Abstract

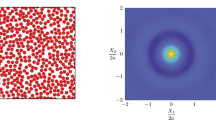

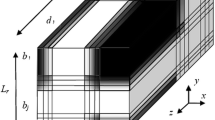

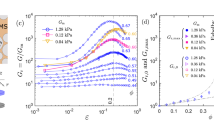

Most biological soft tissues are multiphase composite materials, and the determination of their effective constitutive relations is a major concern in medical engineering. In this paper, we consider a class of soft two-phase composites, in which both phases are isotropic and hyperelastic neo-Hookean materials. For such an isotropic composite consisting of inclusions uniformly distributed but randomly oriented in a matrix, two constitutive parameters are required to characterize its hyperelastic constitutive relation. Micromechanics methods, including dilute concentration method, Mori–Tanaka method, self-consistent method, and differential method are extended to predict the effective properties of this kind of composites. Analytical solutions are given for the hyperelastic neo-Hookean composites reinforced by spherical particles, long fibers, and penny-shaped platelets, respectively. Finite element simulations are performed to evaluate the accuracy of these theoretical methods.

Similar content being viewed by others

References

Miracle, D.B.: Metal matrix composites-From science to technological significance. Compos. Sci. Technol. 65(15–16), 2526–2540 (2005)

Ashori, A.: Wood-plastic composites as promising green-composites for automotive industries!. Bioresour. Technol. 99(11), 4661–4667 (2008)

Holbery, J., Houston, D.: Natural-fiber-reinforced polymer composites applications in automotive. J. Miner. Met. Mater. Soc. 58(11), 80–86 (2006)

Rezwan, K., Chen, Q.Z., Blaker, J.J., Boccaccini, A.R.: Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 27(18), 3413–3431 (2006)

Kokubo, T., Kim, H.M., Kawashita, M.: Novel bioactive materials with different mechanical properties. Biomaterials 24(13), 2161–2175 (2003)

Fu, S.Y., Feng, X.Q., Lauke, B., Mai, Y.W.: Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. Part B Eng. 39(6), 933–961 (2008)

Zhou, K., Hoh, H.J., Wang, X., Keer, L.M., Pang, J.H.L., Song, B., Wang, Q.J.: A review of recent works on inclusions. Mech. Mater. 60, 144–158 (2013)

Sun, C.T., Vaidya, R.S.: Prediction of composite properties, from a representative volume element. Compos. Sci. Technol. 56(2), 171–179 (1996)

Frogley, M.D., Ravich, D., Wagner, H.D.: Mechanical properties of carbon nanoparticle-reinforced elastomers. Compos. Sci. Technol. 63(11), 1647–1654 (2003)

Ji, X.Y., Cao, Y.P., Feng, X.Q.: Micromechanics prediction of the effective elastic moduli of graphene sheet-reinforced polymer nanocomposites. Model. Simul. Mater. Sci. Eng. 18(4), 045005 (2010)

Eshelby, J.D.: The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 241(1226), 376–396 (1957)

Mori, T., Tanaka, K.: Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 21(5), 571–574 (1973)

Hill, R.: A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 13(4), 213–222 (1965)

Christensen, R.M.: A critical evaluation for a class of micromechanics models. J. Mech. Phys. Solids 38(3), 379–404 (1990)

Roscoe, R.: The viscosity of suspensions of rigid spheres. Br. J. Appl. Phys 3(8), 267–269 (1952)

Mura, T.: Micromechanics of Defects in Solids. Martinus Nijhoff Publishers, Dordrecht (1987)

Rivlin, R.S.: Large elastic deformations of isotropic materials IV: further developments of the general theory. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 241(835), 379–397 (1948)

Ahn, B., Kim, J.: Measurement and characterization of soft tissue behavior with surface deformation and force response under large deformations. Med. Image Anal. 14(2), 138–148 (2010)

Cox, M.A.J., Driessen, N.J.B., Boerboorn, R.A., Bouten, C.V.C., Baaijens, F.P.T.: Mechanical characterization of anisotropic planar biological soft tissues using finite indentation: experimental feasibility. J. Biomech. 41(2), 422–429 (2008)

Guo, Z.Y., Peng, X.Q., Moran, B.: A composites-based hyperelastic constitutive model for soft tissue with application to the human annulus fibrosus. J. Mech. Phys. Solids 54(9), 1952–1971 (2006)

Li, B., Cao, Y.P., Feng, X.Q., Gao, H.: Surface wrinkling of mucosa induced by volumetric growth: Theory, simulation and experiment. J. Mech. Phys. Solids 59(4), 758–774 (2011)

Miller, K.: Method of testing very soft biological tissues in compression. J. Biomech. 38(1), 153–158 (2005)

Meyers, M.A., Chen, P.Y., Lin, A.Y.M., Seki, Y.: Biological materials: Structure and mechanical properties. Prog. Mater. Sci. 53(1), 1–206 (2008)

Gasser, T.C., Ogden, R.W., Holzapfel, G.A.: Hyperelastic modelling of arterial layers with distributed collagen fibre orientations. J. R. Soc. Interface 3(6), 15–35 (2006)

Chen, H., Zhao, X.F., Lu, X., Kassab, G.: Non-linear micromechanics of soft tissues. Int. J. Non-Linear Mech. 56, 79–85 (2013)

Abolhassani, N., Patel, R., Moallem, M.: Needle insertion into soft tissue: a survey. Med. Eng. Phys. 29(4), 413–431 (2007)

Dorozhkin, S.V., Epple, M.: Biological and medical significance of calcium phosphates. Anal. Chem. 41(17), 3130–3146 (2002)

Cvetkovic, C., Raman, R., Chan, V., Williams, B.J., Tolish, M., Bajaj, P., Sakar, M.S., Asada, H.H., Saif, M.T.A., Bashir, R.: Three-dimensionally printed biological machines powered by skeletal muscle. Proc. Natl. Acad. Sci. USA 111(28), 10125–10130 (2014)

Liu, Y., Terrell, J.L., Tsao, C.Y., Wu, H.C., Javvaji, V., Kim, E., Cheng, Y., Wang, Y., Ulijn, R.V., Raghavan, S.R., Rubloff, G.W., Bentley, W.E., Payne, G.F.: Biofabricating multifunctional soft matter with enzymes and stimuli-responsive materials. Adv. Funct. Mater. 22(14), 3004–3012 (2012)

Qiu, G.Y., Pence, T.J.: Remarks on the behavior of simple directionally reinforced incompressible nonlinearly elastic solids. J. Elast. 49(1), 1–30 (1997)

Merodio, J., Ogden, R.W.: Mechanical response of fiber-reinforced incompressible non-linearly elastic solids. Int. J. Non-Linear Mech. 40(2–3), 213–227 (2005)

Guo, Z.Y., Peng, X.Q., Moran, B.: Mechanical response of neo-Hookean fiber reinforced incompressible nonlinearly elastic solids. Int. J. Solids Struct. 44(6), 1949–1969 (2007)

Chen, H., Liu, Y., Zhao, X., Lanir, Y., Kassab, G.S.: A micromechanics finite-strain constitutive model of fibrous tissue. J. Mech. Phys. Solids 59(9), 1823–1837 (2011)

Lopez-Pamies, O., Castaneda, P.P.: Second-order estimates for the macroscopic response and loss of ellipticity in porous rubbers at large deformations. J. Elast. 76(3), 247–287 (2004)

Castaneda, P.P.: Second-order homogenization estimates for nonlinear composites incorporating field fluctuations: I-Theory. J. Mech. Phys. Solids 50(4), 737–757 (2002)

Lopez-Pamies, O., Goudarzi, T., Nakamura, T.: The nonlinear elastic response of suspensions of rigid inclusions in rubber: I-An exact result for dilute suspensions. J. Mech. Phys. Solids 61(1), 1–18 (2013)

Lopez-Pamies, O., Goudarzi, T., Danas, K.: The nonlinear elastic response of suspensions of rigid inclusions in rubber: II-A simple explicit approximation for finite-concentration suspensions. J. Mech. Phys. Solids 61(1), 19–37 (2013)

Lopez-Pamies, O., Idiart, M.I., Nakamura, T.: Cavitation in elastomeric solids: I-A defect-growth theory. J. Mech. Phys. Solids 59(8), 1464–1487 (2011)

Shen, G.L., Hu, G.K.: Mechanics of Composite Materials. Tsinghua University Press, Beijing (2006)

Feng, X.Q.: On estimation methods for effective moduli of microcracked solids. Arch. Appl. Mech. 71(8), 537–548 (2001)

Walpole, L.J.: On overall elastic moduli of composite materials. J. Mech. Phys. Solids 17(4), 235–251 (1969)

Hashin, Z., Shtrikman, S.: A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 11(2), 127–140 (1963)

Ogden, R.W.: Non-linear Elastic Deformations. Ellis Horwood, Chichester (1984)

Acknowledgments

Supports from the National Natural Science Foundation of China (Grant Nos. 11432008 and 11542005) and Tsinghua University (20121087991) are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Nonlinear elasticity

Refer to \(\mathbf{X}\) and \(\mathbf{x}\) as the position of a material point in the initial and current configurations, respectively. The displacement of the material point is \(\mathbf{u}=\mathbf{x}-\mathbf{X}\). Thus the deformation gradient tensor \(\mathbf{F}\) reads

where \(\delta _{ij}\) is the Kronecker delta, \(u_{i,j}={\partial u_i }/{\partial X_j}\) are the displacement gradients, and \(\mathbf{e}_i\) are the base vectors.

The strain energy density function of a neo-Hookean hyperelastic material can be expressed as Eq. (1) in the main text. According to the theory of nonlinear elasticity [43], the Cauchy stress tensor can be derived as

where \(\mathbf{I}\) is the second-order identical tensor. Substituting Eq. (55) into (56), we obtain the Cauchy stresses

In the principal stretch coordinate system, the deformation gradient tensor becomes \(\mathbf{F}=\text {diag}\left\{ {\lambda _1, \lambda _2 ,\lambda _3} \right\} \), with \(\lambda _i \left( {i=1,2,3} \right) \) being the principal stretches. Correspondingly, \(I_1\) and \(I_3\) can be re-expressed as

where \(\varepsilon _i=\lambda _i-1\) are the principal Cauchy strains.

In the case of infinitesimal deformation, \(\left| {u_{i,j}} \right| <<1\), substituting Eq. (58) into (57) produces

where \(\varepsilon _{ij}\) denote the Cauchy strains.

Therefore, in the cases of infinitesimal deformation, the neo-Hookean constitutive model in Eq. (1) in the main text degenerates to the linear elastic Hooke’s law.

Appendix B: Simplified calculation of transversely isotropic tensors

An arbitrary transversely isotropic tensor \(\mathbf{H}\) possesses six independent parameters. When it has rotational symmetry about the \(x_1\) axis, \(\mathbf{H}\) can be written in a matrix form [39] as

where the six italic alphabets a – f are defined by

Using the Walpole’s method, a transversely isotropic tensor \(\mathbf{H}\) can be simply expressed as \(\mathbf{H}=\left( {b,g,h,d,e,f} \right) \). The algorithms of transversely isotropic tensors can readily be obtained in terms of matrices. For two transversely isotropic tensors \(\mathbf{H}_\chi =\left( {b_\chi , g_\chi , h_\chi ,d_\chi , e_\chi , f_\chi } \right) \), \((\chi =1,2)\), for example, their algorithms can be expressed as

Moreover, if \(\mathbf{H}\) is an isotropic tensor, it can be further simplified as \(\mathbf{H}=\left[ {\zeta , \eta } \right] \), where \(\zeta =3H_{1111}-4H_{1212} \)and\(\eta =2H_{1212}\). For two isotropic tensors \(\mathbf{H}_\chi =\left[ {\zeta _\chi , \eta _\chi } \right] \;\;,\;\;\left( {\chi =1,2} \right) \), one has the relations

Given the above notations, the algorithms of transversely isotropic tensors will become more intuitive. For example, the effective elastic stiffness tensor for the composites considered in this paper is isotropic and thus can be expressed as

For the inclusions, one can express their Eshelby tensors in similar forms, which can be used to calculate the LST tensor \({\varvec{\Pi }}\) and the OST tensor \({\varvec{\Omega }}\) easily.

Rights and permissions

About this article

Cite this article

Lin, SZ., Zhang, LY., Sheng, JY. et al. Micromechanics methods for evaluating the effective moduli of soft neo-Hookean composites. Arch Appl Mech 86, 219–234 (2016). https://doi.org/10.1007/s00419-015-1116-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-015-1116-2