Abstract

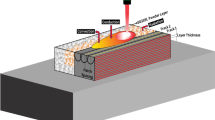

This paper describes a three-dimensional numerical model based on finite volume method to simulate heat transfer and fluid flow in laser–tungsten inert gas (TIG) hybrid welding process. To simplify the model and reduce the calculation time, keyhole dynamics are not considered; instead, a new modified volumetric heat source model is presented for the laser source to take into account the effect of the keyhole on the heat transfer into the workpiece. Due to the presence of arc current, an appropriate electromagnetic model based on the Maxwell equations are also solved to calculate electromagnetic forces in the weld pool. The results of computer simulation, including temperature, current density, electromagnetic, and melted material velocity field, are presented here. Furthermore, several dimensionless numbers are employed to recognize the importance of fluid flow driving forces in the weld pool. It is deduced that the fluid flow has an important effect on the weld pool shape. It is also founded that among the driving forces, Marangoni force is dominant fluid force in the weld pool. Besides, calculated results of hybrid welding process are compared with those of TIG and laser welding processes. The weld pool depth is relatively the same, but the width of the weld pool is highly larger in hybrid welding than lone laser welding. Eventually, the presented model is validated by comparison between calculated and experimental weld pool shape. It is founded that there is a good agreement as the capability of this model can be proved.

Similar content being viewed by others

References

Bagger C, Olsen FO (2005) Review of laser hybrid welding. J Laser Appl 17(1):2–14. doi:10.2351/1.1848532

Mahrle A, Beyer E (2006) Hybrid laser beam welding—classification, characteristics, and applications. J Laser Appl 18(3):169–180. doi:10.2351/1.2227012

Ribic B, Rai R, DebRoy T (2008) Numerical simulation of heat transfer and fluid flow in GTA/laser hybrid welding. Sci Technol Weld Join 13(8):683–693. doi:10.1179/136217108x356782

Ribic B, Palmer TA, DebRoy T (2009) Problems and issues in laser–arc hybrid welding. Int Mater Rev 54(4):223–244. doi:10.1179/174328009x411163

Gao M, Zeng X, Hu Q, Yan J (2009) Laser–TIG hybrid welding of ultra-fine grained steel. J Mater Process Technol 209(2):785–791. doi:10.1016/j.jmatprotec.2008.02.062

Casalino G, Campanelli SL, Dal Maso U, Ludovico AD (2013) Arc leading versus laser leading in the hybrid welding of aluminium alloy using a fiber laser. Procedia CIRP 12:151–156. doi:10.1016/j.procir.2013.09.027

Möller F, Thomy C (2013) Interaction effects between laser beam and plasma arc in hybrid welding of aluminum. Phys Procedia 41:81–89. doi:10.1016/j.phpro.2013.03.054

Maletta C, Falvo A, Furgiuele F, Barbieri G, Brandizzi M (2009) Fracture behaviour of nickel–titanium laser welded joints. J Mater Eng Perform 18(5–6):569–574. doi:10.1007/s11665-009-9351-8

Rai R, Elmer JW, Palmer TA, DebRoy T (2007) Heat transfer and fluid flow during keyhole mode laser welding of tantalum, Ti–6Al–4 V, 304 L stainless steel and vanadium. J Phys D Appl Phys 40(18):5753–5766

Cho W-I, Na S-J, Thomy C, Vollertsen F (2012) Numerical simulation of molten pool dynamics in high power disk laser welding. J Mater Process Technol 212(1):262–275. doi:10.1016/j.jmatprotec.2011.09.011

Han S-W, Cho W-I, Na S-J, Kim C-H (2013) Influence of driving forces on weld pool dynamics in GTA and laser welding. Weld World 57(2):257–264. doi:10.1007/s40194-012-0020-4

Chen YB, Lei ZL, Li LQ, Wu L (2006) Experimental study on welding characteristics of CO2 laser TIG hybrid welding process. Sci Technol Weld Join 11(4):403–411. doi:10.1179/174329306X129535

Faraji AH, Bahmani A, Goodarzi M, Seyedein SH, Shbani MO (2014) Numerical and experimental investigations of weld pool geometry in GTA welding of pure aluminum. J Cent South Univ 21:20–26. doi:10.1007/s11771-014-1910-y

Faraji A, Goodarzi M, Seyedein S, Zamani M (2014) Experimental study and numerical modeling of arc and weld pool in stationary GTA welding of pure aluminum. Int J Adv Manuf Technol:1–13. doi:10.1007/s00170-014-5651-8

Dong W, Lu S, Li D, Li Y (2011) GTAW liquid pool convections and the weld shape variations under helium gas shielding. Int J Heat Mass Transf 54(7–8):1420–1431. doi:10.1016/j.ijheatmasstransfer.2010.07.069

Traidia A, Roger F (2011) Numerical and experimental study of arc and weld pool behaviour for pulsed current GTA welding. Int J Heat Mass Transf 54(9–10):2163–2179. doi:10.1016/j.ijheatmasstransfer.2010.12.005

Dong W, Lu S, Li D, Li Y (2010) Modeling of the weld shape development during the autogenous welding process by coupling welding arc with weld pool. J Mater Eng Perform 19(7):942–950. doi:10.1007/s11665-009-9570-z

Zhang W, Kim CH, DebRoy T (2004) Heat and fluid flow in complex joints during gas metal arc welding—part II: application to fillet welding of mild steel. J Appl Phys 95(9):5220–5229. doi:10.1063/1.1699486

Goodarzi M, Choo R, Takasu T, Toguri JM (1998) The effect of the cathode tip angle on the gas tungsten arc welding arc and weld pool: II. The mathematical model for the weld pool. J Phys D Appl Phys 31(5):569–583

Rai R, Kelly SM, Martukanitz RP, DebRoy T (2008) A convective heat-transfer model for partial and full penetration keyhole mode laser welding of a structural steel. Metall Mat Trans A 39(1):98–112. doi:10.1007/s11661-007-9400-6

Rai R, Roy GG, DebRoy T (2007) A computationally efficient model of convective heat transfer and solidification characteristics during keyhole mode laser welding. J Appl Phys 101(5):1–11. doi:10.1063/1.2537587

Moradi M, Ghoreishi M, Frostevarg J, Kaplan AFH (2013) An investigation on stability of laser hybrid arc welding. Opt Lasers Eng 51(4):481–487. doi:10.1016/j.optlaseng.2012.10.016

Brandizzi M, Satriano AA, Sorgente D, Tricarico L (2013) Laser–arc hybrid welding of Ti6Al4V titanium alloy: mechanical characterization of joints and gap tolerance. Weld Int 27(2):113–120. doi:10.1080/09507116.2011.600045

Tani G, Campana G, Fortunato A, Ascari A (2007) The influence of shielding gas in hybrid LASER–MIG welding. Appl Surf Sci 253(19):8050–8053. doi:10.1016/j.apsusc.2007.02.144

Piekarska W, Kubiak M (2011) Three-dimensional model for numerical analysis of thermal phenomena in laser–arc hybrid welding process. Int J Heat Mass Transf 54(23–24):4966–4974. doi:10.1016/j.ijheatmasstransfer.2011.07.010

Piekarska W, Kubiak M (2013) Modeling of thermal phenomena in single laser beam and laser—arc hybrid welding processes using projection method. Appl Math Model 37(4):2051–2062. doi:10.1016/j.apm.2012.04.052

Kong F, Ma J, Kovacevic R (2011) Numerical and experimental study of thermally induced residual stress in the hybrid laser–GMA welding process. J Mater Process Technol 211(6):1102–1111. doi:10.1016/j.jmatprotec.2011.01.012

Kong F, Kovacevic R (2010) 3D finite element modeling of the thermally induced residual stress in the hybrid laser/arc welding of lap joint. J Mater Process Technol 210(6–7):941–950. doi:10.1016/j.jmatprotec.2010.02.006

Gao Z, Ojo OA (2012) Modeling analysis of hybrid laser—arc welding of single-crystal nickel-base superalloys. Acta Mater 60(6–7):3153–3167. doi:10.1016/j.actamat.2012.02.021

Xu GX, Wu C, Qin GL, Wang XY, Lin SY (2011) Adaptive volumetric heat source models for laser beam and laser + pulsed GMAW hybrid welding processes. Int J Adv Manuf Technol 57(1–4):245–255. doi:10.1007/s00170-011-3274-x

Le Guen E, Carin M, Fabbro R, Coste F, Le Masson P (2011) 3D heat transfer model of hybrid laser Nd:Yag-MAG welding of S355 steel and experimental validation. Int J Heat Mass Transf 54(7–8):1313–1322. doi:10.1016/j.ijheatmasstransfer.2010.12.010

P-q X, Bao C-m, F-g L, C-w M, J-p H, H-c C, Yang S-l (2011) Numerical simulation of laser–tungsten inert arc deep penetration welding between WC–Co cemented carbide and invar alloys. Int J Adv Manuf Technol 53(9–12):1049–1062. doi:10.1007/s00170-010-2898-6

Zhou J, Tsai HL (2008) Modeling of transport phenomena in hybrid laser—MIG keyhole welding. Int J Heat Mass Transf 51(17–18):4353–4366. doi:10.1016/j.ijheatmasstransfer.2008.02.011

Cho JH, Na SJ (2009) Three-dimensional analysis of molten pool in GMA—laser hybrid welding. Weld J (Miami, Fla) 88(2):35s–43s

Cho WI, Na SJ, Cho MH, Lee JS (2010) Numerical study of alloying element distribution in CO2 laser—GMA hybrid welding. Comput Mater Sci 49(4):792–800

Abderrazak K, Bannour S, Mhiri H, Lepalec G, Autric M (2009) Numerical and experimental study of molten pool formation during continuous laser welding of AZ91 magnesium alloy. Comput Mater Sci 44(3):858–866. doi:10.1016/j.commatsci.2008.06.002

Patankar SV (1980) Numerical heat transfer and fluid flow. McGraw-Hill, New York

Roy GG, Elmer JW, DebRoy T (2006) Mathematical modeling of heat transfer, fluid flow, and solidification during linear welding with a pulsed laser beam. J Appl Phys 100(3):1–7. doi:10.1063/1.2214392

He X, Elmer JW, DebRoy T (2005) Heat transfer and fluid flow in laser microwelding. J Appl Phys 97(8):\084909. doi:10.1063/1.1873032

Zhang W, Kim C-H, DebRoy T (2004) Heat and fluid flow in complex joints during gas metal arc welding—part I: numerical model of fillet welding. J Appl Phys 95(9):5210–5219. doi:10.1063/1.1699485

Lago F, Gonzalez JJ, Freton P, Gleizes A (2004) A numerical modelling of an electric arc and its interaction with the anode: part I. The two-dimensional model. J Phys D: Appl Phys 37(6):883–897

Lu F, Yao S, Lou S, Li Y (2004) Modeling and finite element analysis on GTAW arc and weld pool. Comput Mater Sci 29(3):371–378. doi:10.1016/j.commatsci.2003.10.009

Gonzalez JJ, Lago F, Freton P, Masquère M, Franceries X (2005) Numerical modelling of an electric arc and its interaction with the anode: part II. The three-dimensional model—influence of external forces on the arc column. J Phys D Appl Phys 38(2):306–318

Jamshidi Aval H, Farzadi A, Serajzadeh S, Kokabi AH (2009) Theoretical and experimental study of microstructures and weld pool geometry during GTAW of 304 stainless steel. Int J Adv Manuf Technol 42(11–12):1043–1051. doi:10.1007/s00170-008-1663-6

Farzadi A, Serajzadeh S, Kokabi AH (2010) Investigation of weld pool in aluminum alloys: geometry and solidification microstructure. Int J Therm Sci 49(5):809–819. doi:10.1016/j.ijthermalsci.2009.11.007

Cantin GMD, Francis JA (2005) Arc power and efficiency in gas tungsten arc welding of aluminium. Sci Technol Weld Join 10(2):200–210. doi:10.1179/174329305X37033

Tsai NS, Eagar TW (1985) Distribution of the heat and current fluxes in gas tungsten arcs. MTB 16(4):841–846. doi:10.1007/bf02667521

Wu CS, Gao JQ (2002) Analysis of the heat flux distribution at the anode of a TIG welding arc. Comput Mater Sci 24(3):323–327. doi:10.1016/S0927-0256(01)00254-3

Haiyan Z, Wenchong N, Bin Z, Yongping L, Masaru K, Takashi I (2011) Modelling of keyhole dynamics and porosity formation considering the adaptive keyhole shape and three-phase coupling during deep-penetration laser welding. J Phys D Appl Phys 44(48):485302

Farzadi A, Serajzadeh S, Kokabi AH (2008) Modeling of heat transfer and fluid flow during gas tungsten arc welding of commercial pure aluminum. Int J Adv Manuf Technol 38(3–4):258–267. doi:10.1007/s00170-007-1106-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faraji, A.H., Goodarzi, M., Seyedein, S.H. et al. Numerical modeling of heat transfer and fluid flow in hybrid laser–TIG welding of aluminum alloy AA6082. Int J Adv Manuf Technol 77, 2067–2082 (2015). https://doi.org/10.1007/s00170-014-6589-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6589-6