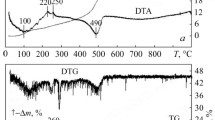

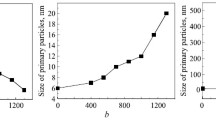

Ultrafine 90AZK, 80AZK, 70AZK, and 58.5AZK powders in the Al2O3–ZrO2–Y2O3–CeO2 system were produced for the first time by a combined method involving hydrothermal synthesis followed by mechanical mixing with α-Al2O3 (HTSM). The properties of the powders heat treated in the range 400-1450°C were examined by differential thermal analysis, X-ray diffraction, electron microscopy, and nitrogen thermal adsorption–desorption (BET). The sizes of primary particles were calculated with the Scherrer equation. The AMIC (Automatic Microstructure Analyzer) software was applied to process the powder morphology analysis results. The F-ZrO2 → T-ZrO2 phase transformation was found to proceed completely when the powders were mechanically mixed in the HTSM process. The M-ZrO2 phase was identified as traces in the ultrafine 90AZK and 80AZK powders after mechanical mixing, was not found in the 70AZK powder, and emerged as traces in the 58.5AZK powder above 1150°C. Heat treatment was shown to induce a topochemical memory effect in the ceramics: the morphology and shape factor of the ultrafine powders following heat treatment at 400–1450°C varied topologically continuously. The dependence of primary particle sizes and specific surface area of the powders on the heat treatment temperature indicated that they had high sintering activity. The powders are needed to produce highly efficient ZTA composites in the Al2O3–ZrO2–Y2O3–CeO2 system, consisting of fine particles of the viscous zirconia-based solid solution, codoped with ceria and yttria, distributed in a rigid alumina matrix.

Similar content being viewed by others

References

R.H.J. Hannink, P.M. Kelly, and B.C. Muddle, “Transformation toughening in zirconia-containing ceramics,” J. Am. Ceram. Soc., 83, No. 3, 461–487 (2000).

J. Chevalier and L. Gremillard, “Zirconia as a biomaterial,” Ref. Mod. Mater. Sci. Mater. Eng. Compr. Biomater. II, 1, 122–144 (2017): https://doi.org/10.1016/B978-0-12-803581-8.10245-0.

J. Chen, Z. Xie, W. Zeng, and W. Wu, “Toughening mechanisms of ZTA ceramics at cryogenic temperature (77 K),” J. Ceram. Int., 43, Issue 5, 3970–3974 (2017): https://doi.org/10.1016/j.ceramint.2016.11.072.

Ernesto Byron Benalcazar Jalkh, Kelli Nunes Monteiro, Paulo Francisco Cesar, Luis Antonio Genova, Edmara T.P. Bergamo, Adolfo Coelho de Oliveira Lopes, Erick Lima, Paulo Noronha Lisboa-Filho, Tiago Moreira Bastos Campos, Lukasz Witek, Paulo G. Coelho, Ana Flavia Sanches Borges, and Estevam A. Bonfante, “Aging resistant ZTA composite for dental applications: Microstructural, optical and mechanical characterization,” J. Dental Mater., 36, Issue 9, 1190–1200 (2020): https://doi.org/10.1016/j.dental.2020.05.011.

J. Сhevalier and L. Gremillard, “Ceramics for medical applications: A picture for the next 20 years,” J. Eur. Ceram. Soc., 29, Issue 7, 1245–1255 (2009).

N.V. Sharova, N.A. Popova, and E.S. Lukin, “Effect of a eutectic addition in the Al2O3–ZrO2–Y2O3 system on the properties of corundum ceramics,” Usp. Khim. Khim. Tekhnol., 31, No. 3, 119–121 (2017).

V.V. Kulyk, Z.A. Duriagina, B.D. Vasyliv, V.I. Vavrukh, P.Ya. Lyutyy, T.M. Kovbasiuk, and M.Ya. Holovchuk, “Effects of yttria content and sintering temperature on the microstructure and tendency to brittle fracture of yttria-stabilized zirconia,” Arch. Mater. Sci. Eng., 109, No. 2, 65–79 (2021): https://doi.org/10.5604/01.3001.0015.2625.

A.K. Pandey, U.R. Jena, and K. Biswas, “In vitro ageing and wear behavior of ceria stabilized zirconia toughened alumina (CSZ-TA) bio-ceramic,” Mater. Chem. Phys., 146, 456 (2014).

N.A. Rejab, A.Z.A. Azhar, K.S. Kian, M.M. Ratnam, and Z.A. Ahmad, “Effects of MgO addition on the phase, mechanical properties, and microstructure of zirconia-toughened alumina added with CeO2 (ZTA-CeO2) ceramic composite,” Mater. Sci. Eng. A, 595, 18–24 (2014).

N.A. Rejab, A.Z.A. Azhar, M.M. Ratnam, and Z.A. Ahmad, “The effects of CeO2 addition on the physical, microstructural and mechanical properties of yttria stabilized zirconia toughened alumina (ZTA),” Int. J. Refract. Met. Hard Mater., 36, 162–166 (2013).

V. Ponnilavan and S. Kannan, “Structural, morphological and mechanical characteristics on the role of excess ceria additions in zirconia toughened alumina systems,” J. Alloys Compd., 694, 1073–1082 (2017).

A.M. Abyzov, “Latest research on the development of high-quality aluminum-oxide ceramics (Review). Part 2. Synthesis and sintering of nanopowders, sol-gel and other methods of producing finely disperse and fibrous aluminum oxide,” Glass Ceram., 75, No. 9–10, 352–362 (2019).

M.Y. Smyrnova-Zamkova, O.K. Ruban, O.I. Bykov, and O.V. Dudnik, “Physicochemical properties of fine-grained powder in Al2O3–ZrO2–Y2O3–CeO2 system produced by combined method,” Compos. Theory Pract., 18, No. 4, 234–240 (2018).

Yu.D. Tretiakov, “New generations of ceramics,” Vest. AN SSSR, No. 2, 98–111 (1987).

M.M. Basha, S.M. Basha, B.K. Singh, N. Mandal, and M.R. Sankar, “A review on synthesis of zirconia toughened alumina (ZTA) for cutting tool applications,” Mater. Today: Proc., 26, Part 2, 534–541 (2020).

E.V. Dudnik, S.N. Lakiza, Ya.S. Tishchenko, A.K. Ruban, V.P. Redko, A.V. Shevchenko, and L.M. Lopato, “Phase diagrams of refractory oxide systems and microstructural design of materials,” Powder Metall. Met. Ceram., 53, No. 5–6, 303–311 (2014).

K.C. Patil, S.T. Aruna, and S. Ekamtaran, “Combustion synthesis,” Curr. Opin. Solid State Mater. Sci., No. 2, 158–165 (1997).

M.Yu. Smirnova-Zamkova, Effect of Production Methods on the Physicochemical Properties of Nanocrystalline Powders in the Al2O3–ZrO2–Y2O3–CeO2 System: Author’s Abstract of PhD Thesis in Chemistry [in Ukrainian], Inst. Probl. Materialoznav. NAN Ukrainy, Kyiv (2021), p. 25.

Yu.D. Tretiakov and V.I. Putliaev, Introduction to the Chemistry of Solid-State Materials: University Book [in Russian], Nauka, Moscow (2006), p. 400.

E.V. Dudnik, S.N. Lakiza, V.V. Tsukrenko, Ya.S. Tishchenko, A.K. Ruban, and V.P. Redko, “Nanocrystalline oxide powders for microstructural design of materials,” Nanosyst. Nanomater. Nanotekhnol., 14, No. 4, 561–575 (2016).

F. Trubelja and V. Stubican, “Phase equilibria and ordering in the system zirconia-hafnia-yttria,” J. Am. Ceram. Soc., 71, No. 8, 662–666 (1988).

I.O. Marek, O.K. Ruban, V.P. Redko, M.I. Danilenko, S.A. Korniy, and O.V. Dudnik, “Physicochemical properties of hydrothermal nanocrystalline ZrO2–Y2O3–CeO2 powders,” Powder Metall. Met. Ceram., 58, No. 3–4, 125–132 (2019).

O.I. Khomenko and O.V. Khomenko, “Use of the AMIC software for quantitative metallography,” in: Mathematical Models and Computational Experiment in Materials Science, Proc. Inst. Materialoznav. NAN Ukrainy, Issue 16, 35–42 (2014).

V.V. Panichkina and I.V. Uvarova, Methods for Controlling the Particle Size and Specific Surface Area of Metallic Powders [in Russian), Nauk. Dumka, Kyiv (1973), p. 168.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 9–10 (541), pp. 3–16, 2021.

Rights and permissions

About this article

Cite this article

Smyrnova-Zamkova, M., Dudnik, O., Bykov, O. et al. Changes in the Properties of Ultrafine Al2O3–ZrO2–Y2O3–CeO2 Powders After Heat Treatment in the Range 400–1450°C. Powder Metall Met Ceram 60, 519–530 (2022). https://doi.org/10.1007/s11106-022-00265-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-022-00265-1