Abstract

The objective of this study was to investigate the influence of pH on texture, rheological properties and meltability of processed cheese analogues obtained using acid casein (AC) at 11, 12 or 13 % concentration or using 10 % AC with 1, 2 or 3 % acetylated distarch adipate (ADA) or hydroxypropyl distarch phosphate (HDP). Hardness, adhesiveness, cohesiveness and viscosity increased with protein or starch concentration. The increase in complex viscosity (η*) was greater for samples contained ADA than HDP. In general, starch-containing cheese analogues exhibited more viscous properties (tan δ > 1) in higher pH values (6.0–7.0) and more elastic properties (tan δ < 1) in lower pH values (4.5–5.5). All processed cheese analogues obtained at pH 5.0–7.0 presented good melting characteristics. These various characteristics analysed in the present study may ensure the valuable information for obtaining cheeses with proper textural/rheological properties and meltability.

Similar content being viewed by others

Introduction

Processed cheese is a food product obtained from the raw ingredients (cheddar cheese, skim milk powder, butter, salt, emulsifying salt and water) in the heating and shear processes [1]. A widespread consumption of processed cheese is due to its functional characteristics. Processed cheese has to comply with the requirements such as ability to form individual slices and melting in an assumed manner [2]. As a base for the production of processed cheese, natural cheeses are used, while processed cheese analogues are obtained through the partial or entire replacement of natural cheeses by milk or other proteins [3]. As a source of protein, rennet casein is widely used in the manufacture of processed cheese and analogues [4–7]. Recently, some studies were made in which acid casein was utilized [8, 9].

Waxy maize starch exhibits unique composition and has many food applications. It contains only the traces of amylose unlike the common starch which comprises 20–30/100 g of amylose. Therefore, waxy maize starch has many specific characteristics, e.g. good swellability, hard retrogradation and moreover present better digestibility than do normal starches [10]. Among all its features, the ability to form very viscous paste is considered as the most important property for starch application in food [11]. Native starches, albeit extensively used in food industry, have finite resistance to physical conditions used by contemporary food processing [12]. Compared to modified starches, they are characterized by low thermal stability, sensitivity to extreme pH conditions, and shear forces, likewise unsuitable rheological properties of pastes and gels [13]. Moreover, the usage of native starches is limited due to the retrogradation and tendency to syneresis. Thus, chemical or physical modification of starches is performed to obtain their improved physicochemical properties [14]. One of the most important chemical modifications in the starch industry is crosslinking, which involves replacement of the hydrogen bonding between starch chains by stronger covalent bonds. The examples of such starches commonly utilized in the food industry are distarch phosphates and distarch adipates. Crosslinking is very often used in conjunction with stabilization. As a consequence, for example, acetylated distarch adipate and hydroxypropyl distarch phosphate are obtained [15].

Casein is used in food products because of their functional properties, e.g. required structure, consistency, and fat emulsifying properties. Acid casein is characterized by higher water binding capacity compared to rennet casein [8] and prescribed as the product received after isolelectric precipitation (pH 4.6) of the caseins from milk followed by washing and drying [16]. Acetylated distarch adipate (ADA) provides better resistance to high temperature, shear and low pH, and it amends the textural properties of the finished product [14]. Hydroxypropyl distarch phosphate (HDP) characterizes by higher viscosity, resistance to retrogradation, stability in response to acids than native starches. Moreover, from nutrition point of view, it increases fat catabolism [17].

Ma et al. [18] found that pH, fat and moisture content influence the meltability of cheese. In the available literature, there is a lack of studies that compare starches in the processed cheese analogues at a wide range of different pH values, especially obtained on the basis of acid casein. Lee and Klostermeyer [19] also noticed that published studies upon the effect of pH on processed cheese foods are limited and include only products’ sensory or empirical evaluation. The use of oscillatory rheometry to characterize processed cheese analogues viscoelastic properties at different pH values is also limited. Moreover, it is an interesting issue to combine the excellent nutritional and functional properties of acid casein and modified maize starch in one product of numerous applications. Therefore, the present work investigates the effect of pH and two commercial modified waxy maize starches with different compositions (E-1422—acetylated distarch adipate and E-1442 hydroxypropyl distarch phosphate) on textural, rheological properties and meltability of processed cheese analogues obtained from acid casein.

Materials and methods

Materials

Modified waxy maize starch ADA (E-1422—acetylated distarch adipate) and HDP (E-1442 hydroxypropyl distarch phosphate) were produced by Cerestar Cargill (Indianapolis, IN, USA) and supplied by Agrotrade (Warsaw, Poland), while acid casein (AC, 92.1 % proteins, 1.4 % fat and 2.2 % ash) and anhydrous milk fat (AMF) were products of Polsero (Sokołów Podlaski, Poland) and Mlekovita (Wysokie Mazowieckie, Poland), respectively. Citric acid, disodium phosphate and sodium hydroxide were supplied by POCH S.A. (Gliwice, Poland).

Protein, fat and ash contents in acid casein were stated by the supplier.

Preparation of processed cheese analogues

AC (11, 12 or 13 %, w/w) or AC (10 %, w/w) with ADA (1, 2 or 3 %, w/w) or HDP (1, 2 or 3 %, w/w) was dissolved in distilled water using a magnetic stirrer (temperature 21 °C, 300 rpm). Dispersions were then mixed together with AMF (30 %, w/w) and AC (10 %, w/w) using a H 500 homogenizer (Pol-Eko Aparatura, Wodzisław Śląski, Poland) for 2 min at 10,000 rpm. After adding disodium phosphate (0.8 %), the pH was adjusted to 4.5, 5.0, 5.5, 6.0, 6.5 and 7.0 using 40 % citric acid or 2 mol dm−3 sodium hydroxide before the mixture was immersed in an 80 °C water bath and the contents were mixed at 10,000 rpm for 10 min according to the method proposed by Mleko and Foegeding [20]. Finished processed cheese analogues were poured into plastic containers. The samples were stored at room temperature for 30 min, and after that, they were stored overnight at 4 °C. The samples were removed from the refrigerator 1 h before measurement in order to reach the temperature of 21 °C. Due to the spreadable consistency of the samples, puncture test, texture and viscosity measurements were taken in plastic containers (cylindrical, sample size—40 mm in diameter and 40 mm in height). Every sample was prepared in triplicate. Final samples of processed cheese analogues were abbreviated as follows: AC—control sample, processed cheese analogue obtained solely from acid casein; AC + ADA—processed cheese analogue obtained on the basis of acid casein with the addition of acetylated distarch adipate; AC + HDP—processed cheese analogue obtained on the basis of acid casein with the addition of hydroxypropyl distarch phosphate.

Puncture test

Measurements were taken with a TA-XT2i Texture Analyser (Stable Micro Systems, Godalming, UK). The cheese samples were penetrated to 20 mm by a testing set (10 mm diameter). The penetration rate was 1 mm s−1. Three measurements were taken for each of the three replicates.

Texture profile analysis (TPA)

Measurements were taken with a TA-XT2i Texture Analyser (Stable Micro Systems, Godalming, UK). The processed cheese analogue samples were double punctured to 50 % of deformation by a testing set (15 mm diameter) according to the protocol described by Bonczar, Wszołek and Siuta [21]. The penetration rate was 1 mm s−1, and the intervals between measurements were 5 s. Cheese analogue samples were evaluated for adhesiveness and cohesiveness using Texture Expert software. Six measurements were taken for each of the three replicates.

Viscosity

Viscosity of processed cheese analogues was analysed using a Brookfield DV II + viscometer (Stoughton, MA, USA) with a Helipath Stand and T-bar spindle F according to the method described by Sołowiej et al. [8]. Measurements were taken in constant temperature (21 °C) with the spindle velocity 0.5 rpm. Three measurements were taken for each of the three replicates.

Viscoelastic properties

Processed cheese analogues were heated at 30–80 °C, and dynamic oscillatory measurement was taken using RS 300 oscillatory rheometer with parallel plate geometry (ThermoHaake, Karlsruhe, Germany). Complex viscosity (η*) and loss tangent (δ) were evaluated as described by Mounsey and O’Riordan [22]. A PP35Ti (Ø 35 mm) parallel plate geometry, gap of 2.8 mm, strain of 5 %, rate of temperature sweep (1.2 °C min−1) and frequency of 1 Hz were used for all oscillatory measurements. The strain corresponded to the maximum within the linear viscoelastic region. Rheological properties were analysed in triplicate.

Meltability

Meltability of processed cheese analogues was measured using a modified Schreiber test. Samples (4.8 mm thick, 41 mm in diameter) were placed on Petri dishes and heated in a microwave oven (Samsung, South Korea) at 300 W for 60 s, after which they were removed and cooled. Their expansion was measured along six lines marked on a concentric set of circles according to the method described by Mleko and Foegeding [20]. Schreiber meltability (arbitrary scale of 0–10 units) was given as the mean of three measurements for each of three replicates.

Statistical analysis

The statistical analyses were executed using the statistical software STATISTICA 7.0 PL (StatSoft Polska Sp. z o. o., Kraków, Poland). A four-factor ANOVA (casein concentration, starch concentration, the starch type and pH values) was carried out, and significant differences between samples were determined by Tukey’s post hoc test at P < 0.05.

Results and discussion

Puncture test

Table 1 shows the effect of pH and starch type and concentration on hardness of different processed cheese analogues measured by puncture test. Presented results indicate that hardness increased significantly (P < 0.05) with starch concentration. The samples containing ADA or HDP were characterized with higher hardness than the control samples with AC solely. The highest force was used to puncture the analogues obtained at pH 5.0 (i.e. 3.56 N for 10 % AC with 3 % ADA; 3.15 N for 10 % AC with 2 % ADA), and the lowest force was used to puncture the analogues obtained at pH 7.0 (i.e. 0.59 N for 10 % AC with 3 % ADA; 0.45 N for 10 % AC with 2 % ADA).

Lee and Klostermeyer [19] investigated the effect of pH on the rheological properties of model processed cheese spreads with reduced-fat content, made of sunflower oil and sodium caseinate. They noted significant (P < 0.05) decrease in the hardness values with an increase in pH from 5.0 to 5.4. Samples with higher pH values (up to 6.0) presented only slight decrease in hardness. Our research data are consistent with the Gampala and Brennan [1] observations who noticed that after the 1 or 2 % addition of starch to the processed cheese the hardness of the final product increased. Microscopic observations of imitation cheese have shown that there is little or no interaction between starch and the protein matrix [23]. So the main role of this polysaccharide seems to be constraining water and higher hardness of the product obtained in our study can be related to lower water mobility and, in consequence, lower protein hydration in the cheese matrix. The moisture in the cheese protein network acts as plasticizer making it more elastic. Addition of starch to processed cheese analogue (partial replacement of casein with starch) can improve its texture and consistency by immobilizing water. Cheese in which water is less mobile becomes harder.

Evaluation of the texture profile

Table 1 presents the effect of pH and starch type and concentration on the textural properties of the processed cheese analogues such as adhesiveness and cohesiveness. Samples with ADA at pH 4.5, 5.0 and 5.5 exhibited lower adhesiveness than control samples. On the contrary, processed cheese analogues with modified maize starches obtained at pH 6.0, 6.5 and 7.0 were characterized by higher adhesiveness than control samples. The highest adhesiveness values were noted for the samples with 3 % HDP addition obtained at pH 5.5 and 6.0 (7.63 N s and 8.25 N s, respectively). In our study, the most cohesive were samples with 3 % ADA or HDP obtained at pH 5.0 (0.99). The least cohesive was control sample obtained solely with 11 % AC at pH 5.0.

Gampala and Brennan [1] studied the effect of three commercially available starches (Amioca, Hi-maize 958 and Melogel) on the adhesiveness of processed cheese on the basis of the natural cheeses. Interestingly, no significant difference was observed between the adhesiveness of starch-enriched samples and the control ones. Mounsey and O’Riordan [7] observed that generally, in the imitation cheese products containing native starches of different botanical source, cohesiveness values decreased significantly (P ≤ 0.05) in comparison with the control samples. The authors explained this phenomenon with disruption of the imitation cheese matrix by swollen starch granules. Because crosslinked and stabilized waxy corn starches have limited swelling power in comparison with their native counterpart [24], they did not cause such effect.

Evaluation of the viscosity

Table 2 shows the effect of pH and starch type and concentration on viscosity of different processed cheese analogues. The viscosity of cheese samples increased significantly with increasing starch concentration. Among the control samples, processed cheese analogues with 11 % AC presented the lowest viscosity values. Interestingly, samples obtained at pH 6.5–7.0 presented the lowest viscosity values. Processed cheese analogues containing 3 % of ADA or HDP obtained at pH 6.0 had the highest viscosity values (9330 and 8790 Pa s, respectively). Similar results were obtained by Gampala and Brennan [1]. The starch addition to a model processed cheese formulation influenced on the higher values of the samples’ cook viscosity in comparison with the control samples. Authors noted that many causative factors affected these results. Ability to bind water and form a complex matrix after heating, but also the viscosity profile was connected to protein and fat presence in the processed cheese matrices (although the composition of these components remained unchanged). The replacement of the protein (at 15 %) with pre-gelatinized starches increased the apparent viscosity values as follows: “rice starch (26.3 mPa s) > waxy-maize (24.6 mPa s) > wheat (22.2 mPa s) > potato (21.6 mPa s) > maize (20.0 mPa s) starch” [7]. Luo et al. [25] studied the viscosity of acetylated distarch adipate at the range of pH values: 3.0–7.0. They observed that the viscosity of ADA slowly decreased with the decrease in pH value. It is also shown in our study in the pH ranges: 4.5–6.0. Probably, the effect was caused by the crosslinking groups that built ADA molecular chain, which made the swelling of the starch granules more difficult. Starch molecules became more resistant to the degradation process in the acidic pH. In our study, lower viscosity in pH 6.5 and 7.0 can be due to the environment of starch composed with acid casein and milk fat. Probably, in the more neutral pH, high concentration of casein and fat molecules effectively isolated the starch globules from each other making the internal cheese analogue’s structure more resistant.

Hydroxypropyl distarch phosphate (crosslinked and stabilized starch) is widely chosen modified starch in the manufacture of yoghurt production, where it maintains clarity, reduces syneresis and increases the viscosity. Crosslinking strengthens hydroxypropylated waxy corn starch which results in more vicious pastes and it gives higher stability to acid, heat treatment and shear forces [15]. That is why, within all range of pH values, the processed cheese analogues with HDP presented greater viscosity in comparison with the control samples. Addition of modified starch resulted in the ultimately more rigid structure of the processed cheese analogues with highly linked molecules.

Viscoelastic properties of processed cheese analogues

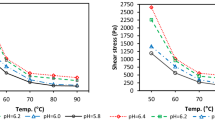

The complex viscosity values (η*) for the samples with 10 % AC and 2 % ADA or HDP were measured as a function of temperature (30–80 °C) (Fig. 1). Complex viscosity (η*) refers to both elastic and viscous deformation response [26]. Generally, in the first stage of heating, starch-containing cheese analogues were characterized with the decrease in η* values in the function of increasing temperature (except samples obtained at pH 5.0). At the temperature of about 40–45 °C, sudden increase in η* values was observed in most of the tested samples. The greatest η* values were observed for the samples obtained at pH 5.5 with 2 % ADA in the heating temperature range 45–50 °C (781.8–703.7 Pa s) and for the samples with 2 % ADA obtained at pH 6.0 in the heating temperature range 42–60 °C (399.4–297.9 Pa s). The lowest η* values were noted for the processed cheese analogues with 2 % ADA obtained at pH 6.5 in the heating temperature range 40–80 °C (11.05–2.35 Pa s). The highest η* values among the samples with HDP addition were observed at pH 5.5 in the heating temperature range 48–54 °C (508.4–460.7 Pa s).

Table 3 presents the effect of heating temperature on the tan δ value of processed cheese analogues prepared using 10 % AC with 2 % ADA or 10 % AC with 2 % HDP obtained at different pH values. The loss tangent (δ) values can provide a valuable information on meltability [22]. It gives an indication whether the material exhibits more liquid-like or solid-like behaviour [27]. When the tan (δ) > 1, processed cheese/analogues exhibit viscous characteristics, if not (i.e. tan (δ) < 1) processed cheese/analogues show elastic (gel) properties [8]. The transition temperature (crossover point) can be used to evaluate the transition from solid-like to liquid-like behaviour and vice versa [9]. In the present study, samples prepared with 10 % AC and 2 % ADA exhibited the lowest loss tangent (δ) value in 30 °C (0.539) at pH 5.5. With regard to samples prepared with 10 % AC and 2 % HDP presented the lowest loss tangent (δ) value in 30 °C at pH 5.0 and 5.5 (0.462 and 0.492 respectively), therefore these samples were among the most elastic. On the other hand, for the samples prepared with 10 % AC and 2 % ADA or HDP, the highest tan δ value was observed at pH 6.5 (2.946 and 2.962, respectively).

Boubellouta and Dufour [28] investigated the structure and rheology of cheeses: Comté and Raclette as a function of temperature. They assessed the complex viscosity (η*) tan δ of the samples and observed that η* values decreased, whereas tan δ values increased from 20 to 80 °C. Rise in complex viscosity at 40–45 °C in our study can be associated with the melting of milk fat (Fig. 1). According to Lopez et al. [29], the melting temperature of AMF ranges between 31 and 41 °C; however, in cheese analogues it oscillates within 40–41 °C. Melted fat in part fills spaces in the casein and starch matrix, and such structure is more packed, which increases the elasticity of cheese samples as previously confirmed by Sołowiej et al. [8].

Processed cheese analogues meltability

One of the functional properties of a great importance for processed cheese analogues and imitation cheese is meltability [30]. Schreiber melt test was implemented by Schreiber Foods (Green Bay, Wisconsin, USA) and is known as the commonly used empirical test for these types of products [31] albeit modified over the years. Table 2 illustrates the effect of pH and starch type on meltability of different processed cheese analogues measured by modified Schreiber test. All of the samples presented good melting characteristics (Schreiber test number >4) at all pH values, except the sample with 3 % ADA and 10 % of AC at the pH 4.5 (3.12). Samples containing starch illustrated lower meltability than control samples. As starch concentration increased in the samples at pH 4.5–7.0, their meltability decreased. Ye, Hewitt and Taylor [32] examined the effect of normal maize starch (25 % amylose), waxy maize starch (99 % amylopectin) and high amylose maize starch—HAMS (with 70 % amylose) on the rheological characteristics of model processed cheese. The modified Schreiber test was implemented to measure the meltability of the processed cheese. Processed cheese with normal maize starch presented very low melt values (0.6), which was due to the high ratio of starch to protein in the sample (0.83). Samples containing waxy maize starch also had lower meltability with increasing concentration of starch: ~4.7 (ratio of starch to protein 0.83). The reduction in the processed cheese meltability may be due to the bicontinuous phase structure with both: the protein and a starch phase observed in the processed cheese samples with a high concentration of starch [32]. Low meltability of imitation cheeses with low protein content is one of the main technological issues in these products [33], as water can be immobilized by swollen starch granules which can result in dehydration of the protein matrix. Lower water availability can increase hydrophobic protein–protein interactions [34]. It also leads to poor interaction of protein with fat phase which is responsible for good emulsification and in effect for good meltability of the cheese [35]. According to Finnie and Olsen [36], to have a meltability in an imitation cheese which would be similar to that of cheese, modified starch has to be used in an amount less than 5 %.

Conclusions

Variations in the type, concentration as well as casein and starch ratios caused significant modifications in the rheology, textural and melting properties of processed cheese analogues. Presented results in this study indicate that hardness, adhesiveness, cohesiveness and viscosity increased with increasing casein or starch concentration in the final product. A formation of firm casein–starch structure created during homogenization in high temperature caused an increase in processed cheese analogues hardness. In the case of processed cheese with ADA, in the neutral pH (6.5–7.0), high concentration of casein and fat molecules can isolate the starch globules from each other, making the internal cheese analogue’s structure more resistant and decrease the viscosity value of cheese samples. All samples obtained at pH 5.0–7.0 exhibited good meltability. Samples containing ADA were characterized by the greater increase in complex viscosity than samples with HDP. Rise in complex viscosity at 40–45 °C can be connected with the melting of milk fat in cheese samples. Generally, starch-containing cheese analogues exhibited more elastic properties (tan δ < 1) in lower pH values (4.5–5.5) and more viscous properties (tan δ > 1) in higher pH values (6.0–7.0). Samples containing HDP presented higher values of adhesiveness, meltability and viscosity than samples with ADA, in pH range 4.5–7.0 (except 5.0), 6.0–7.0 and 7.0, respectively. On the other hand, cheese analogues containing ADA exhibited better meltability in pH range 5.0–5.5. All presented results indicate that pH adjustment during manufacturing of starch-containing processed cheese analogues can diversify the finished product in terms of texture and meltability. The application of polysaccharide hydrocolloids, i.e. modified starches, can be used for obtaining highly viscous products intended primarily for spreading, packed in glass containers, or in thermoplastic materials, giving them different shapes. Moreover, the increase in hardness of the final product may be important for the preparation of cheese products for slicing. Furthermore, the use of modified starches in the preparation of processed cheese analogues can lower their production costs.

References

Gampala P, Brennan C (2008) Potential starch utilisation in a model processed cheese system. Starch Starke 60:685–689

Lucey JA, Johnson ME, Horne DS (2003) Perspectives on the basis of the rheology and texture properties of cheese. J Dairy Sci 86:2725–2743

Gustaw W, Mleko S (2007) The effect of polysaccharides and sodium chloride on physical properties of processed cheese analogs containing whey proteins. Milchwissenschaft 62:59–62

Chatziantoniou SE, Thomareis AS, Kontominas MG (2015) Effect of chemical composition on physico-chemical, rheological and sensory properties of spreadable processed whey cheese. Eur Food Res Technol 241:737–748

Lee SK, Huss M, Klostermeyer H, Anema SG (2013) The effect of pre-denatured whey proteins on the textural and microstructural properties of model processed cheese spreads. Int Dairy J 32:79–88

Mounsey JS, O’Riordan ED (2008) Influence of pre-gelatinised maize starch on the rheology, microstructure and processing of imitation cheese. J Food Eng 84:57–64

Mounsey JS, O’Riordan ED (2008) Modification of imitation cheese structure and rheology using pre-gelatinised starches. Eur Food Res Technol 226:1039–1046

Sołowiej B, Cheung IWY, Li-Chan ECY (2014) Texture, rheology and meltability of processed cheese analogues prepared using rennet or acid casein with or without added whey proteins. Int Dairy J 37:87–94

Sołowiej B, Glibowski P, Muszyński S, Wydrych J, Gawron A, Jeliński T (2015) The effect of fat replacement by inulin on the physicochemical properties and microstructure of acid casein processed cheese analogues with added whey protein polymers. Food Hydrocolloid 44:1–11

Diamantino VR, Beraldo FA, Sunakozawa TN, Penna ALB (2014) Effect of octenyl succinylated waxy starch as a fat mimetic on texture, microstructure and physicochemical properties of Minas fresh cheese. Lebensm Wiss Technol 56:356–362

Sarker MZI, Elgadir MA, Ferdosh S, Akanda MJH, Aditiawati P, Noda T (2013) Rheological behavior of starch-based biopolymer mixtures in selected processed foods. Starch Starke 65:73–81

Tharanathan RN (2005) Starch—value addition by modification. Crit Rev Food Sci 45:371–384

Witczak M, Juszczak L, Ziobro R, Korus J (2012) Influence of modified starches on properties of gluten-free dough and bread. Part I: rheological and thermal properties of gluten-free dough. Food Hydrocolloid 28:353–360

Gałkowska D, Długosz M, Juszczak L (2013) Effect of high methoxy pectin and sucrose on pasting, rheological, and textural properties of modified starch systems. Starch Stärke 65:499–508

White PJ, Tziotis A (2004) New corn starches. In: Eliasson A-C (ed) Starch in food Structure, functions and applications. CRC Press, Boca Raton

Rollema HS, Muir DD (2009) Casein and related products. In: Tamime AY (ed) Dairy powders and concentrated products. Wiley-Blackwell, Chichester

Shimotoyodome A, Suzuki J, Kameo Y, Hase T (2011) Dietary supplementation with hydroxypropyl-distarch phosphate from waxy maize starch increases resting energy expenditure by lowering the postprandial glucose-dependent insulinotropic polypeptide response in human subjects. Br J Nutr 106:96–104

Ma X, James B, Zhang L, Emanuelsson-Patterson EAC (2013) Correlating mozzarella cheese properties to its production processes and microstructure quantification. J Food Eng 115:154–163

Lee SK, Klostermeyer H (2001) The effect of pH on the rheological properties of reduced-fat model processed cheese spreads. Lebensm Wiss Technol 34:288–292

Mleko S, Foegeding EA (2000) Physical properties of rennet casein gels and processed cheese analogs containing whey proteins. Milchwissenschaft 55:513–516

Bonczar G, Wszołek M, Siuta A (2002) The effects of certain factors on the properties of yoghurt made from ewe’s milk. Food Chem 79:85–91

Mounsey JS, O’Riordan ED (1999) Empirical and dynamic rheological data correlation to characterize melt characteristics of imitation cheese. J Food Sci 64:701–703

Noronha N, O’Riordan ED, O’Sullivan M (2007) Replacement of fat with functional fibre in imitation cheese. Int Dairy J 17:1073–1082

Wo Y, Seib PA (1990) Acetylated and hydroxypropylated distarch phosphates from waxy barley: paste properties and freeze-thaw stability. Cereal Chem 67:202–208

Luo F, Huang Q, Fu X, Zhang L, Yu S (2009) Preparation and characterisation of crosslinked waxy potato starch. Food Chem 115:563–568

Kealy T (2006) Application of liquid and solid rheological technologies to the textural characterisation of semi-solid foods. Food Res Int 39:265–276

Yılmaz MT, Karaman S, Cankurt H, Kayacier A, Sagdic O (2011) Steady and dynamic oscillatory shear rheological properties of ketchup–processed cheese mixtures: effect of temperature and concentration. J Food Eng 103:197–210

Boubellouta T, Dufour É (2012) Cheese-matrix characteristics during heating and cheese melting temperature prediction by synchronous fluorescence and mid-infrared spectroscopies. Food Bioprocess Technol 5:273–284

Lopez C, Lavigne F, Lesieur P, Keller G, Ollivon M (2001) Thermal and structural behavior of anhydrous milk fat. 2. Crystalline forms obtained by slow cooling. J Dairy Sci 84:2402–2412

Hennelly PJ, Dunne PG, O’Sullivan M, O’Riordan D (2005) Increasing the moisture content of imitation cheese: effects on texture, rheology and microstructure. Eur Food Res Technol 220:415–420

Kapoor R, Metzger LE (2008) Process cheese: technological aspects—a review. Compr Rev Food Sci F 7:194–214

Ye A, Hewitt S, Taylor S (2009) Characteristics of rennet–casein-based model processed cheese containing maize starch: rheological properties, meltabilities and microstructures. Food Hydrocolloid 23:1220–1227

Kiziloz MB, Cumhur O, Kilic M (2009) Development of the structure of an imitation cheese with low protein content. Food Hydrocolloid 23:1596–1601

Trivedi D, Bennett RJ, Hemar Y, Reid DCW, Lee SK, Illingworth D (2008) Effect of different starches on rheological and microstructural properties of (II) commercial processed cheese. Int J Food Sci Technol 43:2197–2203

Ennis MP, Mulvihill DM (1999) Compositional characteristics of rennet caseins and hydration characteristics of the caseins in a model system as indicators of performance in Mozzarella cheese analogue manufacture. Food Hydrocolloid 13:325–337

Finnie KJ, Olsen RL (1996) Imitation cheese composition and products containing starch. United States Patent No: 5807601, 09.09.1996

Acknowledgments

We gratefully acknowledge Agrotrade (Warsaw, Poland) for providing starches, used in the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Sołowiej, B., Dylewska, A., Kowalczyk, D. et al. The effect of pH and modified maize starches on texture, rheological properties and meltability of acid casein processed cheese analogues. Eur Food Res Technol 242, 1577–1585 (2016). https://doi.org/10.1007/s00217-016-2658-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-016-2658-4