Abstract

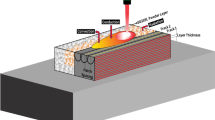

One of the inherent problems associated with laser metal deposition using gas-assisted powder transfer is the formation of porosity, which can be detrimental to the mechanical properties of the bulk material. In this work, a comprehensive investigation of porosity is carried out using gas atomised Inconel 718 powder. In the analysis, a clear distinction is made between two types of porosity; namely lack of fusion and gas porosity. The results show that the two types of porosity are attributed by different factors. The gas porosity, which is more difficult to eliminate than the lack of fusion, can be as high as 0.7%. The study shows that the gas porosity is dependent on the process parameters and the melt pool dynamics. The flotation of entrapped gas bubbles was analysed, showing that in a stationary melt pool the gas would be retained by Marangoni-driven flow. The overall Marangoni-driven flow of the melt pool is in the order of five times higher than the flotation effect, and this is the reason why the melt pool geometry would tend to dominate the flow direction of the gas bubbles. Through optimisation, the gas porosity can be reduced to 0.037%.

Similar content being viewed by others

References

L. Li, J. Mater. Sci. 41, 7886 (2006)

P.A. Kobryn, E.H. Moore, S.L. Semiatin, Scr. Mater. 43, 299 (2000)

R.H. Morgan, A.J. Papworth, C. Sutcliffe, P. Fox, W. O’Neill, J. Mater. Sci. 37, 3093 (2002)

P.A. Kobryn, S.L. Semiatin, J. Mater. Process. Technol. 135, 330 (2003)

X.H. Wu, J. Liang, J.F. Mei, C. Mitchell, P.S. Goodwin, W. Voice, Mater. Des. 25, 137 (2004)

J. Mazumder, D. Dutta, N. Kikuchi, A. Ghosh, Opt. Lasers Eng. 34, 397 (2000)

J. Choi, Y. Chang, Int. J. Mach. Tools Manuf. 45, 597 (2005)

P.L. Blackwell, A. Wisbey, J. Mater. Process. Technol. 170, 268 (2005)

L.J. Li, J. Mater. Sci. 41, 7886 (2006)

S. Sun, M. Brandt, J. Harris, Y. Durandet, Surf. Coat. Technol. 201, 998 (2006)

J. Choi, Y. Hua, J. Laser Appl. 4, 245 (2004)

V.E. Beal, P. Erasenthiran, N. Hopkinson, P. Dickens, C.H. Ahrens, J. Mater. Process. Technol. 174, 145 (2006)

H. Qi, J. Mazumder, J. Laser Appl. 3, 136 (2005)

X. Zhao, J. Chen, X. Lin, W. Huang, Mater. Sci. Eng. A 478, 119 (2008)

J. Mazumder, Opt. Eng. 8, 1208 (1991)

R.B. Bird, W.E. Stewart, E.N. Lightfoot, Transport Phenomena (Wiley, New York, 1960)

A. Bergman, H. Fredriksson, H. Shahani, J. Mater. Sci. 23, 1573 (1988)

T. Ida, R.I.L. Guthrie, The Physical Properties of Liquid Metals (Clarendon, Oxford, 1988)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ng, G.K.L., Jarfors, A.E.W., Bi, G. et al. Porosity formation and gas bubble retention in laser metal deposition. Appl. Phys. A 97, 641–649 (2009). https://doi.org/10.1007/s00339-009-5266-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-009-5266-3