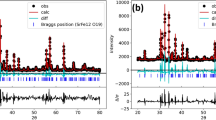

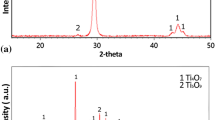

The nanosized 90 mol.% ZrO2–2 mol.% Y2O3–8 mol.% CeO2 powder was produced by hydrothermal synthesis in an alkaline environment and heat-treated in the range 400–1300°C. The powder properties were examined by X-ray diffraction (XRD), SEM and TEM, petrography, and BET. According to the XRD data, a low-temperature metastable cubic ZrO2 (F-ZrO2) solid solution formed after hydrothermal synthesis. According to the petrography and electron microscopy data, TZrO2 began to form already in the hydrothermal synthesis process. The F-ZrO2 → T-ZrO2 phase transformation was completed in the range 700–850°C. Some T-ZrO2 particles were characterized by a twin substructure. The T-ZrO2 unit cell volume monotonically increased from 133.58 · 10–3 nm3 to 137.09 · 10–3 nm3 and the degree of tetragonality from 1.0033 to 1.0140. No M-ZrO2 was found to form. The powder specific surface area decreased from 94 to 2 m2/g in the heat treatment process. The sizes of primary powder particles (5–10 nm) remained almost unchanged in heat treatment up to 1150°C. The Vickers hardness of the ceramics produced from the powder treated at 850°C was 3.1 GPa and critical fracture toughness factor KIc was 8.4 MPa · m1/2. The preservation of the tetragonal structure (T-ZrO2), which is capable of the martensitic T-ZrO2 → M-ZrO2 transformation, and the strength characteristics determined open ways for microstructural design of smart materials, including shape memory ones, in the ZrO2–Y2O3–CeO2 system.

Similar content being viewed by others

References

R.S. Garvie, R.H.J. Hannink, and R.T. Pascoe, “Ceramic steel,” Nature, 205, 703–705 (1975).

P.M. Kelly and L.R. Francis Rose, “The martensitic transformation in ceramics—its role in transformation toughening,” Prog. Mater. Sci., 47, 463–557 (2002).

Z.G. Wei, R. Sandstrom, and S. Miyazaki, “Review shape-memory materials and hybrid composites for smart systems. Part I. Shape-memory materials,” J. Mater. Sci., 33, 3743–3762 (1998).

Z. Du, X.M. Zeng, Q. Liu, A. Lai, Sh. Amini, A. Miserez, Ch.A. Schuh, and Ch.L. Gan, “Size effects and shape memory properties in ZrO2 ceramic micro- and nano-pillars,” Scr. Mater., 101, 40–43 (2015).

M.V. Swain, “Shape memory behavior in partially stabilized zirconia ceramics,” Nature, 322, No. 17, 234–236 (1986).

P.E. Reyes-Morel, J.-Sh. Cherg, and I-W. Chen, “Transformation plasticity of CeO2-stabilized tetragonal zirconia polycrystals. II. Pseudoelasticity and shape memory effect,” J. Am. Ceram. Soc., 71, 648–657 (1988).

M.A. Zaeema, N. Zhang, and M. Mamivand, “A review of computational modeling techniques in study and design of shape memory ceramics,” Comput. Mater. Sci., 160, 120–136 (2019).

X.-J. Jin, “Martensitic transformation in zirconia containing ceramics and its applications,” Curr. Opin. Solid State Mater. Sci., 9, 313–318 (2005).

Y.L. Zhang, X.J. Jin, Y.H. Rong, T.Y. Hsu, D.Y. Jiang, and J.L. Shi, “On the t → m martensitic transformation in Ce–Y-TZP ceramics,” Acta Mater., 54, 1289–1295 (2006).

A. Lai, Z.H. Du, C.L. Gan, and C.A. Schuh, “Shape memory and superelastic ceramics at small scales,” Science, 341, 1505–1508 (2013).

X.M. Zeng, Z. Du, N. Tamura, Q. Liu, Ch.A. Schuh, and Ch.L. Gan, “In-situ studies on martensitic transformation and high-temperature shape memory in small volume zirconia,” Acta Mater., 134, 257–266 (2017).

N. Zhang and M.A. Zaeem, “Nanoscale self-healing mechanisms in shape memory ceramics,” Comput. Mater., 2019. https://doi.org/10.1038/s41524-019-0194-z.

H.A. Rauch, Y. Chen, K. An, and H.Z. Yu, “In situ investigation of stress-induced martensitic transformation in granular shape memory ceramic packings,” Acta Mater., 168, 362–375 (2019). https://doi.org/10.1016/j.actamat.2019.02.028.

Z. Du, X.M. Zeng, Q. Liu, Ch.A. Schuh, and Ch.L. Gan, "Superelasticity in micro-scale shape memory ceramic particles," Acta Mater., 123, 255–263 (2017).

E.L. Pang, C.A. Candler, and C.A. Schuh, “Reduced cracking in polycrystalline ZrO2–CeO2 shape-memory ceramics by meeting the cofactor conditions,” Acta Mater., 177, 230–239 (2019). https://doi.org/10.1016/j.actamat.2019.07.028.

E.V. Dudnik, A.V. Shevchenko, A.K. Ruban, V.P. Red’ko, and L.M. Lopato, “Microstructural design of ZrO2–Y2O3–CeO2–Al2O3 materials,” Powder Metall. Met. Ceram., 49, No. 9–10, 528–536 (2011).

E.V. Dudnik, S.N. Lakiza, Ya.S. Tishchenko, A.K. Ruban, V.P. Red’ko, A.V. Shevchenko, and L.M. Lopato, “Phase diagrams of refractory oxide systems and microstructural design of materials,” Powder Metall. Met. Ceram., 53, No. 5–6, 303–311 (2014).

I.O. Marek, O.K. Ruban, V.P. Redko, M.I. Danilenko, S.A. Korniy, and O.V. Dudnik, “Physicochemical properties of hydrothermal nanocrystalline ZrO2–Y2O3–CeO2 powders,” Powder Metall. Met. Ceram., 58, No. 3–4, 125–132 (2019).

V.A. Perepelitsyn, Fundamentals of Technical Mineralogy and Petrography [in Russian], Nedra, Moscow (1987), p. 255.

J. Res, J.-D. Kamminga, and L.J. Seijbel, “Diffraction line broadening analysis if broadening is caused by both dislocations and limited crystallite size,” Natl. Inst. Stand. Technol., 109, 65–74 (2004). http://dx.doi.10.6028/jres.109.005.

G.Ya. Akimov, G.A. Marinin, and V.Yu. Kameneva, “Evolution of the phase composition and mechanical properties of ZrO2 + 4 mol.% Y2O3 ceramics,” Fiz. Tverd. Tela, 46, 250–252 (2004).

V.V. Panichkina and I.V. Uvarova, Methods for Controlling the Particle Size and Specific Surface Area of Metallic Powders [in Russian], Naukova Dumka, Kyiv (1973), p. 168.

T. Sakuma, “Phase transformation and microstructure of partially-stabilized zirconia,” Trans. Jpn. Inst. Met., 29, 879–893 (1988).

R.H.J. Hannink, P.M. Kelly, and B.C. Muddle, “Transformation toughening in zirconia-containing ceramics,” J. Am. Ceram. Soc., 83, No. 3, 461–487 (2000).

S.V. Belov, M.A. Borik, M.A. Vishniakova, Yu.K. Danileiko, and A.V. Kulebiakin, “Study of the structural and physicochemical properties of nanosized zirconium dioxide crystals for developing innovation electrosurgical tools,” Dokl. RAN, 450, No. 1, 32–35 (2013).

B.K. Vainshtein, Modern Crystallography [in Russian], Nauka, Moscow (1979), Vol. 1, p. 384.

B.A. Galanov and O.N. Grigoriev, “Analytical model of indentation for brittle materials,” Elektron. Mikrosk. Prochn. Mater., No. 14, 4–42 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 1–2 (531), pp. 3–13, 2020.

Rights and permissions

About this article

Cite this article

Dudnik, O., Marek, I., Ruban, O. et al. Effect of Heat Treatment on the Structure and Phase Composition of the Nanosized Powder Based on a ZrO2 Solid Solution. Powder Metall Met Ceram 59, 1–8 (2020). https://doi.org/10.1007/s11106-020-00132-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00132-x