Abstract

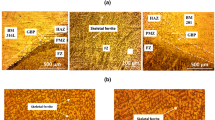

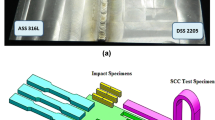

To obtain high-quality dissimilar weld joints, the processes of metal inert gas (MIG) welding and tungsten inert gas (TIG) welding for duplex stainless steel (DSS) and low alloy steel were compared in this paper. The microstructure and corrosion morphology of dissimilar weld joints were observed by scanning electron microscopy (SEM); the chemical compositions in different zones were detected by energy-dispersive spectroscopy (EDS); the mechanical properties were measured by microhardness test, tensile test, and impact test; the corrosion behavior was evaluated by polarization curves. Obvious concentration gradients of Ni and Cr exist between the fusion boundary and the type II boundary, where the hardness is much higher. The impact toughness of weld metal by MIG welding is higher than that by TIG welding. The corrosion current density of TIG weld metal is higher than that of MIG weld metal in a 3.5wt% NaCl solution. Galvanic corrosion happens between low alloy steel and weld metal, revealing the weakness of low alloy steel in industrial service. The quality of joints produced by MIG welding is better than that by TIG welding in mechanical performance and corrosion resistance. MIG welding with the filler metal ER2009 is the suitable welding process for dissimilar metals jointing between UNS S31803 duplex stainless steel and low alloy steel in practical application.

Similar content being viewed by others

References

Z. Sun and R. Karppi, The application of electron beam welding for the joining of dissimilar metals: an overview, J. Mater. Process. Technol., 59(1996), No.3, p.257.

M.K. Samal, M. Seidenfuss, E. Roos, and K. Balani, Investigation of failure behavior of ferritic-austenitic type of dissimilar steel welded joints, Eng. Failure Anal., 18(2011), No.3, p.999.

G. Phanikumar, K. Chattopadhyay, and P. Dutta, Joining of dissimilar metals: issues and modeling techniques, Sci. Technol. Weld. Joining, 16(2011), No.4, p.313.

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657, J. Mater. Process. Technol., 209(2009), No.7, p.3628.

R. Paventhan, P.R. Lakshminarayanan, and V. Balasubramanian, Fatigue behaviour of friction welded medium carbon steel and austenitic stainless steel dissimilar joints, Mater. Des., 32(2011), No.4, p.1888.

S.G. Wang, Q.H. Ma, and Y. Li, Characterization of microstructure, mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR, Mater. Des., 32(2011), No.2, p.831.

T.W. Nelson, J.C. Lippold, and M.J. Mills, Nature and evolution of the fusion boundary in ferritic-austenitic dissimilar weld metals: Part 1. Nucleation and growth, Weld. J., 78(1999), No.10, p.329.

T. Hattori, T. Fujita, K. Kinoshita, A. Ebata, H. Tsukamoto, and M. Ando, Hydrogen induced disbonding of stainless steel overlay weld and its preventive measures, Nippon Kokan Tech. Rep. Overseas, 47(1986), p.17.

T.W. Nelson, J.C. Lippold, and M.J. Mills, Nature and evolution of the fusion boundary in ferritic-austenitic dissimilar metal welds: Part 2. On-cooling transformations, Weld. J., 55(2000), No.10, p.267.

P. Bala Srinivasan, V. Muthupandi, W. Dietzel, and V. Sivan, Microstructure and corrosion behavior of shielded metal arc-welded dissimilar joints comprising duplex stainless steel and low alloy steel, J. Mater. Eng. Perform., 15(2006), No.6, p.758.

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa, and H. Maza, Phase transformation and mechanical behavior in annealed 2205 duplex stainless steel welds, Mater. Charact., 59(2008), No.4, p.447.

K. Migiakis and G.D. Papadimitriou, Effect of nitrogen and nickel on the microstructure and mechanical properties of plasma welded UNS S32760 super-duplex stainless steels, J. Mater. Sci., 44(2009), No.23, p.6372.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Science and Technology Major Project of China (Grant No.2011ZX05056).

Rights and permissions

About this article

Cite this article

Wang, J., Lu, Mx., Zhang, L. et al. Effect of welding process on the microstructure and properties of dissimilar weld joints between low alloy steel and duplex stainless steel. Int J Miner Metall Mater 19, 518–524 (2012). https://doi.org/10.1007/s12613-012-0589-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0589-z