Abstract

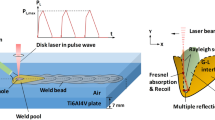

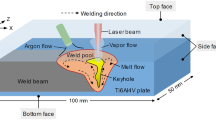

Continuous wave laser beam welding (CWLBW) of titanium alloy has been widely investigated experimentally and numerically in terms of scientific understanding and technology application. The existing CWLBW related to numerical modeling mostly ignored the essence of continuous laser input, and the simulation was usually performed using a constant laser power. In this study, the deep penetration CWLBW process of Ti6Al4V plates was modeled mathematically by taking the high-frequency pulsed laser into account. The dynamics of the keyhole and weld pool at different welding speeds were numerically solved and contrastively analyzed. The results show that the improved heat source model yields sufficient accuracy on seam profile prediction. As the welding proceeds, temperature field and the keyhole morphology fluctuate significantly due to the variation of the heat input within a pulse period, which is hardly a common observation under a constant laser irradiating condition. With the increase of welding speed, the depth of weld pool decreases, and the keyhole dimensions becomes less symmetrical along the welding direction and less oscillating in quasi-steady stage, indicating a higher in-process dynamic stability. The current work provides a more precise description and a further understanding of heat and mass transfer behaviors during a CWLBW process.

Similar content being viewed by others

References

Gao F, Lian Z, Li W (2012) Welding method and research of titanium and titanium alloy. Aero Manuf Technol Z2:86–90

Qu H, Zhou Y, Zhou L, Zhao Y, Zeng W, Feng L (2005) Research progress of new titanium alloys in recent years. Mater Rep 02:94–97

Panwisawas C, Perumal B, Ward RM, Turner N, Turner RP, Brooks JW, Basoalto HC (2017) Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: experimental and modelling. Acta Mater 126:251–263

Matsunawa A, Seto N, Kim J, Mizutani M, Katayama S (1998) Dynamics of keyhole and molten pool in high-power CO2 laser welding. J Laser Appl 10(6):247–254

Meng W, Li Z, Huang J, Wu Y, Cao R (2013) Effect of gap on plasma and molten pool dynamics during laser lap welding for T-joints. Int J Adv Manuf Technol 69(5–8):1105–1112

Zou J, Na H, Xiao R, Qiang W, Zhang Q (2017) Interaction between the laser beam and keyhole wall during high power fiber laser keyhole welding. Opt Express 25:17650–17656

Zhang Y, Chen G, Wei H, Zhang J (2008) A novel sandwich method for observation of the keyhole in deep penetration laser welding. Opt Laser Technol 46:133–139

Wang H, Shi Y, Gong S (2006) Study on flow and heat transfer phenomena in laser deep penetration welding of titanium alloy. 2006 National Doctoral Forum on Aerospace Science and Technology, Peking 529–535

Zhang S (2014) Numerical simulation and plasma control of laser deep penetration welding process. Dissertation Nanjing Univ Aeronaut Astronaut

Yang Z, Tao W, Li L, Chen Y, Shi C (2017) Numerical simulation of heat transfer and fluid flow during double-sided laser beam welding of T-joints for aluminum aircraft fuselage panels. Opt Laser Technol 91:120–129

Chen S, Zhao Y, Tian S, Gu Y, Zhan X (2020) Study on keyhole coupling and melt flow dynamic behaviors simulation of 2219 aluminum alloy T-joint during the dual laser beam bilateral synchronous welding. J Manuf Process 60:148–158

Bachmann M, Avilov V, Gumenyuk A, Rethmeier M (2013) About the influence of a steady magnetic field on weld pool dynamics in partial penetration high power laser beam welding of thick aluminium parts. Int J Heat Mass Tran 60:309–321

Chen J, Wei Y, Zhan X, Gao Q, Zhang D, Gao X (2018) Influence of magnetic field orientation on molten pool dynamics during magnet-assisted laser butt welding of thick aluminum alloy plates. Opt Laser Technol 104:148–158

Fujinaga S, Takenaka H, Narikiyo T, Katayama S, Matsunawa A (2000) Direct observation of keyhole behaviour during pulse modulated high-power Nd:YAG laser irradiation. J Phys D Appl Phys 33:492

Zhang L, Bo W, Zhang G, Gong S, Zhang J (2011) An investigation on the effects of side assisting gas flow and metallic vapour jet on the stability of keyhole and molten pool during laser full-penetration welding. J Phys D Appl Phys 44:135201

Zhou J, Tsai HL, Wang PC (2006) Transport phenomena and keyhole dynamics during pulsed laser welding. J Heat Trans 128:680–690

Courtois M, Carin M, Masson PL, Gaied S, Balabane M (2014) A complete model of keyhole and melt pool dynamics to analyze instabilities and collapse during laser welding. J Laser Appl 26:042001

Pang S, Chen L, Zhou J, Yin Y, Chen T (2011) A three-dimensional sharp interface model for self-consistent keyhole and weld pool dynamics in deep penetration laser welding. J Phys D Appl Phys 44:25301

Luo M, Hu R, Li Q, Huang A, Pang S (2019) Physical understanding of keyhole and weld pool dynamics in laser welding under different water pressures. Int J Heat Mass Tran 137:328–336

Feng Y, Gao X, Zhang Y, Peng C, Xiao X (2021) Simulation and experiment for dynamics of laser welding keyhole and molten pool at different penetration status. Int J Adv Manuf Technol 112:2301–2312

Cho WI, Na SJ, Thomy C, Vollertsen F (2012) Numerical simulation of molten pool dynamics in high power disk laser welding. J Mater Process Tech 212:262–275

Katayama S, Kawahito Y (2009) Elucidation of phenomena in high-power fiber laser welding and development of prevention procedures of welding defects. Proc SPIE Int Soc Opt Eng 146

Voller VR, Prakash C (1987) A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int J Heat Mass Tran 30:1709–1719

Qian L, Wei Y, Xiao F (2018) Coupled THINC and level set method: a conservative interface capturing scheme with arbitrary-order surface representations. J Comput Phys 373:284–303

Cho JH, Na SJ (2006) Implementation of real-time multiple reflection and Fresnel absorption of laser beam in keyhole. J Phys D Appl Phys 39:5372

Stretton JA (1941) Electromagnetic Theory. Am J Phys 33:1094–1095

Schulz W, Simon G, Urbassek HM, Decker I (2000) On laser fusion cutting of metals. J Phys D Appl Phys 20:481–488

Norman AF, Ducharme R, Mackwood A, Kapadia P, Prangnell PB (1998) Application of thermal modelling to laser beam welding of aluminium alloys. Sci Technol Weld Join 260–266

Pariona MM, Taques AF, Woiciechowski LA (2018) The Marangoni effect on microstructure properties and morphology of laser-treated Al-Fe alloy with single track by FEM: Varying the laser beam velocity. Int J Heat Mass Tran 119:10–19

Wang R, Lei Y, Shi Y (2011) Numerical simulation of transient temperature field during laser keyhole welding of 304 stainless steel sheet. Opt Laser Technol 43:870–873

Wu J, Zhang H, Feng Y, Luo B (2018) 3D multiphysical modelling of fluid dynamics and mass transfer in laser welding of dissimilar materials. Metals 8:443

Li Z, Rostam K, Panjehpour A, Akbari M, Karimipour A, Rostami S (2020) Experimental and numerical study of temperature field and molten pool dimensions in dissimilar thickness laser welding of Ti6Al4V alloy. J Manuf Process 49:438–436

Huang L, Hua X, Wu D, Ye Y (2019) Role of welding speed on keyhole-induced porosity formation based on experimental and numerical study in fiber laser welding of Al alloy. Int J Adv Manuf Technol 103:913–925

Chang B, Allen C, Blackburn J, Hilton P, Du D (2015) Fluid flow characteristics and porosity behavior in full penetration laser welding of a titanium alloy. Metall Mater Trans B 46:906–918

Acknowledgements

The authors gratefully acknowledged the projects funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and China Postdoctoral Science Foundation No. 2020M671479.

Funding

The research is funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and China Postdoctoral Science Foundation No. 2020M671479.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors declare their consent to participate.

Consent for publication

The authors declare their consent for publication.

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Wei, Y., Chang, Y. et al. Study on keyhole characteristics and weld pool dynamics of Ti6Al4V alloy fabricated by continuous wave laser beam welding. Int J Adv Manuf Technol 119, 2999–3012 (2022). https://doi.org/10.1007/s00170-021-08595-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08595-x