Abstract

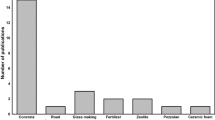

China is the largest producer and consumer of calcium carbide in the world. The calcium carbide industry is an indispensable industry to support the basic life of people. The huge production capacity of calcium carbide is accompanied by a large number of solid waste carbide slag. Due to the immature treatment technology of carbide slag, a large number of carbide slag are stacked on-site, resulting in land occupation, air-drying, easy take-off ash, and pollution of the environment and water resources. In China, calcium carbide is mainly used to produce acetylene and further utilized, 80% of which is used to produce polyvinyl chloride (PVC). A large amount of carbide slag is not used, while only a small part is used in the traditional building materials industry, flue gas desulfurization, sewage treatment, etc., however, the economic benefits are poor. Therefore, converting the solid waste carbide slag produced by the calcium carbide industry into high value-added CaCO3, CaCl2, CaSO4 whiskers, etc. has become a potential way to expand the development field of the calcium carbide industry and is environmentally friendly. This paper focuses on summarizing the traditional and emerging high value-added utilization technologies of carbide slag, and then introduces the application research of carbide slag in carbon emission reduction. Finally, the defects of these technologies are summarized and further research directions are prospected. This study provides basic guidance for the diversified development of efficient resource utilization of carbide slag.

Graphical abstract

Diversified development of calcium carbide industry, resource utilization of solid waste carbide slag and its application of carbon emission reduction have been fully reviewed.

Similar content being viewed by others

References

Liu, C.Y., and Peng, S.C. 2007. On optimum resource direction and approach of calcium carbide sludge. Research and Application of Building Materials 3: 20–22. https://doi.org/10.3969/j.issn.1009-9441.2007.03.009.

Yang, X.D., and Li, J. 2017. Comprehensive utilization of carbide slag. Polyvinyl Chloride 45: 1–4. https://doi.org/10.3969/j.issn.1009-7937.2017.09.001.

Wang, Y.Q., Li, Y.C., Yuan, A., et al. 2014. Preparation of calcium sulfate whiskers by carbide slag through hydrothermal method. Crystal Research and Technology 49: 800–807. https://doi.org/10.1002/crat.201400155.

Cheng, J., Zhou, J., Liu, J., et al. 2009. Physicochemical characterizations and desulfurization properties in coal combustion of three calcium and sodium industrial wastes. Energy Fuels 23: 2506–2516. https://doi.org/10.1021/ef8007568.

Zhang, J., Gong, X., Wang, Z., et al. 2020. Inducible regulation of spherical CaO particle for the recycling of carbide slag. Powder Technology 362: 671–679. https://doi.org/10.1016/j.powtec.2019.12.030.

Wen, Q., Pan, S., Hu, L., 2014. Industrial Solid Waste Treatment in China. In: 7th International Congress on Environmental Geotechnics, Melbourne, Australia, pp. 1082–1088.

Xu, W.Y., Wang, H.X., Cui, X.M., et al. 2021. Research progress on cleaner production and engineering of calcium carbide preparation. Chemical Industry and Engineering Progress 40: 5337–5347.

Deng, J.M., and Yang, G.Q. 2018. Study on utilization of carbide slag. China Chlor-Alkali (in Chinese) 2018: 43–44. https://dx.chinadoi.cn/10.3969/j.issn.1009-1785.2018.01.017 .

Wang, Y., Ye, B., Hong, Z., et al. 2020. Uniform calcite mircro/nanorods preparation from carbide slag using recyclable citrate extractant. Journal of Cleaner Production 253: 119930. https://doi.org/10.1016/j.jclepro.2019.119930.

Liu, W.Z., Teng, L.M., Rohani, S., et al. 2021. CO2 mineral carbonation using industrial solid wastes: a review of recent developments. Chemical Engineering Journal 416: 109093. https://doi.org/10.1016/J.Cej.2021.129093.

Ma, Z.H., Liao, H.Q., and Cheng, F.Q. 2021. Synergistic mechanisms of steelmaking slag coupled with carbide slag for CO2 mineralization. International Journal of Greenhouse Gas Control 105: 103229. https://doi.org/10.1016/J.Ijggc.2020.103229.

Yang, J., Liu, S., Ma, L., et al. 2021. Mechanism analysis of carbide slag capture of CO2 via a gas-liquid-solid three-phase fluidization system. Journal of Cleaner Production 279: 123712. https://doi.org/10.1016/j.jclepro.2020.123712.

Wang, X., Li, Y., Zhang, W., et al. 2020. Simultaneous SO2 and NO removal by pellets made of carbide slag and coal char in a bubbling fluidized-bed reactor. Process Safety and Environmental Protection 134: 83–94. https://doi.org/10.1016/j.psep.2019.11.022.

Guo, W., Zhang, Z., Zhao, Q., et al. 2021. Mechanical properties and microstructure of binding material using slag-fly ash synergistically activated by wet-basis soda residue-carbide slag. Construction and Building Materials 269: 121301. https://doi.org/10.1016/j.conbuildmat.2020.121301.

Song, K., Jang, Y.N., Kim, W., et al. 2012. Precipitation of calcium carbonate during direct aqueous carbonation of flue gas desulfurization gypsum. Chemical Engineering Journal 213: 251–258. https://doi.org/10.1016/j.cej.2012.10.010.

Jimoh, O.A., Ariffin, K.S., Hussin, H.B., et al. 2018. Synthesis of precipitated calcium carbonate: a review. Carbonates and Evaporites 33: 331–346. https://doi.org/10.1007/s13146-017-0341-x.

Xiong, M.Y. 1989. Calcium carbide production and its deep-processed products. Beijing, China: Chemical Industry Press.

Wang, R.X., Ji, L.M., Liu, Q.Y., et al. 2014. Development of auto-thermal production of calcium carbide. CIESC Jorunal 7: 2417–2425. https://doi.org/10.3969/j.issn.0438-1157.2014.07.003.

Paizullakhanov, M.S., and Faiziev, S.A. 2006. Calcium carbide synthesis using a solar furnace. Technical Physics Letters 32: 211–212. https://doi.org/10.1134/S1063785006030102.

Liu, Z.Y., Liu, Q.Y. 2010. Method and system for the production of calcium carbide. Patent No. WO/2010/012193.

Xue, Z. 2009. Techno-commercial evaluation, advice and outlook of PVC production by two process routes using carbide/ethylene as raw materials. Modern Chemical Industry 29: 19–26.

Han, G. 2017. Calcium carbide process for the production of polyvinyl chloride in the process of mercury replacement of mercury effect analysis and mercury pollution control. Inner Mongolia, China: Inner Mongolia University.

Zhang, S., Li, J., Li, G., et al. 2021. Life cycle assessment of acetylene production from calcium carbide and methane in China. Journal of Cleaner Production 322: 129055. https://doi.org/10.1016/j.jclepro.2021.129055.

Li, Z.K. 2018. Fundamental study on a novel low temperatures production of calcium carbide and conversion of calcium carbide residue. Beijing, China: Beijing University of Chemical Technology.

Jiang, S.P. 2017. Economic operation analysis of China’s calcium carbide industry in 2016 and prospects for 2017. Economic Analysis of China's Petroleum and Chemical Industry (in Chinese). pp. 42–45.

Zhang, W.Y., Pan, H.W., Zheng, H., et al. 2014. Study of the process of preparing the high purity calcium oxide by using carbide residue. Journal of Northeast Dianli University 34: 48–51. https://doi.org/10.3969/j.issn.1005-2992.2014.02.010.

Huang, C.H., Deng, Y.S., Xing, X.L., et al. 2004. Comprehensive utilization of carbide slag. Journal of Jiaozuo Institute of Technology 23: 143–146. https://doi.org/10.3969/j.issn.1673-9787.2004.02.017.

Hao, J.T., Jiang, X.F., Yang, H.W., et al. 2013. Research Progress and Application of Carbide Slag. Guangzhou Chemical Industry 41: 45–46. https://doi.org/10.3969/j.issn.1001-9677.2013.08.016.

Ma, L.F. 2018. Study on preparation of high activated calcium oxide from carbide slag. Beijing, China: China University of Petroleum.

Rodygin, K.S., Werner, G., Kucherov, F.A., et al. 2016. Calcium carbide: a unique reagent for organic synthesis and nanotechnology. Chemistry-An Asian Journal 11: 965–976. https://doi.org/10.1002/asia.201501323.

Diederich, F., Stang, P.J., and Tykwinski, R.R. 2005. Acetylene chemistry: chemistry, biology, and material science. Journal of the American Chemical Society 38 (29): 15990–15991. https://doi.org/10.1002/3527605487.

Singh, R.P., Kumar, S., Dubey, S., et al. 2020. A review on working and applications of oxy-acetylene gas welding. Materials Today Proceedings 38: 34–39. https://doi.org/10.1016/j.matpr.2020.05.521.

Lokachari, N., Burke, U., Ramalingam, A., et al. 2019. New experimental insights into acetylene oxidation through novel ignition delay times, laminar burning velocities and chemical kinetic modelling. Proceedings of the Combustion Institute 37: 583–591. https://doi.org/10.1016/j.proci.2018.07.027.

Voronin, V.V., Ledovskaya, M.S., Bogachenkov, A.S., et al. 2018. Acetylene in organic synthesis: recent progress and new uses. Molecules 23: 2442. https://doi.org/10.3390/molecules23102442.

Schobert, H. 2014. Production of acetylene and acetylene-based chemicals from coal. Chemical Reviews 114: 1743–1760. https://doi.org/10.1021/cr400276u.

Wang, L. 2019. Environmental protection technology and development direction of PVC resin production by calcium carbide method. Chemical Enterprise Management (in Chinese). pp. 119–120.

Gao, Y.Y. 2020. Research progress on energy saving and emission reduction technology of PVC resin by calcium carbide process in China. Chemical Enterprise Management (in Chinese). pp. 129–130.

Cao, H.Z. 2019. Selection of and analysis process technology route of 1,4-butanediol. Coal and Chemical Industry 42 (123–128): 160. https://doi.org/10.19286/j.cnki.cci.2019.10.033 .

Galkin, K.I., and Ananikov, V.P. 2016. Alkynes as a versatile platform for construction of chemical molecular complexity and realization of molecular 3D printing. Russian Chemical Reviews 85: 226–247. https://doi.org/10.1070/RCR4611.

Ledovskaya, M.S., Voronin, V.V., and Rodygin, K.S. 2018. Methods for the synthesis of O-, S- and N-vinyl derivatives. Russian Chemical Reviews 87: 167–191. https://doi.org/10.1070/RCR4782.

Rodygin, K.S., Vikenteva, Y.A., and Ananikov, V.P. 2019. Calcium-based sustainable chemical technologies for total carbon recycling. Chem Sus Chem 12: 1483–1516. https://doi.org/10.1002/cssc.201802412.

Lei, G., Rong, L.Z., Long, M.X., et al. 2020. Direct synthesis of propen-2-yl sulfones through cascade reactions using calcium carbide as an alkyne source. Organic letters 22: 5246–5250. https://doi.org/10.1021/acs.orglett.0c01915.

Teong, S.P., and Zhang, Y. 2020. Calcium carbide and its recent advances in biomass conversion. Journal of Bioresources and Bioproducts 5: 96–100. https://doi.org/10.1016/j.jobab.2020.04.002.

Mabood, F., Jan, M.R., Shah, J., et al. 2010. Catalytic conversion of waste inner tube rubber (isobutylene isoprene) into valuable products. Journal of the Chemical Society of Pakistan 32: 767–773.

Mabood, F., Shah, J., Jan, M.R., et al. 2010. Catalytic conversion of waste low density polyethylene into valuable products. Journal of the Chemical Society of Pakistan 32: 574–581.

Li, Y.J., Meng, H., Lu, Y.Z., et al. 2016. Efficient catalysis of calcium carbide for the synthesis of isophorone from acetone. Industrial & Engineering Chemistry Research 55: 5257–5262. https://doi.org/10.1021/acs.iecr.6b00484.

Xu, X.B., Meng, H., Lu, Y.Z., et al. 2018. Aldol condensation of refluxing acetone on CaC2 achieves efficient coproduction of diacetone alcohol, mesityl oxide and isophorone. RSC Advances 8: 30610–30615. https://doi.org/10.1039/C8RA05965A.

Wang, D., Liu, Z.Y., and Liu, Q.Y. 2019. Efficient conversion of ethanol to 1-butanol and C5–C9 alcohols over calcium carbide. RSC Advances 9: 18941–18948. https://doi.org/10.1039/C9RA02568E.

Dai, C.L., Wang, X.Y., Ying, W., et al. 2008. Synthesis of nanostructured carbon by chlorination of calcium carbide at moderate temperatures and its performance evaluation. Materials Chemistry & Physics 112: 461–465. https://doi.org/10.1016/j.matchemphys.2008.05.093.

Guo, M., Chen, X.C., Zhang, X., et al. 2019. Molten alkaline synthesis of highly porous carbon from calcium carbide. Microporous and Mesoporous Materials 278: 397–402. https://doi.org/10.1016/j.micromeso.2019.01.014.

Tang, H.J., and An, Z.M. 2009. Development and application of production technologies of dry-process acetylene matched with new dry-process cement. Polyvinyl Chloride 37: 9–11. https://doi.org/10.3969/j.issn.1009-7937.2009.12.002.

Li, S., and Lu, B. 2021. Technological measures for preparation of cement raw meal from dry and wet calcium carbide slag. China Cement 7: 103–105. https://doi.org/10.3969/j.issn.1671-8321.2021.07.027.

Xiong, L. 2019. Application of dry and wet carbide slag interchange system in cement production line. Cement 2019: 15–16. https://doi.org/10.13739/j.cnki.cn11-1899/tq.2019.11.005 .

Lin, X.P., Liu, A.W., Feng, Y.F., et al. 2020. Life cycle assessment of comprehensive utilization of calcium carbide slag in cement kiln. Materials Science Forum 993: 1487–1495. https://doi.org/10.4028/www.scientific.net/MSF.993.1487.

IEA. Simplified levelised cost of competing low-carbon technologies in cement production. Paris, France: IEA. Available at: https://www.iea.org/data-and-statistics/charts/simplified-levelised-cost-of-competing-low-carbon-technologies-in-cement-production. [Accessed 26 Sept 2021].

Tian, W.J., and Lai, N.B. 2010. Process research and production practice of recovering calcium oxide from carbide slag. Inorganic Chemicals Industry 42: 36–38. https://doi.org/10.3969/j.issn.1006-4990.2010.08.012.

Wang, X., and Huang, Y.D. 2018. Application of calcium carbide slag desulphurizer. Polyvinyl Chloride 46: 41–44.

Li, Y., Zhou, J., Zhu, T., et al. 2013. Calcium sulfite oxidation and crystal growth in the process of calcium carbide residue to produce gypsum. Acta Astronautica 5: 125–131. https://doi.org/10.1007/s12649-013-9206-2.

Wang, X., Li, Y., Shi, J., et al. 2018. Simultaneous SO2/NO removal performance of carbide slag pellets by bagasse templating in a bubbling fluidized bed reactor. Fuel Processing Technology 180: 75–86. https://doi.org/10.1016/j.fuproc.2018.08.007.

Liu, D.S. 2009. Application of wet desulfuration of flue-gas with carbide slaggypsum in Tianjin Dagu Chemical Co., Ltd., and its discussion on problems. China Chlor-Alkali 2: 42–45. https://doi.org/10.3969/j.issn.1009-1785.2009.02.014.

Yu, Z., He, Y.D., Li, X.H., et al. 2016. Design and operation characteristics of limestone-gypsum desulfurization double-tower series system. Thermal Power Generation 45: 91–95. https://doi.org/10.3969/j.issn.1002-3364.2016.02.091.

Wu, W.G. 2020. Application of PVC calcium carbide slurry in the ultra-low emission project of boiler flue gas. China Chlor-Alkali (in Chinese) 2020: 12–14.

Lv, L.N. 2016. Research on desulfurization additives based on the limestone-gypsum wet flue gas desulfurization technology. Shanghai, China: East China University of Science and Technology.

Liang, D.D., Li, D.J., Guo, C.H., et al. 2015. Development status and trend of flue gas desulfuration in China. Nonferrous Metals 4: 69–73. https://doi.org/10.3969/j.issn.1007-7545.2015.04.017.

Li, C.H., Wang, H., Hu, J.H., et al. 2006. Study on desulphurization using CaO powder strengthened by Fe2O3 at medium temperature. Applied Chemical Industry 35: 92–95. https://doi.org/10.3969/j.issn.1671-3206.2006.02.005.

Lang, L. 2016. Study on carbide slag-gypsum wet flue gas desulfurization process technology. Electric power 49: 166–169.

Zhang, T., Lu, F., and Jiao, Y. 2021. Application of calcium carbide slag-gypsum wet desulfurization process in power plant. Chemical Enterprise Management 28: 169–170.

Dong, W.B. 2020. Approach to comprehensive utilization of carbide slag. Henan Chemical Industry 37 (10–11): 16.

Guo, L.L., Fan, X.Z., Zhang, W.Y., et al. 2017. Research progress on preparation of calcium carbonate with carbide slag. Chemical Industry and Engineering Progress 36: 364–371.

Shu, J.J. 2012. Study on Preparation of light calcium carbonate with carbide slag. Guangdong Chemical Industry 39: 60–62. https://doi.org/10.3969/j.issn.1007-1865.2012.14.029.

Tian, F.Y., Mou, H.J., and Gu, W.R. 2013. Preparation of light calcium carbonate from carbide slag by two-step method. Modern Chemical Industry 33: 95–99. https://doi.org/10.3969/j.issn.0253-4320.2013.04.023.

Guo, J.W., Wang, J.Z., and Sun, W.Y. 2015. Research on preparation of light calcium carbonate from carbide slag and sodium carbonate. Synthetic Materials Aging and Application 44: 91–94.

Wang, J.X. 2006. Method for producing nanometer active calcium carbonate and co-producing carbon powder from calcium carbide slag. Patent No. CN200410093237.5.

Zhang, A.H., Zhu, M., Guan, Y.S., et al. 2013. Experimental study on preparation of nanosized calcium carbonate from carbide slag treated by ammonium chloride. Science Technology and Engineering 13: 2880–2883. https://doi.org/10.3969/j.issn.1671-1815.2013.10.053.

Wang, C., Yang, B.J., Zhou, J.G., et al. 2017. Preparation of highly dispersed nano calcium carbonate from calcium carbide residue. Chemical Industry and Engineering Progress 36: 346–352.

Shuai, H., Wang, L.J., Li, N., et al. 2018. Study on leaching and carbonization process of preparation of nano calcium carbonate from calcium carbide slag. Non-Metallic Mines 41: 10–12.

Zhao, X.J., Yang, Z.J., Lin, X.W., et al. 2016. Development status of comprehensive utilization of carbide slag. China Chlor-Alkali. https://doi.org/10.3969/j.issn.1009-1785.2016.07.021.

Zhou, P.F., Ping, H.R., Zhang, F., et al. 2019. Research on the technology of developing circular economy with solid waste calcium carbide slag. Chemical Enterprise Management (in Chinese). pp. 176–177.

Tang, S.W, Zhou, F., and Liang, B. 2012. A process for producing ammonia and calcium chloride from ammonium chloride and carbide slag. Patent No. CN201210424926.4.

Zeng, R., Qiao, X.W., Guo, L.L., et al. 2014. Preparation of high purity calcium chloride with cycle of calcium carbide residue and ammonium chloride. Journal of Shihezi University 32: 665–670. https://doi.org/10.3969/j.issn.1007-7383.2014.06.002.

Ma, X.L., Du, P.Y., Zhang, Z.J., et al. 2017. Progress on Resource Utilization of Carbide Slag. Shandong Chemical Industry 46: 71–72.

Li, G.X., Tan, J.H., and Li, B. 2016. Research progress on aalcium sulfate whisker. Guangzhou Chemical Industry 44: 23–25.

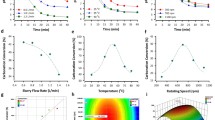

Qiu, Y.S., Li, J.W., Lv, G., et al. 2008. The research of preparation of gypsum whiskers using calcium carbide residue by hydrothermal method. China Non-Metallic Minerals Industry 4: 30–32. https://doi.org/10.3969/j.issn.1007-9386.2008.04.010.

Lv, G., Li, J.W., Qiu, Y.S., et al. 2008. Research on key factors in preparation of gypsum crystal whiskers from acetylene sludge. Non-Metallic Mines 31: 19–21. https://doi.org/10.3969/j.issn.1000-8098.2008.06.007.

Wang, Y.Q., Ma, Q., Yuan, A., et al. 2014. Research on preparation of calcium sulfate whisker from carbide slag and influence factors. Journal of Synthetic Crystals 43: 3284–3289.

Chen, S., Wang, Y.F., and Deng, J.M. 2019. Study on the process of producing calcium sulfate whisker by chlor-alkali waste. China Chlor-Alkali 33: 41–42. https://doi.org/10.3969/j.issn.1009-1785.2019.05.013.

Yang, X., Xu, J., Chen, G., et al. 2020. Present situation and prospect of carbide slag used in chemical industry. Shaanxi Meitan 39: 159–162. https://doi.org/10.3969/j.issn.1671-749X.2020.z1.033.

Zhang, S., Gong, X.Z., Wang, Z., et al. 2014. Preparation of block CaO from carbide slag and its compressive strength improved by H3PO4. International Journal of Mineral Processing 129: 6–11. https://doi.org/10.1016/j.minpro.2014.04.003.

Fan, Q.P., Han, W., and Yiming·Perhat, M. 2015. Feasibility analysis of active calcium oxide technology by carbide slag in PVC industry. China Chlor-Alkali 2015: 14–17.

Ma, H., Feng, X., Yang, Y., et al. 2016. Preparation of feed grade calcium formate from calcium carbide residue. Clean Technologies & Environmental Policy 18: 1905–1915. https://doi.org/10.1007/s10098-016-1119-x.

Sun, H.F., Li, Z.S.S., Bai, J., et al. 2015. Properties of chemically combusted calcium carbide residue and its influence on cement properties. Materials 8: 638–651. https://doi.org/10.3390/ma8020638.

Alahrache, S., Winnefeld, F., Champenois, J.-B., et al. 2016. Chemical activation of hybrid binders based on siliceous fly ash and Portland cement. Cement & Concrete Composites 66: 10–23. https://doi.org/10.1016/j.cemconcomp.2015.11.003.

Amnadnua, K., Tangchirapat, W., and Jaturapitakkul, C. 2013. Strength, water permeability, and heat evolution of high strength concrete made from the mixture of calcium carbide residue and fly ash. Materials & Design 51: 894–901. https://doi.org/10.1016/j.matdes.2013.04.099.

Yi, Y., Li, C., Liu, S., et al. 2016. Magnesium sulfate attack on clays stabilised by carbide slag- and magnesia-ground granulated blast furnace slag. Géotechnique Letters 5: 306–312. https://doi.org/10.1680/jgele.15.00129.

Lang, L., Chen, B., and Li, N. 2020. Utilization of lime/carbide slag-activated ground granulated blast-furnace slag for dredged sludge stabilization. Marine Georesources and Geotechnology 39: 659–669. https://doi.org/10.1080/1064119X.2020.1741050.

Li, W.T., and Yi, Y.L. 2020. Use of carbide slag from acetylene industry for activation of ground granulated blast-furnace slag. Construction and Building Materials 238: 117713. https://doi.org/10.1016/j.conbuildmat.2019.117713.

Guo, W.C., Zhang, Z.Y., Bai, Y.Y., et al. 2021. Development and characterization of a new multi-strength level binder system using soda residue-carbide slag as composite activator. Construction and Building Materials 291: 123367. https://doi.org/10.1016/j.conbuildmat.2021.123367.

Cao, C.X., Wang, B., Cheng, H., et al. 2021. The present situation and prospect of the utilization of calcium carbide slag and carbon dioxide [J/OL]. Industrial Minerals & Processing (in Chinese). 2021: 1–10.

Zhao, L.W., Zhu, G.Y., Li, S.P., et al. 2021. Research progress on characteristics and comprehensive utilization of calcium carbide slag. Clean Coal Technology 27: 13–26.

Wang, Y., Dong, S., Liu, L., et al. 2013. Using calcium carbide slag as one of calcium-containing raw materials to produce cement clinker. Proceedings of Materials Science Forum 2231: 171–174.

Gao, X., Yao, X., Yang, T., et al. 2021. Calcium carbide residue as auxiliary activator for one-part sodium carbonate-activated slag cements: compressive strength, phase assemblage and environmental benefits. Construction and Building Materials 308: 125015. https://doi.org/10.1016/j.conbuildmat.2021.125015.

Ridha, F.N., Manovic, V., Macchi, A., et al. 2012. The effect of SO2 on CO2 capture by CaO-based pellets prepared with a kaolin derived Al(OH)3 binder. Applied Energy 92: 415–420. https://doi.org/10.1016/j.apenergy.2011.11.036.

Serris, E., Fa Vergeon, L., Pijolat, M., et al. 2011. Study of the hydration of CaO powder by gas–solid reaction. Cement & Concrete Research 41: 1078–1084. https://doi.org/10.1016/j.cemconres.2011.06.014.

Guo, L.L., Fan, X.Z., Zhang, W.Y., et al. 2017. Research progress on preparation of calcium carbonate with carbide slag. Chemical Industry and Engineering Progress 36: 364–371.

Jiang, M., Huang, X.F., Liu, H.P., et al. 2016. Research progress on resource utilization of carbide slag. Bulletin of the Chinese Ceramic Society 35: 4025–4031.

Qiao, B.B., and Kang, A. 2019. Application for desulfurizer of calcium hydroxide in wet desulphurization for sintering flue gas. Science & Technology of Baotou Steel 45: 80–83. https://doi.org/10.3969/j.issn.1009-5438.2019.02.023.

Hu, Y., Wu, S., Li, Y., et al. 2021. H2S removal performance of Ca3Al2O6-stabilized carbide slag from CO2 capture cycles using calcium looping. Fuel Processing Technology 218: 106845. https://doi.org/10.1016/j.fuproc.2021.106845.

Li, G., Liu, Q., and Liu, Z. 2010. Production of calcium carbide from fine biochars. Angewandte Chemie International Edition 49: 92–101. https://doi.org/10.1002/anie.201004169.

Gong, X., Wang, Z., Wang, Z., et al. 2018. Roles of impurities on sintering structure and thermal strength of CaO-containing carbon pellet and the CaO sintering kinetic analysis. Powder Technology 336: 92–101. https://doi.org/10.1016/j.powtec.2018.05.053.

Li, Y., Sun, R., Liu, C., et al. 2012. CO2 capture by carbide slag from chlor-alkali plant in calcination/carbonation cycles. International Journal of Greenhouse Gas Control 9: 117–123. https://doi.org/10.1016/j.ijggc.2012.03.012.

Yang, J., Ma, L., Liu, H., et al. 2019. Thermodynamics and kinetics analysis of Ca-looping for CO2 capture: application of carbide slag. Fuel 242: 1–11. https://doi.org/10.1016/j.fuel.2019.01.018.

Li, Y., Su, M., Xie, X., et al. 2015. CO2 capture performance of synthetic sorbent prepared from carbide slag and aluminum nitrate hydrate by combustion synthesis. Applied Energy 145: 60–68. https://doi.org/10.1016/j.apenergy.2015.01.061.

Wang, L., Tian, X., Fu, D., et al. 2019. Experimental investigation on CO2 absorption capacity and viscosity for high concentrated 1-dimethylamino-2-propanol—monoethanolamine aqueous blends. The Journal of Chemical Thermodynamics 139: 105865. https://doi.org/10.1016/j.jct.2019.07.007.

Fu, K., Zhang, P., and Fu, D. 2019. Absorption capacity and CO2 removal efficiency in tray tower by using 2-(ethylamino)ethanol activated 3-(dimethylamino)propan-1-ol aqueous solution. The Journal of Chemical Thermodynamics 139: 105862. https://doi.org/10.1016/j.jct.2019.07.004.

Sun, J., Sun, Y., Yang, Y., et al. 2019. Plastic/rubber waste-templated carbide slag pellets for regenerable CO2 capture at elevated temperature. Applied Energy 242: 919–930. https://doi.org/10.1016/j.apenergy.2019.03.165.

Ma, X., Li, Y., Chi, C., et al. 2017. CO2 capture performance of mesoporous synthetic sorbent fabricated using carbide slag under realistic calcium looping conditions. Energy & Fuels 31: 7299–7308. https://doi.org/10.1021/acs.energyfuels.7b00676.

Zhang, J., Zhang, S., Zhong, M., et al. 2019. Relationship between pore structure and hydration activity of CaO from carbide slag. Chinese Journal of Chemical Engineering 27: 2771–2782. https://doi.org/10.1016/j.cjche.2019.02.024.

Yang, J., Liu, S., and Ma, L. 2021. Thermodynamic analysis of hydrogen production from carbide slag used as oxygen carrier, hydrogen carrier and in-situ carbon capture agent during the gasification of lignite. Energy Conversion and Management 244: 114456. https://doi.org/10.1016/j.enconman.2021.114456.

Chen, X., Li, S., Liu, Z., et al. 2021. Negative-carbon pyrolysis of biomass (NCPB) over CaO originated from carbide slag for on-line upgrading of pyrolysis gas and bio-oil. Journal of Analytical and Applied Pyrolysis 156: 105063. https://doi.org/10.1016/j.jaap.2021.105063.

Wang, N., Mao, M., Mao, G., et al. 2021. Investigation on carbide slag catalytic effect of Mongolian bituminous coal steam gasification process. Chemosphere 264: 128500. https://doi.org/10.1016/j.chemosphere.2020.128500.

Ma, Z., Liao, H., and Cheng, F. 2021. Synergistic mechanisms of steelmaking slag coupled with carbide slag for CO2 mineralization. International Journal of Greenhouse Gas Control 105: 103229. https://doi.org/10.1016/j.ijggc.2020.103229.

Wu, L., Qi, G., Lu, W., et al. 2020. Study on preparation and performance of calcium carbide slag foam for coal mine disaster reduction and CO2 storage. Colloids and Surfaces A: Physicochemical and Engineering Aspects 606: 125322. https://doi.org/10.1016/j.colsurfa.2020.125322.

Ma, X., Li, Y., Zhang, C., et al. 2020. Development of Mn/Mg-copromoted carbide slag for efficient CO2 capture under realistic calcium looping conditions. Process Safety and Environmental Protection. https://doi.org/10.1016/j.psep.2020.05.051.

Cai, J., Yan, F., Luo, M., et al. 2020. Highly stable CO2 capture performance of binary doped carbide slag synthesized through liquid precipitation method. Fuel 280: 118575. https://doi.org/10.1016/j.fuel.2020.118575.

Liu, K., Zhao, B., Wu, Y., et al. 2020. Bubbling synthesis and high-temperature CO2 adsorption performance of CaO-based adsorbents from carbide slag. Fuel 269: 117481. https://doi.org/10.1016/j.fuel.2020.117481.

Zhang, C., Li, Y., Bian, Z., et al. 2021. Simultaneous CO2 capture and thermochemical heat storage by modified carbide slag in coupled calcium looping and CaO/Ca(OH)2 cycles. Chinese Journal of Chemical Engineering 36: 76–85. https://doi.org/10.1016/j.cjche.2020.09.026.

Gu, B., Zhang, Y., Pudukudy, M., et al. 2021. Study and kinetic analysis of calcined carbide slag doped with silicon nitride for cyclic CO2 capture. Materials Chemistry and Physics 259:124016. https://doi.org/10.1016/j.matchemphys.2020.124016.

Acknowledgements

The authors would like to acknowledge the support from the National Natural Science Foundation of China (Nos. 51876150 and 21736008).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Xu, W., Sharif, M. et al. Resource utilization of solid waste carbide slag: a brief review of application technologies in various scenes. Waste Dispos. Sustain. Energy 4, 1–16 (2022). https://doi.org/10.1007/s42768-021-00090-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42768-021-00090-z