Abstract

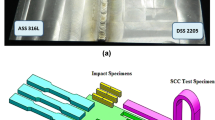

There are many industrial situations particularly in petro-chemical, marine, power plant and other such industries where the use of dissimilar metal weldments is necessary, mainly due to economic benefits and also sometimes to improve the performance of the component. Both austenitic stainless steels and duplex stainless steels have received much attention in recent days due to their superior anti-corrosive and mechanical properties. Further, the use of shielded metal arc welding (SMAW) process is inevitable in engineering industries. In the present work, microstructure, mechanical and intergranular corrosion behavior of dissimilar 2205 duplex stainless steel and 316L austenitic stainless steel fabricated by SMAW process using E2209 electrode by taking two different heat input (0.45–0.60 kJ/mm) was investigated. The microstructures were characterized by using optical microscopy and scanning electron microscopy (SEM), while the localized chemical information was obtained by an energy dispersive spectrometer attached to the SEM. Double loop electrochemical potentiokinetic reactivation test was performed to quantitatively assessing the intergranular corrosion based on degree of sensitization. The effect of weld dilution on mechanical properties (i.e. tensile/hardness properties) was also studied. The ferrite content was experimentally measured by using ferritoscope and it was observed that the weld joint achieved the required ferrite content for both the heat inputs. Higher ferrite content (results of faster cooling rate) increased the hardness and tensile strength of low heat input as compared to high heat input. While, high heat input improved the corrosion resistance due to formation of higher austenitic phases. Higher impact energy was observed in E2209 weld metal than that of the base metals. No welding defects were observed and recommended for industrial use.

Similar content being viewed by others

References

Plauta R L, Herrera C, Escriba D M, Rios P R, and Padilha A F, Mater Res 10 (2007) 453.

Kim Y H, Kim D G, Sung J H, Kim I S, Ko D E, Kang N H, Hong H U, Park J H, and Lee H W, Met Mater Int 17 (2011) 151.

Labanowski J, J Arch Mater Sci Eng 28 (2007) 27.

Padilha A F, and Rios P R, ISIJ Int 42 (2002) 325.

Hoffman J P, J S Afr Inst Min Metal 86 (1986) 433.

Chowdhury S G, Das S and De P K, Acta Materialia 53 (2005) 3951.

Valsan M, and Nagesha A, Trans Ind Inst Met 63 (2010) 209.

Amudarasan N V, Palanikumar K, and Shanmugam K, Int J App. Innov Eng Manag 2 (2013) 269.

Mathew M D, Latha S, and Bhanu Sankara Rao K, Mater Sci Eng A 456 (2007) 28.

Charles J, in Proc Conf A Review after DSS07, Stainless Steel World, Grado, Italy, (2007).

Labanowski J, J Achiev Mater Manuf Eng 20 (2007) 255.

Malik A U, Al-Fozan S A, and Romiahl M Al, in Proc of 2nd Scientific Symp on Relevance of Corrosion Research in the Material Selection for Desalination Plants Maintenance Planning and Operations, Saud University, Riyadh, 24–26 April, (1993) p 885.

Sieurin H, and Sandstrom R, Mater Sci Eng A 418 (2006) 250.

Voronenko B I, Met Sci Heat Treat 39 (1997) 428.

Hwang H, and Park Y, Mater Trans 50 (2009) 1548.

Chakrabarti B, Das H, Das S, and Pal T K, Trans Ind Inst Met 66 (2013) 221.

Olsson J, and Snis M, Desalin 205 (2007) 104.

Hassan A M, and Malik A U, Desalin 74 (1989) 157.

Kuwayama K, Water Tank built to last 60 years, Nickel Development Institute 10 (1994) available at http://www.nickelinstitute.org/~/Media/Files/TechnicalLiterature/WaterTankBuilttoLast60Years.

Tuthill A H, Stainless Steels and Specialty Alloys for Modern Pulp and Paper Mills, Nickel Development Instistitute, Reference Book Series no. 11025, 87.

Reddy G M, and Rao K S, Int J Adv Manuf Technol 45 (2009) 875.

Wang S, Ma Q, and Li Y, Mater Des 32 (2011) 831.

Hariom and Pandey S, Sadhana 38 (2013) 1369.

Sidhu G S, and Chatha S S, Int J Emerg Technol Adv Eng 2 (2012) 746.

Gunn R N, Duplex Stainless Steels, Microstructure Properties and Applications, Abington Publishing, Cambridge, England (1997).

Mvola B, Kah P, and Martikainen J, Rev Adv Mater Sci 38 (2014) 125.

Rahmani M, Eghlimi A, and Shamanian M, J Mater Eng Perform 23 (2014) 3745.

Bala Srinivasan P, Muthupandi V, Dietzel W, and Sivan V, Mater Des 27 (2006) 182.

Barnhouse E J, and Lippold J C, Weld J 77 (1998) 477s.

Wang J, Lu M, Zhang L, Chang W, Xu L, and Hu L, Int J Miner Metall Mater 19 (2012) 518.

Vashishtha H, Taiwade R V, Khatirkar R K, Ingle A V, and Dayal R K, ISIJ Int 54 (2014) 1361.

Unnikrishnan R, Satish Idury K S N, Ismail T P, Bhadauria A, Shekhawat S K, Khatirkar R K, and Sapate S G, Mater Charact 3 (2014) 10.

Standard Practice for Preparation of Metallographic Specimens, E 3-95, ASTM, PA, USA (1995).

Metallography and Microstructures, Materials Park, OH: ASM International, ASM Handbook (2004).

Standard Test Methods for Tensile Testing of Metallic Materials, E 8-04, ASTM, PA, USA (2004).

Standard Practice for Preparation Notched Impact Testing of Metallic Material, E23-04, ASTM, PA, USA (2004).

Standard Test Method for Electrochemical Reactivation (EPR) for Detecting Sensitization of AISI Type 304 and 304L Stainless Steels, ASTM G108-94, ASTM, PA, USA (1994).

Arıkan M E, Arıkan R, and Doruk M, Int J Corros (2012), doi:10.1155/2012/478508.

Majidi A P, and Streicher M A, Corros (1984), doi: 10.5006/1.3581921.

Luz T, Farias J P, and Neto P, Weld Int 20 (2006) 959.

Taiwade R V, Patil A P, Ghugal R D, Patre S J, and Dayal R K, ISIJ Int 53 (2013) 102.

Akbari D, and Sattari-Far I, Int J Press Vessel Pip 86 (2009) 769.

Samir Y M, Int J Res Eng Technol 4 (2015) 44.

Duan Z, Qin R, and Guo H E, Metall Mater Trans A 45A (2013) 843.

Sun P, Liu C, and Xu J, Commun Comput Phys 6 (2009) 1095.

Lu S, Fujii H, Sugiyama H, Tanaka M, and Nogi K, Mater Trans 43 (2002) 2926.

Sadeghian M, Shamanian M, and Shafyei A, Mater Des 60 (2014) 678.

Ramkumar K D, Bajpai A, Raghuvanshi S, Singh A, Chandrasekhar A, Arivarasu M, and Arivazhagan N, Mater Sci Eng A 638 (2015) 60.

Reick W, Pohl M, and Padilha A F, ISIJ Int 38 (1998) 567.

Leone G L, and Kerr H W, Weld J 61 (1982) 13s.

Kacar R, Mater Des 25 (2004) 1.

Jayachitra R, Muthupandi V and Vijayalakshmi K, Int J Sci Res Publ 2 (2012) 1.

Armas I A, and Moreuil S D (ed) Duplex Stainless Steels, Wiley, NJ, USA (2009).

Fu J W, Yang Y S, Guo J J, Ma J C, and Tong W H, Mater Sci Technol 25 (2009) 1013.

Fourie J W, and Robinson F P A, J S Atr Inst Min Metall 90 (1990) 59.

Abdel Rahman M S, Abdel Rahman N A, and Koussy M R El, Acta Metallurgica Sinica 72 (2014) 259.

Badji R, Bouabdallah M, Bacroix B, Kahloun C, Belkessa B, and Maza H, Mater Charact 59 (2008) 447.

Eghlimi A, Shamanian M, and Raeissi K, J Mater Eng Perform 22 (2013) 3657.

Karlsson L, Rigdal S, and Andersson S, Weld World 39 (1999) 99.

Shankar V, Gill T P S, Mannan S L, and Sundaresan S, Sadhana 28 (2003) 359.

Lippold J C, and Kotecki D J, Welding Metallurgy and Weldability of Stainless Steel, Wiley, Hoboken, New Jersey (2005).

Aguilar S, Tabares R, and Serna C, J Mater Phys Chem 1 (2013) 65.

Mukherjee M, and Pal T K, J Mater Sci Technol 28 (2012) 343.

Kotecki D J and Siewert T A, Weld J 71 (1992) 171. Duplex World 2010

Sandor T, and Dobranszky J, Duplex World 2010 (2010). http://www.att.bme.hu/~femtech/letoltes/duplex-Sandor-2010.pdf.

Chuaiphana W, and Srijaroenpramong L, J Mater Proc Technol 214 (2014) 408.

Hansen N, Scr Mater 51 (2004) 801.

Keskitalo M, Mantyjarvi K, Sundqvist J, Powell J and Kaplan A F H, J Mater Process Technol 216 (2015) 381.

Aydogdu G H and Aydinol M K, Corros Sci 48 (2006) 3565.

Gideon B, Ward L and Biddle G, J Miner Mater Chract Engg 7 (2008) 247.

Yang Y, Yan B, Li J, Wang J, Corros Sci 53 (2011) 3756.

Acknowledgments

The authors would like to thank Director, VNIT Nagpur for providing necessary facilities and constant encouragement to publish this paper. The authors are also thankful to Mr. J. P Bhardwaj, General Manager, Weldfast Electrodes, Nagpur for providing the welding facilities and DSS 2209 electrode. The authors would also like to thank Mrs. Varsha Patankar (Technical staff, Testing of Materials Laboratory, Department of Metallurgical and Materials Engineering) for her help in conducting mechanical testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, J., Taiwade, R.V., Khatirkar, R.K. et al. Microstructure, Mechanical and Intergranular Corrosion Behavior of Dissimilar DSS 2205 and ASS 316L Shielded Metal Arc Welds. Trans Indian Inst Met 70, 225–237 (2017). https://doi.org/10.1007/s12666-016-0878-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0878-8