Abstract

Carbon-based materials have been widely used in gaseous pollutant removal because of their sufficient surface functional groups; however, its removal efficiency for elemental mercury (Hg0) is low. In this study, we fabricated biomass using a chelated coupled pyrolysis strategy and further constructed the regulated adsorption sites for gaseous Hg0 uptake. A series of Mnδ-N2O2/BC with different manganese cluster sizes demonstrated that manganese clusters anchored on biochar acted as highly active and durable adsorbents for Hg0 immobilization, which increased the adsorption efficiency of Hg0 by up to 50%. Shrimp- and crab-based biochar adsorbents exhibited excellent Hg0 removal because of their chitosan-like structure. In particular, small Mn clusters and oxygen species around the defect led to a boost in the Hg0 adsorption by carbon. The results of density functional theory calculation revealed that the presence of oxygen in the carbon skeleton can tune the electrons of small-sized Mn clusters, thereby promoting the affinity of mercury atoms. The newly developed Mnδ-N2O2/BCshrimp had an adsorption capacity of 7.98–11.52 mg g−1 over a broad temperature range (50–200 °C) and showed a high tolerance to different industrial flue gases (H2O, NO, HCl, and SO2). These results provide novel green and low-carbon disposal methods for biomass resource utilization and industrial Hg0 emission control.

Graphical Abstract

Highlights

-

A facile chelated coupled pyrolysis strategy was reported to prepare Mn single-cluster Hg0 adsorbent.

-

The nitrogen-containing group in biomass determined the size of atomically dispersed manganese.

-

The presence of oxygen and small size Mn clusters in biochar promoted Hg0 adsorption.

Similar content being viewed by others

1 Introduction

The development of renewable biomass resources is of great significance for energy conservation and emission reduction to achieve carbon peak and carbon neutrality goals in China (Guigo et al. 2010; Wei et al. 2022). At present, biochar preparation from solid organic matter, such as fruit shells, seafood shells, and activated sludge, is an essential method for biomass utilization using direct pyrolysis methods (Pietrzak and Bandosz 2007; Mohammed et al. 2018; Fu et al. 2019). Prepared biochar is mostly used as an adsorbent in soil remediation and wastewater treatment (Qambrani et al. 2017; Vithanage et al. 2017; Xu et al. 2019). However, biochar prepared by the traditional method primarily relies on its functional groups, such as hydroxyl and carboxyl, for adsorption (Uchimiya et al. 2011; Fan et al. 2018). Consequently, its general efficiency is low, and the properties of carbon-based materials, such as their large specific surface area and good chemical stability, cannot be completely utilized. Therefore, exploring suitable methods for developing more efficient biochar materials remains a challenge.

Regarding heterogeneous adsorption and catalytic processes, conventional functional materials achieve efficient pollutant removal based on dispersed active components (Shen et al. 2013; Wang et al. 2019b; Li et al. 2020b). Single-atom materials are a popular trend in the development of functional materials (Yang et al. 2013; Wang et al. 2018a; Baby et al. 2021). Single-atom materials are generally anchored with oxygen and nitrogen, and their activities can be adjusted through the coordination environment (Yang et al. 2018). Carbon-based single-atom materials, commonly found in nature, are considered to be the most promising sustainable nanomaterials, making carbon materials easier to obtain (Gawande et al. 2020). Heteroatoms can be employed in situ to control the electronic environment around an active site (Fan et al. 2020; Zhang et al. 2020). Furthermore, carbon materials have more advantages in some characterizations, which contributes to confirming the nature of the reaction process. However, the current synthesis of carbon-based single-atom materials primarily focuses on pure chemical reagents, and there is little research on the use of biomass as a raw material. Whether conventional synthesis methods can achieve atomic-level synthesis has rarely been reported.

Mercury, a global pollutant, is primarily transported globally in the form of gaseous elemental mercury (Hg0), and a small part comprises the oxidized form of divalent mercury (Hg2+) and particulate mercury (Hgp) (Galbreath and Zygarlicke 1996; O'Connor et al. 2019). In the atmosphere, Hg0 is transformed into oxidized mercury through photochemical changes, accumulates on the surface through wet and dry deposition, and is subsequently transformed to methylmercury, thereby posing a risk to humans and ecosystems (Selin et al. 2007; Mahaffey et al. 2011). Because most mercury emissions originate from industrial activities, controlling Hg0 emissions from factories at the sources is crucial (Streets et al. 2011). Activated carbon injection technology is currently the most popular Hg0 removal process in industry (Sjostrom et al. 2010). Coal is primarily used as the precursor for commercial activated carbons (e.g., Norit), resulting in high preparation costs and secondary pollution owing to its complex components (Gong et al. 2009).

Biomass can be used as a perfect substitute for coal precursors. First, the cost of biochar is low owing to the wide range of biomass sources and relatively simple components (Mohan et al. 2014; Wang et al. 2019a). Being environment-friendly is an advantage of the prepared biochar and allows the utilization of the biochar system to realize a sustainable circular economy. Second, the by-products produced in the biomass pyrolysis process are utilized for energy substitution, such as in the cogeneration process, which has better benefits than the direct combustion of biomass (Azzi et al. 2019). Third, biochar systems are considered as one of the most readily available negative emission technologies, enlightening global carbon neutrality (Wang et al. 2015; Smith 2016; Borchard et al. 2019). Biochar has also been used to remove Hg0 from industrial flue gas (Li et al. 2015; Shen et al. 2015; Shan et al. 2019; Jia et al. 2021). The performance of biochar in removing Hg0 is poor, although it is rich in functional groups and has a high specific surface area that can be used as a gas adsorption material.

In this study, several Hg0 adsorbents with atomically regulated single clusters on different biochars were fabricated via a chelated coupled pyrolysis strategy. The effect of different biomass structures on Mn chelation was first elucidated to clarify the formation process of atomic Mn. Subsequently, the interaction mechanism of the manganese size and its surrounding coordination environment on Hg0 were clarified through multiple advanced analyses and DFT calculations. Finally, a feasibility analysis of industrial mercury emission control through biomass resource utilization is presented.

2 Materials and methods

2.1 Preparation of Mnδ-N2O2/BC

Before the modification process, each raw biomass was screened by a crushing and vibrating machine, and then biomass with particle sizes in the range of 125–150 μm was obtained by a certain size of the screen. There is no significant change in particle size before and after pyrolysis.

Regarding the Mnδ-N2O2/BC synthesis, the mild reaction environment is crucial to the precise size control of active metal, which may be even more pivotal in the case of an atomically dispersed system. Combined with the green and low-cost preparation concept, we proposed a chelated coupled pyrolysis strategy modified in our previous work (Li et al. 2020a). Briefly, the metal salt was first chelated on the biomass to form the carbon precursors and the Mnδ-N2O2/BC was obtained by pyrolysis at 600 °C under an N2 atmosphere for 1 h, followed by acid etching, and the chemical structure of Mnδ-N2O2/BC was systematically explored. The details of synthesis methods are shown in the Supporting Information.

2.2 Material characterizations

X-ray diffraction patterns (XRD) were collected on a Bruker-AXS D8 Advance with Cu-Kα radiation at a step of 10° min−1 with 2θ from 10 to 80°. The scanning electron microscopy (SEM) was obtained by ZEISS MERLI Compact. The high-resolution transmission electron microscopy (TEM) with energy-dispersive X-ray spectroscopy (EDS) elemental mapping analysis function was taken on a JEM-2100F instrument. Aberration-corrected HAADF-STEM measurements were acquired on JEM-ARM200F. The content of Mn was quantified by an Epsilon 3 × X-Ray Fluorescence (XRF). The X-ray photoelectron spectroscopy (XPS) was conducted using Thermo Scientific K-Alpha. The Fourier-transform infrared spectroscopy (FTIR) and Raman scattering spectra were recorded with Nicolet Nexus 410 and HORIBA LabRAM HR800, respectively. H2 temperature-programmed reduction (H2-TPR) was carried out on Chemisorp TPx 290 instrument; 200 mg of sample was firstly pretreated under Ar stream at 200 °C for 180 min and then cooled to 50 °C. A 10 vol.% H2/Ar stream was passed over the sample while it was being heated from room temperature to 900 °C at a heating rate of 10 °Cmin−1. Thermogravimetry analysis(TGA) was carried out using a Mettler Toledo in an air atmosphere with a heating rate of 10 °C min−1. The Brunauer–Emmett–Teller (BET) surface area, average pore volume, and pore size were determined by Quantachrome 2200e. Mercury temperature-programmed desorption (Hg-TPD) test was conducted by Lumex 915 + at the heating rate of 5 °Cmin−1 in the range of 25–550 °C.

2.3 Evaluation method for Hg0 adsorption

The schematic diagram of the reaction device is shown in Additional file 1: Fig. S1, which is mainly composed of a gas configuration system, fixed bed reactor, mercury generator, mercury analyzer (Lumex, Russia) by cold-vapor atomic absorption method (CVAAS), and tail gas purification system. The stable Hg0 vapor of 800 μg m−3 was generated by the Hg0 penetration device (VICI, Metronics Inc., USA), and the flowing gas containing Hg0, 5% O2, and N2 as balance at a total flow rate of 500 ml min−1. In the flue gas composition effect experiment, Hg0, HCl, NO, H2O, and SO2 were added independently to the reaction system as needed, which was also balanced with Hg0, O2, and N2. 10 mg adsorbent was placed in a 6 mm inner diameter quartz tube in the fixed bed reactor. The adsorption efficiency (\(\eta\)) and adsorption capacity (q) of Hg0 were calculated by Eq. (1) and Eq. (2), respectively.

where [Hg0]in and [Hg0]out are the concentration (μg m−3) of Hg0 at the inlet and outlet of the fixed bed reactor, V is the total gas flow rate (m3 min−1), t is the Hg0 adsorption time (min), and m is the mass of the sorbent (g).

Detailed computer methods of Hg0 adsorption are described in Supporting Information.

2.4 Computational method

We have employed the Vienna Ab Initio Package (VASP) to perform all DFT calculations within the generalized gradient approximation (GGA) using the PBE formulation(Kresse and Furthmüller 1996; Perdew et al. 1996; Grimme 2006). We have chosen the projected augmented wave (PAW) potentials to describe the ionic cores and taken valence electrons into account using a plane-wave basis set with a kinetic energy cutoff of 400 eV(Kresse and Joubert 1999). Partial occupancies of the Kohn–Sham orbitals were allowed using the Gaussian smearing method and a width of 0.05 eV. The electronic energy was considered self-consistent when the energy change was smaller than 10−5 eV. Geometry optimization was considered convergent when the force change was smaller than 0.02 eV/Å. A supercell of 12.3 Å × 21.3 Å × 15 Å with periodic boundary conditions was used for all the systems. For structural optimization, 2 × 2 × 1 k-points meshes with the original Monkhorst–Pack scheme were used. 4 × 4 × 1 k-points meshes were used for static calculations. A 15 Å vacuum layer in the z-axis direction was added to avoid the interference of the layer image coupling caused by the periodic boundary conditions. Bader charge analysis was done to analyze charge populations in the periodic(Sanville et al. 2007).

The adsorption energy of an adsorbate (Eads) was calculated by Eq. (3).

3 Results and discussion

3.1 Characterization of Mnδ-N2O2/BC

Prior to the Hg0 adsorption test, Mnδ-N2O2/BC was first characterized by aberration-corrected HAADF-STEM to confirm that the atom-precise synthesis of clusters appeared as bright dots. However, significant differences in the sizes of the clusters were observed for different biomasses. Briefly, the size of the Mnδ-N2O2/BCshrimp was between 1 and 2 nm (Fig. 1a), whereas that of Mnδ-N2O2/BCsludge was greater than 5 nm (Fig. 1d). In addition, both Mnδ-N2O2/BC for crabs and peanuts had diameters of more than 3 nm (Fig. 1b, c). This suggests that the structure of the different precursors can influence the agglomeration state of Mn even under the same synthesis conditions.

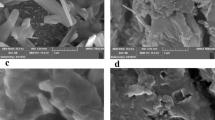

Additionally, the Mn loading of each Mnδ-N2O2/BC sample was measured via XRF. The Mn content in Mnδ-N2O2/BC, except for Mnδ-N2O2/BCpeanut, was less than 1% (Additional file 1: Fig. S2), which is consistent with the atomically dispersed metal content. Concerning Mnδ-N2O2/BCpeanut, the high Mn content may be derived from a specific peanut structure that allows more Mn to be stably anchored in the carbon matrix. However, the four types of Mnδ-N2O2/BC exhibited similar XRD patterns, with no characteristic peaks for Mn (Fig. 2a). A broad peak occurring at approximately 25.5 °C was assigned to low-graphitized carbon. Moreover, an increase in the chlorine element of N2O2/BC and Mnδ-N2O2/BC was caused by the introduction of Cl in the hydrochloric acid and manganese salts (Additional file 1: Table S1). The sludge showed abundant elements, and the Si content remained relatively high after carbonization and acid leaching, consistent with the XRD results that observed SiO2. In addition, Ca dominated in both crab and shrimp, which was ascribed to the high content of calcium carbonate in these two biomasses. After the acid leaching process, the Ca content in N2O2/BCcrab (11.6%) and N2O2/BCshrimp (6.8%) was significantly higher than that in Mnδ-N2O2/BCcrab (0.2%) and Mnδ-N2O2/BCshrimp (0.3%), implying that these inorganic substances were more unstable and susceptible to acid leaching after the introduction of manganese salts. Furthermore, the presence of two sharp peaks in the Mnδ-N2O2/BCsludge was attributed to SiO2 (PDF#85-0795) from the original sludge, which could not be removed by acid leaching. Several minerals (PDF#71-1663) were also present in the shrimp and crab shell-based materials (Additional file 1: Fig. S3); however, all the extras were removed after the formation of Mnδ-N2O2/BC. In comparison, the TEM images (Additional file 1: Fig. S4) of Mnδ-N2O2/BCshrimp and Mnδ-N2O2/BCpeanut revealed no significant metal nanoparticles and only a different carbon skeleton structure. The above-mentioned characterizations demonstrated that Mn was well dispersed as clusters without evidently aggregated nanoparticles via the biomass precise anchoring method. Additional file 1: Fig. S5 illustrates the Raman spectra of Mnδ-N2O2/BCshrmip and Mnδ-N2O2/BCpeanut. The intensity ratio of the 2D/G value of Mnδ-N2O2/BCshrmip (0.42) was considerably higher than that of Mnδ-N2O2/BCpeanut (0.10), indicating that the graphitized structure of Mnδ-N2O2/BCshrmip was thinner than that of Mnδ-N2O2/BCpeanut. This result was attributed to the effective prevention of π–π stacking in the shrimp shell during pyrolysis (Xi et al. 2018). These findings are in accordance with the SEM images (Additional file 1: Fig. S6), in which Mnδ-N2O2/BCshrmip was in pieces and Mnδ-N2O2/BCpeanut was in bulk.

3.2 Effect of different biomass structures on manganese chelation

The structure of the carbon material precursor is crucial for the formation of atomically dispersed metals. As shown in Fig. 2b, the features and chemical structure of the four Mn-chelated biomasses during pyrolysis were investigated via TGA and derivative thermogravimetric analysis (DTG). The decomposition of the four samples was multi-step, indicating that the reassembly of Mn sites is a multi-stage process. The rate of weight loss is represented by the DTG curve (dashed line in Fig. 2b). The appearance of three peaks could be evidently observed before 200 °C in each sample, which is attributed to the loss of bound water at near 70 °C and the removal of crystal water from manganese chloride hydrate at 100–200 °C. At approximately 235 °C, the oxygen-containing functional groups began to dehydrate and polymerize to form polycyclic aromatic structures, and the weight loss of peanut-Mn was most evident at this stage because of the large amount of cellulose in the peanut shell. In particular, the weight loss step with a peak temperature of 350 °C only appeared in shrimp-Mn and crab-Mn, which corresponds to the decomposition of acetamido. In addition, the TGA results for pure manganese chloride showed the conversion of Mn compounds at 560 °C (Additional file 1: Fig. S7), which is consistent with the DTG results for peanut-Mn and sludge-Mn. However, a red shift in the decomposition peak at 595 °C was found for shrimp-Mn and crab-Mn, indicating that the unique coordination environment in shrimp and crab shells is suitable for the formation of a stable structure with manganese.

An FTIR analysis was performed to obtain a comprehensive understanding of the effect of different biomass structures on the size of Mn clusters. As shown in Fig. 2c, all four types of biomasses demonstrated many functional group peaks comprising aromatic C=O at 1616 cm−1 and –C–O–C at 1026–1070 cm−1 (Chen et al. 2015). Among them, crab and shrimp shells exhibited almost identical surface structures, with the main difference from peanut shells and sludge being the –OH starch primary alcoholic group at 1415 cm−1 and two absorption peaks at 1070 and 1026 cm−1 ascribed to C–O glucose bending and a peak at 874 cm−1 assigned to –NH stretching. These specific structures were generated owing to the existence of a chitin structure, whereas the structures of peanut-Mn and sludge-Mn were contributed by cellulose (Raja et al. 2012; Torres-Garcia et al. 2020; Zhu et al. 2021). Notably, the biomass structure exhibited variations after Mn was chelated. The slight blue shift of –C=O in all four samples was primarily owing to the interactions between –C=O and Mn compounds. Compared with those in crab-Mn, the peak intensities of –OH, –C–O–C, and –N–H decreased in shrimp-Mn, demonstrating that oxygen-containing groups and amino groups participate in the anchoring process of the Mn site.

As shown in Fig. 2d, the effect of different biomass structures on manganese chelation was depicted in combination with the STEM, TGA, and FTIR results. Comparing the samples related to crab and shrimp, the nitrogen-containing group played a positive role in the formation of small clusters of Mn species, which is consistent with the laws of atomic-scale metal formation (Yang et al. 2021). Because nitrogen-containing species in crab samples did not contribute to Mn, the size of the anchored Mn was similar to that of peanut shell samples with only oxygen-containing functional groups, indicating that the coordination environment without nitrogen atoms can only provide weak binding for Mn. Furthermore, the larger manganese clusters in the sludge are due to the insufficient number of functional groups, which can be inferred from the lower weight loss of the TGA curves at around 235 °C.

The FTIR spectra for Mnδ-N2O2/BC and N2O2/BC revealed that the structure of each material changed after pyrolysis (Additional file 1: Fig. S8). The abundance of functional groups in the four types of biomass decreased when pyrolyzed at 600 °C. The wavenumbers of several functional groups changed. For example, the peaks of aromatic C=C or C=O in the four biomasses all shifted to lower wavenumbers owing to the increasing bond of carbon in the graphitization process at higher pyrolysis temperatures (Xiao et al. 2018b). Similarly, there was an increase in the wavenumbers of –C–O–C in peanut and sludge-based samples, suggesting that the structures of these two biomasses were more favorable for the conversion of alkylating oxygen to aromatic C–O groups (Sun et al. 2019). Moreover, –C–O–C in the benzene ring significantly decreased in Mnδ-N2O2/BCcrab and Mnδ-N2O2/BCshrimp, indicating the critical role of the –C–O–C group as a direct anchoring site for the stabilization of Mn species.

3.3 Evaluation of Hg0 removal performance

The Hg0 adsorption activity of Mnδ-N2O2/BC was evaluated at 100 °C under 5% O2. The Hg0 removal performance of Mnδ-N2O2/BC was significantly better than that of N2O2/BC. The adsorption capacity of Hg0 within 300 min was significantly improved, up to 11.27 mg/g in Mnδ-N2O2/BCshrimp, verifying the universality of this method. Regardless of whether it is a conventional commercial activated carbon or manganese oxide adsorbent, its adsorption capacity for Hg0 is generally limited under the same conditions (Li et al. 2021; Ye et al. 2021). Compared with other biomass-based Hg0 removal materials, the adsorption capacity was improved by several orders of magnitude (Table 1). Briefly, the in-situ dispersion of Mn species in biomass can achieve high activity. Among the four types of Mnδ-N2O2/BC, Mnδ-N2O2/BCshrimp and Mnδ-N2O2/BCcrab retained a high Hg0 removal performance of 99.7% (Fig. 3a, b), whereas Mnδ-N2O2/BCpeanut and Mnδ-N2O2/BCsludge were only 92.8% (Fig. 3c) and 85.7% (Fig. 3d), respectively.

Comparing Mnδ-N2O2/BCcrab and Mnδ-N2O2/BCpeanut with similar Mn cluster sizes, the adsorption capacities for mercury were quite different. Thus, the different coordination environments around them may have changed the electronic environment around the clusters. Notably, both Mnδ-N2O2/BCshrimp and Mnδ-N2O2/BCcrab exhibited high adsorption capacities and adsorption efficiencies, suggesting that the “chitosan-like” structure played a crucial role in the generation of highly active Mn sites. Based on this, pure chitosan was used to prepare biochar for comparison. In Additional file 1: Fig. S9a, Mnδ-N2O2/BCchitosan and Mnδ-N2O2/BCshrimp show consistent adsorption breakthrough curve behavior. Additionally, the Hg0-TPD (Additional file 1: Fig. S9b) test was performed to analyze the bound states of mercury in the material. The results revealed that the Hg0 desorption peaks were concentrated in a narrow interval from 226 to 259 °C for all three materials, implying that the active site of Hg0 was consistent. Therefore, biochars formed from biomass with a chitosan-like structure are more conducive to the formation of active components with a strong affinity for Hg0. H2-TPR tests were also conducted to investigate the reducibility of the Mnδ-N2O2/BCcrab and Mnδ-N2O2/BCshrimp (Additional file 1: Fig. S10). Both of the samples presented sharp peaks at about 500 °C with another peak at approximately 750 °C. With respect to low-temperature peaks, this is the typical feature of the metal in an oxidation state. Considering that the Mnδ-N2O2/BCshrimp exhibited a reduced peak at low temperatures, it possessed active Mn species for Hg0 oxidation. The peaks at approximately 750 °C for both samples corresponded to carbon gasification (Zhang et al. 2015).

3.4 Effect of biomass structure on adsorption efficiency

Shrimp shells were pyrolyzed at different temperatures to further understand the adsorption behavior of mercury in the material. Thus, the manganese clusters had different coordination environments, labeled as Mnδ-N2O2/BCshrimp (600–1000). The mercury adsorption curve of Mnδ-N2O2/BCshrimp (600–1000) is shown in Fig. 4a, and the test was completed under 5% O2 at 100 °C. Both the adsorption efficiency and capacity of Mnδ-N2O2/BCshrimp gradually decreased with an increase in the pyrolysis temperature. The efficiencies of the best-performing samples Mnδ-N2O2/BCshrimp (600) and Mnδ-N2O2/BCshrimp (700) reached 99.5% and 99.7% at 50 min, respectively. The mercury removal performance of Mnδ-N2O2/BCshrimp decreased when the pyrolysis temperature reached 900 °C, which is consistent with our previous research revealing that a high pyrolysis temperature exerted a negative effect on the affinity of the active components for Hg0 (Li et al. 2021). However, the Hg0-TPD results (Fig. 4b) did not match the same rule, in which the positions of the desorption peaks were concentrated at 200–300 °C. The binding ability to mercury increased from 600 to 900 °C. The desorption peak position returned to a low temperature when the pyrolysis temperature was further elevated to 1000 °C. Energy-dispersive spectroscopy elemental mapping further corroborated the presence of C, N, O, Hg, and Mn, as well as the sparse dispersion of Mn throughout Mnδ-N2O2/BCshrimp (Fig. 1e). The uniform distribution of Hg also demonstrated that Hg0 was immobilized in the sample.

The N 1 s spectra of XPS (Fig. 4c) for Mnδ-N2O2/BCshrimp (600–1000) confirmed the presence of three different bonding configurations of N species at 398.3, 398.9, and 400.4 eV, representing pyridinic, pyrrolic, and quaternary N, respectively (Xiao et al. 2018a). Quaternary N was more dominant in the N 1 s region, whereas there was no direct contribution to the adsorption of Hg0 because of the high proportions of Mnδ-N2O2/BCshrimp (900–1000). The anchoring effect of doped-N on Mn atoms primarily occurred in pyridinic-N and pyrrolic-N. The deconvoluted O 1 s spectrum (Fig. 4d) of Mnδ-N2O2/BCshrimp (600–1000) presented four peaks: –C–O–C (533.93 eV), –C–O–H (532.83 eV), –C=O (532.03 eV), and –M–O (530.98 eV). A quantitative analysis of the O- suggested a decline in the Mn–O content in Mnδ-N2O2/BCshrimp (600–1000) (20.0–4.0%) and a further decrease in –C=O to 45.3–25.1%. Meanwhile, the stable ratios of –C–O–C and –C–O–H may be attributed to the nature of the biochar itself. For the rapidly deactivated samples, Mnδ-N2O2/BCshrimp (900) and Mnδ-N2O2/BCshrimp (1000), both pyridinic-N and Mn–O ratios decreased, illustrating that heteroatoms N and O associated with Mn contributed to the improvement in mercury adsorption performance.

An increase in the specific surface area generally exerts positive effects on the activity of carbon materials (Tan et al. 2008). Thus, Zn species was introduced in the biomass pyrolysis process to increase the specific surface area of carbon materials, which had the effect of pore expansion (Demiral et al. 2008). As the boiling point of zinc chloride was approximately 700 °C, 800 °C was selected as the biomass pyrolysis temperature to further verify the effect of specific surface area on the activity of biochar. As shown in Additional file 1: Fig. S11a, the N2 adsorption–desorption isotherms were adopted to measure the surface areas (BET methods) of the samples. All the samples presented type IV adsorption curves, which reflected the presence of mesopores. This result was validated in the pore size distribution curves (Additional file 1: Fig. S11b). Additional file 1: Table S2 shows that the pore volume increased from 0.56 to 0.93 cm3 g−1, and the BET surface area was determined to be 754.73 m2 g−1 for Mnδ-N2O2/BCshrimp (800), which was significantly larger than that of the samples without Zn (419.89 m2 g−1). Thus, the pore structure was optimized by the extra Zn. Nevertheless, the Hg0 adsorption curve (Additional file 1: Fig. S12) showed no difference between the two samples; both exhibited excellent mercury removal performance, and the adsorption efficiency remained above 97% within 300 min. Therefore, the effect of metal active sites on Hg0 was higher than that of pore structure in biomass, confirming the importance of using biomass to anchor metals for the activation.

3.5 Mechanism of Hg0 adsorption on Mnδ-NδOδ/BC

Using DFT calculations, the changes in the electronic structure of the Mn cluster size or its coordination environment in carbon were investigated to reveal the influence of Hg0 adsorption. Based on the structural formation provided by the spectroscopic results, several models were optimized to accurately simulate the actual situation (Fig. 5a). Mn with different atom numbers was constructed (Mn4, Mn7, and Mn10) to better demonstrate the influence of Mn cluster size in the reaction. Different coordination environments were achieved by replacing part of the carbon atoms in the defect with oxygen atoms or nitrogen atoms; however, two cases of both the presence of oxygen and nitrogen (N2O2) and the presence of only nitrogen (N4) were considered. After optimizing the models for different Mn sizes, oxygen and nitrogen in the carbon skeleton exhibited different relaxation behaviors. Specifically, the oxygen atoms underwent downward displacements of average values of − 0.33, − 0.53, and − 0.97 Å as the Mn clusters became larger. Briefly, the force between the clusters and oxygen weakened. In addition, the nitrogen atoms that tended to be close to Mn clusters shifted by + 0.02 to + 0,67 Å. Furthermore, changes in oxygen and nitrogen atoms can be corroborated by the charge-transfer analysis, as revealed by differential charge density in Fig. 5b. The large electron charge distribution around O in Mn4-N2O2/C suggested that O 2p orbitals interacted with the nearby Mn 5d orbital to form σ-type Mn–O interactions. On the contrary, the electron transfer of N ligands in Mn4-N4/C was not significant, and thus, O atoms possessed a significant effect on the electron distribution of manganese clusters compared to N atoms. However, larger Mn clusters led to a weakened interaction of oxygen with Mn, and the electron charge distribution was not even visible in model Mn10-N2O2/C. The above rules also impacted the electronic changes during Hg0 adsorption, with the mercury adsorption free energy of -0.66, − 0.57, and − 0.41 eV for Mn4-N2O2/C, Mn7-N2O2/C, and Mn10-N2O2/C, respectively (Fig. 5c). Hence, in the cases of oxygen atom substitution, small manganese clusters favored the formation of strong Hg-Mn interactions. In the case of Mn4-N4/C without oxygen atoms, the adsorption energy (− 0.37 eV) was lower than that of Mn10-N2O2/C. This implies that the coordination environment of the Mn clusters had a more significant effect on mercury adsorption than size. The Bader charge analysis was also consistent with the above results that Hg presented more charge loss in Mn4-N2O2/C (Additional file 1: Table S3). In addition, Additional file 1: Fig. S13 shows the diagram for the mercury removal mechanism to better understand the removal mechanism. Additionally, the mercury removal mechanism digram is shown in Additional file 1: Fig. S13 to better understand the removal mechanism.

(a) Optimized structures of Mn4-N2O2/C, Mn4-N4/C, Mn7-N2O2/C, and Mn10-N2O2/C after Hg0 adsorption. (b) Differential charge density plots of the structure for Mn4-N2O2/C, Mn4-N4/C, Mn7-N2O2/C, and Mn10-N2O2/C after Hg0 adsorption. Green and Yellow contours indicate electron deletion and electron accumulation. (c) Free energy profiles of Hg0 adsorption on four optimized models

3.6 Feasibility analysis of industrial flue gas treatment application

The properties of the materials under different flue gas conditions favor industrial applications. First, Mnδ-N2O2/BCshrimp with better Hg0 removal behavior in Mnδ-N2O2/BC was selected for testing at different temperatures (50–250 °C). As indicated in Fig. 6a, the Hg0 adsorption efficiency of Mnδ-N2O2/BCshrimp remained above 99% at 50–200 °C and decreased to 75.34% after the temperature increased to 250 °C. The optimum reaction temperature for Mnδ-N2O2/BCshrimp was 150 °C, where the adsorption capacity reached 11.52 mg g-1. According to the results of other temperature sections (Additional file 1: Table S4), the adsorption capacity of the current commercial activated carbon (Yang et al. 2007), Mnδ-N2O2/BCshrimp, has the potential for industrial application at 50–200 °C. Additionally, SO2, HCl, NO, and H2O, which are common components of industrial flue gas, can influence the mercury adsorption performance of adsorbents owing to the competing adsorption effect. Thus, common component concentrations under different flue gas conditions were selected to investigate the selectivity of Mnδ-N2O2/BCshrimp. These components showed a limited effect on the adsorption properties of Hg0 (Fig. 6b). The results for adsorption efficiency within 50 min showed that the adsorption efficiency of the material was maintained above 99% under all flue gas conditions, verifying that the Mnδ-N2O2/BCshrimp was highly tolerant and stable for Hg0 removal. In addition, flue gases, such as those in the nonferrous smelting industry, have ultra-high concentrations of SO2, which can severely influence the activity of the adsorbents. Consequently, the concentration of SO2 in the simulated flue gas increased, and the results indicated that the adsorption efficiency was above 97%, even in the presence of 5% SO2. The mercury adsorption capacities under different conditions are provided in Additional file 1: Table S5, which demonstrate the ultra-high selectivity of this material for Hg0.

Figure 6c shows the resource utilization and industrial application of biomass for Hg0 capture. First, biomass feedstock was subjected to a series of pretreatment processes, such as collection, milling, washing, and drying. The pure biomass precursor obtained in this manner is an ideal reaction medium for subsequent processing. Second, biomass was transformed into biochars for mercury adsorption using the method described herein. Finally, it was packaged to form a product for sale. The technology adopted in the entire process is simple and comprehensive, and the prepared material is a candidate for commercial activated carbon. Furthermore, the material has wide industrial applications in terms of mercury removal owing to the special properties of the material, such as resistance to the interference of flue gas components and a wide range of adsorption temperatures. The carbon injection device can be added before the dust removal device, which is between 150 and 220 °C. Thus, most of the carbon that has adsorbed mercury can be removed by the dust collector and collected as a mixture with other particulates. Because the desorption temperature of mercury in this material is between 220 and 300 °C, the mercury-immobilized dust can easily be separated via thermal desorption with low energy consumption. Moreover, industries such as the nonferrous metal smelting industry produce value-added products (such as sulfuric acid and sludge) at low temperatures (< 150 °C). In this case, Hg0 was removed at a higher temperature to ensure the high quality of the additional product.

4 Conclusions

In summary, our results showed that the structure of biomass affects the size of atomically dispersed Mn, and nitrogen-containing groups play a positive role in small size Mn clusters (1–2 nm). Mn clusters of small sizes and oxygen species around the defect were found in Mnδ-N2O2/BCshrimp, leading to a boost in the Hg0 adsorption of carbon, which demonstrated an adsorption capacity of 7.98–11.52 mg g−1 at broad temperature ranges (50–200 °C). DFT calculation results also revealed that the presence of oxygen in the carbon skeleton can tune the electrons of small-sized Mn clusters, thereby promoting the affinity of mercury atoms, with mercury adsorption free energy of approximately − 0.37 (Mn4-N4/C) to − 0.66 eV (Mn4-O2N2/C). Moreover, owing to the high tolerance of different industrial flue gases (H2O, NO, HCl, and SO2) to Mn δ-N2O2/BCshrimp, the adsorption efficiency of the material was maintained above 99% under all flue gas conditions, establishing the feasibility of industrial mercury emission control and low-carbon disposal methods for biomass resource utilization.

Availability of data and materials

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Azzi ES, Karltun E, Sundberg C (2019) Prospective life cycle assessment of large-scale biochar production and use for negative emissions in Stockholm. Environ Sci Technol 53(14):8466–8476. https://doi.org/10.1021/acs.est.9b01615

Baby A, Trovato L, Di Valentin C (2021) Single atom catalysts (SAC) trapped in defective and nitrogen-doped graphene supported on metal substrates. Carbon 174:772–788. https://doi.org/10.1016/j.carbon.2020.12.045

Borchard N, Schirrmann M, Cayuela ML, Kammann C, Wrage-Monnig N, Estavillo JM et al (2019) Biochar, soil and land-use interactions that reduce nitrate leaching and N2O emissions: a meta-analysis. Sci Total Environ 651(Pt 2):2354–2364. https://doi.org/10.1016/j.scitotenv.2018.10.060

Chen Z, Xiao X, Chen B, Zhu L (2015) Quantification of chemical states, dissociation constants and contents of oxygen-containing groups on the surface of biochars produced at different temperatures. Environ Sci Technol 49(1):309–317. https://doi.org/10.1021/es5043468

Demiral H, Demiral I, Tümsek F, Karabacakoğlu B (2008) Pore structure of activated carbon prepared from hazelnut bagasse by chemical activation. Surf Interface Anal 40(3–4):616–619. https://doi.org/10.1002/sia.2631

Fan Q, Sun J, Chu L, Cui L, Quan G, Yan J et al (2018) Effects of chemical oxidation on surface oxygen-containing functional groups and adsorption behavior of biochar. Chemosphere 207:33–40. https://doi.org/10.1016/j.chemosphere.2018.05.044

Fan M, Cui J, Wu J, Vajtai R, Sun D, Ajayan PM (2020) Improving the catalytic activity of carbon-supported single atom catalysts by polynary metal or heteroatom doping. Small 16(22):e1906782. https://doi.org/10.1002/smll.201906782

Fu M, Chen W, Zhu X, Yang B, Liu Q (2019) Crab shell derived multi-hierarchical carbon materials as a typical recycling of waste for high performance supercapacitors. Carbon 141:748–757. https://doi.org/10.1016/j.carbon.2018.10.034

Galbreath KC, Zygarlicke CJ (1996) Mercury speciation in coal combustion and gasification flue gases. Environ Sci Technol 30(8):2421–2426. https://doi.org/10.1021/es950935t

Gawande MB, Fornasiero P, Zbořil R (2020) Carbon-based single-atom catalysts for advanced applications. ACS Catal 10(3):2231–2259. https://doi.org/10.1021/acscatal.9b04217

Gong G-z, Qiang X, Zheng Y-f, Ye S-f, Chen Y-f (2009) Regulation of pore size distribution in coal-based activated carbon. New Carbon Mater 24(2):141–146. https://doi.org/10.1016/S1872-5805(08)60043-8

Grimme S (2006) Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J Comput Chem 27(15):1787–1799

Guigo N, Mija A, Vincent L, Sbirrazzuoli N (2010) Eco-friendly composite resins based on renewable biomass resources: polyfurfuryl alcohol/lignin thermosets. Eur Polymer J 46(5):1016–1023. https://doi.org/10.1016/j.eurpolymj.2010.02.010

Jia L, Yu Y, Li Z-p, Qin S-n, Guo J-r, Zhang Y-Q et al (2021) Study on the Hg0 removal characteristics and synergistic mechanism of iron-based modified biochar doped with multiple metals. Biores Technol 332:125086

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54(16):11169. https://doi.org/10.1103/PhysRevB.54.11169

Kresse G, Joubert D (1999) From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B 59(3):1758. https://doi.org/10.1103/PhysRevB.59.1758

Li G, Shen B, Li F, Tian L, Singh S, Wang F (2015) Elemental mercury removal using biochar pyrolyzed from municipal solid waste. Fuel Process Technol 133:43–50. https://doi.org/10.1016/j.fuproc.2014.12.042

Li J, Xu H, Liao Y, Qiu Y, Yan N, Qu Z (2020a) Atomically dispersed manganese on a carbon-based material for the capture of gaseous mercury: mechanisms and environmental applications. Environ Sci Technol 54(8):5249–5257. https://doi.org/10.1021/acs.est.9b07524

Li Z, Ji S, Liu Y, Cao X, Tian S, Chen Y et al (2020b) Well-defined materials for heterogeneous catalysis: from nanoparticles to isolated single-atom sites. Chem Rev 120(2):623–682. https://doi.org/10.1021/acs.chemrev.9b00311

Li J, Xu H, Huang Z, Hong Q, Qiu Y, Yan N et al (2021) Strengthen the affinity of element mercury on the carbon-based material by adjusting the coordination environment of single-site manganese. Environ Sci Technol 55(20):14126–14135. https://doi.org/10.1021/acs.est.1c04094

Mahaffey KR, Sunderland EM, Chan HM, Choi AL, Grandjean P, Mariën K et al (2011) Balancing the benefits of n-3 polyunsaturated fatty acids and the risks of methylmercury exposure from fish consumption. Nutr Rev 69(9):493–508

Mohammed NAS, Abu-Zurayk RA, Hamadneh I, Al-Dujaili AH (2018) Phenol adsorption on biochar prepared from the pine fruit shells: equilibrium, kinetic and thermodynamics studies. J Environ Manage 226:377–385. https://doi.org/10.1016/j.jenvman.2018.08.033

Mohan D, Sarswat A, Ok YS, Pittman CU Jr (2014) Organic and inorganic contaminants removal from water with biochar, a renewable, low cost and sustainable adsorbent—a critical review. Bioresour Technol 160:191–202. https://doi.org/10.1016/j.biortech.2014.01.120

Niu Q, Luo J, Xia Y, Sun S, Chen Q (2017) Surface modification of bio-char by dielectric barrier discharge plasma for Hg0 removal. Fuel Process Technol 156:310–316. https://doi.org/10.1016/j.fuproc.2016.09.013

O’Connor D, Hou D, Ok YS, Mulder J, Duan L, Wu Q et al (2019) Mercury speciation, transformation, and transportation in soils, atmospheric flux, and implications for risk management: a critical review. Environ Int 126:747–761. https://doi.org/10.1016/j.envint.2019.03.019

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77(18):3865. https://doi.org/10.1103/PhysRevLett.77.3865

Pietrzak R, Bandosz TJ (2007) Activated carbons modified with sewage sludge derived phase and their application in the process of NO2 removal. Carbon 45(13):2537–2546. https://doi.org/10.1016/j.carbon.2007.08.030

Qambrani NA, Rahman MM, Won S, Shim S, Ra C (2017) Biochar properties and eco-friendly applications for climate change mitigation, waste management, and wastewater treatment: a review. Renew Sustain Energy Rev 79:255–273. https://doi.org/10.1016/j.rser.2017.05.057

Raja R, Chellaram C, John AA (2012) Antibacterial properties of chitin from shell wastes. Indian J Innov Dev 1(S8):7–10

Sanville E, Kenny SD, Smith R, Henkelman G (2007) Improved grid-based algorithm for Bader charge allocation. J Comput Chem 28(5):899–908. https://doi.org/10.1002/jcc.20575

Selin NE, Jacob DJ, Park RJ, Yantosca RM, Strode S, And LJ et al (2007) Chemical cycling and deposition of atmospheric mercury: global constraints from observations. J Geophys Res Atmos. https://doi.org/10.1029/2006jd007450

Shan Y, Yang W, Li Y, Liu Y, Pan J (2019) Preparation of microwave-activated magnetic bio-char adsorbent and study on removal of elemental mercury from flue gas. Sci Total Environ 697:134049. https://doi.org/10.1016/j.scitotenv.2019.134049

Shen L, Wu W, Liang R, Lin R, Wu L (2013) Highly dispersed palladium nanoparticles anchored on UiO-66 (NH 2) metal-organic framework as a reusable and dual functional visible-light-driven photocatalyst. Nanoscale 5(19):9374–9382. https://doi.org/10.1039/C3NR03153E

Shen B, Li G, Wang F, Wang Y, He C, Zhang M et al (2015) Elemental mercury removal by the modified bio-char from medicinal residues. Chem Eng J 272:28–37. https://doi.org/10.1016/j.cej.2015.03.006

Sjostrom S, Durham M, Bustard CJ, Martin C (2010) Activated carbon injection for mercury control: overview. Fuel 89(6):1320–1322. https://doi.org/10.1016/j.fuel.2009.11.016

Smith P (2016) Soil carbon sequestration and biochar as negative emission technologies. Glob Chang Biol 22(3):1315–1324. https://doi.org/10.1111/gcb.13178

Streets DG, Devane MK, Lu Z, Bond TC, Sunderland EM, Jacob DJ (2011) All-time releases of mercury to the atmosphere from human activities. Environ Sci Technol 45(24):10485–10491. https://doi.org/10.1021/es202765m

Sun Y, Yu IKM, Tsang DCW, Cao X, Lin D, Wang L et al (2019) Multifunctional iron-biochar composites for the removal of potentially toxic elements, inherent cations, and hetero-chloride from hydraulic fracturing wastewater. Environ Int 124:521–532. https://doi.org/10.1016/j.envint.2019.01.047

Tan IA, Ahmad AL, Hameed BH (2008) Adsorption of basic dye on high-surface-area activated carbon prepared from coconut husk: equilibrium, kinetic and thermodynamic studies. J Hazard Mater 154(1–3):337–346. https://doi.org/10.1016/j.jhazmat.2007.10.031

Torres-Garcia E, Ramirez-Verduzco LF, Aburto J (2020) Pyrolytic degradation of peanut shell: activation energy dependence on the conversion. Waste Manag 106:203–212. https://doi.org/10.1016/j.wasman.2020.03.021

Uchimiya M, Chang S, Klasson KT (2011) Screening biochars for heavy metal retention in soil: role of oxygen functional groups. J Hazard Mater 190(1–3):432–441. https://doi.org/10.1016/j.jhazmat.2011.03.063

Vithanage M, Herath I, Joseph S, Bundschuh J, Bolan N, Ok YS et al (2017) Interaction of arsenic with biochar in soil and water: a critical review. Carbon 113:219–230. https://doi.org/10.1016/j.carbon.2016.11.032

Wang J, Xiong Z, Kuzyakov Y (2015) Biochar stability in soil: meta-analysis of decomposition and priming effects. GCB Bioenergy 8(3):512–523. https://doi.org/10.1111/gcbb.12266

Wang A, Li J, Zhang T (2018a) Heterogeneous single-atom catalysis. Nat Rev Chem 2(6):65–81. https://doi.org/10.1038/s41570-018-0010-1

Wang T, Liu J, Zhang Y, Zhang H, Chen W-Y, Norris P et al (2018b) Use of a non-thermal plasma technique to increase the number of chlorine active sites on biochar for improved mercury removal. Chem Eng J 331:536–544. https://doi.org/10.1016/j.cej.2017.09.017

Wang T, Wu J, Zhang Y, Liu J, Sui Z, Zhang H et al (2018c) Increasing the chlorine active sites in the micropores of biochar for improved mercury adsorption. Fuel 229:60–67. https://doi.org/10.1016/j.fuel.2018.05.028

Wang Y, Qu Q, Gao S, Tang G, Liu K, He S et al (2019a) Biomass derived carbon as binder-free electrode materials for supercapacitors. Carbon 155:706–726. https://doi.org/10.1016/j.carbon.2019.09.018

Wang Y, Wang S, Lou XWD (2019b) Dispersed nickel cobalt oxyphosphide nanoparticles confined in multichannel hollow carbon fibers for photocatalytic CO2 reduction. Angew Chem Int Ed Engl 58(48):17236–17240. https://doi.org/10.1002/anie.201909707

Wei Y-M, Chen K, Kang J-N, Chen W, Wang X-Y, Zhang X (2022) Policy and management of carbon peaking and carbon neutrality: a literature review. Engineering. https://doi.org/10.1016/j.eng.2021.12.018

Xi J, Sun H, Wang D, Zhang Z, Duan X, Xiao J et al (2018) Confined-interface-directed synthesis of Palladium single-atom catalysts on graphene/amorphous carbon. Appl Catal B 225:291–297. https://doi.org/10.1016/j.apcatb.2017.11.057

Xiao P, Wang P, Li H, Li Q, Shi Y, Wu X-L et al (2018a) New insights into bisphenols removal by nitrogen-rich nanocarbons: synergistic effect between adsorption and oxidative degradation. J Hazard Mater 345:123–130. https://doi.org/10.1016/j.jhazmat.2017.11.001

Xiao X, Chen B, Chen Z, Zhu L, Schnoor JL (2018b) Insight into multiple and multilevel structures of biochars and their potential environmental applications: a critical review. Environ Sci Technol 52(9):5027–5047. https://doi.org/10.1021/acs.est.7b06487

Xu Z, Xu X, Tao X, Yao C, Tsang DCW, Cao X (2019) Interaction with low molecular weight organic acids affects the electron shuttling of biochar for Cr(VI) reduction. J Hazard Mater 378:120705. https://doi.org/10.1016/j.jhazmat.2019.05.098

Yang H, Xu Z, Fan M, Bland AE, Judkins RR (2007) Adsorbents for capturing mercury in coal-fired boiler flue gas. J Hazard Mater 146(1–2):1–11. https://doi.org/10.1016/j.jhazmat.2007.04.113

Yang XF, Wang A, Qiao B, Li J, Liu J, Zhang T (2013) Single-atom catalysts: a new frontier in heterogeneous catalysis. Acc Chem Res 46(8):1740–1748. https://doi.org/10.1021/ar300361m

Yang J, Zhao Y, Ma S, Zhu B, Zhang J, Zheng C (2016) Mercury removal by magnetic biochar derived from simultaneous activation and magnetization of sawdust. Environ Sci Technol 50(21):12040–12047. https://doi.org/10.1021/acs.est.6b03743

Yang Y, Mao K, Gao S, Huang H, Xia G, Lin Z et al (2018) O-, N-atoms-coordinated Mn cofactors within a graphene framework as bioinspired oxygen reduction reaction electrocatalysts. Adv Mater 30(28):1801732. https://doi.org/10.1002/adma.201801732

Yang J, Li W, Wang D, Li Y (2021) Single-atom materials: small structures determine macroproperties. Small Struct 2(2):2000051. https://doi.org/10.1002/sstr.202000051

Ye D, Wang X, Wang R, Wang S, Liu H, Wang H (2021) Recent advances in MnO2-based adsorbents for mercury removal from coal-fired flue gas. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2021.105993

Zhang G, Li Z, Zheng H, Fu T, Ju Y, Wang Y (2015) Influence of the surface oxygenated groups of activated carbon on preparation of a nano Cu/AC catalyst and heterogeneous catalysis in the oxidative carbonylation of methanol. Appl Catal B 179:95–105. https://doi.org/10.1016/j.apcatb.2015.05.001

Zhang Z, Xiong D-G, Shao A-H, Huang X-Y, Huang Y, Yu J et al (2020) Integrating metallic cobalt and N/B heteroatoms into porous carbon nanosheets as efficient sulfur immobilizer for lithium-sulfur batteries. Carbon 167:918–929. https://doi.org/10.1016/j.carbon.2020.06.017

Zhao R, Jia L, Yao Y-x, Huo R-p, Qiao X-l, Fan B-g (2019) Study of the effect of adsorption temperature on elemental mercury removal performance of iron-based modified biochar. Energy Fuels 33(11):11408–11419. https://doi.org/10.1021/acs.energyfuels.9b02468

Zhu Q, Dai L, Wang Y, Tan F, Chen C, He M et al (2021) Enrichment of waste sewage sludge for enhancing methane production from cellulose. Bioresour Technol 321:124497. https://doi.org/10.1016/j.biortech.2020.124497

Acknowledgements

Funding from the National Natural Science Foundation of China is gratefully acknowledged.

Funding

This work was supported by the National Natural Science Foundation of China (No. 52070129).

Author information

Authors and Affiliations

Contributions

JL: conceptualization, methodology, data curation, investigation, visualization, writing-original draft preparation. HL, HX, QH, LJ, ZL: methodology, investigation, validation, writing–review and editing. WH, YQ, NY: validation, writing–review and editing. ZQ: conceptualization, supervision, resources, project administration, funding acquisition, visualization, validation, writing–review and editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interest.

Supplementary Information

Additional file 1.

Details of the materials and preparation methods; schematic diagram of the reaction device; element content of each sample obtained by XRF; XRD patterns and FTIR spectra of four types of N2O2/BC and biomass; Raman spectra TEM, and SEM images of Mnδ-N2O2/BCshrimp and Mnδ-N2O2/BCpeanut; Hg0 adsorption curves and Hg0-TPD profiles of Mnδ-N2O2/BCshrimp, Mnδ-N2O2/BCcrab, and Mnδ-N2O2/BCchitosan; H2-TPR profiles of Mnδ-N2O2/BCshrimp and Mnδ-N2O2/BCcrab; N2 adsorption and desorption isotherms, pore size distribution, Hg0 adsorption curves and adsorption capacity of Mnδ-N2O2/BCshrimp (800) and Mnδ-N2O2/BCshrimp (800) (without Zn); TGA and DTG curves of MnCl2 4H2O; Hg0 removal mechanism diagram; elemental analysis of Mn (SA)-biomass-C; table of BET, pore size, and pore volume of shrimp-MnδNCs800 and shrimp-MnδNCs800 (without Zn); table of shrimp-MnδNCs adsorption capacity at the different reaction temperatures; Bader charge analysis of four models (Mn10-N2O2/C, Mn7-N2O2/C, Mn4-N2O2/C, and Mn4-N4/C); Table of shrimp-MnδNCs adsorption capacity at different flue gas components. Fig. S1. Schematic diagram of the reaction device. Fig. S2. Mn content of each sample obtained by XRF. Fig. S3. XRD pattern of four types of N2O2/BC and biomass: (a) crab. (b) shrimp. (c) sludge. (d) peanut. Fig. S4. TEM images: (a) Mnδ- N2O2/BCshrimp. (b) Mnδ- N2O2/BCpeanut. Fig. S5. Raman spectra of Mnδ- N2O2/BCshrimp and Mnδ- N2O2/BCpeanut. Fig. S6. SEM images: (a) Mnδ- N2O2/BCshrimp. (b) Mnδ- N2O2/BCpeanut. Fig. S7. TGA and DTG curves of MnCl2 4H2O. Fig. S8. FTIR spectra of four types of N2O2/BC and biomass: (a) crab. (b) shrimp. (c) peanut. (d) sludge. Fig. S9. (a) Hg0 adsorption curves and (b) Hg0-TPD profiles of Mnδ- N2O2/BCshrimp, Mnδ- N2O2/BCcrab, and Mnδ- N2O2/BCchitosan. Fig. S10. H2-TPR profiles of Mnδ- N2O2/BCshrimp and Mnδ- N2O2/BCcrab. Fig. S11. (a) N2 adsorption and desorption isotherms and (b) Pore size distribution of Mnδ-N2O2/BCshrimp (800) and Mnδ-N2O2/BCshrimp (800) (without Zn). Fig. S12. Hg0 adsorption curves and adsorption capacity of Mnδ-N2O2/BCshrimp (800) and Mnδ-N2O2/BCshrimp (800) (without). Fig. S13. Hg0 removal mechanism diagram. Table S1. Elemental analysis of Mn (SA)-biomass-C. Table S2. Table of BET, pore size, and pore volume of shrimp-MnδNCs800 and shrimp-MnδNCs800 (without Zn). Table S3. Bader charge analysis of four models. Table S4. Table of shrimp-MnδNCs adsorption capacity at the different reaction temperatures Table S5. Table of shrimp-MnδNCs adsorption capacity at different flue gas components

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, J., Li, H., Xu, H. et al. Regulated adsorption sites using atomically single cluster over biochar for efficient elemental mercury uptake. Biochar 5, 13 (2023). https://doi.org/10.1007/s42773-022-00200-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-022-00200-y