Abstract

The adsorption of ethidium bromide (EtBr) by single-walled carbon nanotubes (SWCNTs) and nanoscale of zero valent iron (NZVI) were investigated to assess its possible use as adsorbents. The effect of various factors, namely initial adsorbate concentration, adsorbent dosage, and contact time, were studied to identify adsorption capacity of SWCNTs and NZVI surfaces. The experiment demonstrated the maximum EtBr which was obtained at 5 min to attain equilibrium for SWCNTs and NZVI surfaces. Adsorption data were modeled with the Langmuir, Freundlichand, Temkin isotherms. Langmuir adsorption model was used for the mathematical description of the adsorption equilibrium, and the equilibrium data fitted very well with this model for both surfaces as adsorbents. The study showed that SWCNTs and NZVI surfaces could be used as new and efficient adsorbent materials for the removal of EtBr from aqueous solution. Also, the result showed that the SWCNTs were more effective than NZVI in the removal of EtBr from aqueous solution.

Similar content being viewed by others

Background

Ethidium bromide (EtBr; 3,8-diamino-6-phenyl-5-ethylphenanthridinium bromide), commonly used in research laboratories as a stain for the visualization of nucleic acids in electrophoresis gels, is a toxic chemical and a potent mutagen [1]. When used in nucleic acid staining, ethidium bromide fluoresces a red-orange to pink color under ultraviolet light and with increased fluorescence when bound to double-stranded DNA. While it is not specifically regulated as a hazardous waste, the mutagenic properties may present health hazards and disposal concerns if it is not managed properly in the laboratory [2]. Adsorption has been found to be an effective and economical method with high potential for the removal, recovery, and recycle of pollution from the wastewater [3]. In this decade, the use of single-walled carbon nanotubes (SWCNTs) and nanoscale of zero valent iron (NZVI) as a reactive medium for the treatment of toxic chemicals is one of the most significant techniques and has attracted a lot of attention because the iron metal is of low cost, low toxicity, is easy to get, and has good effectiveness and ability to degrading contaminants. Laboratory studies have demonstrated that SWCNTs and NZVI surfaces as adsorbents can effectively transform chlorinated solvents, organochlorine pesticides, organic dyes and heavy metals [4–11] into nontoxic forms. Nanoscale of zero valent iron has drawn great attention as an inexpensive and environmentally friendly strong reducing agent [12, 13]. Addition of NZVI to oxygen-containing water results in oxidation of organic compounds [14]. Therefore, extensive efforts have been directed to assess the potential application of NZVI for the decomposition of organic pollutants in the wastewater. SWCNTs, ever since their discovery, have attracted extensive attention due to their unique properties. They have shown potential applications in many areas, such as conductive and high-strength composites. With the significant increase in production and use of SWCNTs, one major concern is the health and environmental risks posed by these nanomaterials once they are released to the environment. Evidences for potential risks of SWCNTs to humans and ecosystems are accumulating rapidly [15]. Due to their highly hydrophobic surfaces, SWCNTs exhibit strong adsorption affinities to synthetic organic chemicals, such as polycyclic aromatic hydrocarbons. As a consequence, toxicity of SWCNTs may be further enhanced by adsorption of toxic chemicals. Therefore, understanding of SWCNT interactions is critical for the environmental of both SWCNTs and toxic pollutants as well as for the applications of SWCNTs as potential adsorbents [16].

The objective of this research is to investigate the adsorption kinetics and isotherm models of EtBr removal by SWCNT and NZVI surfaces. Equilibrium data can be used to predict the rate at which the target contaminant is removed from aqueous solutions, and equilibrium adsorption isotherms are used to quantify the adsorptive capacity of an adsorbent. Results from this study can be used to assess the utility of SWCNT and NZVI surfaces for EtBr removal, in particular EtBr adsorption, at the field scale.

Results and discussion

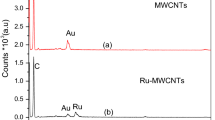

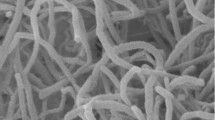

Characterization of the adsorbent

Figure 1 shows the SEM image of freshly synthesized SWCNTs (a,b) and iron nanoparticles (c,d). It can be observed that the iron particles are in the form of nanospheres, which exist in contact with each other and form chains having diameters of 50 to 100 nm [17]. Figure 1b,d showed that the EtBr molecules removed by SWCNT and NZVI surfaces were covered in aqueous solution.

Effect of contact time

In these experiments, initial concentration of EtBr molecules on SWCNT and NZVI surfaces was 20 mg/L (Figure 2). The effects of contact time (0 to 10 min) were investigated at 20 mg/50 mL sample dosage. The extent of removal of EtBr by SWCNT and NZVI surfaces was found to increase and has reached its maximum with the increase in contact time. The time at which the maximum percentage removal of EtBr occurs is fixed as the contact time (Figure 2a for the removal of SWCNTs and Figure 2b for the removal of NZVI).

Effect of initial EtBr concentration

The effect of initial concentration (10 to 40 mg/L) of EtBr adsorption on to SWCNTs and NZVI surfaces are presented in Figure 3 (Figure 3a for the removal of SWCNTs and Figure 3b for the removal of NZVI). A rapid removal is observed at the initial stages, and it then proceeds slowly until equilibrium is reached. This may be due to the availability of the number of vacant adsorption sites at the initial stage. The equilibrium adsorption capacity of SWCNT and NZVI surfaces were decreased as there is increasing concentration from 10 to 40 mg/L. At lower EtBr concentration, the available adsorption sites are relatively high, and consequently, the EtBr species can easily find the accessible adsorption sites for both adsorbents (SWCNT and NZVI surfaces).

Effect of adsorbent dosage

From Figure 4 (Figure 4a for the removal of SWCNTs and Figure 4b for the removal of NZVI), we see that the optimum dose of SWCNT and NZVI surfaces for the EtBr were 30 mg/50 mL. Though at 40 mg/50 mL, there is a slight increase in adsorption value, but if we get nearly the same result as we get at an adsorbent dosage of 50 mg/50 mL, then going for 70 mg/50 mL will be expensive and there will be loss of adsorbent. It is obvious, with increasing the amount, what the active sites are for adsorption of three dyes.

Effect of temperature

To study the effect of temperature on the removal of EtBr, the experiments were carried out at temperatures varying from 283 to 313 K. It is revealed from Figure 5 (Figure 5a for the removal of SWCNTs and Figure 5b for the removal of NZVI), that the removal of EtBr with temperatures would increase the mobility of the EtBr and produce a swelling effect within the internal structure of adsorbent thus enabling the large molecules of EtBr to penetrate further. The greater removal of EtBr due to increasing temperature may have more interaction between the adsorbate and adsorbent.

Adsorption isotherms

Equilibrium isotherm equations are used to describe the experimental adsorption data. In this study, three adsorption models, that is the Langmuir, Freundlich, and Temkin isotherms, were used to describe the reactive dye equilibrium. The Langmuir isotherm [18] which is valid for monolayer sorption onto a completely homogeneous surface with a finite number of identical sites and with negligible interaction between adsorbed molecules is given by Equation 1:

where qe (mg/g) and Ce (mg/L) are the amount of adsorbed EtBr per unit mass of adsorbent and an adsorbed EtBr concentration in solution at equilibrium, respectively. qm is the maximum amount of the EtBr per unit mass of adsorbent to form a complete monolayer on the surface bound at high Ce (mg/g), and KL is a constant related to the affinity of the binding sites (L/mg). The two linear transformations of the Langmuir isotherm is often expressed as Equation 2 (Type1) and Equation 3 (Type 2):

The essential characteristics of the Langmuir equation can be expressed in terms of a dimensionless separation factor, RL, defined by [19]:

where C0 is the initial EtBr concentration (mg/L). RL values indicate the type of isotherm to be irreversible (RL = 0), favorable (0 < RL < 1), linear (RL = 1), or unfavorable (RL > 1). The empirical Freundlich isotherm based on sorption on a heterogeneous surface is given by Equation 5 [20]:

or can be written in linearized form (Equation 6) as:

where KF and n are the Freundlich constants characteristic of the system. KF and n are indicators of adsorption capacity and adsorption intensity, respectively. qe is the equilibrium EtBr concentration in solid phase (mg/g), and Ce is the equilibrium EtBr concentration in liquid phase (mg/L). Temkin isotherm contains a factor that explicitly takes into the account the adsorbing species-adsorbent interactions. The Temkin equation is given as [21]:

which can be linearized as:

where B T = RT/b, T (K) is the absolute temperature, R (8.314 J/mol) is the universal gas constant, K T (per milligram) is the equilibrium binding constant, and b (J/mol) is related to the heat of adsorption. The isotherm constants K T and B T are calculated from the slope and intercept of the qe versus lnCe plot. The plots of linearized Langmuir, Freundlich, and Temkin isotherms are illustrated in Figures 6, 7, and 8, respectively. Parameters of the three isotherms were calculated and listed in Table 1. Based on the values of R2, it can be concluded that the Langmuir isotherm best fits the equilibrium data. The maximum adsorption capacity (qm) of adsorbent calculated from Langmuir isotherm defines the total capacity of the adsorbent for EtBr. The values of RL calculated from Equation 4 are listed in Table 2. The RL values are between 0 and 1, and the adsorption process is favorable. The fact that the Langmuir isotherm fits the experimental data very well may be due to the homogeneous distribution of active sites on the SWCNTs and NZVI surface because application of the Langmuir equation involves the assumption that the surface were homogeneous.

Conclusions

The removal of ethidium bromide by SWCNTs and nanoparticle zero valent iron were studied in a batch system with respect to the temperature, adsorbent dose, and contact time. Removal of EtBr from aqueous solution was possible using SWCNTs and NZVI surfaces. It was seen that maximum adsorption takes place after 5 to 7 min. The optimum doses of adsorbents were 30 mg for NZVI. The Langmuir, Freundlich, and Temkin isotherm models provided the best fits to predict the adsorption for the EtBr by SWCNTs and NZVI surfaces. From the above results, we conclude that the adsorbent NZVI was effective in removing EtBr from aqueous solution. Also, the removal of EtBr by SWCNT surfaces was more effective than that of NZVI surfaces.

Methods

Materials

Ethidium bromide was supplied by Merck, Darmstadt, Germany (maximum purity available). All solutions were prepared with deviations of less than ±0.1% from the desired concentrations. SWCNTs (Armchair (6,6), purity >95; diameter, 1 to 2 nm; length, 5 to 30 nm; surface area, 400 m2/g; and manufacturing method, catalytic chemical vapor deposition).

Preparation of NZVI particles

NZVI particles were prepared by liquid-phase reduction method. All solvents were degassed and saturated for 30 min with N2 before use. NZVI was synthesized by adding 1 M NaBH4 solution into 0.5 M FeCl3 solution during vigorous stirring under N2 atmosphere. The mixture's color turned from red brown to light yellow and then eventually to black. At the same time, the mixture gradually produced more black grain particles in the three-neck flask. Ferric iron (Fe+3) was reduced to elemental iron according to the following reaction:

Then, black NZVI particles were vacuum-filtered and washed with deionized water and 1:1 (V/V) ethanol/acetone; doing so prevented the NZVI from oxidizing, and then, resulting gray-black solid was dried under nitrogen atmosphere before use.

Batch equilibrium studies

Adsorption experiments were carried out by agitating 50 mg of SWCNTs and NZVI for each individually in aqueous solution with 30 ml of EtBr solution of desired concentration for each surfaces (SWCNTs and NZVI) and pH at 180 rpm, 25°C in a thermostated mechanical shaker (ORBITEK, Chennai). Concentration of EtBr was estimated spectrophotometrically by monitoring the absorbance at 274 nm using a UV–vis spectrophotometer (Hitachi model 8543, Chiyoda-ku, Japan).

The effect of adsorbent dosage was studied by agitating 30 mL of EtBr solutions with different adsorbent doses (10 to 70 mg) at equilibrium time. The amounts of EtBr adsorbed by the adsorbent were calculated using the following equation:

where C0 is the initial EtBr concentration, Ct is the EtBr concentration (mg/ L) at any time, V is the volume of solution (L), and W is the mass of the adsorbents (g).

References

Lunn G, Sansone EB: Ethidium bromide: destruction and decontamination of solutions. Anal Biochem 1987, 162: 453–458. 10.1016/0003-2697(87)90419-2

Bountiff L, Levantis P, Oxford J: Electrophoretic Analysis of Nucleic Acids Isolated from Scrapie-infected Hamster Brain. J Gen Virol 1996, 77: 2371–2378. 10.1099/0022-1317-77-9-2371

Bailey SE, Olin TJ, Bricka RM, Adrian DD: A review of potentially low-cost sorbents for heavy metals. Water Res 1999, 33: 2469–2479. 10.1016/S0043-1354(98)00475-8

Uzum C, Shahwan T, Eroglu AE, Lieberwirth I, Scott TB, Hallam KR: Application of zero-valent iron nanoparticles for the removal of aqueous Co2+ ions under various experimental conditions. Chem Eng J 2008, 144: 213–220. 10.1016/j.cej.2008.01.024

Cantrell KJ, Kaplan DI, Wietsma TW: Zero-valent iron for the in situ remediation of selected metals in groundwater. J Hazard Mater 1995, 42: 201–212. 10.1016/0304-3894(95)00016-N

Cho HH, Park JW: Sorption and reduction of tetrachloroethylene with zero valent iron and amphiphilic molecules. Chemosphere 2006, 64: 1047–1052. 10.1016/j.chemosphere.2005.12.062

Dombek T, Dolan E, Schultz J, Klarup D: Rapid reductive dechlorination of atrazine by zero-valent iron under acidic conditions. Environ Pollut 2001, 111: 21–27. 10.1016/S0269-7491(00)00033-6

Ghauch A, Rima J, Amine C, Martin-Bouyer M: Rapid treatment of water contamined with atrazine and parathion with zero-valent iron. Chemosphere 1999, 39: 1309–1315. 10.1016/S0045-6535(99)00034-X

Noubactep C: Characterizing the discoloration of methylene blue in Fe0/H 2 O systems. J Hazard Mater 2009, 166: 79–87. 10.1016/j.jhazmat.2008.11.001

Noubactep C, Kurth AMF, Sauter M: Evaluation of the effects of shaking intensity on the process of methylene blue discoloration by metallic iron. J Hazard Mater 2009, 169: 1005–1011. 10.1016/j.jhazmat.2009.04.046

Noubactep C: Characterizing the reactivity of metallic iron upon methylene blue discoloration in Fe0/MnO 2 /H 2 O systems. J Hazard Mater 2009, 168: 1613–1616. 10.1016/j.jhazmat.2009.02.121

Li XQ, Elliott DW, Zhang WX: Zero-Valent Iron Nanoparticles for Abatement of Environmental Pollutants: Materials and Engineering Aspects. Crit. Rev. Solid State Mater. Sci. 2006, 31: 111–122. 10.1080/10408430601057611

Noubactep C: A Critical review on the process of contaminant removal in fe0–h2o systems. Environ. Technol. 2008, 29: 909–920. 10.1080/09593330802131602

Noradoun CE, Cheng IF: EDTA Degradation Induced by Oxygen Activation in a Zerovalent Iron/Air/Water System. Environ. Part Sci Technol 2005, 39: 7158–7163. 10.1021/es050137v

Wang H, Zhou A, Peng F, Yu H, Yang J: Mechanism study on adsorption of acidified multi-walled carbon nanotubes to Pb(II). J Colloid Interface Sci 2007, 316: 277–283. 10.1016/j.jcis.2007.07.075

Lu C, Chiu H, Liu C: Removal of zinc(II) from aqueous solution by purified carbon nanotubes: Kinetics and equilibrium studies. Ind Eng Chem Res 2006, 45: 2850–2855. 10.1021/ie051206h

Feng J, Lim TT: Iron-mediated reduction rates and pathways of halogenated methanes with nanoscalePd/Fe: Analysis of linear free energy relationship. Chemosphere 2007, 66: 1765–1774. 10.1016/j.chemosphere.2006.06.068

Langmuir I: The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 1918, 40: 1361–1368. 10.1021/ja02242a004

Mahmoodi NM, Arami M: Modeling and sensitivity analysis of dyes adsorption onto natural adsorbent from colored textile wastewater. J Appl Polym Sci 2008, 109: 4043–4048. 10.1002/app.28547

Freundlich HMF: Uber die adsorption in l osungen (adsorption in solution). J Phys Chem 1906, 57: 385–470.

Moradi O, Zare K, Monajjemi M, Yari M, Aghaie H: The studies of equilibrium and thermodynamic adsorption of Pb(II), Cd(II) and Cu(II) ions from aqueous solution on SWCNTs and SWCNT–COOH surfaces. Fullerenes, Nanotubes, and Carbon Nanostructures 2010, 18: 285–302. 10.1080/15363831003783005

Acknowledgements

The authors would like to thank the Islamic Azad University Roudehen Branch for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

FN carried out the result analysis, participated to draft the manuscript and in the manuscript elaboration, carried out the experiments, and obtained most of the experimental images. MN, KZ, and AF coordinated the project, discussed the results, and helped to draft the manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Najafi, F., Norouzi, M., Zare, K. et al. Removal of ethidium bromide by carbon nanotube in aqueous solution: isotherms, equilibrium mechanism studies, and its comparison with nanoscale of zero valent iron as adsorbent. J Nanostruct Chem 3, 60 (2013). https://doi.org/10.1186/2193-8865-3-60

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-60