Abstract

This paper presents simulation methodology that combines a local nonmatching grid with a discrete fracture model. Designed for 2D and 3D multiphase flow simulations in standard simulators, the method handles matrix–matrix, fracture–fracture, and matrix–fracture connections in the context of an unstructured, local nonmatching grid. The grid is generated at the fracture intersections, enabling accurate modeling of small control volumes between connecting fractures. Grids are obtained simply by redistributing the volume of small control volumes surrounding the small control volumes, making the method computationally efficient. A unified method to calculate the interblock transmissibility is used for both matching and nonmatching mesh. An unstructured finite-volume graph-based reservoir simulator with a two-point flux approximation reads the new grid by making a simple modification to the graph of connections between the control volumes. The method requires no special treatment of fracture–fracture or matrix–fracture transmissibility calculations and has the flexibility to simulate any flow problem efficiently. Several 2D and 3D numerical examples demonstrate the method’s performance and accuracy. Both simple and complex fracture configurations are presented with various levels of geologic and fluid complexity. The numerical results are in good agreement with those of a reference solution obtained on a finely structured grid.

Similar content being viewed by others

Notes

Mark of Schlumberger, Chevron and TOTAL.

Abbreviations

- A :

-

Area of the interface

- H :

- e :

-

Fracture thickness

- u:

- K :

-

Absolute permeability

- n:

- p :

-

Pressure

- P c :

-

Capillary pressure

- F :

-

Flow rate

- Φ:

-

Potential

- T :

-

Transmissibility

- c :

-

Defined in Eq. 4

- λ :

-

Fluid mobility

- μ :

-

Viscosity

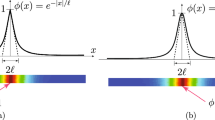

- ϕ :

-

Porosity

References

Mustapha H, Dimitrakopoulos R (2009) Discretizing complex fractured fields for incompressible two-phase flow. Int J Numer Methods Fluids 65:764–780

Mustapha H, Dimitrakopoulos R, Graf T, Firoozabadi A (2011) An efficient method for discretizing 3D fractured media for subsurface flow and transport simulations. Int J Numer Methods Fluids 67:651–670

Silliman SE, Berkowitz B (2000) The impact of biased sampling on the estimation of the semivariogram within fractured media containing multiple fracture sets. Math Geol 32:543–560

Michael S, Riley M (2004) An algorithm for generating rock fracture patterns: mathematical analysis. Math Geol 36:683–702

Dowd PA, Xu C, Mardia K et al (2007) A comparison of methods for the stochastic simulation of rock fractures. Math Geol 39:697–714

Bourgueat A (1984) Homogenized behavior of diphasic flow in naturally fissured reservoir with uniform fractures. Comput Methods Appl Mech Eng 47:205–217

Kazemi H, Gilman J (1969) Pressure transient analysis of naturally fractured reservoirs with uniform fracture distribution. SPE J 9:451–462

Kazemi H, Gilman J (1992) Analytical and Numerical solution of oil recovery from fractured reservoirs with empirical transfer functions. SPE J 7:219–227

Arbogast T, Douglas J, Hornung U (2004) Derivation of the double porosity model of single phase via homogenization theory. SIAM J Math Anal 21:823–836

Noorishad J, Mehran M (1982) An upstream finite element method for solution of transient transport equation in fractured porous media. Water Resour Res 18:588–596

Baca R, Arnett R, Langford D (1984) Modeling fluid flow in fractured porous rock masses by finite element techniques. Int J Numer Methods Fluids 4:337–348

Granet S, Fabrie P, Lemmonier P et al (1998) A single phase flow simulation of fractured reservoir using a discrete representation of fractures. Presented at the 6th European conference on the mathematics of oil recovery, Peebles, Scotland

Slough K, Sudicky E, Forsyth P (1999) Grid refinement for modeling multiphase flow in discretely fractured porous media. Adv Water Resour 23:261–269

Slough K, Sudicky E, Forsyth P (1999) Importance of rock matrix entry pressure on DNAPL migration in fractured geologic materials. Ground Water 37:237–243

Slough K, Sudicky E, Forsyth P (1999) Numerical simulation of multiphase flow and phase partitioning in discretely fractured geologic media. J Contam Hydrol 40:107–136

Kim J, Deo M (1999) Comparison of the performance of a discrete fracture multiphase model with those using conventional methods. Paper SPE 51928 presented at the SPE reservoir simulation symposium, Houston, Texas, 14–17 February 1999

Kim J, Deo M (2000) Finite element discrete fracture model for multiphase flow in porous media. AIChE J 46:1120–1130

Bastian P, Helmig R, Jakobs H et al (2000) Numerical simulation of multiphase flow in fractured porous media. In: Chen Z, Ewing RE, Shi ZC (eds) Numerical treatment of multiphase flows in porous media, vol 552., Lecture notes in physicsSpringer, Berlin, pp 1–18

Bastian P, Helmig R (1999) Efficient fully-coupled solution techniques for two-phase flow in porous media: parallel multigrid solution and large scale computations. Adv Water Resour 23:199–216

Bogdanov I, Mourzenko V, Thovert J et al (2003) Two-phase flow through fractured porous media. Phys Rev E 68:1–24

Geiger S, Roberts S, Matthai S et al (2004) Combining finite element and finite volume methods for efficient multiphase flow simulations in highly heterogeneous and structurally complex geologic media. Geofluids 4:284–299

Monteagudo J, Firoozabadi A (2004) Control-volume method for numerical simulation of two-phase immiscible flow in two- and three-dimensional discrete-fractured media. Water Resour Res 40:1–20

Matthai S, Mezentsev A, Belayneh M (2005) Control-volume finite-element two-phase flow experiments with fractured rock represented by unstructured 3D hybrid meshes. Paper SPE 93341 presented at the SPE reservoir simulation symposium, The Woodlands, Texas, 31 January–2 February 2005

Hoteit H, Firoozabadi A (2006) An efficient numerical model for incompressible two-phase flow in fractured media. Adv Water Resour 31:891–905

Karimi-Fard M, Durlofsky L, Aziz K (2006) An efficient discrete-fracture model applicable for general-purpose reservoir simulators. SPE J 9:227–236

Sandve TH, Berre I, Nordbotten JM (2012) An efficient multi-point flux approximation method for discrete fracture-matrix simulations. J Comput Phys 231:3784–3800

King PR (1989) The use of renormalization for calculating effective permeability. Transp Porous Media 4:37–58

Bernier C, Candus E, Faille I et al (2003) Maillages non Coincidents pour la Modelisation des Ecoulements en Milieux Poreux. Technical report 54 332, Institut Francais du Petrole, Rueil-Malmaison, France

Faille I, Nataf F, Saas L et al (2004) Finite volume methods on non-matching grids with arbitrary interface conditions and highly heterogeneous media. Domain decomposition methods in science and engineering, vol 40., Lecture notes in computer science engineeringSpringer, Berlin, pp 243–250

Saas L, Faille I, Nataf F et al (2005) Finite volume methods for domain decomposition on nonmatching grids with arbitrary interface conditions. SIAM J Numer Anal 43:860–890

Cao H, Tchelepi HA, Wallis J et al (2005) Parallel scalable unstructured CPR-type linear solver for reservoir simulation. Paper SPE 96809 presented at the SPE annual technical conference and exhibition, 9–12 October, Dallas, Texas. ISBN 978-1-55563-150-5

DeBaun D, Byer T, Childs P et al (2005) An extensible architecture for next generation scalable parallel reservoir simulation. Paper SPE 93274 presented at the SPE reservoir simulation symposium, Houston, Texas, 31 January–2 February 2005

Fjerstad PA, Sikandar AS, Cao H et al (2005) Next generation parallel computing for large-scale reservoir simulation. In: SPE international improved oil recovery conference in Asia Pacific, 5–6 December, Kuala Lumpur, Malaysia. ISBN 978-1-61399-001-8

INTERSECT Simulator. http://www.slb.com/services/software/reseng/intersect.aspx

Frey P, George PL (2008) Mesh generation: application to finite elements. Wiley, London

Karimi-Fard M, Firoozabadi A (2003) Numerical simulation of water injection in fractured media using discrete-fracture model and the Galerkin method. SPE Reserv Eval Eng 6:117

Coats KH, Thomas LK, Pierson RG (1998) Compositional and black oil reservoir simulation. SPE Res Eng 4:149–162. SPE-50990

Young LC, Russell TF (1993) Implementation of an adaptive implicit method. Paper SPE 25245 presented at the SPE reservoir simulation symposium, New Orleans, 28 February–3 March 1993

Quandalle P, Savary D (1989) An implicit in pressure and saturations approach to fully compositional simulation. Paper SPE 18423 presented at the SPE reservoir simulation symposium, Houston, 6–8 February 1989

Cao H, Aziz K (2002) Performance of IMPSAT and IMPSAT-AIM models in compositional simulation. Paper SPE 77720 presented at the SPE annual technical conference and exhibition, San Antonio, Texas, 29 September–2 October 2002

Coats KH (2003) IMPES stability: selection of stable timesteps. SPE J 8(2):181–187. SPE-84924

Ponting DK (1989) Corner point geometry in reservoir simulation. In: Proceedings of the European conference on the mathematics of oil recovery, Cambridge, England, 25–27 July 1989

Acknowledgments

We thank the Editor-in-Chief of Engineering with Computers handling our manuscript and the anonymous reviewers for their detailed comments that have helped improve the manuscript. The authors thank Schlumberger for the support and the permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mustapha, H. An efficient hybrid local nonmatching method for multiphase flow simulations in heterogeneous fractured media. Engineering with Computers 31, 347–360 (2015). https://doi.org/10.1007/s00366-014-0355-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-014-0355-0