Abstract

Rheological deformation of coal could severely jeopardize the extraction performance during deep coal mining and coalbed methane development by causing instability, shrinkage and collapse of drilling boreholes in the long run. Standard macroscale creep test could only reveal the bulk properties of coal while neglecting the high heterogeneity nature of coal mainly composed of various organic macerals. This study took a low-rank (0.39% Ro) humic coal as research object, and employed nanoindentation technique to study its mechanical and rheological heterogeneity from the particle level. The results showed that mechanical heterogeneity within the humic coal is manifested as inertinite being much harder and less likely to undergo creep than vitrinite. By focusing on vitrinite, both mechanical properties and creep resistance showed negative relationships with loading rate and indentation size. The relationship of creep displacement and time can be best depicted by the model with one spring and two Kelvin–Voigt bodies. To probe into the structure-dependent rheological properties of organic matter in geo-field, carbon stacking structure from X-ray diffraction, creep behavior via nanoindentation and stress distribution simulated by finite-element analysis of coal were compared with another natural carbon aggregation as solid bitumen. The results showed that the coal investigated exhibited a relatively weaker creep resistance than solid bitumen, which is a consequence of its looser stacking manner with small size of crystallites in plane but large layer space inside. The observations here signified the role of chemical structure in determining rheology of organic matter.

Similar content being viewed by others

References

Baral, P., Orekhov, A., Dohmen, R., Coulombier, M., Raskin, J. P., Cordier, P., Idrissi, H., & Pardoen, T. (2021). Rheology of amorphous olivine thin films characterized by nanoindentation. Acta Materialia, 219, 117257.

Bennett, K. C., Berla, L. A., Nix, W. D., & Borja, R. I. (2015). Instrumented nanoindentation and 3D mechanistic modeling of a shale at multiple scales. Acta Geotechnica, 10(1), 1–14.

Borodich, F. M., Bull, S. J., & Epshtein, S. A. (2016). Nanoindentation in studying mechanical properties of heterogeneous materials. Journal of Mining Science, 51(3), 470–476.

Bower, A. F., Fleck, N. A., Needleman, A., & Ogbonna, N. (1993). Indentation of a power law creeping solid. Proceedings of the Royal Society A, 441(1911), 97–124.

Bruening, F. A., & Cohen, A. D. (2005). Measuring surface properties and oxidation of coal macerals using the atomic force microscope. International Journal of Coal Geology, 63(3), 195–204.

Deirieh, A., Ortega, J. A., Ulm, F. J., & Abousleiman, Y. (2012). Nanochemomechanical assessment of shale: A coupled WDS-indentation analysis. Acta Geotechnica, 7(4), 271–295.

Dokukin, M. E., & Sokolov, I. (2012). Quantitative Mapping of the elastic modulus of soft materials with harmonix and peakforce QNM AFM modes. Langmuir, 28(46), 16060–16071.

Elmustafa, A. A., & Stone, D. S. (2002). Indentation size effect in polycrystalline F.C.C. metals. Acta Materialia, 50(14), 3641–3650.

Epshtein, S. A., Borodich, F. M., & Bull, S. J. (2015). Evaluation of elastic modulus and hardness of highly inhomogeneous materials by nanoindentation. Applied Physics A, 119(1), 325–335.

Field, J. S., & Swain, M. V. (1996). The indentation characterisation of the mechanical properties of various carbon materials: Glassy carbon, coke and pyrolytic graphite. Carbon, 34(11), 1357–1366.

Herbert, E. G., Hackney, S. A., Thole, V., Dudney, N. J., & Phani, P. S. (2018). Nanoindentation of high-purity vapor deposited lithium films: A mechanistic rationalization of the transition from diffusion to dislocation-mediated flow. Journal of Materials Research, 33(10), 1361–1368.

Hower, J. C., Eric, J. T., & Richard, P. R. (2008). Vickers microhardness of telovitrinite and pseudovitrinite from high volatile bituminous Kentucky coals. International Journal of Coal Geology, 75(2), 76–80.

Kang, J., Zhou, F., Liu, C., & Liu, Y. (2015). A fractional non-linear creep model for coal considering damage effect and experimental validation. International Journal of Non-Linear Mechanics, 76, 20–28.

Karacan, C. O., Diamond, W. P., & Schatzel, S. J. (2007). Numerical analysis of the influence of in-seam horizontal methane drainage boreholes on longwall face emission rates. International Journal of Coal Geology, 72(1), 15–32.

Karimpoor, A. A., Erb, U., Aust, K. T., & Palumbo, G. (2003). High strength nanocrystalline cobalt with high tensile ductility. Scripta Materialia, 49(7), 651–656.

Kelly, B. T., (1981), Physics of Graphite, Applied Science Publishers Ltd.

Kerr, M., & Chawla, N. (2004). Creep deformation behavior of Sn-3.5Ag solder at small length scales. Acta Materialia, 52(15), 4527–4535.

Li, H., & Ngan, A. H. W. (2004). Size effects of nanoindentation creep. Journal of Materials Research, 19(2), 513–522.

Li, P. (1992). On grain size dependence of minimum creep rate. Chinese Journal of Metallic Science and Technology, 8, 119–122.

Liu, K., Rassouli, F. S., Liu, B., & Ostadhassan, M. (2020). Creep behavior of shale: Nanoindentation vs. triaxial creep tests. Rock Mechanics & Rock Engineering, 54, 321–335.

Liu, K., Wang, L., Ostadhassan, M., Zou, J., Bubach, B., & Rezaee, R. (2018). Nanopore structure comparison between shale oil and shale gas: examples from the Bakken and Longmaxi formations. Petroleum Science, 16(1), 77–93.

Liu, Y., Xiong, Y., Liu, K., Yang, C., & Peng, P. (2019). Indentation size and loading rate sensitivities on mechanical properties and creep behavior of solid bitumen. International Journal of Coal Geology, 216, 103295.

Lu, L., Sahajwallaa, V., Konga, C., & Harris, D. (2001). Quantitative X-ray diffraction analysis and its application to various coals. Carbon, 39, 1821–1833.

Lucas, B. N., & Oliver, W. C. (1999). Indentation power-law creep of high-purity indium. Metallurgical and Materials Transactions A, 30(3), 601–610.

Ma, Z., Pathegama Gamage, R., & Zhang, C. (2020). Application of nanoindentation technology in rocks: A review. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 6, 1–27.

Ma, Z., Zhang, C., Pathegama Gamage, R., & Zhang, G. (2021). Uncovering the creep deformation mechanism of rock-forming minerals using nanoindentation. International Journal of Mining Science and Technology, 32(2), 283–294.

Mahmudi, R., Geranmayeh, A. R., & Rezaee-Bazzaz, A. (2007). Impression creep behavior of lead-free Sn-5Sb solder alloy. Materials Science and Engineering A, 448(1/2), 287–293.

Mahmudi, R., & Rezaee-Bazzaz, A. (2005). Superplastic indentation creep of Sn–Pb–Sb peritectic. Materials Letters, 59(13), 1705–1708.

Manjunath, G. L., & Jha, B. (2019). Nanoscale fracture mechanics of Gondwana coal. International Journal of Coal Geology, 204, 102–112.

Marques, V. M. F., Wunderle, B., Johnston, C., & Grant, P. S. (2013). Nanomechanical characterization of Sn–Ag–Cu/Cu joints—Part 2: Nanoindentation creep and its relationship with uniaxial creep as a function of temperature. Acta Materialia, 61(7), 2471–2480.

Menčík, J. (2011). Determination of parameters of viscoelastic materials by instrumented indentation. Part 2: Viscoelastic-plastic response. Chemicke Listy, 105(14), 318–325.

Mencík, J., He, L. H., & Swain, M. V. (2009). Determination of viscoelastic-plastic material parameters of biomaterials by instrumented indentation. Journal of the Mechanical Behavior of Biomedical Materials, 2(4), 318.

Menčík, J., Li, H. H., & Němeček, J. (2011). Characterization of viscoelastic-plastic properties of solid polymers by instrumented indentation. Polymer Testing, 30(1), 101–109.

Meng, J., Cao, Z., Zhang, S., Wang, C., & Nie, B. (2022). Micro-mechanical properties and damage mechanisms of coal under cyclic loading: A nanoindentation experiment and molecular dynamics simulation. Molecular Simulation, 48(4), 354–365.

Mighani, S., Taneja, S., Sondergeld, C. H., & Rai, C. S. (2015, June). Nanoindentation creep measurements on shale. In 49th US rock mechanics/geomechanics symposium. OnePetro, https://onepetro.org/ARMAUSRMS/proceedings-abstract/ARMA15/All-ARMA15/65018.

Mighani, S., Bernabé, Y., Boulenouar, A., Mok, U., & Evans, B. (2019). Creep deformation in Vaca Muerta shale from nanoindentation to triaxial experiments. Journal of Geophysical Research: Solid Earth, 124(8), 7842–7846.

Mohammed, Y. S., Stone, D. S., & Elmustafa, A. A. (2021). Strain rate sensitivity of hardness in indentation creep with conical and spherical indenters taking into consideration elastic deformations. International Journal of Solids and Structures, 212, 143–151.

Nix, W. D., & Gao, H. (1998). Indentation size effects in crystalline materials: A law for strain gradient plasticity. Journal of The Mechanics and Physics of Solids, 46(3), 411–425.

Oliver, W. C., & Pharr, G. M. (1992). An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. Journal of Materials Research Home, 7(6), 1564–1583.

Peralta, P., Ledoux, R., Hakik, M., Dickerson, R., & Dickerson, P. (2004). Characterization of surface deformation around vickers indents in monocrystalline materials. Metallurgical & Materials Transactions A, 35(8), 2247–2255.

Saha, R., & Nix, W. D. (2002). Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Materialia, 50(1), 23–38.

Schneibel, J. H., Coble, R. L., & Cannon, R. M. (1981). The role of grain size distributions in diffusional creep. Acta Metallurgica, 29(7), 1285–1290.

Sharma, P., Prakash, R., & Abedi, S. (2019). Effect of temperature on nano- and microscale creep properties of organic-rich shales. Journal of Petroleum Science and Engineering, 175, 375–388.

Sun, C., Li, G., Gomah, M. E., Xu, J., & Sun, Y. (2020). Creep characteristics of coal and rock investigated by nanoindentation. International Journal of Mining Science and Technology, 30(6), 769–776.

Sun, C., Li, G., Zhang, S., Xu, J., & Yang, H. (2020). Mechanical and heterogeneous properties of coal and rock quantified and mapped at the microscale. Applied Sciences, 10(1), 342.

Sun, W., Jiang, Y., Sun, G., Hu, J., Zhou, T., Jiang, Z., & Lian, J. (2019). Nanoindentation creep behavior and its relation to activation volume and strain rate sensitivity of nanocrystalline Cu. Materials Science and Engineering: A, 751, 35–41.

Tong, J., Han, X., Wang, S., & Jiang, X. (2011). Evaluation of structural characteristics of Huadian Oil shale kerogen using direct techniques (Solid-State 13C NMR, XPS, FT-IR, and XRD). Energy & Fuels, 25(25), 4006–4013.

Vandamme, M., & Ulm, F. J. (2013). Nanoindentation investigation of creep properties of calcium silicate hydrates. Cement & Concrete Research, 52, 38–52.

Wang, J., Liu, Y., Yang, C., Jiang, W., Li, Y., & Xiong, Y. (2022). Modeling the viscoelastic behavior of quartz and clay minerals in shale by nanoindentation creep tests. Geofluids, 2022, 2860077.

Wang, Y. M., Hodge, A. M., Bythrow, P. M., Barbee, T. W., & Hamza, A. V. (2006). Negative strain rate sensitivity in ultrahigh-strength nanocrystalline tantalum. Applied Physics Letters, 89(8), 241917.

Yang, C., Xiong, Y., Wang, J., Li, Y., & Jiang, W. (2020). Mechanical characterization of shale matrix minerals using phase-positioned nanoindentation and nano-dynamic mechanical analysis. International Journal of Coal Geology, 229, 103571.

Yu, H., Zhang, Y., Lebedev, M., Han, T., Verrall, M., Wang, Z., Al-Khdheeawi, E., Al-Yaseri, A., & Iglauer, S. (2018). Nanoscale geomechanical properties of Western Australian coal. Journal of Petroleum Science & Engineering, 162, 736–746.

Zhang, Y., Lebedev, M., Al-Yaseri, A., Yu, H., Xu, X., & Iglauer, S. (2018). Characterization of nanoscale rockmechanical properties and microstructures of a Chinese sub-bituminous coal. Journal of Natural Gas Science and Engineering, 52, 106–116.

Zhang, Y., Lebedev, M., Smith, G., Jing, Y., Busch, A., & Iglauer, S. (2019). Nano-mechanical properties and pore-scale characterization of different rank coals. Natural Resources Research, 29, 1787–1800.

Zhao, J., Huang, P., Xu, K. W., Wang, F., & Lu, T. J. (2018). Indentation size and loading strain rate dependent creep deformation of nanocrystalline Mo. Thin Solid Films, 653, 365–370.

Acknowledgments

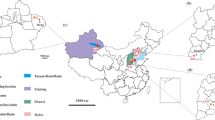

This work was financially supported by the National Natural Science Foundation of China (Grant No. 42002158; No. 41802165), the Special Fund for Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDA14010102). The authors appreciate the support from Dr. An Qi from Harbin Institute of Technology for ABAQUS modeling. We are grateful to Editor-in-Chief Dr. John Carranza and anonymous reviewers for their instructive comments and suggestions that significantly help clarify this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Yang, C., Wang, J. et al. Rheology of Coal at Particle Level Characterized by Nanoindentation. Nat Resour Res 32, 1359–1380 (2023). https://doi.org/10.1007/s11053-023-10188-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-023-10188-2