Abstract

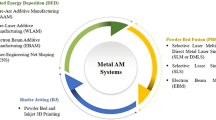

Tungsten (W) materials are gaining more and more attention due to the extended applications of metallic systems in the extreme environments. Given W’s unique characteristics like room-temperature brittleness, additive manufacturing (AM) techniques could give them a higher design flexibility and manufacturability. With the growing focus and thriving development of W-faced AM techniques, since the mechanical performance of additively manufactured W parts is still unsatisfactory, a critical review to further explore the possibilities of combining W and AM processes is urgently needed. In this review, we systematically explain the fundamentals of AM processes for W materials. Following the traditional classification, we further discuss the widely used AM processes including wire arc additive manufacturing (WAAM), electron beam melting (EBM), laser powder bed fusion (LPBF), laser direct energy deposition (laser DED), and other modified yet emergent AM techniques. Accordingly, since additively manufacturing W materials is processing parameter-sensitive, we illustrated the effects of various important processing parameters on the AM process control and final parts’ quality. With this detailed understanding, various categories of AM-compatible W materials (i.e., pure W, W alloys, and W composites) were presented, and their general mechanical performance, distinct role (particularly the role of different alloying elements and added secondary-phase particles in W), and application-oriented benefits have been summarized. After clarifying the current status, main challenges, and triumphant successes for additively manufacturing W materials, we further provide a concise prospect into the development of additively manufactured (AMed) W materials by integrating potential fabrication, measurement, alloy design, and application’s considerations. In summary, this critical review investigates the fundamental and practical problems crucially limiting the applications of AMed W materials, and the comprehensive discussion concentrates the history of the development and combination between AM techniques and W design. All the understanding is of great importance to achieving foreseeable successful future applications of AMed W materials.

Reproduced with permission from Ref. [24], © Elsevier Ltd. 2020

Reproduced with permission from Ref. [7], © Elsevier Ltd. 2018

Reproduced with permission from Ref.[179], © Acta Materialia Inc. by Elsevier Ltd. 2022

Similar content being viewed by others

References

Xie J, Lu H, Lu J, Song X, Wu S, Lei J. Additive manufacturing of tungsten using directed energy deposition for potential nuclear fusion application. Surf Coat Technol. 2021;409: 126884.

Wang G, Qin Y, Yang S. Influence of Ni additions on the microstructure and tensile property of W-Cu composites produced by direct energy deposition. J Alloy Compd. 2022;899: 163272.

Wei C, Liu L, Gu Y, Huang Y, Chen Q, Li Z, Li L. Multi-material additive-manufacturing of tungsten—copper alloy bimetallic structure with a stainless-steel interlayer and associated bonding mechanisms. Addit Manuf. 2022;50: 102574.

Su S, Lu Y. Densified WCu composite fabricated via laser additive manufacturing. Int J Refract Metal Hard Mater. 2020;87: 105122.

Oponowicz A, Marciszko-Wiąckowska M, Baczmański A, Klaus M, Genzel C, Wroński S, Kollbek K, Wróbel M. Gradient of residual stress and lattice parameter in mechanically polished tungsten measured using classical x-rays and synchrotron radiation. Metall Mater Trans A. 2020;51(11):5945.

Iveković A, Omidvari N, Vrancken B, Lietaert K, Thijs L, Vanmeensel K, Vleugels J, Kruth J. Selective laser melting of tungsten and tungsten alloys. Int J Refract Metal Hard Mater. 2018;72:27.

Li K, Wang D, Xing L, Wang Y, Yu C, Chen J, Zhang T, Ma J, Liu W, Shen Z. Crack suppression in additively manufactured tungsten by introducing secondary-phase nanoparticles into the matrix. Int J Refract Metal Hard Mater. 2019;79:158.

Ren X, Liu H, Lu F, Huang L, Yi X. Effects of processing parameters on the densification, microstructure and mechanical properties of pure tungsten fabricated by optimized selective laser melting: from single and multiple scan tracks to bulk parts. Int J Refract Metal Hard Mater. 2021;96: 105490.

Matthews M, Trapp J, Guss G, Rubenchik A. Direct measurements of laser absorptivity during metal melt pool formation associated with powder bed fusion additive manufacturing processes. J Laser Appl. 2018;30(3): 032302.

Vrancken B, Ganeriwala R, Matthews M. Analysis of laser-induced microcracking in tungsten under additive manufacturing conditions: experiment and simulation. Acta Mater. 2020;194:464.

Zhou X, Liu X, Zhang D, Shen Z, Liu W. Balling phenomena in selective laser melted tungsten. J Mater Process Technol. 2015;222:33.

Ellis E, Sprayberry M, Ledford C, Hankwitz J, Kirka M, Rock C, Horn T, Katoh Y, Dehoff R. Processing of tungsten through electron beam melting. J Nucl Mater. 2021;555: 153041.

Seeger A. Peierls barriers, kinks, and flow stress: recent progress. Int J Mater Res. 2002;93(8):760.

Müller A, Schlick G, Neu R, Anstätt C, Klimkait T, Lee J, Pascher B, Schmitt M, Seidel C. Additive manufacturing of pure tungsten by means of selective laser beam melting with substrate preheating temperatures up to 1000 ∘C. Nucl Mater Energy. 2019;19:184.

Lassner E, Schubert W. Tungsten: properties, chemistry, technology of the elements, alloys, and chemical compounds. New York: Springer Science & Business Media; 1978.

Mitteau R, Missiaen J, Brustolin P, Ozer O, Durocher A, Ruset C, Lungu C, Courtois X, Dominicy C, Maier H, Grisolia C, Piazza G, Chappuis P. Recent developments toward the use of tungsten as armour material in plasma facing components. Fusion Eng Des. 2007;82(15):1700.

Gu D, Meiners W, Wissenbach K, Poprawe R. Laser additive manufacturing of metallic components: materials, processes and mechanisms. Int Mater Rev. 2012;57(3):133.

Tan C, Zhou K, Ma W, Attard B, Zhang P, Kuang T. Selective laser melting of high-performance pure tungsten: parameter design, densification behavior and mechanical properties. Sci Technol Adv Mater. 2018;19(1):370.

Chen H, Ye L, Han Y, Chen C, Fan J. Additive manufacturing of W-Fe composites using laser metal deposition: microstructure, phase transformation, and mechanical properties. Mater Sci Eng A. 2021;811: 141036.

Wang G, Sun X, Huang M, Qin Y, Yao Y, Yang S. Influence of processing parameters on the microstructure and tensile property of 85 W-15Ni produced by laser direct deposition. Int J Refract Metal Hard Mater. 2019;82:227.

Chen H, Zi X, Han Y, Dong J, Liu S, Chen C. Microstructure and mechanical properties of additive manufactured W–Ni–Fe–Co composite produced by selective laser melting. Int J Refract Metal Hard Mater. 2020;86:105111.

Guo Z, Wang L, Wang X. Additive manufacturing of W-12Ta(wt%) alloy: processing and resulting mechanical properties. J Alloy Compd. 2021;868:159193.

Tan Z, Zhou Z, Wu X, Wang Y, Shao W, Guo X, Zhou Z, Yang Y, Wang G, He D. In situ synthesis of spherical WMo Alloy powder for additive manufacturing by spray granulation combined with thermal plasma spheroidization. Int J Refract Metal Hard Mater. 2021;95: 105460.

Wang G, Qin Y, Yang S. Characterization of laser-powder interaction and particle transport phenomena during laser direct deposition of W-Cu composite. Addit Manuf. 2021;37: 101722.

Rosenthal D. Mathematical theory of heat distribution during welding and cutting. Weld J. 1941;20:220.

Nunes A. An extended rosenthal weld model. Weld J. 1983;62(6):165.

Vilar R. Laser powder deposition. Compr Mater Process. 2014;10:163.

Thompson S, Bian L, Shamsaei N, Yadollahi A. An overview of direct laser deposition for additive manufacturing; Part I: transport phenomena, modeling and diagnostics. Addit Manuf. 2015;8:36.

Zhao X, An N, Yang G, Wang J, Tang H, Li M, Zhou J. Enhancing standard finite element codes with POD for reduced order thermal analysis: application to electron beam melting of pure tungsten. Mater Today Commun. 2021;29: 102796.

Han Y, Fan J, Liu T, Cheng H, Tian J. The effect of trace nickel additive and ball milling treatment on the near-full densification behavior of ultrafine tungsten powder. Int J Refract Metal Hard Mater. 2012;34:18.

Du Z, Lv Y, Han Y, Fan J, Ye L. Sintering densification behavior and kinetic mechanism of nano-tungsten powder prepared by sol-spray drying. Tungsten. 2020;2(4):371.

Chalmers B. Principles of solidification. 1st ed. Boston: Springer; 1970. p. 161.

Pan S, Yao G, Sokoluk M, Guan Z, Li X. Enhanced thermal stability in Cu-40 wt% Zn/WC nanocomposite. Mater Des. 2019;180: 107964.

Pan S, Guan Z, Yao G, Yuan J, Li X. Mo-enhanced chemical stability of TiC nanoparticles in molten Al. J Alloy Compd. 2020;856: 158169.

Wang H, Zak Fang Z, Hwang K. Kinetics of initial coarsening during sintering of nanosized powders. Metall Mater Trans A. 2011;42(11):3534.

Wang L, Wu J, Zhang D. Properties evolution of additive manufacture used tungsten powders prepared by radio frequency induction plasma. Int J Refract Metal Hard Mater. 2017;67:90.

Zi X, Chen C, Wang X, Wang P, Zhang X, Zhou K. Spheroidisation of Tungsten Powder by Radio Frequency Plasma for Selective Laser Melting. Mater Sci Technol. 2018;34(6):735.

Wu Y. Manufacturing of tungsten and tungsten composites for fusion application via different routes. Tungsten. 2019;1(1):80.

Klopp W, Raffo P, Witzke W. Mechanical properties of dilute tungsten-rhenium alloys. Urbana-Champaign: NASA; 1966.

Marinelli G, Martina F, Lewtas H, Hancock D, Mehraban S, Lavery N, Ganguly S, Williams S. Microstructure and thermal properties of unalloyed tungsten deposited by wire + arc additive manufacture. J Nucl Mater. 2019;522:45.

Marinelli G, Martina F, Ganguly S, Williams S. Development of wire + arc additive manufacturing for the production of large-scale unalloyed tungsten components. Int J Refract Metal Hard Mater. 2019;82:329.

Klein T, Schnall M, Gomes B, Warczok P, Fleischhacker D, Morais P. Wire-arc additive manufacturing of a novel high-performance Al–Zn–Mg–Cu alloy: processing, characterization and feasibility demonstration. Add Manuf. 2021;37: 101663.

Galati M. Electron beam melting process: a general overview. Handbooks in advanced manufacturing. Amsterdam: Elsevier; 2021. p. 277.

Yang G, Yang P, Yang K, Liu N, Jia L, Wang J, Tang H. Effect of processing parameters on the density, microstructure and strength of pure tungsten fabricated by selective electron beam melting. Int J Refract Metal Hard Mater. 2019;84: 105040.

Wright J. Additive manufacturing of tungsten via selective laser melting and electron beam melting. Degree thesis. University of Sheffield, Sheffield. 2019.

Liao W, Liu Z, He M, Feng C, Wang F, Huang J. Effect of Electron Beam Remelting Treatments on the Microstructure and Properties of Atmospheric Plasma Sprayed Tungsten Coatings. J Therm Spray Tech. 2021;30(8):2128.

Guo M, Gu D, Xi L, Du L, Zhang H, Zhang J. Formation of scanning tracks during selective laser melting (SLM) of pure tungsten powder: morphology, geometric features and forming mechanisms. Int J Refract Metal Hard Mater. 2019;79:37.

Wang D, Wang Z, Li K, Ma J, Liu W, Shen Z. Cracking in laser additively manufactured W: initiation mechanism and a suppression approach by alloying. Mater Des. 2019;162:384.

AbuShanab W, Moustafa E. Effects of friction stir processing parameters on the wear resistance and mechanical properties of fabricated metal matrix nanocomposites (MMNCs) surface. J Market Res. 2020;9(4):7460.

Wang D, Yu C, Zhou X, Ma J, Liu W, Shen Z. Dense pure tungsten fabricated by selective laser melting. Appl Sci. 2017;7(4):430.

Wen S, Wang C, Zhou Y, Duan L, Wei Q, Yang S, Shi Y. High-density tungsten fabricated by selective laser melting: densification, microstructure, mechanical and thermal performance. Opt Laser Technol. 2019;116:128.

Bai S, Liu J, Yang P, Zhai M, Huang H, Yang L. Femtosecond fiber laser additive manufacturing of tungsten. Laser 3D Manuf III. 2016;9738:96.

Zhou S, Liang Y, Zhu Y, Wang B, Wang L, Xue Y. Ultrashort-time liquid phase sintering of high-performance fine-grain tungsten heavy alloys by laser additive manufacturing. J Mater Sci Technol. 2021;90:30.

Jeong W, Kwon Y, Kim D. Three-dimensional printing of tungsten structures by directed energy deposition. Mater Manuf Processes. 2019;34(9):986.

Li C, Ma S, Liu X, Li J, Le G. Microstructures and properties of 80w–20Fe alloys prepared using laser melting deposition process. Int J Refract Metal Hard Mater. 2018;77:113.

Gokcekaya O, Ishimoto T, Todo T, Wang P, Nakano T. Influence of powder characteristics on densification via crystallographic texture formation: pure tungsten prepared by laser powder bed fusion. Addit Manuf Lett. 2021;1: 100016.

Klahn C, Leutenecker B, Meboldt M. Design strategies for the process of additive manufacturing. Procedia CIRP. 2015;36:230.

Gokuldoss P, Kolla S, Eckert J. Additive manufacturing processes: selective laser melting, electron beam melting and binder jetting—selection guidelines. Materials. 2017;10(6):672.

Dohale V, Akarte M, Gupta S, Verma V. Additive manufacturing process selection using MCDM. Singapore: Springer; 2021. p. 601.

Zaman U, Rivette M, Siadat A, Mousavi S. Integrated product-process design: material and manufacturing process selection for additive manufacturing using multi-criteria decision making. Robot Comput Integr Manuf. 2018;51:169.

Qin Y, Qi Q, Scott P, Jiang X. An additive manufacturing process selection approach based on fuzzy archimedean weighted power bonferroni aggregation operators. Robot Comput Integr Manuf. 2020;64: 101926.

Agrawal R. Sustainable material selection for additive manufacturing technologies: a critical analysis of rank reversal approach. J Clean Prod. 2021;296: 126500.

Wang Y, Ma S, Yang X, Zhou Y, Liu X, Li J, Zhang J, Li C, Wang X, Le G, Zhang Y. Microstructure and strengthening mechanisms of 90W–7Ni–3Fe alloys prepared using laser melting deposition. J Alloy Compd. 2020;838: 155545.

Stawovy M, Myers K, Ohm S. Binder jet printing of tungsten heavy alloy. Int J Refract Metal Hard Mater. 2019;83: 104981.

Cole N, Gilliland R, Slaughter G. Weldability of tungsten and its alloys. Weld J. 1971;50(9):419.

Kurishita H, Matsuo S, Arakawa H, Sakamoto T, Kobayashi S, Nakai K, Okano H, Watanabe H, Yoshida N, Torikai Y, Hatano Y, Takida T, Kato M, Ikegaya A, Ueda Y, Hatakeyama M, Shikama T. Current status of nanostructured tungsten-based materials development. Phys Scr. 2014;T159: 014032.

Nagy D, Humphry-Baker S. An oxidation mechanism map for tungsten. Scr Mater. 2022;209: 114373.

Braun J, Kaserer L, Stajkovic J, Leitz K, Tabernig B, Singer P, Leibenguth P, Gspan C, Kestler H, Leichtfried G. Molybdenum and tungsten manufactured by selective laser melting: analysis of defect structure and solidification mechanisms. Int J Refract Metal Hard Mater. 2019;84: 104999.

Warren A, Nylund A, Olefjord I. Oxidation of tungsten and tungsten carbide in dry and humid atmospheres. Int J Refract Metal Hard Mater. 1996;14(5):345.

Ledford C, Rock C, Carriere P, Frigola P, Gamzina D, Horn T. Characteristics and processing of hydrogen-treated copper powders for EB-PBF additive manufacturing. Appl Sci. 2019;9(19):3993.

Li C, Wang Y, Ma S, Yang X, Li J, Zhou Y, Liu X, Tang J, Wang X, Le G. Densification, microstructural evolutions of 90W–7Ni-3Fe tungsten heavy alloys during laser melting deposition process. Int J Refract Metal Hard Mater. 2020;91: 105254.

Savitskii E. Physical metallurgy of refractory metals and alloys. 3rd ed. New York: Springer; 2012.

Wendel J. Thermodynamics and kinetics of tungsten oxidation and tungsten oxide sublimation in the temperature interval 200°–1100°C. Degree thesis, Lund University, Lund, 2014

Sochalski-Kolbus L, Payzant E, Cornwell P, Watkins T, Babu S, Dehoff R, Lorenz M, Ovchinnikova O, Duty C. Comparison of residual stresses in inconel 718 simple parts made by electron beam melting and direct laser metal sintering. Metall Mater Trans A. 2015;46(3):1419.

Yamamoto T, Hara M, Hatano Y. Effects of fabrication conditions on the microstructure, pore characteristics and gas retention of pure tungsten prepared by laser powder bed fusion. Int J Refract Metal Hard Mater. 2021;95: 105410.

Xue J, Feng Z, Tang J, Tang C, Zhao Z. Selective laser melting additive manufacturing of tungsten with niobium alloying: microstructure and suppression mechanism of microcracks. J Alloy Compd. 2021;874: 159879.

Cunningham R, Zhao C, Parab N, Kantzos C, Pauza J, Fezzaa K, Sun T, Rollett A. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed X-ray imaging. Science. 2019;363(6429):849.

Gan Z, Kafka O, Parab N, Zhao C, Fang L, Heinonen O, Sun T, Liu W. Universal scaling laws of keyhole stability and porosity in 3D printing of metals. Nat Commun. 2021;12(1):2379.

Srivatsan T, Sudarshan T. Additive manufacturing: innovations, advances, and applications. 1st ed. Boca Raton: CRC Press; 2015.

Tang M, Pistorius P. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int J Fatigue. 2017;94:192.

Wysocki B, Maj P, Sitek R, Buhagiar J, Kurzydłowski K, Święszkowski W. Laser and electron beam additive manufacturing methods of fabricating titanium bone implants. Appl Sci. 2017;7(7):657.

Enneti R, Morgan R, Atre S. Effect of process parameters on the selective laser melting (SLM) of tungsten. Int J Refract Metal Hard Mater. 2018;71:315.

Aversa A, Moshiri M, Librera E, Hadi M, Marchese G, Manfredi D, Lorusso M, Calignano F, Biamino S, Lombardi M, Pavese M. Single scan track analyses on aluminium based powders. J Mater Process Technol. 2018;255:17.

Vrancken B, Ganeriwala R, Martin A, Matthews M. Microcrack mitigation during laser scanning of tungsten via preheating and alloying strategies. Addit Manuf. 2021;46: 102158.

Zhong M, Liu W, Ning G, Yang L, Chen Y. Laser direct manufacturing of tungsten nickel collimation component. J Mater Process Technol. 2004;147(2):167.

Zhang D, Cai Q, Liu J. Formation of nanocrystalline tungsten by selective laser melting of tungsten powder. Mater Manuf Processes. 2012;27(12):1267.

Ng G, Jarfors A, Bi G, Zheng H. Porosity formation and gas bubble retention in laser metal deposition. Appl Phys A. 2009;97(3):641.

Adamson A. Potential distortion model for contact angle and spreading. II. Temperature dependent effects. J Colloid Interface Sci. 1973;44(2):273.

Muramatsu Y, Harada K, Dan T, Isoda Y. Solid-liquid interfacial tension of the W-Cu system. J Jpn Inst Met. 1990;54:6.

Pan S, Zheng T, Yao G, Chi Y, De Rosa I, Li X. High-strength and high-conductivity in situ Cu–TiB2 nanocomposites. Mater Sci Eng A. 2022;831: 141952.

Hamidi A, Arabi H, Rastegari S. Tungsten-copper composite production by activated sintering and infiltration. Int J Refract Metal Hard Mater. 2011;29(4):538.

Gupta V, Yoon D, Meyer H, Luo J. Thin intergranular films and solid-state activated sintering in nickel-doped tungsten. Acta Mater. 2007;55(9):3131.

Wei C, Gu H, Gu Y, Liu L, Huang Y, Cheng D, Li Z, Li L. Abnormal interfacial bonding mechanisms of multi-material additive-manufactured tungsten-stainless steel sandwich structure. Int J Extrem Manuf. 2022;4: 025002.

Zhang J, Gu D, Yang Y, Zhang H, Chen H, Dai D, Lin K. Influence of particle size on laser absorption and scanning track formation mechanisms of pure tungsten powder during selective laser melting. Engineering. 2019;5(4):736.

Field A, Carter L, Adkins N, Attallah M, Gorley M, Strangwood M. The effect of powder characteristics on build quality of high-purity tungsten produced via laser powder bed fusion (LPBF). Metall Mater Trans A. 2020;51(3):1367.

Enneti R, Morgan R, Wolfe T, Harooni A, Volk S. Direct metal laser sintering (DMLS) of tungsten powders. Proceedings for Additive Manufacturing with Powder Metallurgy (AMPM). Las Vegas, USA, 2017

Guo M, Gu D, Xi L, Zhang H, Zhang J, Yang J, Wang R. Selective laser melting additive manufacturing of pure tungsten: role of volumetric energy density on densification, microstructure and mechanical properties. Int J Refract Metal Hard Mater. 2019;84: 105025.

Wang D, Li K, Yu C, Ma J, Liu W, Shen Z. Cracking behavior in additively manufactured pure tungsten. Acta Metall Sin (Engl Lett). 2019;32(1):127.

Deprez K, Vandenberghe S, Van Audenhaege K, Van Vaerenbergh J, Van Holen R. Rapid additive manufacturing of MR compatible multipinhole collimators with selective laser melting of tungsten powder. Med Phys. 2013;40(1): 012501.

Sidambe A, Judson D, Colosimo S, Fox P. Laser powder bed fusion of a pure tungsten ultra-fine single pinhole collimator for use in gamma ray detector characterisation. Int J Refract Metal Hard Mater. 2019;84: 104998.

Gear J, Taprogge J, White O, Flux G. Characterisation of the attenuation properties of 3D-printed tungsten for use in gamma camera collimation. EJNMMI Phys. 2019;6(1):1.

Sidambe A, Tian Y, Prangnell P, Fox P. Effect of processing parameters on the densification, microstructure and crystallographic texture during the laser powder bed fusion of pure tungsten. Int J Refract Metal Hard Mater. 2019;78:254.

Zhou Z, Tan Z, He D, Zhou Z, Cui L, Wang Y, Shao W, Wang G. Fabrication of three-dimensional connected W-Cu10Sn composites by selective laser melting. Mater Lett. 2020;264: 127377.

Li J, Wei Z, Zhou B, Wu Y, Chen S, Sun Z. Densification, microstructure and properties of 90W–7Ni-3Fe fabricated by selective laser melting. Metals. 2019;9(8):884.

Song C, Yang Y, Liu Y, Luo Z, Yu J. Study on manufacturing of W-Cu alloy thin wall parts by selective laser melting. Int J Adv Manuf Technol. 2015;78(5):885.

Li R, Shi Y, Liu J, Xie Z, Wang Z. Selective laser melting W–10 w.t% Cu composite powders. Int J Adv Manuf Technol. 2010;48(5):597.

Hu Z, Liu Y, Wu J, Dong J, Ma Z, Liu Y. The simultaneous improvement of strength and ductility of the 93W–4.6Ni-2.4Fe prepared by additive manufacturing via optimizing sintering post-treatment. Addit Manuf. 2021;46:102216.

Bose A, Schuh C, Tobia J, Tuncer N, Mykulowycz N, Preston A, Barbati A, Kernan B, Gibson M, Krause D, Brzezinski T, Schroers J, Fulop R, Myerberg J, Sowerbutts M, Chiang Y, John Hart A, Sachs E, Lomeli E, Lund A. Traditional and additive manufacturing of a new tungsten heavy alloy alternative. Int J Refract Metal Hard Mater. 2018;73:22.

Zhang D, Liu Z, Cai Q, Liu J, Chua C. Influence of Ni content on microstructure of W-Ni Alloy produced by selective laser melting. Int J Refract Metal Hard Mater. 2014;45:15.

Bose A, German R. Microstructural refinement of W-Ni-Fe heavy alloys by alloying additions. Metall Mater Trans A. 1988;19(12):3100.

Chookajorn T, Park M, Schuh C. Duplex nanocrystalline alloys: entropic nanostructure stabilization and a case study on W-Cr. J Mater Res. 2015;30(2):151.

Li K, Li Y, Chen W, Zhao C, Yuan Y, Cheng L, Morgan T, Liu W, Shen Z. Effect of Ta addition on the fuzz formation of additively manufactured W-based materials. Nucl Fusion. 2020;60(6): 064004.

Li J, Wei Z, Zhou B, Wu Y, Chen S, Sun Z. Preparation, microstructure, and microhardness of selective laser-melted W–3Ta sample. J Mater Res. 2020;35(15):2016.

Yamamoto T, Hara M, Hatano Y. Cracking behavior and microstructural, mechanical and thermal characteristics of tungsten-rhenium binary alloys fabricated by laser powder bed fusion. Int J Refract Metal Hard Mater. 2021;100: 105651.

Li K, Ma G, Xing L, Wang Y, Yu C, Chen J, Ma J, Wu G, Liu W, Shen Z, Huang X. Crack suppression via in-situ oxidation in additively manufactured W-Ta alloy. Mater Lett. 2020;263: 127212.

Calvo A, Schlueter K, Tejado E, Pintsuk G, Ordás N, Iturriza I, Neu R, Pastor J, García-Rosales C. Self-passivating tungsten alloys of the system W–Cr–Y for high temperature applications. Int J Refract Metal Hard Mater. 2018;73:29.

Pan S, Jin K, Wang T, Zhang Z, Zheng L, Umehara N. Metal matrix nanocomposites in tribology: manufacturing, performance, and mechanisms. Friction. 2022. https://doi.org/10.1007/s40544-021-0572-7.

Rieth M, Dafferner B. Limitations of W and W–1%La2O3 for use as structural materials. J Nucl Mater. 2005;342(1):20.

Xie Z, Liu R, Miao S, Yang X, Zhang T, Wang X, Fang Q, Liu C, Luo G, Lian Y, Liu X. Extraordinary high ductility/strength of the interface designed bulk W-ZrC alloy plate at relatively low temperature. Sci Rep. 2015;5(1):16014.

Deng H, Xie Z, Wang Y, Liu R, Zhang T, Hao T, Wang X, Fang Q, Liu C. Mechanical properties and thermal stability of pure W and W-0.5wt% ZrC alloy manufactured with the same technology. Mater Sci Eng A. 2018;715:117.

Chen J, Zhao C, Li K, Li M, Sun S, Zhang S, Ma J, Liu W. Effect of TaC addition on microstructure and microhardness of additively manufactured tungsten. J Alloy Compd. 2022;897: 162978.

Lang S, Sun N, Cao J, Yu W, Yang Z, Hou S. Fabrication of ultra-fine-grained W-TiC alloys by a simple ball-milling and hydrogen reduction method. Materials. 2021;14(19):5865.

Gu D, Dai D, Chen W, Chen H. Selective laser melting additive manufacturing of hard-to-process tungsten-based alloy parts with novel crystalline growth morphology and enhanced performance. J Manuf Sci Eng. 2016;138(8): 081003.

Hu Z, Zhao Y, Guan K, Wang Z, Ma Z. Pure tungsten and oxide dispersion strengthened tungsten manufactured by selective laser melting: microstructure and cracking mechanism. Addit Manuf. 2020;36: 101579.

Hu W, Dong Z, Wang H, Ahamad T, Ma Z. Microstructure refinement and mechanical properties improvement in the W-Y2O3 alloys via optimized freeze-drying. Int J Refract Metal Hard Mater. 2021;95: 105453.

Chen L, Xu J, Choi H, Pozuelo M, Ma X, Bhowmick S, Yang J, Mathaudhu S, Li X. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature. 2015;528(7583):539.

Jiang Q, Cao C, Lin T, Wu S, Li X. Strong and tough glass with self-dispersed nanoparticles via solidification. Adv Mater. 2019;31(33):1901803.

Sokoluk M, Yuan J, Pan S, Li X. Nanoparticles enabled mechanism for hot cracking elimination in aluminum alloys. Metall Mater Trans A. 2021;52(7):3083.

Yuan J, Yao G, Pan S, Murali N, Li X. Size control of in situ synthesized TiB2 particles in molten aluminum. Metall Mater Trans A. 2021;52(6):2657.

Maleki E, Bagherifard S, Guagliano M. Application of artificial intelligence to optimize the process parameters effects on tensile properties of Ti–6Al–4V fabricated by laser powder-bed fusion. Int J Mech Mater Des. 2021;18(1):199.

Wang C, Tan X, Tor S, Lim C. Machine learning in additive manufacturing: state-of-the-art and perspectives. Addit Manuf. 2020;36: 101538.

Zhu Q, Liu Z, Yan J. Machine learning for metal additive manufacturing: predicting temperature and melt pool fluid dynamics using physics-informed neural networks. Comput Mech. 2021;67(2):619.

Payal H, Maheshwari S, Bharti P, Sharma S. Multi-objective optimisation of electrical discharge machining for inconel 825 using Taguchi-fuzzy approach. Int j inf tecnol. 2019;11(1):97.

Kumar S, Batish A, Singh R, Singh T. A hybrid Taguchi-artificial neural network approach to predict surface roughness during electric discharge machining of titanium alloys. J Mech Sci Technol. 2014;28(7):2831.

Radhwan H, Shayfull Z, Farizuan M, Effendi M, Irfan A. Optimization parameter effects on the quality surface finish of the three-dimensional printing (3D-printing) fused deposition modeling (FDM) using RSM. AIP Conf Proc. 2019;2129(1): 020155.

Pradhan M. Estimating the effect of process parameters on MRR, TWR and radial overcut of EDMed AISI D2 tool steel by RSM and GRA coupled with PCA. Int J Adv Manuf Technol. 2013;68(1):591.

Lee J, Yamashita S, Ogura T, Saida K. Suppression of solidification cracking via thermal strain control in multi-beam welding. Mater Today Commun. 2020;24: 101094.

Hu Y, Ning F, Cong W, Li Y, Wang X, Wang H. Ultrasonic vibration-assisted laser engineering net shaping of ZrO2–Al2O3 bulk parts: effects on crack suppression, microstructure, and mechanical properties. Ceram Int. 2018;44(3):2752.

Li Y, Zhang D, Wang H, Cong W. Fabrication of a TiC-Ti matrix composite coating using ultrasonic vibration-assisted laser directed energy deposition: the effects of ultrasonic vibration and TiC content. Metals. 2021;11(5):693.

Cong W, Ning F. A fundamental investigation on ultrasonic vibration-assisted laser engineered net shaping of stainless steel. Int J Mach Tools Manuf. 2017;121:61.

Yao G, Pan S, Yuan J, Guan Z, Li X. A novel process for manufacturing copper with size-controlled in-situ tungsten nanoparticles by casting. J Mater Process Technol. 2021;296:117187.

Pan S, Zhang Z. Fundamental theories and basic principles of triboelectric effect: a review. Friction. 2018;7(1):2.

Pan S, Wang T, Jin K, Cai X. Understanding and designing metal matrix nanocomposites with high electrical conductivity: a review. J Mater Sci. 2022;57:6487.

Mercado Rojas J, Wolfe T, Fleck B, Qureshi A. Plasma transferred arc additive manufacturing of nickel metal matrix composites. Manuf Lett. 2018;18:31.

Choudhury S, Marya S, Amirthalingam M. Improving arc stability during wire arc additive manufacturing of thin-walled titanium components. J Manuf Process. 2021;66:53.

Rosli N, Alkahari M, Abdollah M, Maidin S, Ramli F, Herawan S. Review on effect of heat input for wire arc additive manufacturing process. J Market Res. 2021;11:2127.

Ren B, Chen C, Zhang M. Effect of heat treatment on the microstructure of Co–Cr–W alloy fabricated by laser additive manufacturing. OE. 2018;57(4):041409.

Chen J, Li K, Wang Y, Xing L, Yu C, Liu H, Ma J, Liu W, Shen Z. The effect of hot isostatic pressing on thermal conductivity of additively manufactured pure tungsten. Int J Refract Metal Hard Mater. 2020;87: 105135.

Vrancken B, King W, Matthews M. In-situ characterization of tungsten microcracking in selective laser melting. Procedia CIRP. 2018;74:107.

Shi M, Xiong J, Zhang G, Zheng S. Monitoring process stability in GTA additive manufacturing based on vision sensing of arc length. Measurement. 2021;185: 110001.

Yasa E, Deckers J, Kruth J, Rombouts M, Luyten J. Charpy impact testing of metallic selective laser melting parts. Virtual Phys Prototyp. 2010;5(2):89.

Lang S, Yan Q, Sun N, Zhang X, Deng L, Wang Y, Ge C. Microstructure, basic thermal-mechanical and Charpy impact properties of W-0.1 wt.% TiC alloy via chemical method. J Alloy Compd. 2016;660:184.

Ren C, Fang Z, Koopman M, Butler B, Paramore J, Middlemas S. Methods for improving ductility of tungsten—a review. Int J Refract Metal Hard Mater. 2018;75:170.

Stephens J. Dislocation structures in single-crystal tungsten and tungsten alloys. Metall Mater Trans B. 1970;1(5):1293.

Leonhardt T. Properties of tungsten-rhenium and tungsten-rhenium with hafnium carbide. JOM. 2009;61(7):68.

Luo A, Jacobson D, Shin K. Solution softening mechanism of iridium and rhenium in tungsten at room temperature. Int J Refract Metal Hard Mater. 1991;10(2):107.

Wang Y, Xie Z, Wang M, Deng H, Yang J, Jiang Y, Zhang T, Wang X, Fang Q, Liu C. The superior thermal stability and tensile properties of hot rolled W-HfC alloys. Int J Refract Metal Hard Mater. 2019;81:42.

Li P, Li S, Wang Z, Zhang Z. Fundamental factors on formation mechanism of dislocation arrangements in cyclically deformed FCC single crystals. Prog Mater Sci. 2011;56(3):328.

Feltner C, Laird C. Cyclic stress-strain response of F.C.C. metals and alloys—I phenomenological experiments. Acta Metall. 1967;15(10):1621.

Feltner C, Laird C. Cyclic stress-strain response of F.C.C. metals and alloys—II dislocation structures and mechanisms. Acta Metall. 1967;15(10):1633.

Lukáš P, Klesnil M. Dislocation structures in fatigued single crystals of Cu–Zn system. Phys Status Solidi (A). 1971;5(1):247.

Haasen P, Gerold V, Kostorz G. Strength of metals and alloys. In: Proceedings of the 5th international conference, Aachen, Federal Republic of Germany. 1st ed. Aachen: Pergamon Press, 1979

Steffens T, Schwink C, Korner A, Karnthaler H. Transmission electron microscopy study of the stacking-fault energy and dislocation structure in CuMn alloys. Philos Mag A. 1987;56(2):161.

Lei Z, Liu X, Wu Y, Wang H, Jiang S, Wang S, Hui X, Wu Y, Gault B, Kontis P, Raabe D, Gu L, Zhang Q, Chen H, Wang H, Liu J, An K, Zeng Q, Nieh T, Lu Z. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature. 2018;563(7732):546.

Wu Y, Zhang F, Yuan X, Huang H, Wen X, Wang Y, Zhang M, Wu H, Liu X, Wang H, Jiang S, Lu Z. Short-range ordering and its effects on mechanical properties of high-entropy alloys. J Mater Sci Technol. 2021;62:214.

Nasser A, Kassem M, Elsayed A, Gepreel M, Moniem A. Influence of grain refinement on microstructure and mechanical properties of tungsten carbide/zirconia nanocomposites. J Mater Eng Perform. 2016;25(11):5065.

Li X, Zhang L, Dong Y, Qin M, Wei Z, Que Z, Yang J, Qu X, Li J. Towards pressureless sintering of nanocrystalline tungsten. Acta Mater. 2021;220: 117344.

Xie Z, Liu R, Zhang T, Fang Q, Liu C, Liu X, Luo G. Achieving high strength/ductility in bulk W-Zr-y2o3 alloy plate with hybrid microstructure. Mater Des. 2016;107:144.

Dong Z, Liu N, Ma Z, Liu C, Guo Q, Alothman Z, Yamauchi Y, Shahriar A, Hossain M, Liu Y. Microstructure refinement in W-Y2O3 alloy fabricated by wet chemical method with surfactant addition and subsequent spark plasma sintering. Sci Rep. 2017;7(1):6051.

Chen Y, Wu Y, Yu F, Chen J. Microstructure and mechanical properties of tungsten composites Co-strengthened by dispersed TiC and La2O3 particles. Int J Refract Metal Hard Mater. 2008;26(6):525.

Hu W, Dong Z, Yu L, Ma Z, Liu Y. Synthesis of W-Y2O3 alloys by freeze-drying and subsequent low temperature sintering: microstructure refinement and second phase particles regulation. J Mater Sci Technol. 2020;36:84.

Xie Z, Liu R, Fang Q, Zhang T, Jiang Y, Wang X, Liu C. Microstructure and mechanical properties of nano-size zirconium carbide dispersion strengthened tungsten alloys fabricated by spark plasma sintering method. Plasma Sci Technol. 2015;17(12):1066.

Xie Z, Liu R, Miao S, Zhang T, Wang X, Fang Q, Liu C, Luo G. Effect of high temperature swaging and annealing on the mechanical properties and thermal conductivity of W-Y2O3. J Nucl Mater. 2015;464:193.

Simonelli M, Tse Y, Tuck C. On the texture formation of selective laser melted Ti-6Al-4V. Metall Mater Trans A. 2014;45(6):2863.

Kruth J, Froyen L, Van Vaerenbergh J, Mercelis P, Rombouts M, Lauwers B. Selective laser melting of iron-based powder. J Mater Process Technol. 2004;149(1):616.

Farshidianfar M, Khajepour A, Gerlich A. Effect of real-time cooling rate on microstructure in laser additive manufacturing. J Mater Process Technol. 2016;231:468.

Zhang K, Wang S, Liu W, Shang X. Characterization of stainless steel parts by laser metal deposition shaping. Mater Des. 2014;55:104.

Murr L, Martinez E, Gaytan S, Ramirez D, Machado B, Shindo P, Martinez J, Medina F, Wooten J, Ciscel D, Ackelid U, Wicker R. Microstructural architecture, microstructures, and mechanical properties for a nickel-base superalloy fabricated by electron beam melting. Metall Mater Trans A. 2011;42(11):3491.

Xie X, Xie Z, Liu R, Fang Q, Liu C, Han W, Wu X. Hierarchical microstructures enabled excellent low-temperature strength-ductility synergy in bulk pure tungsten. Acta Mater. 2022;228: 117765.

Gong X, Chou K. Phase-field modeling of microstructure evolution in electron beam additive manufacturing. JOM. 2015;67(5):1176.

Zinoviev A, Zinovieva O, Ploshikhin V, Romanova V, Balokhonov R. Evolution of Grain Structure during Laser Additive Manufacturing. Simulation by a Cellular Automata Method. Materials & Design. 2016;106:321.

Rodgers T, Madison J, Tikare V. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput Mater Sci. 2017;135:78.

Cui Y, Li K, Wang C, Liu W. Dislocation evolution during additive manufacturing of tungsten. Model Simul Mater Sci Eng. 2021;30(2):024001.

Curzadd B, Müller A, Neu R, von Toussaint U. Topology optimization of tungsten/copper structures for plasma-facing component applications. Nucl Fusion. 2019;59(8): 086003.

Pirouzfam N, Sendur K. Tungsten based spectrally selective absorbers with anisotropic rough surface texture. Nanomaterials. 2021;11(8):2018.

Zhou K, Chen W, Yang Y, Li R, Dong L, Fu Y. Microstructure and mechanical behavior of porous tungsten skeletons synthesized by selected laser melting. Int J Refract Metal Hard Mater. 2022;103: 105769.

Moorehead M, Bertsch K, Niezgoda M, Parkin C, Elbakhshwan M, Sridharan K, Zhang C, Thoma D, Couet A. High-throughput synthesis of Mo–Nb–Ta–W high-entropy alloys via additive manufacturing. Mater Des. 2020;187: 108358.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, SH., Yao, GC., Cui, YN. et al. Additive manufacturing of tungsten, tungsten-based alloys, and tungsten matrix composites. Tungsten 5, 1–31 (2023). https://doi.org/10.1007/s42864-022-00153-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-022-00153-6