Abstract

Brewer’s spent grain (BSG) is the most abundant by-product of the brewing industry, constituting approximately 85 % (w/w) of the total by-products generated during beer production. Rich in cellulose and non-cellulosic polysaccharides, lignin, and proteins, BSG provides extra nutritional value, thereby arousing the interest of the food industry. Annually, around 3.4 million t of BSG are produced within the European Union, and Germany contributes approximately 2 million t. BSG is reused either substantial or energetic. However, its main application has been limited to animal feeding. Based on the intense global pressure toward green environmental technology and increasing regulations in the feed sector, alternative application fields have gained importance. Because of its high protein and fiber contents, BSG can be an attractive source for value-added products in human nutrition. The focus is on the reported health effects of (1–3,1–4)-β-d-glucan and arabinoxylan (AX). Several scientific studies have shown that barley (1–3,1–4)-β-d-glucan reduces blood cholesterol levels. A cause and effect relationship has been established between the consumption of AX from wheat endosperm and the reduction of postprandial glycemic responses. The intention of this review is to focus on the extraction of (1–3,1–4)-β-d-glucan and AX from BSG as a source of value-added compounds for use as a nutraceutical. In view of AX and (1–3,1–4)-β-d-glucan yield, different methods of extraction are presented. Finally, technological trends and future perspectives to expand this market are discussed, focusing on promising strategies such as the use of pressurized hot water extraction.

Similar content being viewed by others

Abbreviations

- BSG:

-

Brewer’s spent grain

- LFGB:

-

Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch

- VIG:

-

Verbraucherinformationsgesetz

- EFSA:

-

European Food Safety Authority

- LDL:

-

Low-density lipoprotein

- EU:

-

European Union

- HCR:

-

Health Claims Regulation

- M w :

-

Molecular weight average

- DP:

-

Degree of polymerization

- AX:

-

Arabinoxylan

References

Canadean (2012) Anteil einzelner Getränke am weltweiten Getränkekonsum im Jahr 2011. Statista, Sachon

Brauer-Bund D (2014) Bierausstoß der Brauereien in Deutschland in den Jahren 1991 bis 2013 (in Millionen Hektolitern). Statista, Statista

Group B-H (2014) Bierausstoß weltweit in den Jahren 1995 bis 2013 (in Milliarden Hektoliter). Statista, de.statista.com

Townsley PM (1979) Preparation of commercial products from brewer’s waste grain and trub. MBAA Tech Q 16(3):130–134

McCarthy AL, O’Callaghan YC, Piggott CO, FitzGerald RJ, O’Brien NM (2013) Brewers’ spent grain; bioactivity of phenolic component, its role in animal nutrition and potential for incorporation in functional foods: a review. Proc Nutr Soc 72(1):117–125. doi:10.1017/s0029665112002820

Mussatto SI, Dragone G, Roberto IC (2006) Brewers’ spent grain: generation, characteristics and potential applications. J Cereal Sci 43(1):1–14. doi:10.1016/j.jcs.2005.06.001

Kunze W (1998) Technologie Brauer und Mälzer. Versuchs- und Lehrsnstalt für Brauerei in Berlin (VLB), VLB Brelin

Weber G (2009) Untersuchungen zur Silierung von Biertrebern. Logos Verlag, Berlin

Robertson JA, I’Anson KJA, Treimo J, Faulds CB, Brocklehurst TF, Eijsink VGH, Waldron KW (2010) Profiling brewers’ spent grain for composition and microbial ecology at the site of production. LWT Food Sci Technol 43(6):890–896. doi:10.1016/j.lwt.2010.01.019

Gupta S, Jaiswal AK, Abu-Ghannam N (2013) Optimization of fermentation conditions for the utilization of brewing waste to develop a nutraceutical rich liquid product. Ind Crops Prod 44:272–282. doi:10.1016/j.indcrop.2012.11.015

Pesta G (2008) Biertreberhydrolyseverfahren. Deutschland Patent

Blümelhuber G (2002) Einfluß von Fettsäuren und Pflanzenölen auf die Eigenschaften eines Faser-Epoxydharz-Verbundwerkstoffs. Dissertation TU München

Pappu A, Saxena M, Asolekar SR (2007) Solid wastes generation in India and their recycling potential in building materials. Build Environ 42(6):2311–2320. doi:10.1016/j.buildenv.2006.04.015

Aliyu S, Bala M (2011) Brewer’s spent grain: a review of its potentials and applications. Afr J Biotechnol 10(3):324–331. doi:10.5897/AJBx10.006

Moreira MM, Morais S, Carvalho DO, Barros AA, Delerue-Matos C, Guido LF (2013) Brewer’s spent grain from different types of malt: Evaluation of the antioxidant activity and identification of the major phenolic compounds. Food Res Int 54(1):382–388. doi:10.1016/j.foodres.2013.07.023

Commission E (2012) establishing a list of permitted health claims made on foods, other than those referring to the reduction of disease risk and to children’s development and health. L 136/1, vol 432/2012. Official Journal of the European Union

Endreß HU (2000) High quality resulting from product integrated protection: PIUS. Fruit Process 10:273–276

Kunzek H, Opel H, Senge B (1997) Rheological examination of material with cellular structure. II. Creep and oscillation measurements of apple material with cellular structure. Zeitschrift für Lebensmitteluntersuchung und Forschung 205:193–203

Senge B, Opel H, Kunzek H (1996) Rheologische Untersuchungen von zellstrukturierten Materialien. 1. Mitteilung: Konventionelle Untersuchung von zellstrukturiertem Apfelmaterial. Zeitschrift für Lebensmitteluntersuchung und Forschung 203:351–365

Cao L, Liu X, Qian T, Sun G, Guo Y, Chang F, Zhou S, Sun X (2011) Antitumor and immunomodulatory activity of arabinoxylans: a major constituent of wheat bran. Int J Biol Macromol 48(1):160–164. doi:10.1016/j.ijbiomac.2010.10.014

Estrada A, Yun CH, Van Kessel A, Li B, Hauta S, Laarveld B (1997) Immunomodulatory activities of oat β-glucan in vitro and in vivo. Microbiol Immunol 41(12):991–998

Hussain A, Claussen B, Ramachandran A, Williams R (2007) Prevention of type 2 diabetes: a review. Diabetes Res Clin Pract 76(3):317–326. doi:10.1016/j.diabres.2006.09.020

Meyer D, Stasse-Wolthuis M (2009) The bifidogenic effect of inulin and oligofructose and its consequences for gut health. Eur J Clin Nutr 63(11):1277–1289

Niewold TA, Schroyen M, Geens MM, Verhelst RSB, Courtin CM (2012) Dietary inclusion of arabinoxylan oligosaccharides (AXOS) down regulates mucosal responses to a bacterial challenge in a piglet model. J Funct Foods 4(3):626–635

Qiang X, YongLie C, QianBing W (2009) Health benefit application of functional oligosaccharides. Carbohydr Polym 77(3):435–441. doi:10.1016/j.carbpol.2009.03.016

Samuelsen AB, Rieder A, Grimmer S, Michaelsen TE, Knutsen SH (2011) Immunomodulatory activity of dietary fiber: arabinoxylan and mixed-linked beta-glucan isolated from barley show modest activities in vitro. Int J Mol Sci 12(1):570–587

Zhang C, Huang K (2005) Characteristic immunostimulation by MAP, a polysaccharide isolated from the mucus of the loach, Misgurnus anguillicaudatus. Carbohydr Polym 59(1):75–82

Stojceska V, Ainsworth P (2008) The effect of different enzymes on the quality of high-fibre enriched brewer’s spent grain breads. Food Chem 110(4):865–872. doi:10.1016/j.foodchem.2008.02.074

Celus I, Brijs K, Delcour JA (2007) Enzymatic hydrolysis of brewers’ spent grain proteins and technofunctional properties of the resulting hydrolysates. J Agric Food Chem 55(21):8703–8710. doi:10.1021/jf071793c

da Silva AM, Tavares APM, Rocha CMR, Cristóvão RO, Teixeira JA, Macedo EA (2012) Immobilization of commercial laccase on spent grain. Process Biochem 47(7):1095–1101. doi:10.1016/j.procbio.2012.03.021

Poerschmann J, Weiner B, Wedwitschka H, Baskyr I, Koehler R, Kopinke FD (2014) Characterization of biocoals and dissolved organic matter phases obtained upon hydrothermal carbonization of brewer’s spent grain. Bioresour Technol 164:162–169. doi:10.1016/j.biortech.2014.04.052

Forssell P, Kontkanen H, Schols HA, Hinz S, Eijsink VGH, Treimo J, Robertson JA, Waldron KW, Faulds CB, Buchert J (2008) Hydrolysis of brewers’ spent grain by carbohydrate degrading enzymes. J Inst Brew 114(4):306–314. doi:10.1002/j.2050-0416.2008.tb00774.x

Santos M, Jiménez JJ, Bartolomé B, Gómez-Cordovés C, del Nozal MJ (2003) Variability of brewer’s spent grain within a brewery. Food Chem 80(1):17–21. doi:10.1016/S0308-8146(02)00229-7

Kissel LT, Prentice N (1979) Protein and fiber enrichment of cookie flour with brewers’ spent grain. Cereal Chem 56:261–266

Coelho E, Rocha MA, Saraiva JA, Coimbra MA (2014) Microwave superheated water and dilute alkali extraction of brewers’ spent grain arabinoxylans and arabinoxylo-oligosaccharides. Carbohydr Polym 99:415–422. doi:10.1016/j.carbpol.2013.09.003

Kabel MA, Carvalheiro F, Garrote G, Avgerinos E, Koukios E, Parajó JC, Gı́rio FM, Schols HA, Voragen AGJ (2002) Hydrothermally treated xylan rich by-products yield different classes of xylo-oligosaccharides. Carbohydr Polym 50(1):47–56. doi:10.1016/S0144-8617(02)00045-0

Mandalari G, Faulds CB, Sancho AI, Saija A, Bisignano G, LoCurto R, Waldron KW (2005) Fractionation and characterisation of arabinoxylans from brewers’ spent grain and wheat bran. J Cereal Sci 42(2):205–212. doi:10.1016/j.jcs.2005.03.001

Kanauchi O, Mitsuyama K, Araki Y (2001) Development of a functional germinated barley foodstuff from brewer’s spent grain for the treatment of ulcerative colitis. J Am Soc Brew Chem 59(2):59–62

Mussatto SI, Roberto IC (2005) Acid hydrolysis and fermentation of brewer’s spent grain to produce xylitol. J Sci Food Agric 85(14):2453–2460. doi:10.1002/jsfa.2276

Russ W, Mörtel H, Meyer-Pittroff R (2005) Application of spent grains to increase porosity in bricks. Constr Build Mater 19(2):117–126

Rudi H, Uhlen AK, Harstad OM, Munck L (2006) Genetic variability in cereal carbohydrate compositions and potentials for improving nutritional value. Anim Feed Sci Technol 130(1–2):55–65. doi:10.1016/j.anifeedsci.2006.01.017

Skendi A, Biliaderis CG, Lazaridou A, Izydorczyk MS (2003) Structure and rheological properties of water soluble β-glucans from oat cultivars of Avena sativa and Avena bysantina. J Cereal Sci 38(1):15–31. doi:10.1016/S0733-5210(02)00137-6

Bacic A, Stone B (1981) Isolation and ultrastructure of aleurone cell walls from wheat and barley. Funct Plant Biol 8(5):453–474. doi:10.1071/PP9810453

Fincher GB (1975) Morphology and chemical composition of barley endosperm cell walls. J Inst Brew 81(2):116–122. doi:10.1002/j.2050-0416.1975.tb03672.x

Forrest IS, Wainwright T (1977) The mode of binding of β-glucans and pentosans in barley endosperm cell walls. J Inst Brew 83(5):279–286. doi:10.1002/j.2050-0416.1977.tb03809.x

Gómez C, Navarro A, Manzanares P, Horta A, Carbonell JV (1997) Physical and structural properties of barley (1 → 3), (1 → 4)-β-d-glucan. Part II. Viscosity, chain stiffness and macromolecular dimensions. Carbohydr Polym 32(1):17–22. doi:10.1016/S0144-8617(96)00127-0

Wood PJ (2004) Relationships between solution properties of cereal β-glucans and physiological effects: a review. Trends Food Sci Technol 15(6):313–320. doi:10.1016/j.tifs.2003.03.001

Fincher GB, Stone BA (2004) Chemistry of non-starch polysaccharides. Encyclopedia of grain science. Elsevier, Oxford

Izydorczyk MS, Dexter JE (2008) Barley β-glucans and arabinoxylans: Molecular structure, physicochemical properties, and uses in food products: a review. Food Res Int 41(9):850–868. doi:10.1016/j.foodres.2008.04.001

Bijkerk CJ, Muris JWM, Knottnerus JA, Hoes AW, De Wit NJ (2004) Systematic review: the role of different types of fibre in the treatment of irritable bowel syndrome. Aliment Pharmacol Ther 19(3):245–251. doi:10.1111/j.0269-2813.2004.01862.x

Howarth NC, Saltzman E, Roberts SB (2001) Dietary fiber and weight regulation. Nutr Rev 59(5):129–139

Truswell AS (2002) Cereal grains and coronary heart disease. Eur J Clin Nutr 56(1):1–14. doi:10.1038/sj.ejcn.1601283

Reimer RA, Thomson ABR, Rajotte RV, Basu TK, Ooraikul B, McBurney MI (2000) Proglucagon messenger ribonucleic acid and intestinal glucose uptake are modulated by fermentable fiber and food intake in diabetic rats. Nutr Res 20(6):851–864. doi:10.1016/S0271-5317(00)00169-X

Thorburn A, Muir J, Proietto J (1993) Carbohydrate fermentation decreases hepatic glucose output in healthy subjects. Metabolism 42(6):780–785. doi:10.1016/0026-0495(93)90249-N

Keogh GF, Cooper GJS, Mulvey TB, McArdle BH, Coles GD, Monro JA, Poppitt SD (2003) Randomized controlled crossover study of the effect of a highly β-glucan-enriched barley on cardiovascular disease risk factors in mildly hypercholesterolemic men. Am J Clin Nutr 78(4):711–718

Dikeman CL, Fahey GC (2006) Viscosity as related to dietary fiber: a review. Crit Rev Food Sci Nutr 46(8):649–663. doi:10.1080/10408390500511862

Wood PJ, Weisz J, Blackwell BA (1994) Structural studies of (1/3) (1/4)-b-d-glucans by 13C-NMR by rapid analysis of cellulose-like regions using high-performance anion-exchange chromatography of oligosaccharides released by lichenase. Cereal Chem 71:301–307

Tappy L, Gugolz E, Wursch P (1996) Effects of breakfast cereals containing various amounts of beta-glucan fibers on plasma glucose and insulin responses in NIDDM subjects. Diabetes Care 19(8):831–834

Wood PJ, Beer MU, Butler G (2000) Evaluation of role of concentration and molecular weight of oat beta-glucan in determining effect of viscosity on plasma glucose and insulin following an oral glucose load. Br J Nutr 84(1):19–23

EFSA Panel on Dietetic Products NaAN (2009) Scientific Opinion on the substantiation of health claims related to beta glucans and maintenance of normal blood cholesterol concentrations (ID 754, 755, 757, 801, 1465, 2934) and maintenance or achievement of a normal body weight (ID 820, 823) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J 7(9):1254:18 pp

Venn BJ, Green TJ (2007) Glycemic index and glycemic load: measurement issues and their effect on diet-disease relationships. Eur J Clin Nutr 61(Suppl 1):S122–S131. doi:10.1038/sj.ejcn.1602942

Ceriello A, Davidson J, Hanefeld M, Leiter L, Monnier L, Owens D, Tajima N, Tuomilehto J (2006) Postprandial hyperglycaemia and cardiovascular complications of diabetes: an update. Nutr Metab Cardiovasc Dis 16(7):453–456. doi:10.1016/j.numecd.2006.05.006

EFSA Panel on Dietetic Products NaAN (2011) Scientific Opinion on the substantiation of health claims related to beta-glucans from oats and barley and maintenance of normal blood LDL-cholesterol concentrations (ID 1236, 1299), increase in satiety leading to a reduction in energy intake (ID 851, 852), reduction of post-prandial glycaemic responses (ID 821, 824), and “digestive function” (ID 850) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J 9(6):2207:21 pp

EFSA Panel on Dietetic Products NaAN (2011) Scientific Opinion on the substantiation of a health claim related to barley beta-glucans and lowering of blood cholesterol and reduced risk of (coronary) heart disease pursuant to Article 14 of Regulation (EC) No 1924/2006. EFSA J 9(12):2471:13 pp

Andersson AAM, Elfverson C, Andersson R, Regnér S, Åman P (1999) Chemical and physical characteristics of different barley samples. J Sci Food Agric 79(7):979–986. doi:10.1002/(SICI)1097-0010(19990515)79:7<979:AID-JSFA313>3.0.CO;2-L

Hong BH, Rubenthaler GL, Allen RE (1995) Wheat pentosans. I. Cultivar variation and relationship to kernel hardness. Cereal Chem 66:369–373

Saulnier L, Peneau N, Thibault JF (1995) Variability in grain extract viscosity and water-soluble arabinoxylan content in wheat. J Cereal Sci 22(3):259–264. doi:10.1006/jcrs.1995.0062

Hoffmann RA, Leeflang BR, de Barse MMJ, Kamerling JP, Vliegenthart JFG (1991) Characterisation by 1H-n.m.r. spectroscopy of oligosaccharides, derived from arabinoxylans of white endosperm of wheat, that contain the elements →4)[α-l-Araf-(1-ar3)]-β-d-Xylp-(1→ or →4)[α-l-Araf-(1→2)][α-lAraf-(1→3)]-β-d-Xylp-(1→. Carbohydr Res 221(1):63–81. doi:10.1016/0008-6215(91)80049-S

Izydorczyk MS, Biliaderis CG (1994) Studies on the structure of wheat-endosperm arabinoxylans. Carbohydr Polym 24(1):61–71. doi:10.1016/0144-8617(94)90118-X

Perlin AS (1951) Structure of the soluble pentosans of wheat flours. Cereal Chem 28:382–393

Renard CMGC, Rouau X, Thibault JF (1990) Structure and properties of water-soluble pentosans from wheat flour. Sci Alim 10:283–292

Gruppen H, Hamer RJ, Voragen AGJ (1991) Barium hydroxide as a tool to extract pure arabinoxylans from water-insoluble cell wall material of wheat flour. J Cereal Sci 13(3):275–290. doi:10.1016/S0733-5210(09)80006-4

Li Y, Lu J, Gu G, Shi Z, Mao Z (2005) Studies on water-extractable arabinoxylans during malting and brewing. Food Chem 93(1):33–38. doi:10.1016/j.foodchem.2004.08.040

Vinkx CJA, Delcour JA (1996) Rye (Secale cereale L.) arabinoxylans: a critical review. J Cereal Sci 24(1):1–14. doi:10.1006/jcrs.1996.0032

Bunzel M, Ralph J, Marita JM, Hatfield RD, Steinhart H (2001) Diferulates as structural components in soluble and insoluble cereal dietary fibre. J Sci Food Agric 81(7):653–660. doi:10.1002/jsfa.861

Pritchard JR, Lawrence GJ, Larroque O, Li Z, Laidlaw HKC, Morell MK, Rahman S (2011) A survey of β-glucan and arabinoxylan content in wheat. J Sci Food Agric 91(7):1298–1303. doi:10.1002/jsfa.4316

Belitz H-D, Belitz H-D, Grosch W, Schieberle P (2001) Lehrbuch Der Lebensmittelchemie. Springer, Berlin

Narziss L, Back W (2009) Die Technologie der Würzebereitung 2. Wiley-VCH, Weinheim

Rakszegi M, Lovegrove A, Balla K, Láng L, Bedő Z, Veisz O, Shewry PR (2014) Effect of heat and drought stress on the structure and composition of arabinoxylan and β-glucan in wheat grain. Carbohydr Polym 102:557–565. doi:10.1016/j.carbpol.2013.12.005

Meuser F, Suckow P (1986) Non-starch polysaccharides. Chemistry and physics of baking: materials, processes, and products. Royal Society of Chemistry, Burlington House, London

Frederix SA, Van Hoeymissen KE, Courtin CM, Delcour JA (2004) Water-extractable and water-unextractable arabinoxylans affect gluten agglomeration behavior during wheat flour gluten–starch separation. J Agric Food Chem 52(26):7950–7956. doi:10.1021/jf049041v

Pedreschi R, Campos D, Noratto G, Chirinos R, Cisneros-Zevallos L (2003) Andean yacon root (Smallanthus sonchifolius Poepp. Endl) fructooligosaccharides as a potential novel source of prebiotics. J Agric Food Chem 51(18):5278–5284. doi:10.1021/jf0344744

Wang J, Sun B, Cao Y, Wang C (2010) In vitro fermentation of xylooligosaccharides from wheat bran insoluble dietary fiber by Bifidobacteria. Carbohydr Polym 82(2):419–423. doi:10.1016/j.carbpol.2010.04.082

Pool-Zobel BL (2005) Inulin-type fructans and reduction in colon cancer risk: review of experimental and human data. Br J Nutr 93(Suppl 1):S73–S90

Roberfroid MB (2005) Introducing inulin-type fructans. Br J Nutr 93(1):13–25

Van der Meulen R, Avonts L, De Vuyst L (2004) Short fractions of oligofructose are preferentially metabolized by bifidobacterium animalis DN-173 010. Appl Environ Biol 70(4):1923–1930

Corradini C, Cavazza A, Bignardi C (2012) High-performance anion-exchange chromatography coupled with pulsed electrochemical detection as a powerful tool to evaluate carbohydrates of food interest: principles and applications. Int J Carbohydr Chem 2012:13. doi:10.1155/2012/487564

Lu ZX, Walker KZ, Muir JG, Mascara T, O’Dea K (2000) Arabinoxylan fiber, a byproduct of wheat flour processing, reduces the postprandial glucose response in normoglycemic subjects. Am J Clin Nutr 71(5):1123–1128

EFSA Panel on Dietetic Products NaAN (2011) Scientific Opinion on the substantiation of health claims related to arabinoxylan produced from wheat endosperm and reduction of post-prandial glycaemic responses (ID 830) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J 9(6):2205:15 pp

Meyer-Pittroff R (1988) Die energetische Verwetung von Biertrebern. Brauwelt 26:1156–1158

Zanker G, Kepplinger WL (2002) Die Verwertung von Biertrebern im Brauereiverbund. Brauwelt 142:1742–1747

Nishio N, Nakashimada Y (2007) Recent development of anaerobic digestion processes for energy recovery from wastes. J Biosci Bioeng 103(2):105–112. doi:10.1263/jbb.103.105

Ezeonu FC, Okaka ANC (1996) Process kinetics and digestion efficiency of anaerobic batch fermentation of brewer’s spent grains (BSG). Process Biochem 31(1):7–12. doi:10.1016/0032-9592(94)00064-6

Rieker C, Moeller M, Sommer K (1992) Anaerobic degradation of beer spent grains for biogas production. Brauwelt 132:716–721

Mahmood ASN, Brammer JG, Hornung A, Steele A, Poulston S (2013) The intermediate pyrolysis and catalytic steam reforming of Brewers spent grain. J Anal Appl Pyrol 103:328–342. doi:10.1016/j.jaap.2012.09.009

Baskyr I, Weiner B, Riedel G, Poerschmann J, Kopinke FD (2014) Wet oxidation of char–water-slurries from hydrothermal carbonization of paper and brewer’s spent grains. Fuel Process Technol 128:425–431. doi:10.1016/j.fuproc.2014.07.042

Mussatto SI, Moncada J, Roberto IC, Cardona CA (2013) Techno-economic analysis for brewer’s spent grains use on a biorefinery concept: the Brazilian case. Bioresour Technol 148:302–310. doi:10.1016/j.biortech.2013.08.046

Xiros C, Christakopoulos P (2009) Enhanced ethanol production from brewer’s spent grain by a Fusarium oxysporum consolidated system. Biotechnol Biofuels 2(1):4

Xiros C, Topakas E, Katapodis P, Christakopoulos P (2008) Evaluation of Fusarium oxysporum as an enzyme factory for the hydrolysis of brewer’s spent grain with improved biodegradability for ethanol production. Ind Crops Prod 28(2):213–224. doi:10.1016/j.indcrop.2008.02.004

Xiros C, Topakas E, Katapodis P, Christakopoulos P (2008) Hydrolysis and fermentation of brewer’s spent grain by Neurospora crassa. Bioresour Technol 99(13):5427–5435. doi:10.1016/j.biortech.2007.11.010

Silva JP, Sousa S, Gonçalves I, Porter JJ, Ferreira-Dias S (2004) Modelling adsorption of acid orange 7 dye in aqueous solutions to spent brewery grains. Sep Purif Technol 40(2):163–170. doi:10.1016/j.seppur.2004.02.006

Pedro Silva J, Sousa S, Rodrigues J, Antunes H, Porter JJ, Gonçalves I, Ferreira-Dias S (2004) Adsorption of acid orange 7 dye in aqueous solutions by spent brewery grains. Sep Purif Technol 40(3):309–315. doi:10.1016/j.seppur.2004.03.010

Low K-S, Lee CK, Low CH (2001) Sorption of chromium (VI) by spent grain under batch conditions. J Appl Polym Sci 82(9):2128–2134. doi:10.1002/app.2058

Li Q, Chai L, Yang Z, Wang Q (2009) Kinetics and thermodynamics of Pb(II) adsorption onto modified spent grain from aqueous solutions. Appl Surf Sci 255(7):4298–4303. doi:10.1016/j.apsusc.2008.11.024

Lu S, Gibb SW (2008) Copper removal from wastewater using spent-grain as biosorbent. Bioresour Technol 99(6):1509–1517. doi:10.1016/j.biortech.2007.04.024

Chiang P-C, Chang P, You J-H (1992) Innovative technology for controlling VOC emissions. J Hazard Mater 31(1):19–28. doi:10.1016/0304-3894(92)87036-F

Sodhi HS, Garcha HS, Kiran U (1985) Screening of mycoflora of spent-up brewers’ grains for aflatoxin production. J Res Punjab Agric Univ 22:331–336

Novik GI, Wawrzynczyk J, Norrlow O, Szwajcer-Dey E (2007) Fractions of barley spent grain as media for growth of probiotic bacteria. Mikrobiologiia 76(6):902–907

Szponar B, Pawlik KJ, Gamian A, Szwajcer Dey E (2003) Protein fraction of barley spent grain as a new simple medium for growth and sporulation of soil actinobacteria. Biotechnol Lett 25(20):1717–1721

Gregori A, Švagelj M, Pahor B, Berovič M, Pohleven F (2008) The use of spent brewery grains for Pleurotus ostreatus cultivation and enzyme production. N Biotechnol 25(2–3):157–161. doi:10.1016/j.nbt.2008.08.003

Terrasan CRF, Temer B, Duarte MCT, Carmona EC (2010) Production of xylanolytic enzymes by Penicillium janczewskii. Bioresour Technol 101(11):4139–4143. doi:10.1016/j.biortech.2010.01.011

Panagiotou G, Granouillet P, Olsson L (2006) Production and partial characterization of arabinoxylan-degrading enzymes by Penicillium brasilianum under solid-state fermentation. Appl Microbiol Biotechnol 72(6):1117–1124. doi:10.1007/s00253-006-0394-6

Mussatto SI (2014) Brewer’s spent grain: a valuable feedstock for industrial applications. J Sci Food Agric 94(7):1264–1275. doi:10.1002/jsfa.6486

Mussatto SI, Dragone G, Roberto IC (2005) Influence of the toxic compounds present in brewer’s spent grain hemicellulosic hydrolysate on xylose-to-xylitol bioconversion by Candida guilliermondii. Process Biochem 40(12):3801–3806. doi:10.1016/j.procbio.2005.06.024

Mussatto SI, Dragone G, Roberto IC (2005) Kinetic behavior of Candida guilliermondii yeast during xylitol production from brewer’s spent grain hemicellulosic hydrolysate. Biotechnol Prog 21(4):1352–1356. doi:10.1021/bp0501118

Mussatto SI, Roberto IC (2008) Establishment of the optimum initial xylose concentration and nutritional supplementation of brewer’s spent grain hydrolysate for xylitol production by Candida guilliermondii. Process Biochem 43(5):540–546. doi:10.1016/j.procbio.2008.01.013

Carvalheiro F, Duarte LC, Lopes S, Parajó JC, Pereira H, Gı́rio FM (2005) Evaluation of the detoxification of brewery’s spent grain hydrolysate for xylitol production by Debaryomyces hansenii CCMI 941. Process Biochem 40(3–4):1215–1223. doi:10.1016/j.procbio.2004.04.015

Duarte LC, Carvalheiro F, Lopes S, Marques S, Parajo JC, Girio FM (2004) Comparison of two posthydrolysis processes of Brewery’s spent grain autohydrolysis liquor to produce a pentose-containing culture medium. Appl Biochem Biotechnol 113–116:1041–1058

Islam MS (2011) Effects of xylitol as a sugar substitute on diabetes-related parameters in nondiabetic rats. J Med Food 14(5):505–511. doi:10.1089/jmf.2010.0015

Uittamo J, Nieminen MT, Kaihovaara P, Bowyer P, Salaspuro M, Rautemaa R (2011) Xylitol inhibits carcinogenic acetaldehyde production by Candida species. Int J Cancer 129(8):2038–2041. doi:10.1002/ijc.25844

Elamin K, Sjostrom J, Jansson H, Swenson J (2012) Calorimetric and relaxation properties of xylitol-water mixtures. J Chem Phys 136(10):104508. doi:10.1063/1.3692609

Ritter AV, Bader JD, Leo MC, Preisser JS, Shugars DA, Vollmer WM, Amaechi BT, Holland JC (2013) Tooth-surface-specific effects of xylitol: randomized trial results. J Dent Res 92(6):512–517. doi:10.1177/0022034513487211

Mussatto SI, Fernandes M, Dragone G, Mancilha IM, Roberto IC (2007) Brewer’s spent grain as raw material for lactic acid production by Lactobacillus delbrueckii. Biotechnol Lett 29(12):1973–1976. doi:10.1007/s10529-007-9494-3

Cabacang R, Joson L, Conoza E, Dela Cruz E (1997) Lactic acid production from local agricultural resources. Biotechnol Sustain Util Biol Res Trop 11:237–242

Bamba T, Kanauchi O, Andoh A, Fujiyama Y (2002) A new prebiotic from germinated barley for nutraceutical treatment of ulcerative colitis. J Gastroenterol Hepatol 17(8):818–824

Kanauchi O, Agata K (1997) Protein, and dietary fiber-rich new foodstuff from brewer’s spent grain increased excretion of feces and jejunum mucosal protein content in rats. Biosci Biotechnol Biochem 61(1):29–33

Jacobs DR Jr, Gallaher DD (2004) Whole grain intake and cardiovascular disease: a review. Curr Atheroscler Rep 6(6):415–423

Koh-Banerjee P, Rimm EB (2003) Whole grain consumption and weight gain: a review of the epidemiological evidence, potential mechanisms and opportunities for future research. Proc Nutr Soc 62(1):25–29. doi:10.1079/pns2002232

Liu S, Willett WC, Manson JE, Hu FB, Rosner B, Colditz G (2003) Relation between changes in intakes of dietary fiber and grain products and changes in weight and development of obesity among middle-aged women. Am J Clin Nutr 78(5):920–927

Aldoori WH, Giovannucci EL, Rockett HR, Sampson L, Rimm EB, Willett WC (1998) A prospective study of dietary fiber types and symptomatic diverticular disease in men. J Nutr 128(4):714–719

Jemal A, Ward E, Hao Y, Thun M (2005) Trends in the leading causes of death in the United States, 1970–2002. JAMA 294(10):1255–1259. doi:10.1001/jama.294.10.1255

Fastnaught CE (2001) Barley fiber. In: Cho SS, Dreher ML (eds) Handbook of dietary fiber. Marcel Dekker, New York, p 321

Brennan CS, Cleary LJ (2005) The potential use of cereal (1→3,1→4)-β-d-glucans as functional food ingredients. J Cereal Sci 42(1):1–13. doi:10.1016/j.jcs.2005.01.002

Kanauchi O, Fujiyama Y, Mitsuyama K, Araki Y, Ishii T, Nakamura T, Hitomi Y, Agata K, Saiki T, Andoh A, Toyonaga A, Bamba T (1999) Increased growth of bifidobacterium and eubacterium by germinated barley foodstuff, accompanied by enhanced butyrate production in healthy volunteers. Int J Mol Med 3(2):175–179

Huige NJ (1994) Brewery by-products and effluents. Handbook of Brewing. Marcel Dekker, New York

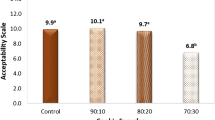

Miranda MZ, Grossmann MVE, Nabeshima EH (1994) Utilization of brewer’s spent grain for the production of snacks with fiber. 1. Physicochemical characteristics. Braz Arch Biol Technol 37:483–493

Miranda MZ, Grossmann MVE, Prudencioferreira SH, Nabeshima EH (1994) Utilization of brewer spent grain (BSG) for production of snacks with fiber. 2. Sensory analysis of snacks. Braz Arch Biol Technol 37:9–21

Stojceska V, Ainsworth P, Plunkett A, İbanogˇlu S (2008) The recycling of brewer’s processing by-product into ready-to-eat snacks using extrusion technology. J Cereal Sci 47(3):469–479. doi:10.1016/j.jcs.2007.05.016

Ainsworth P, İbanoğlu Ş, Plunkett A, İbanoğlu E, Stojceska V (2007) Effect of brewers spent grain addition and screw speed on the selected physical and nutritional properties of an extruded snack. J Food Eng 81(4):702–709. doi:10.1016/j.jfoodeng.2007.01.004

Reis SF, Abu-Ghannam N (2014) Antioxidant capacity, arabinoxylans content and in vitro glycaemic index of cereal-based snacks incorporated with brewer’s spent grain. LWT Food Sci Technol 55(1):269–277. doi:10.1016/j.lwt.2013.09.004

Koukios EG, Pastou A, Koullas DP, Sereti V, Kolosis F (1999) New green products from cellulosics. Biomass: a growth opportunity in green energy and value-added products. Permagon, Oxford

Garrote G, Domínguez H, Parajó JC (1999) Mild autohydrolysis: an environmentally friendly technology for xylooligosaccharide production from wood. J Chem Technol Biotechnol 74(11):1101–1109. doi:10.1002/(SICI)1097-4660(199911)74:11<1101:AID-JCTB146>3.0.CO;2-M

Meneses NGT, Martins S, Teixeira JA, Mussatto SI (2013) Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Sep Purif Technol 108:152–158. doi:10.1016/j.seppur.2013.02.015

Faulds CB, Sancho AI, Bartolome B (2002) Mono- and dimeric ferulic acid release from brewer’s spent grain by fungal feruloyl esterases. Appl Microbiol Biotechnol 60(4):489–494. doi:10.1007/s00253-002-1140-3

Mussatto SI, Dragone G, Roberto IC (2007) Ferulic and p-coumaric acids extraction by alkaline hydrolysis of brewer’s spent grain. Ind Crops Prod 25(2):231–237. doi:10.1016/j.indcrop.2006.11.001

Bartolomé B, Faulds CB, Williamson G (1997) Enzymic release of ferulic acid from barley spent grain. J Cereal Sci 25(3):285–288. doi:10.1006/jcrs.1996.0091

Pepper T, Olinger PM (1988) Xylitol in sugar-free confections. Food Technol 42:98–106

Kabel MA, Schols HA, Voragen AGJ (2002) Complex xylo-oligosaccharides identified from hydrothermally treated Eucalyptus wood and brewery’s spent grain. Carbohydr Polym 50(2):191–200. doi:10.1016/S0144-8617(02)00022-X

Carvalheiro F (2004) Production of oligosaccharides by autohydrolysis of brewery’s spent grain. Bioresour Technol 91(1):93–100. doi:10.1016/s0960-8524(03)00148-2

Böhm N (1998), Universität Hamburg, Hamburg

Ahmad A, Anjum FM, Zahoor T, Nawaz H, Din A (2009) Physicochemical and functional properties of barley β-glucan as affected by different extraction procedures. Int J Food Sci Technol 44(1):181–187. doi:10.1111/j.1365-2621.2008.01721.x

Du B, Zhu F, Xu B (2014) β-Glucan extraction from bran of hull-less barley by accelerated solvent extraction combined with response surface methodology. J Cereal Sci 59(1):95–100. doi:10.1016/j.jcs.2013.11.004

Benito-Román Ó, Alonso E, Cocero MJ (2013) Pressurized hot water extraction of β-glucans from waxy barley. J Supercrit Fluids 73:120–125. doi:10.1016/j.supflu.2012.09.014

Benito-Román Ó, Alonso E, Gairola K, Cocero MJ (2013) Fixed-bed extraction of β-glucan from cereals by means of pressurized hot water. J Supercrit Fluids 82:122–128. doi:10.1016/j.supflu.2013.07.003

Acknowledgments

The authors would like to thank Dr. Martin Zarnkow, Forschungszentrum Weihenstephan für Brau- und Lebensmittelqualität, Technische Universität München, D-85354 Freising, Germany for his assistance.

Conflict of interest

None.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Steiner, J., Procopio, S. & Becker, T. Brewer’s spent grain: source of value-added polysaccharides for the food industry in reference to the health claims. Eur Food Res Technol 241, 303–315 (2015). https://doi.org/10.1007/s00217-015-2461-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-015-2461-7