approach to shape-from-silhouette. In: 7th International fall workshop of vision, modeling, and visualization, vol 603. DFG Graduate Research Center SFB, Erlangen, pp 255–262

Wiederkehr T, Klusemann B, Gies D, Mller H, Svendsen B (2010) An image morphing method for 3d reconstruction and FE-analysis of pore networks in thermal spray coatings. Comput Mater Sci 47: 881–889

Lewiner T, Lopes H, Vieira AW, Tavares G (2003) Efficient implementation of marching cubes’ cases with topological guarantees. J Graph Tools 8: 1–15

Cahn JW, Van Vleck ES (1999) On the co-existence and stability of trijunctions and quadrijunctions in a simple model. Acta Metall 47: 4627–4639

Abaqus (2009) Analysis user’s manual, version 6.9. Dassault Systemes Simulia Corporation, Providence

Bozek JE, Hochhalter JD, Veilleux MG, Liu M, Heber G, Sintay SD, Rollett AD, Littlewood DJ, Maniatty AM, Weiland H, Christ~Jr RJ, Payne J, Welsh G, Harlow DG, Wawrzynek PA, Ingraffea AR (2008) A geometric approach to modeling microstructurally small fatigue crack formation: I probabilistic simulation of constituent particle cracking in AA 7075 T651. Model Simul Mater Sci Eng 16: 065007

Gurtin ME (2003) An introduction to continuum mechanics. Academic Press, San Diego

Lee EH (1969) Elastic–plastic deformation at finite strain. J Appl Mech 36: 1–6

Maniatty AM, Dawson PR, Lee YS (1992) A time integration algorithm for elasto-viscoplastic cubic crystals applied to modeling polycrystalline deformation. Int J Numer Methods Eng 35: 1565–1588

Matouš K, Maniatty AM (2004) Finite element formulation for modeling large deformations in elasto-viscoplastic polycrystals. Int J Numer Methods Eng 60: 2312–2333

Matouš K, Maniatty AM (2009) Multiscale modeling of elasto-viscoplastic polycrystals subjected to finite deformations. Interact Multisc Mechs 2: 375–396

Pyle D (2009) A comparison of 2 methods for FEM simulations of discretized polycrystals. M.S. Thesis. Rensselaer Polytechnic Institute, Troy

Argonne National Laboratory (2011). http://www.mcs.anl.gov/petsc/. Accessed 12 Jan 2011

Ramesh B, Maniatty AM (2005) Stabilized finite element formulation for elasticplastic finite deformations. Comput Methods Appl Mech Eng 194: 775–800

EDAX (2010) OIM Analysis Software, Materials Analysis Division. Ametek Inc., Mahwah

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pyle, D.M., Lu, J., Littlewood, D.J. et al. Effect of 3D grain structure representation in polycrystal simulations. Comput Mech 52, 135–150 (2013). https://doi.org/10.1007/s00466-012-0802-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-012-0802-y