Abstract

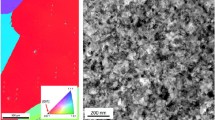

The compressive deformation behavior of a single phase CrMnFeCoNi high-entropy alloy (HEA) is investigated using experimental and theoretical approaches. The equiaxed microstructures are observed using optical microscope, electron backscattered diffraction, and synchrotron X-ray diffraction (XRD) techniques. Compressive results reveal that the CrMnFeCoNi HEA has a high strain-hardening exponent in spite of its large grain size due to increased dislocation density and severe lattice distortion. The compressive texture of the HEA resembles those of typical FCC metals. The phenomenological dislocation-based constitutive model well describes the compressive deformation behavior. The predicted dislocation density is in good quantitative agreement with the experimental value measured using whole-profile fitting of synchrotron XRD peaks. It can be confirmed from the experimental and theoretical findings that the deformation mechanism of the CrMnFeCoNi HEA is the conventional dislocation glide and mechanical twinning is negligible contrary to general belief.

Similar content being viewed by others

References

J. W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

B. Cantor, I. T. H. Chang, P. Knight, and A. J. B. Vincent, Mat. Sci. Eng. A 375-377, 213 (2004).

B. Gludovatz, E. P. George, and R. O. Ritchie, JOM 67, 2262 (2015).

Y. Zhang, T. T. Zuo, Z. Tang, M. C. Gao, K. A. Dahmen, Z. P. Lu, et al., Prog. Mater. Sci. 61, 1 (2014).

B. Schuh, F. Mendez-Martin, B. Völker, E. P. George, H. Clemens, A. Hohenwarter, et al., Acta Mater. 96, 258 (2015).

V. Soare, D. Mitrica, I. Constantin, G. Popescu, I. Csaki, I. Carcea, et al., Metall. Mater. Trans. A 46, 1468 (2015).

J.-M. Wu, S.-J. Lin, J.W. Yeh, S.-K. Chen, Y.-S. Huang, and H.-C. Chen, Wear 261, 513 (2006).

D.-H. Lee, M.-Y. Seok, Y. Zhao, I.-C. Choi, J. He, J.-I. Jang, et al., Acta Mater. 109, 314 (2016).

N. Park, I. Watanabe, D. Terada, Y. Yokoyama, P. K. Liaw, and N. Tsuji, Metall. Mater. Trans. A 46, 1481 (2014).

N. Park, X. Li and N. Tsuji, JOM 67, 2303 (2015).

B. Gludovatz, A. Hohenwarter, D. Catoor, E. H. Chang, E. P. George, and R. O. Ritchie, Science 345, 1153 (2014).

O. N. Senkov, G. B. Wilks, J. M. Scott, and D. B. Miracle, Intermetallics 19, 698 (2011).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E. P. George, Acta Mater. 61, 5743 (2013).

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, G. Salishchev, et al., Intermetallics 59, 8 (2015).

W. Woo, E.-W. Huang, J.W. Yeh, H. Choo, C. Lee, and S.-Y. Tu, Intermetallics 62, 1 (2015).

H. J. Park, Y. S. Na, S. H. Hong, J. T. Kim, Y. S. Kim, K. B. Kim, et al., Met. Mater. Int. 22, 551 (2016).

J. W. Choi, J. W. Lee, J. H. Lee, D. J. Kim, and H. U. Hong, Korean J. Met. Mater. 53, 1 (2015).

S.-W. Choi, H.-S. Lee, Y.-M. Jeon, T.-H. Nam, J.-T. Yeom, J. H. Kim, et al., Korean J. Met. Mater. 53, 151 (2015).

H. M. Heo, S. G. Park, J. H. Kim, S. H. Kim, and M. Y. Heo, Korean J. Met. Mater. 53, 177 (2015).

B.-Y. Choi, Y.-S. Gu, Q. Zhu, H. Zhu, and K. Tieu, Korean J. Met. Mater. 53, 851 (2015).

I.-K. Kwon, Korean J. Met. Mater. 52, 31 (2014).

B.-H. Song, J. Kim, S. Jeong, I. Choi, and Y.-K. Lee, Korean J. Met. Mater. 52, 1 (2014).

M. C. Shim, K. S. Kim, K. S. Cho, J. S. Kim, and K.-A. Lee, Korean J. Met. Mater. 52, 327 (2014).

T. Ungár, Scripta Mater. 51, 777 (2004).

D. J. Lee, E. Y. Yoon, D.-H. Ahn, B. H. Park, H. W. Park, H. S. Kim, et al., Acta Mater. 76, 281 (2014).

T. Ungár and A. Borbély, Appl. Phys. Lett. 69, 3173 (1996).

A. Rohatgi, K. S. Vecchio, and G. T. Gray III, Metall. Mater. Trans. A 32, 135 (2001).

H. Hu, Texture 1, 233 (1974).

N. D. Stepanov, D. G. Shaysultanov, G. A. Salishchev, M. A. Tikhonovsky, E. E. Oleynik, O. N. Senkov, et al., J. Alloy. Compd. 628, 170 (2015).

W. H. Liu, Y. Wu, J. Y. He, T. G. Nieh, and Z. P. Lu, Scripta Mater. 68, 526 (2013).

H. S. Kim, Y. Estrin, and M. B. Bush, Acta Mater. 48, 493 (2000).

H. Mecking and U. F. Kocks, Acta Metall. 29, 1865 (1981).

U. F. Kocks, and H. Mecking, Prog. Mater. Sci. 48, 171 (2003).

Y. Estrin and H. Mecking, Acta Metall. 32, 57 (1984).

C. Lee, Master Thesis, pp. 53–132, National Tsing Hua University, Hsinchu, China (2013).

D.-H. Lee, I.-C. Choi, M.-Y. Seok, J. He, Z. Lu, J. Jang, et al., J. Mater. Res. 30, 2804 (2015).

M. Komarasamy, N. Kumar, R. S. Mishra, and P. K. Liaw, Mat. Sci. Eng. A 654, 256 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jang, M.J., Joo, SH., Tsai, CW. et al. Compressive deformation behavior of CrMnFeCoNi high-entropy alloy. Met. Mater. Int. 22, 982–986 (2016). https://doi.org/10.1007/s12540-016-6304-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-6304-2