Abstract

Heavy metal pollution has become one of the most significant environmental problems globally leading to ecological imbalance. There are many physicochemical and biological methods for the removal of heavy metals. Most of the physicochemical methods are less eco-friendly and less cost-effective, while the biological methods are slow in nature. Recently, nanoparticles have been suggested as efficient alternatives to existing treatment methods, in both resource conservation and environmental remediation of anthropogenic compounds. Nanotechnologies are pervasive solution vectors in our economic environment. Biological synthesis of nanoparticles has grown markedly to create novel materials that are eco-friendly, cost-effective and stable with great importance in wider application in the areas of electronics, medicine and agriculture. Thus, the current work focuses on a comparative remediation of heavy metals using physical, chemical and biological methods and nano-structured copper iodide is used as an adsorbent for the removal of chromium (Cr) and zinc (Zn). In the present study, we have experimented with a few methods in physical (UV light irradiation, adsorption studies using CuI), chemical (UV photocatalysis using CuI) and biological methods (using co-culture bacteria strains). A combination of chemical and biological methods was also probed using CuI–polyvinyl alcohol nano-composite containing bacterial co-cultures. The synthesized nano-composite was characterized using scanning electron microscope. The present study revealed that the most effective and cost-friendly method was using biologically prepared nano-composite of CuI (a combination of both chemical and biological methods) to remediate heavy metals Cr and Zn with a removal efficiency up to ~ 67% for Cr and ~ 55% for Zn at the end of 48 h.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

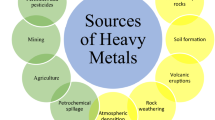

Heavy metals are widely known as environmental pollutants because of their toxicity, bio-accumulative nature and tenacity in the existing surroundings [1, 2]. Their natural sources comprise weathering of metal-bearing rocks and volcanic eruptions, whereas anthropogenic sources embody the development of mining operations, fertilizer industries, tanneries, sheet manufacture, pesticides, etc. Mining and industrial process for the extraction of natural resources and their resultant applications for industrial, agricultural and economic development have drawn a rise in the mobilization of those elements in the environment and disruption of their biogeochemical cycles [3, 4]. Contamination of ecosystems with heavy metals will result in significant risks to public health. In general, high amount of Cr and Zn in the human body causes various diseases [5,6,7,8]. According to WHO, 0.1 mg/l and 5.0 mg/l are the permissible dose of Cr and Zn, respectively, in drinking water [9]. Although the literature reports [10] various adsorbents like activated carbon, hybrid inorganic nano-composites, nano-crystalline polymers, etc., in the removal of Cr and Zn from water, most of them were found to end up in complications such as solid–liquid separation, slow kinetics and low adsorption efficiency. Hence, there is always a need for new, efficient and economically viable materials in this area.

Heavy metals have been reported to be removed by various physical methods comprising treatment of polluted system using physicochemical properties of the metals, which include adsorption [11], electrokinetic method [12], membrane filtration [13], granular activated carbon [14,15,16], photocatalysis [17] and soil washing [18]. The chemical process includes chemical precipitation [19], floatation [20], ion exchange [21], coagulation and flocculation [22]. These techniques are efficient for the removal of heavy metals, but the excessive use of chemicals causes the difficulty in sludge disposal and the possibility of a secondary pollution problem [23,24,25].

Bioremediation is one of the hopeful technologies utilized to detoxify the harmful form of metals to its less harmful state using microbes or its enzymes to purify the contaminated environment [26,27,28,29,30,31]. It is an environmentally friendly and cost-effective approach as it occurs through natural processes for the revitalization of the environment [32,33,34]. However, bioremediation of heavy metals has some limitations. Among those are the production of toxic metabolites by microbes and non-biodegradability of heavy metals [35]. Heavy metals cannot be eliminated during bioremediation but can solely be changed from one organic complex or oxidation state to another.[36,37,38]. This method uses microorganisms or plants or combination of both for the management of contaminated systems. Microorganisms have developed numerous strategies for their survival in heavy metal-polluted habitats; they develop and adopt different detoxifying mechanisms such as biosorption, bioaccumulation and biotransformation. The response of microorganism to heavy metals depends on the concentration and availability of heavy metals and is an interconnected process, which is controlled by several factors such as metal type, nature of medium and microbial species [36].

Nano-bioremediation is an emerging technology for the elimination of environmental pollutants using biosynthesized nanoparticles [39]. Nano-materials are of high significance because of their distinct properties, large surface area and quantum size effects; these materials can deliver extraordinary prospects to the treatment of heavy metal and are also a cost-effective alternative to the existing methods [40,41,42]. The biological synthesis of nanoparticles using plant extract or microorganism is an eco-friendly and economic alternative to chemical and physical methods [43]. The biosynthesized nanoparticles are stable with great importance and are extensively used in detoxification applications [44, 45]. Green-synthesized CuI nanoparticles and chemically synthesized iron nanoparticles have been reported [46,47,48,49] to show high adsorption capacities for heavy metal removal. Hence, it was thought worthwhile to examine Cr and Zn removal using CuI and iron oxide individually first and then in combination with acidophilic bacterial co-cultures isolated from tannery effluent-contaminated soil.

The use of advanced oxidation processes (AOPs) for the effective oxidation of a wide variety of hazardous pollutants has gained special attention in recent years, due to the generation of highly reactive hydroxyl radicals that transform the organic contaminants to non-toxic forms [47]. AOPs include UV/H2O2, Fenton and photo-Fenton processes (Fe2+/H2O2 and Fe2+/H2O2/UV), ultrasonic process, photocatalysis and electrochemical processes. Among them, priority is given to the photocatalytic degradation with respect to the high efficiency and low energy consumption [50, 51].

The present study is aimed at remediation of Cr and Zn using chemical and biological methods separately and in combination using acidophilic bacterial co-cultures isolated from tannery effluent-contaminated soil.

2 Materials and methods

2.1 Estimation of Cr & Zn

Throughout the present study, Cr was determined by the diphenylcarbazide method [48]; Zn was estimated by 3-hydroxybenzylaminobenzoic acid [49].

Diphenylcarbazide method: The reagent used for the estimation of Cr was 1,5-diphenylcarbazide. 500 mg of 1,5-Diphenylcarbazide was mixed in 100 ml of acetone, and the pH was adjusted to 2 ± 0.5 by adding 10% H2SO4. To obtain a standard graph, 10–100 ppm of potassium dichromate was taken in a 100-ml volumetric flask and one flask without Cr served as a blank. 10 ml of 5% H2SO4 was added to the flasks and diluted to 40 ml. 4 ml of diphenylcarbazide was added to this and diluted to mark with 5% H2SO4. Absorbance was measured after 5 min at 540 nm. In sterilized 1.5-ml vials, 1.5 ml of culture (0 to 5th day) was taken and centrifuged at 10,000 rpm for 5 min (Remi C24). 1 ml of supernatant was transferred to a sterile test tube containing 9 ml of distilled water. To this, 1 ml of 1,5-diphenylcarbazide was added and shaken immediately. The absorbance was measured at 540 nm [47].

3-hydroxybenzylaminobenzoic acid: Removal of zinc by the bacterial strains was observed in 5-day interval. The reagent used for the estimation of zinc is 3-hydroxybenzylaminobenzoic acid. 1 g of 3-hydroxybenzaldehyde was dissolved in 25 ml of distilled water and mixed in a flask with 4-aminobenzoic acid and refluxed for 3 h. A pale yellow crystal product formed which is filtered and dried at room temperature, which is re-crystallized using ethanol. To draw a standard graph, 1 ml of 100 ppm to 500 ppm of zinc sulfate solution was taken in a volumetric flask and one flask without zinc was served as a blank. 3 ml of buffer and 2 ml of 3-hydroxybenzylaminobenzoic acid were added. The aqueous phase was brought up to 10 ml by distilled water. The absorbance was measured at 460 nm. In sterilized 1.5-ml vials, 1 ml of culture (0 to 5th day) was taken and centrifuged at 10,000 rpm for 5 minutes (Remi C24). 1 ml of supernatant was transferred to a sterile test tube, and 3 ml of buffer and 2 ml of 3-hydroxybenzylaminobenzoic acid were added. The aqueous phase was brought up to 10 ml by distilled water. The absorbance was measured at 460 nm.

2.2 Removal of Cr and Zn by the biological method using acidophilic bacterial co-cultures

For the removal of Cr and zinc by acidophilic co-cultures, in a sterile 100-ml conical flask 50 ml of the sterilized 9 k medium was added which was supplemented with 40 ppm of metals Cr and Zn. 40 ppm was found to be the optimum concentration where maximum tolerance was observed [52]. The media were maintained at pH 3. 1 ml of the overnight culture (2.3 × 106 cfu/ml—starter culture) was inoculated into the flasks and incubated in a shaker at 37 °C (120 rpm). Kinetic studies were done at a time interval of 30 min after which removal of Cr and zinc was carried out, respectively. The removal study was also carried out for 4 days to check the percentage of removal of Cr and zinc at the end of each day.

2.3 Removal of Cr and Zn by the chemical method using iron oxide nanoparticles and green-synthesized copper iodide nanoparticles and a combination of chemical and biological methods

Iron oxide nanoparticles, copper iodide nanoparticles and polyvinyl alcohol copper iodide nano-composite were synthesized, characterized and employed for metal removal.

2.3.1 Chemical synthesis of iron oxide nanoparticles, green synthesis of copper iodide nanoparticles from Hibiscus rosa-sinensis flower extract

Iron oxide nanoparticles were synthesized by the chemical co-precipitation method. Ferrous sulfate and ferric chloride solutions were taken at a concentration of 0.75 M each. The precursor solutions are taken in a 2:1 ratio and stirred well for 15 min. Then, sodium hydroxide is added at regular intervals to the precursor solution. Upon addition of NaOH, the solution turned black, indicating the formation of magnetite nanoparticles. The nanoparticles were centrifuged and washed with deionized water. The magnetic nanoparticles were then stored for further use [49]. The synthesized magnetite nanoparticles were characterized using powder X-ray diffraction. The assays were recorded by Bruker D8 ADVANCE Powder X-ray Diffraction with 2θ values ranging from 20 to 100.

Copper sulfate and potassium iodide were purchased from Spectrum and Fisher Scientific India Pvt. Ltd., respectively, and were used without further purification. CuI nanoparticles were prepared using the flower extract from Hibiscus rosa-sinensis. Copper sulfate solution was taken in a beaker, and the diluted plant extract was added to it dropwise. Following this, potassium iodide solution was added dropwise to the mixture with continuous stirring. After the complete addition of potassium iodide, the mixture was stirred further for half an hour at room temperature. The resulting cream precipitate obtained was then filtered using Whatman filter paper No. 1 and washed thoroughly with 50% ethanol and heated at 60 °C [50]. The synthesized CuI was characterized using powder X-ray diffraction. The assays were recorded by Bruker D8 ADVANCE Powder X-ray Diffraction with 2θ values ranging from 20 to 100.

2.3.2 Removal of Cr and Zn by the chemical method using chemically synthesized nanoparticles (iron oxide and CuI nanoparticles)

Batch adsorption studies were carried out by mixing 5 mg of iron oxide nanoparticles with 50 ml potassium dichromate solution in different concentrations of 20, 40, 60 and 80 mg/l at pH 8. The same procedure was carried out using a 50 ml zinc sulfate solution in different concentrations of 20, 40, 60 and 80 mg/l at pH 8. All the adsorption studies were carried out at room temperature and using a shaker for 20 min with 250 rpm. Sampling was made at a time interval of 30 min [51]. The concentration of chromium and zinc was analyzed and determined.

Batch experiments for the reduction of chromium and zinc were carried out in 100-ml conical flasks. 50 ml of potassium dichromate solution (20 mg/l) and 50 ml of zinc sulfate solution (20 mg/l) were added, respectively, to each flask along with 5 mg of copper iodide nanoparticles. All the adsorption studies were carried out under optimum conditions. Sampling was made at a time interval of 30 min. After every 30 min, the samples were tested for removal of chromium and zinc.

2.3.3 Removal of Cr and Zn by the combination of chemical and biological methods

2.3.3.1 Iron oxide nanoparticles along with acidophilic bacterial co-cultures

In sterile 100-ml conical flasks, 50 ml sterilized 9 K medium was added which was supplemented with 20 ppm of potassium dichromate and 20 ppm of zinc sulfate. 5 mg of iron oxide nanoparticles was added to the flasks. 1 ml of the overnight culture was inoculated into the flasks and incubated in a shaker at 37 °C (120 rpm). Cr and Zn were determined at the end of 24 h.

2.3.3.2 Copper iodide nanoparticles along with acidophilic bacterial co-cultures

50 ml sterile 9 k medium was supplemented with 40 ppm of Cr and Zn ion solution; to this solution, 5 mg of copper iodide nanoparticles and 1 ml of overnight bacterial cultures were added. The resultant mixture was irradiated with UV light with continuous agitation. Samples of this irradiated mixture were analyzed for Cr and Zn every 15 min for 120 min.

2.3.3.3 Polyvinyl alcohol–CuI nano-composite and acidophilic bacteria co-cultures

Polyvinyl alcohol (2 g) and sodium alginate (1 g) were dissolved in 100 ml of distilled water at 80 °C. To this, silica gel (3 g) was sieved and added to it. The bacterial suspension (10%, v/v) was dissolved in the mixture, which was cooled down to room temperature and continuously stirred for 10–15 min to ensure the mixture was evenly distributed. Then, the mixture was dropped into boric acid (3% w/v) and CaCl2(4% w/v) solution; it was shaped to pellets immediately and kept for 20 h at 30 °C (150 rpm) to enhance their mechanical stabilities. The pellets were washed three times with sterile water and then stored in a refrigerator at 4 °C for further use [53]. To 50 ml of polyvinyl alcohol mixture, 5 mg of CuI was added along with the bacteria. Then, the mixture was dropped into boric acid (3% w/v) and CaCl2 (4% w/v) solution; it was shaped to pellets immediately and stored at 4 °C for further use [53].

The prepared nano-composite of CuI was added to sterile 100-ml conical flasks along with 50 ml of sterilized 9 K medium supplemented with 20 ppm of potassium dichromate and 20 ppm of zinc sulfate. The media were maintained at pH 3 to which 1 ml of the overnight culture was inoculated and incubated in a shaker at 37 °C (120 rpm). The growth pattern was observed at 540 nm from 0th day till 5th day. Cr and Zn were determined at the end of each day.

2.4 Removal of Cr and Zn by the physical methods

2.4.1 UV irradiation in a photocatalytic reactor

For the removal of chromium and zinc using the photocatalytic reactor, 50 ml sterile 9 k medium supplemented with 40 ppm of heavy metals was added to the photocatalytic reactor tubes which were placed inside the reactor. Sampling was done after one hour for which Cr and Zn were determined.

2.4.2 UV irradiation in the presence of CuI nanoparticles in a photocatalytic reactor

50 ml sterile 9 k medium supplemented with 40 ppm of Cr and Zn ions was added to the photocatalytic reactor tubes along with 5 mg of CuI nanoparticles. The sample was irradiated with UV light with continuous agitation. The sample was analyzed for Cr and Zn at the end of 1 h.

2.4.3 Removal of Cr and Zn by the combination of physical and biological methods

50 ml sterile 9 k medium was supplemented with 40 ppm of Cr and Zn ion solution; to this solution, 5 mg of copper iodide nanoparticles and 1 ml of overnight bacterial cultures were added. The resultant mixture was irradiated with UV light with continuous agitation. Samples of this irradiated mixture were analyzed for Cr and Zn every 15 min for 120 min.

3 Results and discussion

The following are the results obtained for the percentage removal of Cr and Zn using biological (acidophilic bacterial co-cultures), chemical (iron oxide nanoparticles, green-synthesized CuI nanoparticles), physical (UV irradiation in a photocatalytic reactor) and combination of biological–chemical, biological–physical, physical–chemical and biological–chemical–physical methods.

3.1 Removal of heavy metals by the biological method using acidophilic bacterial co-cultures

The biological removal using acido-tolerant bacterial co-cultures was performed by using a mixture of 40 mg/l of chromium and 40 mg/l of zinc. It was noted from the experiment (Fig. 1) that chromium removal was ~ 64% (OR1KVG), while the zinc removal was ~ 65% at the end of the 4th day (OR2KVG).

The removal of chromium and zinc using acido-tolerant bacterial co-cultures was also probed by taking at 40 mg/l of Cr and Zn separately. Results showed Cr removal to be ~ 68% (OR1KVG) and the zinc removal to be ~ 45% at the end of the 4th day (OR2KVG). Figure 1b Kinetic studies showed that after 30 min the chromium removal percentage was 4% which increased up to 18% at the end of 2 h. The zinc removal percentage at the end of 30 min was ~ 3% which increased to ~ 15% at the end of 2 h, respectively.

3.2 Removal of heavy metals by the chemical method

Heavy metals are difficult to remove as most of the toxic forms of the metals are in their most stable oxidation states, due to which they react with the biomolecules to form extremely stable bio-toxic compounds, which are often very difficult to dissociate. There are various reports on the chemical removal of heavy metals. Different methods of chemical treatment include chemical precipitation, flotation, adsorption, ion exchange and electrochemical deposition. Recently, researchers have started working on nano-remediation of heavy metals. Hence, this present study involves a comparison carried out with chemically synthesized iron oxide (Fe2O3) nanoparticles and green-synthesized copper iodide (CuI) nanoparticles for the removal of chromium and zinc.

3.2.1 Synthesis, characterization and application of iron oxide nanoparticles in Cr and Zn removal

The iron oxide nanoparticles were synthesized by the co-precipitation method. The iron oxide nanoparticles synthesized were characterized by X-ray diffraction (XRD) to confirm its formation (Fig. 2). The X-ray diffraction pattern of the synthesized nanoparticles was found to match with that reported in the literature [54] (JCPDS No. 33–663) by which we found out that they were hematite nanoparticles. It was observed that there were few peaks which we could decipher and the peaks were not very sharp which may be due to impurities. The broad nature of the few peaks obtained may be attributed to the nano-size of the particles (Table 1). Figure 3 shows the morphology and size of the hematite nanoparticles, which were determined using SEM analysis. In the SEM image, the particle appears to be rod-shaped and the average particle size was 85.61 nm with size ranging from 25.4 to 155.8 nm.

For the removal of heavy metals, chemically synthesized hematite nanoparticles were used. The chromium removal using hematite nanoparticles was done for various concentrations of chromium. Figure 4 shows that the chromium removal was found to be maximum at 20 ppm of chromium with ~ 26% removal at the end of 2 h. The zinc removal using hematite nanoparticles was carried out for various concentrations of zinc. The amount of zinc removal at the end of 2 h was found to be maximum at 40 ppm with ~ 25% zinc removal.

3.2.2 Synthesis, characterization and application of green-synthesized copper iodide nanoparticles in Cr and Zn removal

The copper iodide nanoparticles synthesized by the green route method were characterized by X-ray diffraction (XRD) to determine the structure of the nanoparticles (Fig. 5). The X-ray diffraction pattern of the synthesized CuI was found to match well with that reported in the literature [55] (JCPDS card no. 82–2111). It was observed that the peaks are sharp and well defined and no significant impurities were observed in the XRD pattern, indicating high purity of the product. The X-ray powder pattern data of CuI were found to fit well in fcc lattice. The average ‘a’ value of CuI was found to be 6.0357 Å. Therefore, the synthesized CuI is in γ-phase as out of the three different phases of copper iodide the γ-phase is the most stable one at room temperature which is found to crystallize in an fcc lattice. Using Scherrer’s formula, the crystallite size was calculated. The mean crystallite size of CuI was found to be approximately 77.02 nm (Table 2).

γ-CuI adopts a zinc blende structure with surface crystal defects making it a favorable adsorbent. The vacant positions may act as adsorbing sites for Cr and Zn [51].

Figure 6 shows the morphology and size of the copper iodide nanoparticles, which were determined using SEM analysis. In the SEM image, the particle appears to be in the triangular shape and the particle size was 660.92 nm. The average particle size calculated from SEM is much higher than that calculated from XRD this may be due to agglomeration of particles. The surface morphologies will influence the adsorption of molecules significantly [56]. The triangular shape of the CuI particles, due to the geometrically advantageous properties can act as a good adsorbent.

Figure 7 shows the removal of heavy metals using copper iodide nanoparticles. From the initial amount of 40 mg/l heavy metals, chromium was found to be removed up to ~ 10% at the end of 30 min and ~ 23% at the end of 2 h. Zinc was found to have removed up to ~ 8% at the end of 30 min and ~ 21% removal at the end of 2 h under optimum conditions.

3.3 Metal removal by the combination of chemical and biological methods

3.3.1 Hematite nanoparticles along with acidophilic bacterial co-cultures

The chromium removal was carried out for various concentrations, and Fig. 8 depicts that the maximum was at 60 ppm with ~ 30% chromium removal. Zinc removal was found to be maximum at the end of the 3rd day at 40 ppm concentration with ~ 24% zinc removal using hematite nanoparticles.

From the above comparison study of these nanoparticles along with the bacterial strains, it is concluded that the combination of the bacterial co-cultures with the green-synthesized nanoparticles is more effective in the removal of the heavy metals than with the chemically synthesized magnetic nanoparticles. The copper iodide nano-composites showed up to 67% and 55% of chromium and zinc removal at the end of two days, while the bacterial co-cultures with the hematite nanoparticles showed only up to 30% and 24% at the end of 3 days. Thus, the green-synthesized nanoparticles are more efficient in the removal of heavy metals as they are very good adsorbents.

3.3.2 Removal of heavy metals by the combination of chemical and biological methods using polyvinyl alcohol–copper iodide nano-composite

To enhance the activity of copper iodide nanoparticles, these were added to polyvinyl alcohol (polymer) along with the bacterial strains. The CuI and the bacterial strains get embedded in the polymer, forming a nano-composite. This nano-composite enhances the removal of heavy metals due to its high porosity, strong stability and efficient adsorption ability. These nano-composites were characterized by SEM analysis under 500×, 5000× and 8000× magnification to determine the morphology of the nano-composite that is shown in Fig. 9.

Figure 9a shows the structure of nano-composite of CuI which includes the bacterial strains. They are white, spherical in nature. Figure 9b shows the outer structure of the nano-composites under 500× magnification using scanning electron microscopy. The outer structure consists of long fibers held together to form a porous structure. This nano-composite is further magnified under 5000× magnification depicting the porous structure of the nano-composite (Fig. 9c). Due to their porous structure, they have the ability to entrap the CuI nanoparticles and the bacterial strains. Figure 9d shows the inner structure of the nano-composite (8000×) where the copper iodide nanoparticles and the bacterial strains are embedded in the polymer.

Figure 9d shows the inner structure of the nano-composite (8000×) where the copper iodide nanoparticles and the bacterial strains are embedded in the polymer.

Figure 10 shows that the amount of chromium (40 ppm) which was removed by nano-composites containing acidophilic bacterial co-cultures at the end of 2 days was found to be ~ 67%. The zinc removal percentage using copper iodide nanoparticles at optimum conditions was found to be ~ 55% at the end of 2 days.

3.4 Removal of heavy metals by the physical method using photocatalytic reactor

The physical method for chromium and zinc removal was carried out using the photocatalytic reactor. The photocatalytic removal process is gaining importance in the removal of heavy metals due to complete mineralization, no waste disposal problem and cost-effectiveness. Thus, in the above study the UV irradiation in a photocatalytic reactor was employed in the removal of heavy metals (Cr and Zn). Figure 11 shows the removal of heavy metals using the photocatalytic reactor. The chromium removal using only the physical method was found to be 55%, and the zinc removal was found to be 44% maximum at the end of 2 h, respectively.

3.5 Removal of heavy metals by the combination of chemical and physical methods

The study was also done on the effect of metal removal by the combination of physical and chemical methods, using copper iodide nanoparticles along with heavy metals in the photocatalytic reactor. Figure 12 shows that chromium removal increased up to 83% and for removal of zinc it increased up to 75% at the end of 2 h, respectively.

3.6 Removal of heavy metals by the combination of biological and physical methods

The effect of metal removal by the combination of biological and physical methods was studied using bacterial co-cultures along with heavy metals in the photocatalytic reactor as shown in Fig. 13. The chromium removal by this method was found to be ~ 23%, and the zinc removal was found to be ~ 20% at the end of 2 h, respectively.

3.7 Removal of heavy metals by the combination of biological, chemical and physical methods

A combination of biological, chemical and physical methods was probed using bacterial co-cultures and copper iodide nanoparticles in a photocatalytic reactor along with the heavy metals (Fig. 14). The chromium removal by this method was found to be ~ 42%, and the zinc removal was found to be ~ 48% at the end of 2 h, respectively.

In the present study using green-synthesized nanoparticles (copper iodide nanoparticles), chromium removal was found to be ~ 23% for and ~ 21% for zinc removal at the end of 2 h under optimum conditions. And using chemically synthesized nanoparticles (hematite nanoparticles) chromium removal was found be ~ 26% maximum at 20 ppm at the end of 2 h. The zinc removal was found to be maximum at 40 ppm with ~ 25% removal at the end of 120 min. Mohamed ali et al. [57] and Suresh kumar et al. [50] synthesized a novel material nano-fibers polyacrylonitrile (PAN) and carbon nano-tube (CNT)/titanium dioxide (TiO) nanoparticles functionalized with amine groups (TiO–NH2) composite nano-fibers (fabricated by electrospinning) and chitosan–magnetite nano-composite strip, respectively, and employed in the efficient removal of heavy chromium metal ions. Similarly, in the present study, novel polyvinyl alcohol–CuI containing bacterial cultures was synthesized and employed in the removal of heavy metals and was found to remove Cr ~ 67% and zinc ~ 55% at the end of 2 days. Also, photocatalytic reactor used to irradiate UV light on Cr and Zn samples was efficient in removing Cr of 55% and zinc of 44% maximum at the end of 2 h. In the study on the combination of physical and chemical methods which is using copper iodide nanoparticles along with heavy metal in the photocatalytic reactor, chromium removal showed up to 83% and zinc removal showed up to 75% at the end of 2 h. Table 3 gives the summary of percentage of Cr and Zn removal by various methods.

4 Conclusion

Heavy metals are the major source of contamination of soil through anthropogenic sources. In the tannery effluent-contaminated sites, the most commonly found heavy metals include chromium and zinc. These metals are highly toxic to the environment and pose a severe threat to the biological systems. Hence, there is a need for remediating the contaminated soil in an eco-friendly manner. Of the various methods for removal of heavy metals that were studied, the combination of physical–chemical method employed by using green-synthesized copper iodide nanoparticles in a solution of heavy metal in a photocatalytic reactor was found to be the most effective. A removal of 83% of Cr and 75% of Zn was achieved. By this method, over a long period of time, copper, being a heavy metal, may pollute the environment when used in large scale. The metal removal using a polyvinyl alcohol–CuI nano-composite containing acidophilic bacterial co-cultures was also found to be reasonably good with 67% Cr removal and 55% Zn removal. Although the efficiency is less than that of physical–chemical method, nano-composites of CuI were found to be more environment-friendly with minimum waste disposal. Thus, it can be concluded that the removal efficiency of chromium and zinc using nano-composite of CuI is highly efficient, and studies are being performed for further improvement in treating tannery effluents. The large-scale field application of this technology warrants an improved understanding of the mechanisms involved in resistance and reduction of co-occurring, which could be further studied.

References

Medici L, Bellanova J, Belviso C, Cavalcante F, Lettino A, Pasquale P, Fiore RS (2011) Trace metals speciation in sediments of the Basento River (Italy). Appl Clay Sci 53:414–442. https://doi.org/10.1016/j.clay.2010.10.029

Ali H, Khan E (2017) Environmental chemistry in the twenty-first century. Environ Chem Lett 15(2):329–346. https://doi.org/10.1007/s10311-016-0601-3

Ali H, Khan E, Sajad MA (2013) Phytoremediation of heavy metals—Concepts and applications. Chemosphere 91(7):869–881. https://doi.org/10.1016/j.chemosphere.2013.01.075

Hashem MA, Nur-A-Tomal MS, Mondal NR, Rahman MA (2017) Hair burning and liming in tanneries is a source of pollution by arsenic, lead, zinc, manganese and iron. Environ Chem Lett 15(3):501–506. https://doi.org/10.1007/s10311-017-0634-2

Gautam RK, Sharma SK, Chattopadhyaya MC (2015) Functionalized magnetic nanoparticles for heavy metals removal from aqueous solutions. Royal Society of Chemistry, London, p 57

Sharma YC, Srivastava V, Singh VK, Kaul SN, Weng CH (2009) Nano-adsorbents for the removal of metallic pollutants from water and wastewater. Environ Technol 30(6):583–609. https://doi.org/10.1080/09593330902838080

Kamberg ML (2010) The Transition elements: the 38 transition metals. The Rosen Publishing Group, New York

Zahar MS, Kusin FM, Muhammad SN (2015) Adsorption of manganese in aqueous solution by steel slag. Procedia Environ Sci 30:145–150. https://doi.org/10.1016/j.proenv.2015.10.026

Kumar M, Puri A (2012) A review of permissible limits of drinking water. IJOEM 16(1):40–44. https://doi.org/10.4103/0019-5278.99696

Barakat MA, Kumar R (2015) Modified and new adsorbents for removal of heavy metals from wastewater. R S Chem. https://doi.org/10.1039/9781782620174-00193

Muharrem I, Olcay K I, (2017) An Overview of Adsorption Technique for Heavy Metal Removal from Water/Wastewater: A Critical Review. Int J Pure Appl Sci 3(2): 10–19. https://doi.org/10.29132/ijpas.372335

Venkata Sivapullaiah P, Nagendra Prakash S, Nagahanumantharao Suma B (2015) Electrokinetic removal of heavy metals from soil. J Electrochem Sci Eng 5(1):47–65. https://doi.org/10.5599/jese.2015.0055

Khulbe KC, Matsuura T (2018) Removal of heavy metals and pollutants by membrane adsorption Techniques. Appl Water Sci 8(1):19–49. https://doi.org/10.1007/s13201-018-0661-6

Jusoh A, Shiung LS, Alia N, Noor MJMM (2007) A simulation study of the removal efficiency of granular activated carbon on cadmium and lead. Desalination 206(1–3):9–16. https://doi.org/10.1016/j.desal.2006.04.048

Sani A, Hussaini K, Sani HM (2017) Evaluation of removal efficiency of heavy metals by low-cost activated carbon prepared from African palm fruit. Appl Water Sci 7(6):3151–3155. https://doi.org/10.1007/s13201-016-0460-x

Krishnamoorthy R, Govindan B, Banat F, Sagadevan V, Purushothaman M, Show PL (2019) Date pits activated carbon for divalent lead ions removal. J Biosci Bioeng 128(1):88–97. https://doi.org/10.1016/j.jbiosc.2018.12.011

Bilal Tahir M, Kiran H, Iqbal T (2019) The detoxification of heavy metals from aqueous environment using nano-photocatalysis approach: a review Environ Sci Pollut R. https://doi.org/10.1007/s11356-019-04547-x

Abumaizar RJ, Smith EH (1999) Heavy metal contaminants removal by soil washing. J Haz Mat B 70(1–2):71–86. https://doi.org/10.1016/S0304-3894(99)00149-1

Djedidi Z, Bouda M, Souissi MA, Cheikh R, Mercier G, Tyagi RD, Blais JF (2009) Metals removal from soil, fly ash and sewage sludge leachates by precipitation and dewatering properties of the generated sludge. J Haz Mat 172(2):1372–1382. https://doi.org/10.1016/j.jhazmat.2009.07.144

Rubio J, Souza ML, Smith RW (2002) Overview of flotation as a wastewater treatment technique. Miner Eng 15(3):139–s155. https://doi.org/10.1016/S0892-6875(01)00216-3

Lee IH, Kuan YC, Chern JM (2007) Equilibrium and kinetics of heavy metal ion exchange. J Chin Inst Chem Eng 38(1):71–84. https://doi.org/10.1016/j.jcice.2006.11.001

Renault F, Sancey B, Badot PM, Crini G (2009) Chitosan for coagulation/flocculation processes—an eco-friendly approach. Eur Polym J 45(5):1337–1348. https://doi.org/10.1016/j.eurpolymj.2008.12.027

Renu MA, Kailash S (2017) Methodologies for removal of heavy metal ions from wastewater: an overview. IER 18(2):124–142. https://doi.org/10.1504/IER.2017.087915

Krishna Kumar Y, Gupta N, Kumar V, Kumar Singh J (2017) Bioremediation of heavy metals from contaminated sites using potential species: a review. Indian J Environ Prot 37(1):65–84

Ruchitha D, Wasiullah E, Malaviya D, Pandiyan K, Singh U, Sahu A (2015) Bioremediation of heavy metals from soil and aquatic environment: an overview of principles and criteria of fundamental processes. Sustainability. 7:2189–2221. https://doi.org/10.3390/su7022189

Ndeddy Aka RJ, Babalola OO (2016) Effect of bacterial inoculation of strains of pseudomonas aeruginosa, alcaligenes feacalis and bacillus subtilis on germination, growth and heavy metal (Cd, Cr, and Ni) uptake of brassica juncea. Intl J Phytoremediat 18(2):200–209. https://doi.org/10.1080/15226514.2015.1073671

Akcil A, Erust C, Ozdemiroglu S, Fonti V, Beolchini F (2015) A review of approaches and techniques used in aquatic contaminated sediments: metal removal and stabilization by chemical and biotechnological processes. J Clean Prod 86:24–26. https://doi.org/10.1016/j.jclepro.2014.08.009

Abbas HS, Ismail MI, Mostafa MT, Sulaymon HA (2014) Biosorption of heavy metals: a review. J Chem Sci Technol 3(4):74–102

Okoduwa SIR, Igiri B, Udeh CB, Edenta C, Gauje B (2017) Tannery effluent treatment by yeast species isolates from watermelon. Toxics 5(1):6. https://doi.org/10.3390/toxics5010006

Cheng SY, Show P-L, Lau BF, Chang J-S, Ling TC (2019) New prospects for modified algae in heavy metal adsorption. Trends Biotechnol 37(11):1255–1268. https://doi.org/10.1016/j.tibtech.2019.04.007

Vaxevanidou K, Papassiopi N, Paspaliaris I (2008) Removal of heavy metals and arsenic from contaminated soils using bioremediation and chelant extraction techniques. Chemosphere 70(8):1329–1337. https://doi.org/10.1016/j.chemosphere.2007.10.025

Hrynkiewicz K, Baum C (2014) Application of microorganisms in bioremediation of environment from heavy metals. Natural and Anthropogenic Determinants, Environmental Deterioration and Human Health, pp 215–227

Turpeinen R, Kairesalo T, Haggblom M (2002) Microbial activity community structure in arsenic, chromium and copper contaminated soils. J Environ Microbiol 35(6):998–1002. https://doi.org/10.1016/S01686496(03)00232-0

Ma Y, Rajkumar M, Zhang C, Freitas H (2016) Beneficial role of bacterial endophytes in heavymetal phytoremediation. J Environ Manage 174:14–25. https://doi.org/10.1016/j.jenvman.2016.02.047

Igiri BE, Okoduwa IR, Idoko O, Akabuogu P, Adeyi AO, Ejiogu IK (2018) Toxicity and bioremediation of heavy metals contaminated ecosystem from Tannery wastewater: a review. J Toxicol 2018:1–16. https://doi.org/10.1155/2018/2568038

Chibuike G, Obiora S (2018) Heavy metal polluted soils: effect on plants and bioremediation methods. Appl Environ Soil Sci. https://doi.org/10.1155/2014/752708

Garbisu C, Alkorta I (1997) Bioremediation: principles and future. J Clean Technol Environ Toxicol Occup Med 6(4):351–366

Garbisu C, Alkorta I (2003) Basic concepts on heavy metal soil bioremediation. Eur J Miner Process Environ Prot 3(1):58–66

Yadav K K, Singh J K, Gupta N, Kumar V (2017) A review of nanobioremediation technologies for environmental cleanup: a novel biological approach. J Mater Environ Sci 8(2):740–757

Mohmood I, Lopes CB, Lopes I, Ahmad I, Duarte AC, Pereira E (2013) Nanoscale materials and their use in water contaminants removal—a review. Environ Sci Pollut Res 20:1239–1260. https://doi.org/10.1007/s11356-012-1415-x

Xu P, Zeng GM, Huang DL, Feng CL, Hu S, Zhao MH et al (2012) Use of iron oxide nanomaterials in wastewater treatment: a review. Sci Total Environ 424:1–10. https://doi.org/10.1016/j.scitotenv.2012.02.023

Buzea C, Pacheco II, Robbie K (2007) Nanomaterials and nanoparticles: sources and toxicity Biointerphases 2(4):17–71. https://doi.org/10.1116/1.2815690

Singh P, Kim Y-J, Zhang D, Yang DC (2016) Biological synthesis of nanoparticles from plants and microorganisms. Trends Biotechnol 34(7):588–599. https://doi.org/10.1016/j.tibtech.2016.02.006

Haleemkhan AA, Naseem B, Vidya V (2015) Synthesis of nanoparticles from plant extracts. Int. J. Mod. Chem. Appl. Sci. 2(3):195–203

Li X, Xu H, Chen Z-S, Chen G (2011) Biosynthesis of nanoparticles by microorganisms and their applications. J. Nanomater. https://doi.org/10.1155/2011/270974

Joshi K, Shrivastava V (2011) Photocatalytic removal of Chromium (VI) from wastewater using nanomaterials like TiO2, ZnO, and CdS. Appl Nanosci 1(3):147–155. https://doi.org/10.1007/s13204-011-0023-2

Bhatkhande DS, Pangarkar VG, Beenackers AA (2001) Photocatalytic degradation for environmental applications—a review. J Chem Technol Biotechnol 77(1):102–116. https://doi.org/10.1002/jctb.532

Calomiris Jon J, Armstrong JL, Seidler RJ (1984) Association of metal tolerance with multiple antibiotic resistance of bacteria isolated from drinking water. Appl Environ Microbiol 47(6):1238–1242

Kiran K (2012) Spectrophotometric determination of iron in water samples using 3-Hydroxy Benzyl Amino Benzoic acid. Int J Environ Sci 3(1):201–2018. https://doi.org/10.6088/ijes.2012030131020

Sureshkumar V, Kiruba Daniel S, Rukmani K, Sivakumar M (2015) Fabrication of chitosan–magnetite nanocomposite strip for chromium removal. Appl Nanosci 6(2):277–285. https://doi.org/10.1007/s13204-015-0429-3

Archana KM, Yogalakshmi D, Rajagopal R (2019) Application of green synthesized nanocrystalline CuI in the removal of aqueous Mn(VII) and Cr(VI) ions. SN Appl Sci 1:522–536. https://doi.org/10.1007/s42452-019-0544-y

Yates JR, Holmes DS (1987) Two families of repeated DNA sequences in Thìobaϊìllus ferrooxidans. J Bacteriol 169:1861–1870

Aftabtalab A, Sadabadi H, Shilpa Chakra CH, Venkateswara Rao K, Shaker S, Mahofa EP (2014) Magnetite nanoparticles (Fe3O4) synthesis for removal of Chromium (VI) from waste water. Int J Sci Eng Res. 5(1):1419–1423

Cheng Y, Zhou F, Li S, Chen Z (2015) Removal of mixed contaminants, crystal violet, and heavy metal ions by using immobilized stains as the functional biomaterial. RSC Adv 6:67858–67865. https://doi.org/10.1039/c6ra13337a

Jing Z, Han D, Wu S (2005) Morphological evolution of hematite nanoparticles with and without surfactant by hydrothermal method. Mat Lett 59(7):804–807. https://doi.org/10.1016/j.matlet.2004.11.025

Guo S, Cao Y, Sun T, Zhang J, Gu L, Zhang C, Xu Z (2018) Influence of surface morphology on adsorption of potassium stearate molecules on diamond-like carbon substrate: amolecular dyamics study. Appl Surf Sci 441:708–717. https://doi.org/10.1016/j.apsusc.2018.02.039

Seid MA, Nasser WS, Osman TA, Toprak MS, Muhammed M, Uheida A (2007) Removal of chromium (VI) from aqueous solutions using surface modified composite nanofibers. J Colloid Interface Sci 505(1):682–691. https://doi.org/10.1016/j.jcis.2017.06.066

Acknowledgements

We gratefully acknowledge DST-FIST, Stella Maris College (Autonomous), Chennai; P-XRD lab, Department of Chemistry, IIT-Madras; SAIF-IIT Madras and Crystal Growth Centre, Anna University, Chennai, for their help in SEM characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akhtar, F.Z., Archana, K.M., Krishnaswamy, V.G. et al. Remediation of heavy metals (Cr, Zn) using physical, chemical and biological methods: a novel approach. SN Appl. Sci. 2, 267 (2020). https://doi.org/10.1007/s42452-019-1918-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1918-x