Abstract

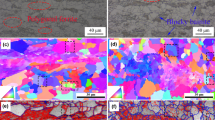

Hot compression tests were carried out with specimens of 20Cr–24Ni–6Mo super-austenitic stainless steel at strain rate from 0.01 to 10 s−1 in the temperature range from 950 to 1150 °C, and flow behavior was analyzed. Microstructure analysis indicated that dynamic recrystallization (DRX) behavior was more sensitive to the temperature than strain rate, and full DRX was obtained when the specimen deformed at 1150 °C. When the temperature reduced to 1050 °C, full DRX was completed at the highest strain rate 10 s−1 rather than at the lowest strain rate 0.01 s−1 because the adiabatic heating was pronounced at higher strain rate. In addition, flow behavior reflected in flow curves was inconsistent with the actual microstructural evolution during hot deformation, especially at higher strain rates and lower temperatures. Therefore, flow curves were revised in consideration of the effects of adiabatic heating and friction during hot deformation. The results showed that adiabatic heating became greater with the increase of strain level, strain rate and the decrease of temperature, while the frictional effect cannot be neglected at high strain level. Moreover, based on the revised flow curves, strain-dependent constitutive modeling was developed and verified by comparing the predicted data with the experimental data and the modified data. The result suggested that the developed constitutive modeling can more adequately predict the flow behavior reflected by corrected flow curves than that reflected by experimental flow curves, even though some difference existed at 950 °C and 0.01 s−1. The main reason was that plenty of precipitates generated at this deformation condition and affected the DRX behavior and deformation behavior, eventually resulted in dramatic increase of deformation resistance.

Similar content being viewed by others

References

L.J. Meng, J. Sun, H. Xing, W.W. Yu, F. Xue, Nucl. Eng. Des. 241, 2839 (2011)

W.G. Guo, Acta Metall. Sin. (in Chinese) 42, 463 (2006)

S. Nemat-Nasser, W.G. Guo, D.P. Kihl, J. Mech. Phys. Solids 49, 1823 (2001)

F.H. Abed, G.Z. Voyiadjis, Int. J. Plast. 21, 1618 (2005)

L.J. Meng, J. Sun, H. Xing, G.W. Wang, J. Nucl. Mater. 394, 34 (2009)

Y.C. Lin, K.K. Li, H.B. Li, J. Chen, X.M. Chen, D.X. Wen, Mater. Des. 74, 108 (2015)

Y.P. Li, H. Matsumoto, A. Chiba, Metall. Mater. Trans. A 40, 1203 (2009)

J.Q. Zhang, H.S. Di, X.Y. Wang, Y. Cao, J.C. Zhang, T.J. Ma, Mater. Des. 44, 354 (2013)

R.L. Goetz, S.L. Semiatin, J. Mater. Eng. Perform. 10, 710 (2001)

M.C. Mataya, V.E. Sackschewsky, Metall. Mater. Trans. A 25, 2737 (1994)

B. Roebuck, J.D. Lord, M. Brooks, M.S. Loveday, C.M. Sellars, R.W. Evans, Mater. High Temp. 23(2), 59 (2006)

F.M. Qin, H. Zhu, Z.X. Wang, X.D. Zhao, W.W. He, H.Q. Chen, Mater. Sci. Eng. A 684, 634 (2017)

Y. Han, H. Wu, W. Zhang, D.N. Zou, G.W. Liu, G.J. Qiao, Mater. Des. 69, 230 (2015)

F. Chen, Z.S. Cui, S.J. Chen, Mater. Sci. Eng. A 528, 5073 (2011)

D. Samantaray, S. Mandal, C. Phaniraj, A.K. Bhaduri, Mater. Sci. Eng. A 528, 8565 (2011)

J. Castellanos, I. Rieiro, M. Carsí, J. Muñoz, M. El Mehtedi, O.A. Ruano, Mater. Sci. Eng. A 517, 191 (2009)

R. Ebrahimi, A. Najafizadeh, Process. Technol. 152, 136 (2004)

K.A. Babu, S. Mandal, C.N. Athreya, B. Shakthipriya, V.S. Sarma, Mater. Des. 115, 262 (2017)

E.X. Pu, H. Feng, M. Liu, W.J. Zheng, H. Dong, Z.G. Song, J. Iron. Steel Res. Int. 23, 178 (2016)

B. Bradaskja, B. Pirnar, M. Fazarinc, P. Fajfar, Steel Res. Int. 82, 346 (2011)

Y. Han, G.J. Qiao, J.P. Sun, D.N. Zou, Comput. Mater. Sci. 67, 93 (2013)

A. Mirzaei, A. Zarei-Hanzaki, N. Haghdadi, A. Marand, Mater. Sci. Eng. A 589, 76 (2014)

G.R. Ebrahimi, H. Keshmiri, A. Momeni, M. Mazinani, Mater. Sci. Eng. A 528, 7488 (2011)

H.J. McQueen, N.D. Ryan, Mater. Sci. Eng. A 322, 43 (2002)

J. Anburaj, S.S.M. Nazirudeen, R. Narayanan, B. Anandavel, A. Chandrasekar, Mater. Sci. Eng. A 535, 99 (2012)

S. Mandal, V. Rakesh, P.V. Sivaprasad, S. Venugopal, K.V. Kasiviswanathan, Mater. Sci. Eng. A 500(1–2), 114 (2009)

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China (No. U1460204).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Hao, YS., Liu, WC. & Liu, ZY. Microstructure Evolution and Strain-Dependent Constitutive Modeling to Predict the Flow Behavior of 20Cr–24Ni–6Mo Super-Austenitic Stainless Steel During Hot Deformation. Acta Metall. Sin. (Engl. Lett.) 31, 401–414 (2018). https://doi.org/10.1007/s40195-017-0657-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0657-5