Abstract

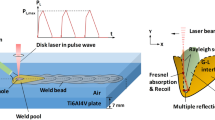

A three-dimensional (3-d) computational fluid dynamics (CFD) based model in which a ray-tracing algorithm was combined with the volume of fluid (VOF) method was used to simulate a pulsed Nd: YAG laser /tungsten inert gas (TIG) hybrid welding process. The calculated weld cross sections in pure laser welding and hybrid welding process were validated by the experimental results, respectively. Then, the variations of keyhole shape and laser energy coupling behaviour in the laser-arc hybrid welding process were calculated at three different laser-arc distances. It was found that the laser-arc distance would affected the shape of keyhole generated in the laser-arc hybrid welding process, thus influencing the laser energy coupling efficiency. In the initial stage of each laser pulse, small laser-arc distances favoured the generation of keyholes and multiple reflections of laser beam within keyhole. However, as the laser irradiation time increased, the smaller the laser-arc distance, the more liquid metal were found around the keyholes, which was more favourable to the expansion of keyhole in radial direction. As a result, the aspect ratio of keyhole, the reflection time of laser beams in keyhole, and the laser energy absorbed by keyhole wall decreased. Given that the interaction between laser and arc was neglected, the maximum keyhole depth increased with reducing laser-arc distances, while the total laser energy coupling efficiency decreased as the laser-arc distance was reduced.

Similar content being viewed by others

References

Steen WM (1980) Arc augmented laser processing of materials. J Appl Phys 51:5636–5641

Yan J, Gao M, Li G, Zhang C, Zeng X, Jiang M (2012) Microstructure and mechanical properties of laser-MIG hybrid welding of 1420 al-li alloy. Int J Adv Manuf Technol 66(9–12):1467–1473

Li C, Liu L (2012) Investigation on weldability of magnesium alloy thin sheet t-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol 65(1–4):27–34

Hu B, Richardson IM (2007) Microstructure and mechanical properties of AA7075(T6) hybrid laser/GMA welds. Mater Sci Eng A 459(1–2):94–100

Xu GX, Wu CS, Qin GL, Wang XY, Lin SY (2011) Adaptive volumetric heat source models for laser beam and laser + pulsed GMAW hybrid welding processes. Int J Adv Manuf Technol 57(1–4):245–255

Liu LM, Wang JF, Song G (2004) Hybrid laser-TIG welding, laser beam welding and gas tungsten arc welding of AZ31B magnesium alloy. Mater Sci Eng A 381(1–2):129–133

Hu B, den Ouden G (2005a) Laser induced stabilisation of the welding arc. Sci Technol Weld Joi 10(1):76–81

Li R, Yu J, Sun R, Mi G, Wang C, Shao X (2016) A study of droplet transfer behavior in ultra-narrow gap laser arc hybrid welding. Int J Adv Manuf Technol:1–12

Hu B, Den Ouden G (2005b) Laser-induced stabilisation of the welding arc. Sci Technol Weld Join 10(1):76–81

Zhang L, Gao X, Sun M, Zhang J (2014a) Weld outline comparison between various pulsed Nd: YAG laser welding and pulsed Nd: YAG laser–TIG arc welding. Int J Adv Manuf Technol 75(1–4):153–160

Zhang LJ, Ning J, Zhang XJ, Zhang GF, Zhang JX (2015) Single pass hybrid laser-MIG welding of 4 mm thick copper without preheating. Mater Des 74:1–18

Hu B, Ouden G (2005) Synergetic effects of hybrid laser/arc welding. Sci Technol Weld Join 10:427–431

Kozakov R, Gött G, Uhrlandt D, Emde B, Hermsdorf J, Wesling V (2015) Study of laser radiation absorption in a TIG welding arc. Welding in the World Le Soudage Dans Le Monde 59(4):1–7

Fuerschbach PW, Eisler GR (2002) Effect of laser spot weld energy and duration on melting and absorption. Science and Technology of Welding & Joining 7:241–246

Fuerschbach PW (1996) Measurement and prediction of energy transfer efficiency in laser beam welding. Weld J 75(1):S24–S34

Jouvard JM, Girard K, Perret O (2001) Keyhole formation and power deposition in Nd:YAG laser spot welding. Journal of Physics D Applied Physics 34(18):2894–2901(8)

Hu B, Hu S, Shen J, Li Y (2015) Modeling of keyhole dynamics and analysis of energy absorption efficiency based on Fresnel law during deep-penetration laser spot welding. Comput Mater Sci 97:48–54

Kaplan AFH (2013) Laser absorptivity on wavy molten metal surfaces: categorization of different metals and wavelengths. Journal of Laser Application 26(1):012007

Weston J (2000) Surface related features of laser welding of aluminium alloys. ISIJ Int 40:S6–S9

Zhang W, Fang LI, Min LI, Hua XM, Cai Y (2016) Study of the laser absorption characteristics of CO2 laser-pulsed GMAW hybrid welding based on spectral diagnosis technique. Spectroscopy & Spectral Analysis 36(4):931–918

Greses J, Barlow CY, Hilton PA, Steen WM (2003) Effects of different gas environments on CO2 and Nd:YAG laser welding process efficiencies. Proceedings of SPIE - The International Society for Optical Engineering 4831:257–262

Matsuda J, Utsumi A (1988) TIG or MIG arc augmented laser welding of thick mild steel plate. Joining and Materials, July 1988:31–34

Katayama S, Uchiumi S, Mizutani M, Wang J, Fujii K (2007) Penetration and porosity prevention mechanism in YAG laser-MIG hybrid welding. Weld Int 21(1):25–31

Liu LM, Yuan ST, Li CB (2012) Effect of relative location of laser beam and TIG arc in different hybrid welding modes. Sci Technol Weld Joi 17(6):441–446

Andersen M, Jensen A (2001) ‘Hybrid Nd:YAG laser MIG welding in aluminium’, in Olsen F and Kristensen J, Proc. 8th Nordic Conference on Laser Materials Processing, Lyngby, Denmark, 371–380

Uchiumi S, Wang JB, Katayama S, Mizutani M, Hongu T, Fujii K (2004) Penetration and welding phenomena in YAG laser -MIG hybrid welding of aluminum alloy. ICALEO 2004 Congress Proceedings, San Francisco, LIA, 97, P530.(CD)

Moradi M, Ghoreishi M, Frostevarg J, Kaplan AFH (2013) An investigation on stability of laser hybrid arc welding. Opt Laser Eng 51(4):481–487

Song G, Liu L, Wang P (2006) Overlap welding of magnesium AZ31B sheets using laser-arc hybrid process. Mater Sci Eng A 429(1):312–319

Kim C, Choi W, Kim J, Rhee S (2008) Relationship between the weldability and the process parameters for laser-TIG hybrid welding of galvanized steel sheets. Mater Trans 49(1):179–186

Abe N, Kunugita Y, Hayashi M, Tsuchitani Y (1997) Dynamic observation of high speed laser-arc combination welding of thick steel plates (physics, processes, instruments & measurements). Trans JWRI 26(2):7–11

Ribic B, Burgardt P, DebRoy T (2011) Optical emission spectroscopy of metal vapor dominated laser-arc hybrid welding plasma. J Appl Phys 109(8):083301

Kiran DV, Na SJ (2014) Numerical studies on submerged arc welding process. Journal of Welding and Joining 32(4):1–9

Kiran DV, Cho DW, Lee HK, Kang CY, Na SJ (2014) A study on the quality of two-wire tandem submerged arc welds under iso-heat input conditions. Int J Adv Manuf Technol 78(1–4):53–62

Kiran DV, Cho DW, Song WH, Na SJ (2015) Arc interaction and molten pool behavior in the three wire submerged arc welding process. Int J Heat Mass Transf 87:327–340

Kiran DV, Cheon J, Arif N, Chung H, Na SJ (2016) Three-dimensional finite element modeling of pulsed AC gas metal arc welding process. Int J Adv Manuf Technol:1–22. doi:10.1007/s00170-015-8297-2

Zhang LJ, Zhang JX, Gumenyuk A, Rethmeier M, Na SJ (2014b) Numerical simulation of full penetration laser welding of thick steel plate with high power high brightness laser. J Mater Process Technol 214(8):1710–1720

Cheon J, Kiran DV, Na SJ (2016a) Thermal metallurgical analysis of GMA welded AH36 steel using CFD-FEM framework. Mater Des 91:230–241

Cheon J, Kiran DV, Na SJ (2016b) CFD based visualization of finger shaped evolution in gas metal arc welding process. Int J Heat Mass Transf 97:1–14

Wu L, Cheon J, Kiran DV, Na SJ (2016) CFD simulations of GMA welding of horizontal fillet joint based on coordinate rotation of arc models. J Mater Process Technol 231:221–238

Pang S, Chen X, Shao X, Gong S, Xiao J (2016a) Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: local evaporation, plume swing and gas entrapment into porosity. Opt Laser Eng 82:28–40

Pang S, Shao X, Li W, Chen X, Gong S (2016b) Dynamic characteristics and mechanisms of compressible metallic vapor plume behaviors in transient keyhole during deep penetration fiber laser welding. Appl Phys A Mater Sci Process 122(7):1–18

Pang S, Chen X, Li W, Shao X, Gong S (2016c) Efficient multiple time scale method for modeling compressible vapor plume dynamics inside transient keyhole during fiber laser welding. Opt Laser Technol 77:203–214

Pang S, Chen X, Zhou J, Shao X, Wang C (2015) 3D transient multiphase model for keyhole, vapor plume, and weld pool dynamics in laser welding including the ambient pressure effect. Opt Laser Eng 74:47–58

Pang S, Chen W, Zhou J, Liao D (2014) Self-consistent modeling of keyhole and weld pool dynamics in tandem dual beam laser welding of aluminum alloy. J Mater Process Technol 217:131–143

Cho YT, Cho WI, Na SJ (2011) Numerical analysis of hybrid plasma generated by Nd: YAG laser and gas tungsten arc. Opt Laser Technol 43(3):711–720

Piekarska W, Kubiak M (2011) Three-dimensional model for numerical analysis of thermal phenomena in laser–arc hybrid welding process. Int J Heat Mass Transf 54(23):4966–4974

Bendaoud I, Matteï S, Cicala E, Tomashchuk I, Andrzejewski H, Sallamand P, Mathieu A, Bouchaud F (2014) The numerical simulation of heat transfer during a hybrid laser–MIG welding using equivalent heat source approach. Opt Laser Technol 56:334–342

Cho WI, Na SJ, Cho MH, Lee JS (2010) Numerical study of alloying element distribution in CO2 laser–GMA hybrid welding. Comp Mater Sci 49(4):792–800

Zhou J, Tsai HL (2009) Investigation of mixing and diffusion processes in hybrid spot laser–MIG keyhole welding. J Phys D Appl Phys 42(9):095502

Ribic B, Rai R, DebRoy T (2008) Numerical simulation of heat transfer and fluid flow in GTA/laser hybrid welding. Sci Technol Weld Joi 13(8):683–693

Flow Science, I, 2008. FLOW 3D User Manual V9.2

Cho JH, Na SJ (2006) Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J Phys D Appl Phys 39:5372

Cho JH, Na SJ (2009) Three-dimensional analysis of molten pool in GMA-laser hybrid welding. Weld Joi 88:35–43

Cho WI, Na SJ, Thomy C, Vollertsen F (2012) Numerical simulation of molten pool dynamics in high power disk laser welding. J Mater Process Technol 212:262–275

Kaplan A (1994) A model of deep penetration laser welding based on calculation of the keyhole profile. J Phys D Appl Phys 27(9):1805–1814

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ning, J., Zhang, LJ., Na, SJ. et al. Numerical study of the effect of laser-arc distance on laser energy coupling in pulsed Nd: YAG laser/TIG hybrid welding. Int J Adv Manuf Technol 91, 1129–1143 (2017). https://doi.org/10.1007/s00170-016-9812-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9812-9