Abstract

The synthesis and characterization of cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles are presented. Out of four functional monomers viz. allylurea, 1-vinylimidazole, acrylamide, and 1-allyl-2-thiourea, the last one was selected to produce a novel and selective separation material towards cadmium(II) ions. The energy dispersive X-ray spectroscopy confirmed the presence of monomer residues in the polymer matrix. The optimization of stoichiometry revealed that the highest binding capacity (3.79 ± 0.12 µg/g) and selectivity (imprinting factor of 13.68) were achieved when ion to monomer ratio was equal to 1:1. The structure, morphology and selectivity of imprinted polymer were examined. The imprinted particles possess regular, spherical shape and their surface is highly extended (10.31 ± 0.14 m2/g). The selectivity study towards ions which are present in the real sample showed highest uptake of cadmium(II) ions when compared to lead(II), cobalt(II) or nickel(II) ions with selectivity factors between 2.1 and 2.4.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cadmium ions take a particular position among other heavy metal ions because of their high environmental level and severe toxicity to humans [1, 2]. Therefore, the effective monitoring of cadmium concentration in the environmental and the biological samples has become mandatory according to the regional safety requirements in the industrialized parts of the world [3].

A number of sorbents were employed to remove cadmium ions, purify the sample or preconcentrate the analyte. Among them are clays, minerals (goethite, calcite), calcareous soil, zeolite, dead biomass or modified wool [4]. These materials possess high binding capacities, but insufficient selectivity. Hence, their practical application is limited. Therefore, the new separation materials that provide high selectivity are required and they could be obtained using the imprinting technology [5, 6].

Recently, several methods have been worked-up to produce the selective imprinted materials towards cadmium ions [7–10]. Candan and co-workers applied N-methacryloyl-(l)-cysteine methylester, a particular functional monomer that could interact with cadmium ions. The time-consuming synthesis of monomer and decrease of reproducibility limited the applicability of material [11]. In this study, thiourea in acidic medium was applied as the efficient ion sorbent in cleaning procedure to remove cadmium(II) ions out of imprinted poly(hydroxyethyl methacrylate-N-methacryloyl-(l)-cysteine methyl ester). Thiourea was also useful in toxic metal ion removal since commercial sorbent, Lewatit® was applied for removal of mercury(II) ions [12]. Moreover, thiourea-based ion-exchange resin for selective removal of cadmium ions was described [13]. The main disadvantages of such treatment were high consumptions of thiourea and the necessity to provide the post-eluting oxidation (to minimize the carcinogenic effect of thiourea). Li and co-workers [14, 15] described the surface imprinting or grafting cadmium ions on the surface of silica gel particles. The main drawback of surface imprinting is low binding capacity of the obtained separation material. The application of chitosan as the component of polymer matrix was described as the alternative material [16]. The imprinted polymer possessed high binding capacity, but unsatisfying mechanical properties hampered its usefulness. Hence, the investigations of new cadmium ion-imprinted polymers are still preponderant trends in scientific research.

The main purpose of our investigations is the preparation of imprinted polymer for the selective separation of cadmium(II) ions from acidified samples (tap water, industrial effluents, mineralized plants).

Hence, in this paper, we selected four functional monomers, viz. allylurea, 1-vinylimidazole, acrylamide, and 1-allyl-2-thiourea and we produced respective cadmium(II)-imprinted polymers. The imprinted polymer build up from 1-allyl-2-thiourea was chosen for detailed analysis on the basis of highest binding capacity and selectivity.

In the optimization of synthesis procedure of cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles, we analyzed the effect of stoichiometry of ion–monomer, the impact of pH of separation medium and the concentration of cadmium(II) ions on the adsorption process. Finally, the selectivity studies were carried out. Moreover, we characterized the structure and morphology of polymers.

Experimental

Materials

Cadmium nitrate tetrahydrate [Cd(NO3)2 × 4H2O] was purchased from POCh (Gliwice, Poland). 1-Allyl-2-thiourea, allylurea, 1-vinylimidazole, acrylamide and ethylene glycol dimethacrylate were from Sigma-Aldrich (Steinheim, Germany), and 2,2′-azobis(2-methylpropionitrile) was from Merck (Darmstadt, Germany). Methanol, acetone, 65 % nitric acid and methylene blue were from POCh (Gliwice, Poland). Ultra-pure water was delivered from Nanopure deionization system (Barnstead, USA) and was used for all water solutions. Cadmium(II), lead(II), cobalt(II) and nickel(II) atomic spectroscopy standards (concentration of 1 g/L) were purchased from Merck (Darmstadt, Germany). All standard solutions were prepared by dilution of appropriate stock solution with water prior to analysis.

Preparation of cadmium(II)-imprinted polymers

Cadmium(II)-imprinted polymers (coded as IP1 γ –IP4 α–ζ ) were prepared using the bulk polymerization technique. Briefly, cadmium nitrate as the template, selected functional monomer (allylurea, M1, 1-vinylimidazole, M2, acrylamide, M3, 1-allyl-2-thiourea, M4) and ethylene glycol dimethacrylate (cross-linker) were dissolved in methanol (porogen) in a thick-walled glass tubes. The stoichiometries between ion and selected functional monomer varied from 1:16 to 1:1 and were coded in greek symbols as follows: α 1:16, β 1:8, γ 1:4, δ 1:2, ε 2:3, ζ 1:1. Next, the initiator of polymerization process, 2,2′-azobis(2-methylpropionitrile), was added (Table 1). The homogeneous solutions were purged with nitrogen for ca. 3–5 min, and the glass tubes were sealed. Subsequently, the polymerization was carried out under a nitrogen atmosphere for 24 h at 64 °C. Generally, the bulk rigid polymer was ground in a mortar with a pestle and wet-sieved into the particles below 45-μm diameter. Fine particles were separated by repeated decantation in acetone. Cadmium(II) ions were then removed from the polymer particles with continuous extraction process in a Soxhlet apparatus (24–36 h, 80 mL, methanol) followed by exhaustive washing with 1 % aqueous nitric acid. Then, the particles were dried under vacuum at room temperature. Final ion removal was carried out in SPE cartridges with 1 % aq. nitric acid. The process was controlled, and the supernatant was analyzed by graphite-furnace atomic absorption spectrometry (GFAAS). Control, non-imprinted polymer (coded as CP4) was prepared from functional monomer M4 under the same polymerization conditions but without the addition of cadmium nitrate and was treated in the same way as the corresponding imprinted polymer.

Characterization of particles and selectivity study

Binding capacities were determined in the dynamic procedure. Empty, 1-mL polypropylene solid phase extraction (SPE) cartridges secured by fiberglass frits were filled with 10 or 25 mg of IP1 γ –IP4 α–ζ or CP4 particles. Next, the particles were conditioned either with water adjusted to pH 1 or pH 6 (1 mL), and the cadmium(II) standard solution (concentration of 20, 50, 100, 150, 200 μg/L) of pH 1 or pH 6 (1 mL), lead(II), cobalt(II) or nickel(II) standard solutions (concentration of 50 μg/L) of pH 1 (1 mL) were loaded. The supernatant was used to analyze the unbound amount of each ion by GFAAS. The bound amount was calculated by subtracting the unbound amount from the initial amount of ion.

The specific surface areas of IP4 γ –IP4 ζ and CP4 were determined by methylene blue adsorption tests followed by UV–Vis detection. The UV–Vis measurements were performed with a UV-1605PC spectrophotometer (Shimadzu, Germany) at λ max = 664.5 nm.

The 13C CP/MAS NMR spectra in solid-state were recorded at the Faculty of Pharmacy, Medical University of Warsaw, Poland, with a Bruker Avance DMX 400 spectrometer (Bruker, Germany). The powdered sample of polymers IP4 ζ was contained in 4-mm ZrO2 rotors, and was spun at 8 kHz. The 90° pulse length was 2.15 μs. A contact time of 4 ms and a repetition time of 10 s were used for accumulation of 8,200 scans. The chemical shifts δ ppm were referenced to TMS.

The thermogravimetry and differential scanning calorimetry analyses (TGA–DSC) of IP4 ζ were performed at the Department of Chemistry, Warsaw University of Technology, Poland, on Q600 thermogravimetric analyzer (TA Instruments, United States) in argon atmosphere with heating rate 5 °C/min.

The scanning electron microscopy (SEM) of IP4 α , IP4 ζ and CP4 and the energy dispersive X-ray spectroscopy analysis (EDS) of IP4 ζ were performed at Department of Chemistry, University of Warsaw, Poland on Merlin FE-SEM (Zeiss, Germany) combined with EDS X-ray detector (Brucker, Germany). The samples of the polymers were Au/Pd sputter coated before SEM analysis or were carbon coated before EDS analysis.

The determination of cadmium(II), lead(II), cobalt(II), and nickel(II) ions in all experiments except the real sample analysis was performed on the graphite-furnace atomic absorption spectrometry (GFAAS) on Avanta Ultra Z atomic absorption spectrometer (GBC Scientific Equippment, Australia) at λ max = 228.8 nm for cadmium(II), λ max = 217.0 nm for lead(II), λ max = 283.3 nm for cobalt(II) and λ max = 232.0 nm for nickel(II) ions. The determination of cadmium(II), lead(II), cobalt(II), and nickel(II) ions in tap water was performed on XSeries Quadrupole ICP MS (Thermo Electron Corporation, United Kingdom) at The Centre for Fire and Hazard Science, School of Forensic and Investigative Sciences, University of Lancashire, United Kingdom.

The preliminary SPE protocol for separation of cadmium(II) ions from cadmium-spiked tap water in the presence of coexisted ions was performed as follows: empty 1-mL polypropylene SPE cartridges secured by fiber glass frits were filled with 30 mg of dry IP4 ζ particles. Next, the particles were conditioned with acidified water adjusted to pH 4 (3 mL). Then acidified tap water spiked with cadmium(II) standard solution of 10 µg/L was loaded (0.05 mL). The cartridges were washed with water (1 mL), and eluted with 4 % aq. nitric acid (1 mL). The eluate was used to analyze the amounts of each ion by ICP MS.

Results and discussion

Effect of functional monomer on binding capacity of cadmium(II)-imprinted particles

In order to determine the binding capacities of imprinted polymers (IP1 γ –IP4 γ ) which were prepared from allylurea (M1), 1-vinylimidazole (M2), acrylamide (M3), 1-allyl-2-thiourea (M4), we carried out the dynamic-binding experiments (“Experimental”). The stoichiometry between the ion and the functional monomer was equal to 1:4. The binding capacities were determined while the cadmium(II) standard solution of pH 1 (concentration 50 µg/L) was applied. The binding capacities (B, μg/g) of imprinted polymers IP1 γ –IP4 γ were calculated [17] according to Eq. (1):

where V represents the volume of portion (mL) in loading step, C i represents the initial solution concentration (mg/L), C f represents the solution concentration after adsorption (mg/L) and m is the mass of polymer particles.

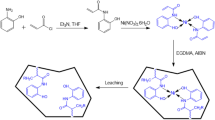

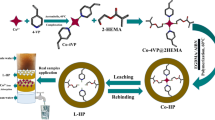

The imprinted polymers IP1 γ –IP4 γ differ significantly in the binding capacities. The interactions between the ion and the functional monomer are responsible for the formation of the prepolymerization complex, which modifies the surface of polymers during the polymerization step. The results revealed that the highest binding capacity was observed for imprinted polymer, which was produced from 1-allyl-2-thiourea (M4) (Table 2). Based on the literature data [18–20], we could suppose that 1-allyl-2-thiourea (M4), the monomer which possesses thiocarbonyl group, can strongly interact with cadmium(II) ions. The interactions between thiourea and cadmium(II) ions by X-ray diffraction method [18] as well as the properties of triallylthiourea cadmium chloride crystals by infrared spectroscopy and thermogravimetry were investigated [19, 20]. Therefore, the stable prepolymerization complex was formed, and the imprinted polymer with highly extended surface was obtained.

The schematic illustration of imprinting process is presented in Fig. 1.

Other monomers in tested polymeric systems possess either nitrogen and oxygen atoms (allylurea, M1 and acrylamide, M3) or only nitrogen atoms (1-vinylimidazole, M2). These monomers also interact with cadmium(II) ions, but those interactions are weaker. This fact could be responsible for the formation of polymers with less extended surface. In consequence, the lower binding capacities of imprinted materials are observed.

On the basis of the highest binding capacity, we selected the imprinted polymer IP4 γ build up from 1-allyl-2-thiourea (M4) for further optimization of synthetic procedures.

Effect of ion–monomer stoichiometry on binding capacity and selectivity of polymers in different pH of adsorption solution

In order to increase the binding capacity and the selectivity of cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles, we analyzed the impact of molar ratio between cadmium(II) ions and 1-allyl-2-thiourea in the polymerization system. We prepared six imprinted polymers with ion to monomer ratio of 1:16 (IP4 α ), 1:8 (IP4 β ), 1:4 (IP4 γ ), 1:2 (IP4 δ ), 2:3 (IP4 ε ), 1:1 (IP4 ζ ) as well as the control polymer (“Experimental”). We determined the binding capacities of IP4 α–ζ and CP4 according to Eq. (1), and we calculated the imprinting factors (IF) [17] according to Eq. (2):

The effect of stoichiometry was investigated when the standard solution of cadmium(II) of concentration 50 μg/L was applied at pH 6 and pH 1. The literature data show higher uptake of cadmium(II) ions on the imprinted polymers at pH 6 then at pH 1 [21–23]. At pH higher than 6, cadmium(II) ions precipitated out because of the high concentration of hydroxyl anions in the adsorption medium. Table 2 (left columns) presents the results for pH 6.

The results revealed that the binding capacities increased together with the increasing participation of cadmium(II) ions during the polymerization. The highest imprinting factor was noted for IP4 ζ when ion to monomer ratio was 1:1.

Table 2 (right columns) provides the results when the standard solution of cadmium(II) of concentration 50 μg/L adjusted to pH 1 with 1 % aq. nitric acid was applied. The same trend was observed and the binding capacities increased together with the increasing participation of cadmium(II) ions during the polymerization. Surprisingly, the polymers prepared with the higher participation of cadmium(II) during the polymerization (IP4 ε and IP4 ζ ) showed significantly higher adsorption in pH 1 than in pH 6. Moreover, nearly threefold lower amount of cadmium(II) was adsorbed on IP4 α , IP2 β and CP4 when compared to amounts adsorbed at pH 6. The significant increase of imprinting factor to 13.68 was observed for IP4 ζ . This is a proof that the high binding capacity and selectivity of prepared imprinted material was achieved while adsorption took place in acidic medium. The results revealed superiority of the novel polymer when compared to previous material which showed very low adsorption of cadmium(II) ions in low values of pH [23].

Impact of concentration on binding capacity

In order to analyze the impact of concentration of cadmium(II) ions in adsorption solution, we carried out the dynamic-binding experiments and we applied cadmium(II) standard solution of concentrations: 20, 50, 100, 150, 200 μg/L adjusted to pH 1 with 1 % aq. nitric acid. The results are presented in Table 3.

The binding capacity of IP4 ζ increased with the increasing concentration of cadmium(II) standard solution adjusted to pH 1. The saturation of imprinted polymer was achieved at the concentration of 100 μg/L, and the binding capacity noted for this concentration was fourfold higher that for concentration of 20 μg/L.

Morphology of particles

In order to determine the specific surface area of IP4 γ –IP4 ζ and CP4, we employed the methodology proposed by Kaewprasit and co-workers [24]. In this methodology, the specific surface area is measured by methylene blue adsorption because this compound is known to be adsorbed as a monolayer on solid sorbents. The methodology was applied successfully for the evaluation of the specific surface area of ion-imprinted materials [25]. The specific surface areas of IP4 γ –IP4 ζ and CP4 particles were calculated using Eq. (3):

where, A s is the imprinted and non-imprinted polymer specific surface area (m2/g), G is the amount of methylene blue adsorbed (g), N AV is the Avogadro’s number (6.02 × 1023/mol), ϕ is the methylene blue molecular cross-section (197.2 Å2), M W is the molecular weight of methylene blue (319.86 g/mol) and M is the mass of evaluated imprinted and non-imprinted polymer (g). The specific surface areas of IP4 γ –IP4 ζ and CP4 are presented in Table 4.

The specific surface areas of IP4 γ –IP4 ζ were higher than corresponding CP4. The specific surface areas of imprinted polymers increased along with the increasing amount of cadmium(II) ions during the polymerization process and was highest for IP4 ζ (with the stoichiometry ion to monomer equal to 1:1). The results confirmed that ion to monomer stoichiometry strongly affects the specific surface area of polymers and is responsible for the extension of surface of imprinted polymers.

The important parameter related to the binding capability of imprinted materials is the particles’ morphology, which is described as macro- and microporous structure. The field emission scanning electron microscopy (FE-SEM) was employed to observe the surface of selected particles, IP4 α , IP4 ζ , and CP4. The obtained micrographs are presented in Fig. 2.

The micrographs revealed the differences in the morphology of polymers prepared with various amounts of cadmium(II) ions during the polymerization. It could be seen that the bulk particles characterize the polymer IP4 α (stoichiometry ion–monomer equal to 1:16). They are irregular in size and shape with average diameter over 10 μm. Their surface is extended, and further magnification shows small non-uniform entitles that are joined together. Completely different is the surface of the polymer IP4 ζ (stoichiometry ion–monomer equal to 1:1). This polymer formed regular, spherical particles that are collected into bigger spherical conglomerates with diameter up to 3 μm. These particles are rather typical for the precipitation polymerization neither the bulk technique. The formation of regular beads is related to different stoichiometry and high concentration of cadmium(II) ions during the polymerization process. It should be underlined that despite of the different stoichiometry, the polymerization conditions were unchanged. The higher magnification revealed that IP4 ζ contains a lot of microspheres which have a diameter below 200 nm. They are also joined together and form bigger structures.

In contrary, the control polymer, CP4, shows moderate extension and relatively high heterogeneity of the surface.

Structure of polymers

To confirm the presence of functional groups in the imprinted material, the 13C CP/MAS NMR technique was used. In the Fig. 3, the spectrum of IP4 ζ is shown. The alkyl C atoms from the cross-linker are represented by broad peaks at 18 ppm (the methyl groups), at 45.4 ppm (the methylene groups in C–CH2–C), at 56.1 ppm (the quaternary C atoms), and at 62.7 ppm (the methylene groups in O–CH2CH2–O). The carbonyl C=O groups are represented by one broad resonance at 176.8 ppm. End fragments of CH2=C(CH3)CO2R are represented by low intensity signals at 166.7, 136.7 and 125.2 ppm. The resonances of thiocarbonyl C=S, and methylene CH2, CH2–N groups from the monomer overlapped on signals at 176.8, 56.1 and 45.4 ppm.

Moreover, we performed the EDS analysis for IP4 ζ . EDS (the energy dispersive X-ray spectroscopy analysis) is an analytical technique, which utilizes X-rays that are emitted from the polymer to identify the elemental composition of the polymer. Spectrum of the energy versus relative counts of detected X-rays was obtained and evaluated for the qualitative determinations of carbon, oxygen and sulfur atoms present in the samples. Additionally, the EDS spectroscopy could confirm the absence of imprinted cadmium(II) ions in the sample. Figure 4 presents the spectrum of IP4 ζ .

The analysis confirmed the qualitative content of imprinted polymer. The atoms originated from the functional monomer 1-allyl-2-thiourea, nitrogen and sulfur were detected in the regions of 0.4 and 2.3 keV, respectively. The analysis is a clear evidence of presence of residues from the functional monomer in the polymer matrix. It could be also seen that the spectrum showed no evidence of cadmium(II) ion (region of 3.1 keV). This fact could be a proof that the imprinted ions were successfully removed out of the polymer matrix.

Finally, we carried out the thermogravimetry analysis (TGA) and the differential scanning calorimetry (DSC) to observe the degradation of IP4 ζ as a function of temperature. The TGA curves are presented in Fig. 5. Line (a) presents the loss of weight as the function of temperature, line (b) is a derivative of weight loss as the function of temperature. As it could be seen, the initial decomposition process started at about 200 °C and was continued until 470 °C. It could be seen that decomposition consists of two stages with first maximum of weight loss at 251.4 °C, and the loss of nearly 16 % of total mass of imprinted polymer and second maximum at 419.8 °C and the loss of nearly 76 % of initial mass of imprinted material (total mass loss was 92 %). We could suppose that the initial decomposition is attributed to the short chain degradation as well as the decarboxylation process which is also responsible for stable decomposition in the range of 300–470 °C. The short maximum of weight loss at about 30–40 °C is associated with the loss of intrinsically bound water [26].

The DSC analysis in the range of temperatures between 150 and 500 °C is presented in Fig. 6.

The DSC curve of imprinted polymer shows two regions that correspond to both stages of decomposition (Fig. 5). Both processes are endothermic with values of 13.2 J/g for first maximum of weight loss at 252.4 °C and 106 J/g for second maximum at 420.4 °C.

Selectivity study and real sample analysis

In order to show the selectivity of IP4 ζ , we carried out the non-competitive dynamic-binding experiments with cadmium(II) ions as well as with lead(II), cobalt(II), and nickel(II) ions. The experiments were carried out with the standard solutions of each ion of 50 μg/L in pH 1. The binding capacity of Pb(II), Co(II) and Ni(II) on IP4 ζ was calculated according to Eq. (1). The selectivity factor (α) [23] was calculated according to Eq. (4):

where B Cd represents the binding capacity of cadmium(II), and B I represents the respective binding capacity of lead(II), cobalt(II) or nickel(II) ions.

The binding capacities were as follows: Cd(II) 1.000 ± 0.046 μg/L, Pb(II) 0.480 ± 0.040 μg/L, Co(II) 0.410 ± 0.060 μg/L, and Ni(II) 0.410 ± 0.050 μg/L. The calculated selectivity factors were: α Cd/Pb = 2.1, α Cd/Co = 2.4 and α Cd/Ni = 2.4. The results showed that the imprinted polymer IP4 ζ possesses the ability to the selective adsorption of cadmium(II) ions when compared to other ions of the same charge, but different ionic radii [27]. The lower adsorption of lead(II) ions could be explained by the bigger ionic radius of lead(II) ion (1.20 Ǻ) when compared to cadmium(II) ion (0.97 Ǻ). The spatial hindrance limited the adsorption of bigger ions into the imprinted polymer cavities. The lower adsorption of cobalt(II) or nickel(II) ions which possess smaller ionic radius (0.72 and 0.69 Ǻ, respectively) could be explained by the different geometries of ions. The results are the proof that the cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles are the promising material for the separation of cadmium(II) ions.

In order to verify applicability of cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles to the selective separation of cadmium(II) ions from the real samples, we analyzed tap water spiked with the cadmium(II) standard solution (concentration of 10 µg/L). We also determined lead(II), cobalt(II), and nickel(II) ions which are present in the sample as the competitive ions (the concentrations of ions in the sample: Cd(II) 10.0 ± 0.3 µg/L (0.04 ± 0.01 µg/L before tap water was spiked), Co(II) 0.1 ± 0.01 µg/L, Ni(II) 5.5 ± 0.3 µg/L, and Pb(II) 0.1 ± 0.01 µg/L). The preliminary SPE protocol (“Experimental”) was applied, and the amounts of ions detected in eluate were as follows: Cd(II) 0.3 ± 0.1 µg/L, Co(II) > LQ, Ni(II) > LQ, Pb(II) > LQ, where LQ is the limit of quantification. The results confirmed the selectivity of cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles towards cadmium(II) ions in competitive binding from real samples.

Conclusions

The novel and selective cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles were produced in the optimized protocol. Among four various functional monomers, viz. allylurea, 1-vinylimidazole, acrylamide, and 1-allyl-2-thiourea, the last one produced the imprinted polymer with the highest binding capacity. The highest selectivity was noted for the stoichiometry cadmium(II) ion to 1-allyl-2-thiourea equal to 1:1. The interactions between thiocarbonyl group in the monomer and cadmium(II) ions are responsible for the formation of stable prepolymerization complex and in consequence the preparation of imprinted material with highly extended surface. The analyses of SEM and specific surface area confirmed high extension of surface of imprinted particles, which possess regular and spherical shape. The EDS and 13C CP/MAS NMR confirmed the qualitative composition of imprinted polymers and the presence of C=S bonds in the polymer matrix. Moreover, the EDS analysis revealed the lack of cadmium(II) ions, which were efficiently removed in the post-polymerization process. The TGA–DSC analysis showed that the degradation process of imprinted polymer started at about 200 °C and lasted until 470 °C with two maxima of weight loss. The process of decomposition is endothermic. The imprinted polymer possesses high selectivity when compared to lead(II), cobalt(II) or nickel(II) ions. The selectivity was confirmed in preliminary SPE protocol proposed for the separation of cadmium(II) ions in the presence of cobalt(II), nickel(II) and lead(II) ions from tap water. The results are the proof that the cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles are promising material for the separation of cadmium(II) ions from acidified samples.

References

Ciftci H (2010) Separation and solid phase extraction method for determination of cadmium in environmental samples. Desalination 263:18–22

Amin AS, Gouda AA (2011) Utility of solid phase spectrophotometry for the modified determination of trace amounts of cadmium in food samples. Food Chem 132:518–524

World Health Organization (2011) Cadmium. In: WHO (ed) Guidelines for drinking water quality, 4th edn. Geneva, WHO, pp 327–328

Yavuz O, Guzel R, Aydin F, Tegin I, Ziyadanogullari R (2007) Removal of cadmium and lead from aqueous solution by calcite. Polish J Environ Stud 16:467–471

Piletsky S, Turner A (2006) Molecular imprinting of polymers. Landes-Bioscience, Georgetown

Prasada Rao T, Kala R, Daniel S (2006) Metal ion-imprinted polymers—novel materials for selective recognition of inorganics. Anal Chim Acta 578:105–116

Zhang N, Hu B (2012) Cadmium(II) imprinted 3-mercaptopropyltrimethoxysilane coated stir bar for selective extraction of trace cadmium from environmental water samples followed by inductively coupled plasma mass spectrometry detection. Anal Chim Acta 723:54–60

Fan H-T, Li J, Li Z-C, Sun T (2012) An ion imprinted amino-functionalized silica gel sorbent prepared by hydrothermal assisted surface imprinting technique for selective removal of cadmium(II) from aqueous solution. Appl Surf Sci 258:3815–3822

Nabid MR, Sedghi R, Bagheri A, Behbahani M, Taghizadeh M, Oskooie HA, Heravi MM (2012) Preparation and application of poly(2-aminothiophenol)/MWCNTs nanocomposite for adsorption and separation of cadmium and lead ions via solid phase extraction. J Hazard Mater 203–204:93–100

Segatelli MG, Santos VS, Braga A, Prestto T, Yoshida IVP, Tarley CRT (2010) Cadmium ion-selective sorbent preconcentration method using ion imprinted poly(ethylene glycol dimethacrylate-co-vinylimidazole). React Funct Polym 70:325–333

Candan N, Tuzmen N, Andac M, Andac CA, Say R, Denizli A (2009) Cadmium removal out of human plasma using ion-imprinted beads in a magnetic column. Mater Sci Eng C 29:144–152

Zuo G, Muhamed M (1995) Selective binding of mercury to thiourea-based coordinating resin. React Funct Polym 27:187–198

Mikhailov IO (2009) United States Patent US 2009/0078649 A1

Li Z-C, Fan H-T, Zhang Y, Chen M-X, Yu Z-Y, Cao X-Q, Sun T (2011) Cd(II)-imprinted polymer sorbents prepared by combination of surface imprinting technique with hydrothermal assisted sol-gel process for selective removal of cadmium(II) from aqueous solution. Chem Eng J 171:703–710

Li F, Jiang H, Zhang S (2007) An ion-imprinted silica-supported organic-inorganic hybrid sorbent prepared by a surface imprinting technique combined with a polysaccharide incorporated sol-gel process for selective separation of cadmium(II) from aqueous solution. Talanta 71:1487–1493

Buhani, Suharso, Sumadi (2010) Adsorption kinetics and isotherm of Cd(II) ion on Nannochloropsis sp. biomass imprinted ionic polymer. Desalination 259:140–146

Okutucu B, Telefoncu A (2008) Optimization of serotonin imprinted polymers and recognition study from platelet rich plasma. Talanta 76:1153–1158

Parvez M, Jalilehvand F, Amini Z (2012) Tetraaquabis(thiourea-κS)cadmium(II) triaquatris(thiourea-κS)cadmium(II) disulfate. Acta Cryst E68:m949–m950

Ginson PJ, Rajarajan K, Vimalan M, Salvakumar S, Ravi Kumar SM, Madhavan J, Sagayaraj P (2007) Spectroscopic, thermal and mechanical behavior of allylthiourea cadmium chloride single crystals. Mater Res Bull 42:2040–2047

Perumal R, Moorthy Babu S (2008) Growth and characterization of an organometallic nonlinear optical material tri-allylthiourea cadmium chloride (ATCC). Mater Chem Phys 107:23–27

Gawin M, Konefał J, Trzewik B, Walas S, Tobiasz A, Mrowiec H, Witek E (2010) Preparation of a new Cd(II)-imprinted polymer and its application to determination of cadmium(II) via flow-injection-flame atomic absorption spectrometry. Talanta 80:1305–1310

Buhani, Narsito, Nuryono, Kunarti ES (2010) Production of metal ion imprinted polymer from mercapto-silica through sol–gel process as selective adsorbent of cadmium. Desalination 251:83–89

Liu Y, Chang X, Wang S, Guo Y, Din B, Meng S (2004) Solid phase extraction and preconcentration of cadmium(II) in aqueous solution with Cd(II)-imprinted resin (poly-Cd(II)-DAAB-VP) packed columns. Anal Chim Acta 519:173–179

Kaewprasit C, Hequet E, Abidi N, Gourlot JP (1998) Application of methylene blue adsorption to cotton fiber specific surface area measurement: part I. methodology. J Cotton Sci 2:164–173

Singh D, Mishra S (2009) Synthesis, characterization and removal of Cd(II) using Cd(II)-ion imprinted polymer. J Hazard Mater 164:1547–1551

Svenson J, Nicholls IA (2001) On the thermal and chemical stability of molecularly imprinted polymers. Anal Chim Acta 435:19–24

Shannon RD, Prewitt CT (1969) Effective ionic radii in oxides and fluorides. Acta Cryst B25:925–946

Acknowledgments

Authors would like to thank Anna Machowska, M. Sc. under supervision of Dr. Anna Stec from The Centre for Fire and Hazard Science, School of Forensic and Investigative Sciences, University of Lancashire, United Kingdom, for ICP MS analysis of real samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Luliński, P., Kalny, P., Giebułtowicz, J. et al. Synthesis and characterization of cadmium(II)-imprinted poly(1-allyl-2-thiourea-co-ethylene glycol dimethacrylate) particles for selective separation. Polym. Bull. 71, 1727–1741 (2014). https://doi.org/10.1007/s00289-014-1151-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-014-1151-0