Abstract

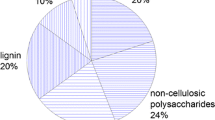

Brewer’s spent grain (BSG) is one of the most abundant residues in the beer industry and has a high nutritional content, such as proteins, fibers, vitamins, minerals, and carbohydrates. It has a high fiber and protein content, and thus it is commonly used in animal feed production or discarded in the environment. However, due to its nutritional value, low cost, and being made available in large quantities throughout the year, BSG can be reused for other purposes, whether in the preparation of new products or in the recovery of its constituents. Several studies are being carried out for the application of this human food, and it has been reported that some components of BSG have bioactive properties and can be used as health promoters. This review addresses the main data on how BSG is generated, its chemical composition, and the latest methods that apply to information on the recovery of compounds of interest.

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

References

Prandi B, Faccini A, Lambertini F et al (2019) Food wastes from agrifood industry as possible sources of proteins: a detailed molecular view on the composition of the nitrogen fraction, amino acid profile and racemisation degree of 39 food waste streams. Food Chem 286:567–575. https://doi.org/10.1016/j.foodchem.2019.01.166

Mussatto SI, Dragone G, Roberto IC (2006) Brewers’ spent grain : generation, characteristics and potential applications. J Cereal Sci 43:1–14. https://doi.org/10.1016/j.jcs.2005.06.001

Saraiva BR, Agustinho BC, Vital ACP et al (2019) Effect of brewing waste (malt bagasse) addition on the physicochemical properties of hamburgers. J Food Process Preserv 43:14135. https://doi.org/10.1111/jfpp.14135

Saraiva BR, Anjo FA, Vital ACP et al (2019) Waste from brewing (trub) as a source of protein for the food industry. Int J Food Sci Technol 54:1247–1255. https://doi.org/10.1111/ijfs.14101

Bonifácio-Lopes T, Vilas-Boas A, Machado M et al (2022) Exploring the bioactive potential of brewers spent grain ohmic extracts. Innov Food Sci Emerg Technol. https://doi.org/10.1016/j.ifset.2022.102943

Emmanuel JK, Nganyira PD, Shao GN (2022) Evaluating the potential applications of brewers’ spent grain in biogas generation, food and biotechnology industry: a review. Heliyon 8:e11140. https://doi.org/10.1016/j.heliyon.2022.e11140

Villacreces S, Blanco CA, Caballero I (2022) Developments and characteristics of craft beer production processes. Food Biosci 45:101495. https://doi.org/10.1016/j.fbio.2021.101495

Mordor I (2022) Craft beer market—growth, trends, Covid-19 impact, and forecasts (2022–2027). 2027

Conway J (2021) Global beer production 1998–2019 Beer production worldwide from 1998 to 2019 (in billion hectoliters ) 2019:1–2

Guido LF, Moreira MM (2017) Techniques for extraction of Brewer’s spent grain polyphenols: a review. Food Bioprocess Technol 10:1192–1209. https://doi.org/10.1007/s11947-017-1913-4

Lech M, Labus K (2022) The methods of brewers’ spent grain treatment towards the recovery of valuable ingredients contained therein and comprehensive management of its residues. Chem Eng Res Des 183:494–511. https://doi.org/10.1016/j.cherd.2022.05.032

Niemi P, Martins D, Buchert J, Faulds CB (2013) Biore source technology pre-hydrolysis with carbohydrases facilitates the release of protein from Brewer’ s spent grain. Bioresour Technol 136:529–534. https://doi.org/10.1016/j.biortech.2013.03.076

Gupta M, Abu-Ghannam N, Gallaghar E (2010) Barley for brewing: characteristic changes during malting, brewing and applications of its by-products. Compr Rev Food Sci Food Saf 9:318–328. https://doi.org/10.1111/j.1541-4337.2010.00112.x

Mussatto SI (2014) Brewer’s spent grain: a valuable feedstock for industrial applications. J Sci Food Agric 94:1264–1275. https://doi.org/10.1002/jsfa.6486

Mussatto SI (2009) Biotechnological potential of brewing industry by-products. In: Nigam P, Pandey A (eds) Biotechnology for agro-industrial residues utilisation. Springer Science

Thiago RdSM, Pedro PMdM, Eliana FCS (2014) Solid wastes in brewing process: a review. J Brew Distill 5:1–9. https://doi.org/10.5897/jbd2014.0043

Ikram S, Huang LY, Zhang H et al (2017) Composition and nutrient value proposition of brewers spent grain. J Food Sci 82:2232–2242. https://doi.org/10.1111/1750-3841.13794

Lynch KM, Steffen EJ, Arendt EK (2016) Brewers’ spent grain: a review with an emphasis on food and health. J Inst Brew 122:553–568. https://doi.org/10.1002/jib.363

Steiner J, Procopio S, Becker T (2015) Brewer’s spent grain: source of value-added polysaccharides for the food industry in reference to the health claims. Eur Food Res Technol 241:303–315. https://doi.org/10.1007/s00217-015-2461-7

Meneses NGT, Martins S, Teixeira JA, Mussatto SI (2013) Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’ s spent grains. Sep Purif Technol 108:152–158. https://doi.org/10.1016/j.seppur.2013.02.015

Paz A, Outeiriño D, Pérez Guerra N, Domínguez JM (2019) Enzymatic hydrolysis of Brewer’s spent grain to obtain fermentable sugars. Bioresour Technol 275:402–409. https://doi.org/10.1016/j.biortech.2018.12.082

de Araújo TP, Quesada HB, Bergamasco R et al (2020) Activated hydrochar produced from Brewer’s spent grain and its application in the removal of acetaminophen. Bioresour Technol 310:123399. https://doi.org/10.1016/j.biortech.2020.123399

Hassan SS, Ravindran R, Jaiswal S et al (2020) An evaluation of sonication pretreatment for enhancing saccharification of brewers’ spent grain. Waste Manag 105:240–247. https://doi.org/10.1016/j.wasman.2020.02.012

Qin F, Johansen AZ, Mussatto SI (2018) Industrial crops & products evaluation of different pretreatment strategies for protein extraction from brewer’s spent grains. Ind Crop Prod 125:443–453. https://doi.org/10.1016/j.indcrop.2018.09.017

Heredia-Sandoval NG, Granados-Nevárez MdC, Calderón de la Barca AM et al (2019) Phenolic acids, antioxidant capacity, and estimated glycemic index of cookies added with Brewer’s spent grain. Plant Foods Hum Nutr. https://doi.org/10.1007/s11130-019-00783-1

Nocente F, Taddei F, Galassi E, Gazza L (2019) LWT—food science and technology upcycling of Brewers’ spent grain by production of dry pasta with higher nutritional potential. LWT Food Sci Technol 114:108421. https://doi.org/10.1016/j.lwt.2019.108421

Bachmann SAL, Calvete T, Féris LA (2022) Potential applications of brewery spent grain: critical an overview. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2021.106951

Roth M, Jekle M, Becker T (2019) Opportunities for upcycling cereal byproducts with special focus on Distiller’s grains. Trends Food Sci Technol 91:282–293. https://doi.org/10.1016/j.tifs.2019.07.041

MacLeod AM (1967) The physiology of malting—a review. J Inst Brew 73:146–162. https://doi.org/10.1002/j.2050-0416.1967.tb03027.x

Santos M, Jiménez JJ, Bartolomé B et al (2003) Variability of Brewer’s spent grain within a brewery. Food Chem 80:17–21. https://doi.org/10.1016/S0308-8146(02)00229-7

Niemi P, Tamminen T, Smeds A et al (2012) Characterization of lipids and lignans in Brewer’s spent grain and its enzymatically extracted fraction. J Agric Food Chem 60:9910–9917. https://doi.org/10.1021/jf302684x

Fărcaş AC, Socaci SA, Mudura E et al (2017) Exploitation of brewing industry wastes to produce functional ingredients. In: Kanauchi M (ed) Brewing technology. IntechOpen

Celus I, Brijs K, Delcour JA (2006) The effects of malting and mashing on barley protein extractability. J Cereal Sci 44:203–211. https://doi.org/10.1016/j.jcs.2006.06.003

Waters DM, Jacob F, Titze J et al (2012) Fibre, protein and mineral fortification of wheat bread through milled and fermented Brewer’s spent grain enrichment. Eur Food Res Technol 235:767–778. https://doi.org/10.1007/s00217-012-1805-9

Ibbett R, White R, Tucker G, Foster T (2019) Hydro-mechanical processing of Brewer’s spent grain as a novel route for separation of protein products with differentiated techno-functional properties. Innov Food Sci Emerg Technol 56:102184. https://doi.org/10.1016/j.ifset.2019.102184

Blandino A, Al-Aseeri ME, Pandiella SS et al (2003) Cereal-based fermented foods and beverages. Food Res Int 36:527–543. https://doi.org/10.1016/S0963-9969(03)00009-7

McCarthy AL, O’Callaghan YC, Neugart S et al (2013) The hydroxycinnamic acid content of barley and brewers’ spent grain (BSG) and the potential to incorporate phenolic extracts of BSG as antioxidants into fruit beverages. Food Chem 141:2567–2574. https://doi.org/10.1016/j.foodchem.2013.05.048

Carciochi RA, Sologubik CA, Fernández MB et al (2018) Extraction of antioxidant phenolic compounds from Brewer’s spent grain: optimization and kinetics modeling. Antioxidants. https://doi.org/10.3390/antiox7040045

McCarthy AL, O’Callaghan YC, Connolly A et al (2013) In vitro antioxidant and anti-inflammatory effects of Brewers’ spent grain protein rich isolate and its associated hydrolysates. Food Res Int 50:205–212. https://doi.org/10.1016/j.foodres.2012.10.022

Río JC, Prinsen P, Gutiérrez A (2013) Chemical composition of lipids in Brewer’s spent grain: a promising source of valuable phytochemicals. J Cereal Sci 58:248–254. https://doi.org/10.1016/j.jcs.2013.07.001

Burton GW, Traber MG (1990) Vitamin E: antioxidant activity, biokinetics, and bioavailability. Annu Rev Nutr 10:357–382. https://doi.org/10.1146/annurev.nu.10.070190.002041

Prýma J, Ehrenbergerová J, Belcredlová N, Vaculová K (2007) Tocol content in barley. Acta Chim Slov 54:102–105

Sen CK, Rink C, Khanna S (2010) Palm oil–derived natural vitamin e α-tocotrienol in brain health and disease. J Am Coll Nutr 29:314S-323S. https://doi.org/10.1080/07315724.2010.10719846

Arauzo PJ, Du L, Olszewski MP et al (2019) Bioresource technology effect of protein during hydrothermal carbonization of brewer’s spent grain. Bioresour Technol 293:122117. https://doi.org/10.1016/j.biortech.2019.122117

Connolly A, Piggott CO, Fitzgerald RJ (2013) Characterisation of protein-rich isolates and antioxidative phenolic extracts from pale and black Brewers’ spent grain. Int J Food Sci Technol 48:1670–1681. https://doi.org/10.1111/ijfs.12137

Rommi K, Niemi P, Kemppainen K, Kruus K (2018) Impact of thermochemical pre-treatment and carbohydrate and protein hydrolyzing enzyme treatment on fractionation of protein and lignin from brewer’s spent grain. J Cereal Sci 79:168–173. https://doi.org/10.1016/j.jcs.2017.10.005

Xiros C, Christakopoulos P (2012) Biotechnological potential of brewers spent grain and its recent applications. Waste Biomass Valorization 3:213–232. https://doi.org/10.1007/s12649-012-9108-8

Vieira MC, Brandelli A, Thys RCS (2022) Evaluation of the technological functional properties and antioxidant activity of protein hydrolysate obtained from brewers’ spent grain. J Food Process Preserv. https://doi.org/10.1111/jfpp.16638

Tang DS, Yin GM, He YZ et al (2009) Recovery of protein from brewer’s spent grain by ultrafiltration. Biochem Eng J 48:1–5. https://doi.org/10.1016/j.bej.2009.05.019

Celus I, Brijs K, Delcour JA (2007) Enzymatic hydrolysis of Brewers’ spent grain proteins and technofunctional properties of the resulting hydrolysates. J Agric Food Chem 55:8703–8710. https://doi.org/10.1021/jf071793c

Cermeño M, Connolly A, O’Keeffe MB et al (2019) Identification of bioactive peptides from Brewers’ spent grain and contribution of Leu/Ile to bioactive potency. J Funct Foods. https://doi.org/10.1016/j.jff.2019.103455

Connolly A, O’Keeffe MB, Nongonierma AB et al (2017) Isolation of peptides from a novel brewers spent grain protein isolate with potential to modulate glycaemic response. Int J Food Sci Technol 52:146–153. https://doi.org/10.1111/ijfs.13260

Connolly A, Piggott CO, FitzGerald RJ (2014) In vitro α-glucosidase, angiotensin converting enzyme and dipeptidyl peptidase-IV inhibitory properties of Brewers’ spent grain protein hydrolysates. Food Res Int 56:100–107. https://doi.org/10.1016/j.foodres.2013.12.021

Kotlar CE, Ponce AG, Roura SI (2013) Improvement of functional and antimicrobial properties of brewery byproduct hydrolysed enzymatically. LWT Food Sci Technol 50:378–385. https://doi.org/10.1016/j.lwt.2012.09.005

Vieira E, Rocha MAM, Coelho E et al (2014) Valuation of brewer’s spent grain using a fully recyclable integrated process for extraction of proteins and arabinoxylans. Ind Crops Prod 52:136–143. https://doi.org/10.1016/j.indcrop.2013.10.012

He Y, Kuhn DD, Ogejo JA et al (2019) Wet fractionation process to produce high protein and high fiber products from brewer’s spent grain. Food Bioprod Process 117:266–274. https://doi.org/10.1016/j.fbp.2019.07.011

Arruda HS, Neri-Numa IA, Kido LA et al (2020) Recent advances and possibilities for the use of plant phenolic compounds to manage ageing-related diseases. J Funct Foods 75:104203. https://doi.org/10.1016/j.jff.2020.104203

Arruda HS, Silva EK, Pereira GA et al (2019) Effects of high-intensity ultrasound process parameters on the phenolic compounds recovery from araticum peel. Ultrason Sonochem 50:82–95. https://doi.org/10.1016/j.ultsonch.2018.09.002

Vargas-Madriz ÁF, Kuri-García A, Vargas-Madriz H et al (2020) Phenolic profile and antioxidant capacity of Pithecellobium dulce (Roxb) Benth: a review. J Food Sci Technol 57:4316–4336. https://doi.org/10.1007/s13197-020-04453-y

Zhao H, Fan W, Dong J et al (2008) Evaluation of antioxidant activities and total phenolic contents of typical malting barley varieties. Food Chem 107:296–304. https://doi.org/10.1016/j.foodchem.2007.08.018

Hernanz D, Nuñez V, Sancho AI et al (2001) Hydroxycinnamic acids and ferulic acid dehydrodimers in barley and processed barley. J Agric Food Chem 49:4884–4888. https://doi.org/10.1021/jf010530u

Osorio-Tobón JF (2020) Recent advances and comparisons of conventional and alternative extraction techniques of phenolic compounds. J Food Sci Technol 57:4299–4315. https://doi.org/10.1007/s13197-020-04433-2

Jin Z, Lan Y, Ohm JB et al (2022) Physicochemical composition, fermentable sugars, free amino acids, phenolics, and minerals in Brewers’ spent grains obtained from craft brewing operations. J Cereal Sci 104:103413. https://doi.org/10.1016/j.jcs.2022.103413

Carvalho DO, Guido LF (2022) A review on the fate of phenolic compounds during malting and brewing: technological strategies and beer styles. Food Chem 372:131093. https://doi.org/10.1016/j.foodchem.2021.131093

Sibhatu HK, Anuradha Jabasingh S, Yimam A, Ahmed S (2021) Ferulic acid production from brewery spent grains, an agro-industrial waste. Lwt 135:110009. https://doi.org/10.1016/j.lwt.2020.110009

Ikram S, Zhang H, Ming H, Wang J (2020) Recovery of major phenolic acids and antioxidant activity of highland barley brewer’s spent grains extracts. J Food Process Preserv 44:14308. https://doi.org/10.1111/jfpp.14308

Birsan RI, Wilde P, Waldron KW, Rai DK (2019) Recovery of polyphenols from brewer’s spent grains. Antioxidants 8:1–12. https://doi.org/10.3390/antiox8090380

Martín-García B, Tylewicz U, Verardo V et al (2020) Pulsed electric field (PEF) as pre-treatment to improve the phenolic compounds recovery from brewers’ spent grains. Innov Food Sci Emerg Technol 64:102402. https://doi.org/10.1016/j.ifset.2020.102402

Fărcaş AC, Socaci SA, Dulf FV et al (2015) Volatile profile, fatty acids composition and total phenolics content of brewers’ spent grain by-product with potential use in the development of new functional foods. J Cereal Sci 64:34–42. https://doi.org/10.1016/j.jcs.2015.04.003

Socaci SA, Fărcaş AC, Diaconeasa ZM et al (2018) Influence of the extraction solvent on phenolic content, antioxidant, antimicrobial and antimutagenic activities of brewers’ spent grain. J Cereal Sci 80:180–187. https://doi.org/10.1016/j.jcs.2018.03.006

Parekh I, Khanvilkar A, Naik A (2017) Barley–wheat brewers’ spent grain: a potential source of antioxidant rich lipids. J Food Process Preserv 41:2017. https://doi.org/10.1111/jfpp.13244

Ghaedi E, Foshati S, Ziaei R et al (2020) Effects of phytosterols supplementation on blood pressure: a systematic review and meta-analysis. Clin Nutr 39:2702–2710. https://doi.org/10.1016/j.clnu.2019.12.020

Liu L, Winter KM, Stevenson L et al (2012) Wheat bran lipophilic compounds with in vitro anticancer effects. Food Chem 130:156–164. https://doi.org/10.1016/j.foodchem.2011.07.023

Hiramoto S, Yahata N, Saitoh K et al (2018) Dietary supplementation with alkylresorcinols prevents muscle atrophy through a shift of energy supply. J Nutr Biochem 61:147–154. https://doi.org/10.1016/j.jnutbio.2018.08.014

Marangoni F, Agostoni C, Borghi C et al (2020) Dietary linoleic acid and human health: focus on cardiovascular and cardiometabolic effects. Atherosclerosis 292:90–98. https://doi.org/10.1016/j.atherosclerosis.2019.11.018

Ribau Teixeira M, Guarda EC, Freitas EB et al (2020) Valorization of raw brewers’ spent grain through the production of volatile fatty acids. N Biotechnol 57:4–10. https://doi.org/10.1016/j.nbt.2020.01.007

Sarkar O, Rova U, Christakopoulos P, Matsakas L (2021) Influence of initial uncontrolled pH on acidogenic fermentation of brewery spent grains to biohydrogen and volatile fatty acids production: optimization and scale-up. Bioresour Technol 319:124233. https://doi.org/10.1016/j.biortech.2020.124233

Castilla-Archilla J, Papirio S, Lens PNL (2020) Two step process for volatile fatty acid production from brewery spent grain: hydrolysis and direct acidogenic fermentation using anaerobic granular sludge. Process Biochem. https://doi.org/10.1016/j.procbio.2020.10.011

Liu W, Huang S, Zhou A et al (2012) Hydrogen generation in microbial electrolysis cell feeding with fermentation liquid of waste activated sludge. Int J Hydrogen Energy 37:13859–13864. https://doi.org/10.1016/j.ijhydene.2012.04.090

Li X, Chen H, Hu L et al (2011) Pilot-scale waste activated sludge alkaline fermentation, fermentation liquid separation, and application of fermentation liquid to improve biological nutrient removal. Environ Sci Technol 45:1834–1839. https://doi.org/10.1021/es1031882

Duque AF, Oliveira CSS, Carmo ITD et al (2014) Response of a three-stage process for PHA production by mixed microbial cultures to feedstock shift: impact on polymer composition. N Biotechnol 31:276–288. https://doi.org/10.1016/j.nbt.2013.10.010

Bohnsack C, Ternes W, Büsing A, Drotleff AM (2011) Tocotrienol levels in sieving fraction extracts of brewer’s spent grain. Eur Food Res Technol 232:563–573. https://doi.org/10.1007/s00217-010-1419-z

Mussatto SI, Fernandes M, Milagres AMF, Roberto IC (2008) Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer’s spent grain. Enzyme Microb Technol 43:124–129. https://doi.org/10.1016/j.enzmictec.2007.11.006

Mussatto SI, Dragone G, Fernandes M et al (2008) The effect of agitation speed, enzyme loading and substrate concentration on enzymatic hydrolysis of cellulose from brewer’s spent grain. Cellulose 15:711–721. https://doi.org/10.1007/s10570-008-9215-7

Outeiriño D, Costa-Trigo I, Paz A et al (2019) Biorefining brewery spent grain polysaccharides through biotuning of ionic liquids. Carbohydr Polym 203:265–274. https://doi.org/10.1016/j.carbpol.2018.09.042

Chen H, Liu J, Chang X et al (2017) A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Process Technol 160:196–206. https://doi.org/10.1016/j.fuproc.2016.12.007

Naidu DS, Hlangothi SP, John MJ (2018) Bio-based products from xylan: a review. Carbohydr Polym 179:28–41. https://doi.org/10.1016/j.carbpol.2017.09.064

Haldar D, Bhattacharjee N, Shabbirahmed AM et al (2023) Purification of biogas for methane enrichment using biomass-based adsorbents: a review. Biomass Bioenergy 173:106804. https://doi.org/10.1016/j.biombioe.2023.106804

Gupta P, Kurien C, Mittal M (2023) Biogas (a promising bioenergy source): a critical review on the potential of biogas as a sustainable energy source for gaseous fuelled spark ignition engines. Int J Hydrogen Energy 48:7747–7769. https://doi.org/10.1016/j.ijhydene.2022.11.195

Yang S, Luo F, Yan J et al (2023) Biogas production of food waste with in-situ sulfide control under high organic loading in two-stage anaerobic digestion process: strategy and response of microbial community. Bioresour Technol 373:128712. https://doi.org/10.1016/j.biortech.2023.128712

Zhou M, Yan B, Wong JWC, Zhang Y (2018) Enhanced volatile fatty acids production from anaerobic fermentation of food waste: a mini-review focusing on acidogenic metabolic pathways. Bioresour Technol 248:68–78. https://doi.org/10.1016/j.biortech.2017.06.121

Deepanraj B, Sivasubramanian V, Jayaraj S (2014) Biogas generation through anaerobic digestion process-an overview. Res J Chem Environ 18:80–94

Buller LS, Sganzerla WG, Lima MN et al (2022) Ultrasonic pretreatment of brewers’ spent grains for anaerobic digestion: biogas production for a sustainable industrial development. J Clean Prod. https://doi.org/10.1016/j.jclepro.2022.131802

Carlini M, Monarca D, Castellucci S et al (2021) Beer spent grains biomass for biogas production: characterization and anaerobic digestion-oriented pre-treatments. Energy Rep 7:921–929. https://doi.org/10.1016/j.egyr.2021.07.049

Castilla-Archilla J, Thorn CE, Pau S, Lens PNL (2022) Screening for suitable mixed microbial consortia from anaerobic sludge and animal dungs for biodegradation of brewery spent grain. Biomass Bioenergy 159:106396. https://doi.org/10.1016/j.biombioe.2022.106396

Li Y, Zhao J, Achinas S et al (2020) The biomethanation of cow manure in a continuous anaerobic digester can be boosted via a bioaugmentation culture containing Bathyarchaeota. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2020.141042

Čater M, Fanedl L, Malovrh Š, Marinšek Logar R (2015) Biogas production from brewery spent grain enhanced by bioaugmentation with hydrolytic anaerobic bacteria. Bioresour Technol 186:261–269. https://doi.org/10.1016/j.biortech.2015.03.029

Spinelli S, Conte A, Del Nobile MA (2016) Microencapsulation of extracted bioactive compounds from brewer’s spent grain to enrich fish-burgers. Food Bioprod Process 100:450–456. https://doi.org/10.1016/j.fbp.2016.09.005

Reis SF, Abu-Ghannam N (2014) Antioxidant capacity, arabinoxylans content and invitro glycaemic index of cereal-based snacks incorporated with brewer’s spent grain. LWT Food Sci Technol 55:269–277. https://doi.org/10.1016/j.lwt.2013.09.004

Öztürk S, Özboy Ö, Cavidoǧlu I, Köksel H (2002) Effects of brewer’s spent grain on the quality and dietary fiber content of cookies. J Inst Brew 108:23–27. https://doi.org/10.1002/j.2050-0416.2002.tb00116.x

Özvural EB, Vural H, Gökbulut I, Özboy-Özbaş Ö (2009) Utilization of brewer’s spent grain in the production of Frankfurters. Int J Food Sci Technol 44:1093–1099. https://doi.org/10.1111/j.1365-2621.2009.01921.x

Stojceska V, Ainsworth P (2008) The effect of different enzymes on the quality of high-fiber enriched brewer’s spent grain breads. Food Chem 110:865–872. https://doi.org/10.1016/j.foodchem.2008.02.074

Steinmacher NC, Honna FA, Gasparetto AV et al (2012) Bioconversion of brewer’s spent grains by reactive extrusion and their application in bread-making. LWT Food Sci Technol 46:542–547. https://doi.org/10.1016/j.lwt.2011.11.011

Moreirinha C, Vilela C, Silva NHCS et al (2020) Antioxidant and antimicrobial films based on brewers spent grain arabinoxylans, nanocellulose and feruloylated compounds for active packaging. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2020.105836

Del Rio Osorio LL, Flórez-López E, Grande-Tovar CD (2021) The potential of selected agri-food loss and waste to contribute to a circular economy: applications in the food, cosmetic and pharmaceutical industries. Molecules. https://doi.org/10.3390/molecules26020515

Olivares-Galván S, Marina ML, García MC (2022) Extraction of valuable compounds from brewing residues: malt rootlets, spent hops, and spent yeast. Trends Food Sci Technol 127:181–197. https://doi.org/10.1016/j.tifs.2022.06.002

Wen C, Zhang J, Duan Y et al (2019) A mini-review on Brewer’s spent grain protein: isolation, physicochemical properties, application of protein, and functional properties of hydrolysates. J Food Sci 84:3330–3340. https://doi.org/10.1111/1750-3841.14906

Panjičko M, Zupančič GD, Fanedl L et al (2017) Biogas production from brewery spent grain as a mono-substrate in a two-stage process composed of solid-state anaerobic digestion and granular biomass reactors. J Clean Prod 166:519–529. https://doi.org/10.1016/j.jclepro.2017.07.197

Camargo FP, Rabelo CABS, Duarte ICS et al (2023) Biogas from lignocellulosic feedstock: a review on the main pretreatments, inocula and operational variables involved in anaerobic reactor efficiency. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2023.02.073

Acknowledgements

This research was developed within the scope of the Capes-PrInt Program (Process #88887.310848/2018-00). The authors thank the National Council for Scientific and Technological Development (CNPq) of Brazil and the Brazilian Coordination for the Improvement of Higher Education Personnel (CAPES) [Finance Code 001].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest, financial or otherwise.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Paula, M., Latorres, J.M. & Martins, V.G. Potential valorization opportunities for Brewer’s spent grain. Eur Food Res Technol 249, 2471–2483 (2023). https://doi.org/10.1007/s00217-023-04313-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04313-x