Abstract

The photocatalytic degradation of Cr(VI) from wastewater by using nanomaterials TiO2, ZnO, and CdS. All the experiments were carried out in the batch process. The wastewater obtained from various industries. The amount of chromium was removed using photocatalyst with UV light and in the dark at different pH range. The maximum removal of Cr(VI) was observed at pH 2; out of these photocatalyst TiO2 showed highest capacity for Cr(VI) removal than TiO2 thin film. The removal of chromium has been studied by considering influent concentration, loading of photocatalyst, pH, and contact time as operating variables. The degradation was characterized by FTIR, XRD, SEM, and EDX analysis before and after application of photocatalysts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The pollution of hazardous metals is increasing with extensive of industrial developments (Bhatkhande et al. 2001). Biological interest in chromium arises from its prominent role in industrial pollution and its toxicity to microbes, plants, and animals (Mills et al. 1996). Large amounts of chromium are introduced into the environment through various industries like dyeing and printing in textile industries, chemical manufacture, leather tannery, metal plating, and processing industrial effluents affected living cells (Lozano et al. 1992; Suksabye et al. 2007). Chromium exists in two oxidation states, Cr(III) and Cr(VI). The hexavalent form is 500 times more toxic than the trivalent form (Kowalski 1994; Gimenez et al. 1996). Several studies have shown that the trace amount of chromium (VI) is considered to be essential for normal metabolic process (Barkat et al. 2004). Chromium discharged into the sewage system causes serious environmental impact. Chromium occurs mainly in Cr(III) form, which is oxidized into chromium (VI) due to the presence of organic compounds (Sarin and Pant 2006). The maximum level of Cr(VI) permitted in wastewater is 0.05 mg L−1 (Acer and Malkoc 2004). However, higher levels of chromium metals have been found to be toxic mainly to the kidney and liver (Kajitvichyanukul et al. 2005; Shrivastava et al. 1996). World health organization (WHO) has determined that chromium (VI) is carcinogenic (Suksabyea et al. 2009). The human toxicity includes lung cancer as well as liver and gastric damage (Acer and Malkoc 2004; Kabra et al. 2008). Nowadays, most of the industries are facing the difficult problem of disposal of chromium (VI) in wastewater produced in huge quantity.

Hexavalent chromium form chromate (CrO −24 ) is considerably more soluble in water than trivalent chromium Cr(III) (Butler and Davis 1993). The chromium removal treatment includes precipitation, ion exchange, photocatalysis, reverse osmosis, and adsorption process (Lin et al. 1993). Most of these methods require high capital and recurring expenditure and consequently they are not suitable for small-scale industries (Lee et al. 2006; Chenthamarakshan et al. 2000). Among all the aforementioned methods, photocatalysis is a highly effective and cheap process than the other methods. Photocatalysis is one of the potential techniques to either oxidize or reduce hazardous pollutants. In the present investigation, photocatalytic degradation method is used for the removal of chromium (VI) from industrial wastewater using TiO2, ZnO, and CdS as photocatalysts. In addition, a comparative study using nanosized TiO2 powder and Sol–gel thin film of TiO2 was also studied under UV irradiation. Besides the above-detailed effect of pH, contact time, photocatalyst dosage, and kinetic study were also investigated.

Photocatalysis

The valence band hole is strongly oxidizing, and the conduction band electron is strongly reducing. At the external surface, the excited electron and the hole can take part in redox reactions with adsorbed species such as water, hydroxide ion (OH−), organic compounds, or oxygen. The charges can react directly with adsorbed pollutants, but reactions with water are far more likely since the water molecules are far more populous than contaminant molecules. Oxidation of water or OH− by the hole produces the hydroxyl radical (OH*), an extremely powerful and indiscriminant oxidant (Fig. 1).

Experimental

Materials and methods

All the chemicals used in this experiment were all of analytical grade. Accurately weighted potassium chromate treated with diphenyl carbazide (DPC) working as masking agent produces reddish purple colour in acid solution, and was neutralized by addition of NaOH. Nanocrystalline titanium dioxide was prepared via sol–gel hydrolysis and condensation of ethanol solutions (Merck Chemicals) of titanium isopropoxide (Ti (OC3H7)); diethyl glycol (DEG) was obtained from Merck Chemicals. Deionized water was used throughout the experiment. The absorbance was measured using a UV–Vis spectrophotometer obtained maximum at λmax = 540 nm. Batch experiments were carried out with different doses (1–5 g/L) of with TiO2, ZnO, and CdS.

Preparation of nanosized photocatalysts

Nanosized semiconductors such as TiO2, ZnO, and CdS are some of the most basic functional materials. The anatase TiO2 was prepared by using TiCl4 (20–30% HCl) solution and ammonia. The pH was adjusted by NH3 between 10 and 12. The TiO2 particles are formed in the beaker, by the hydrolysis of TiCl4. Surface morphology of TiO2 nano particles was analyzed using XRD. Nanosized ZnO semiconductor was prepared using Zinc sulfate and sodium hydroxide solution. During the reaction, ZnO was precipitated and it was annealed in the air at 250° for half an hour. After annealing ZnO nanosized particles are formed. Cadmium sulfide can be prepared by the precipitation from soluble cadmium(II) salts with sulfide ion by washing with H2SO4 and precipitation of CdS is formed. After washing the precipitate, soluble cadmium salts were followed by calcinations at 260°C to convert it in to the hexagonal nanosized particles. These materials are used for photocatalysis for removal of Cr(VI). After adsorption of Cr(VI)ions the size of the photocatalysts particles are increased (Table 1).

Preparation of thin film

Titanium isopropoxide solution was added slowly to 0.1 M nitric acid solution dropwise under vigorous stirring; during the addition, a white precipitate was formed. The solution was then heated at 70°C for 6 h for peptization. In this way, white nanoparticles of TiO2 colloids were obtained as indicated by the appearance of turbidity. Finally, aqueous polyethylene glycol with molecular weight of 20,000 solution, with 40% by weight of TiO2 was added to get the viscous dispersion of TiO2 colloidal solution.

Microscopic glass slides were used as substrates. Prior to coating, the substrates were cleaned thoroughly. First, the substrates were cleaned in water with liquid detergent. Then, they were ultrasonically cleaned in acetone and ethanol for 10 min, respectively. Finally, they were thoroughly rinsed with deionized water. TiO2 thin films were deposited on the substrates by a dip-coating method at room temperature with the withdrawing speed of a dip-coater about 6 cm/min, immediately wiped off an undesired side using isopropyl alcohol. The films were dried in air and then were calcined in air at 100–500°C for 2 h. The dip-coating technique is relatively cheap and easy. Another aspect of this technique is that one can deposit thin films layer by layer.

Instrumentation

The removal of Cr(VI) metal was observed by spectrophotometer (Systronic Model-2203). The solution was exposed to UV light (PHILIPS-400 Watt) by addition of TiO2, ZnO, and CdS. The distance of source and the reaction vessel is 30 cm (Fig. 2). UV-spectrophotometer in glass cuvette with path length 1.00 cm and the progress of photocatalytic reaction can be observed. The sample was separated from the photocatalysts by centrifuging. Samples were withdrawn at different time interval (15 min). Double-distilled water was used throughout the experiment. To study the effect of important parameters like pH, contact time, initial concentration, and photocatalyst dosage on the Cr(VI) concentration, a batch experiment was conducted for each experiment. The kinetics study was determined by removal of Cr(VI) from aqueous solution at different time intervals.

Photocatalytic study

The stock solution of 1,000 ppm of Cr(VI) was prepared by dissolving K2CrO4 (A.R. grade), in the double-distilled water. All the batch studies were carried out using chromate stock solution to 1 L. The absorbance of chromate solution was measured. The calibration curve of Cr(VI) was obtained at λmax = 540 nm. A uniform particle size of the photocatalysts were in between 120 to 500 μ size for photocatalytic degradation.

Kinetics study was determined by analyzing the metal removal from aqueous solution with constant time interval. In each experiment an accurately weighted amount of TiO2, ZnO and CdS was taken in 100 ml solution by adjusting pH of hexavalent chromium solution with addition of requisite volume of A.R. grade NaOH and HCl (E. Merck India) in the different flask at pH 2–7, the flask were placed under UV lamp, with constant shaking by magnetic stirrer. The photocatalyst was separated from the solution by centrifugation. The percentage of removal of Cr(VI) was increased with decrease in pH from 7 to 2. A maximum removal was found to be maximum at pH 2; therefore, pH was finalized at pH 2.

Photocatalysis of industrial wastewater

The tannery and dyeing wastewater containing Cr(VI) ions were extracted by using diphenyl carbazide as masking agent forms reddish purple colour of the solution is form. The absorbance of aqueous solution was measured by using spectrophotometer (systronics, model-2203). It was found maximum at λmax = 540 nm. The wastewater sample solution was introduced with light source UV lamp (PHILIPS-400 Watt) at a distance 30 cm from the reaction vessel. In the experiment an accurately weighted amount of photocatalysts were added in the flask and adjusting a pH by using A.R. grade NaOH and HCl (E. Merck India) in the different flask at pH 2 to 7. The flask were placed under UV lamp, with constant shaking by magnetic stirrer. The percentage of removal of industrial wastewater was 68.4% on TiO2 and 47.6% on ZnO respectively (Fig. 3).

Results and discussion

In the photocatalytic degradation of Cr(VI) batch experiments were carried out using different dosages of photocatalysts TiO2, ZnO, and CdS (1–5 g/L). The influent chromium concentration varies from 10 to 50 mg/L.

Effect of contact time

Effect of contact time and concentration for the removal of Cr(VI) from aqueous solution for TiO2, ZnO and CdS (5.0 g/L). The experiments were carried out at 200 rpm at room temperature, pH 2.0 and at initial concentrations of Cr(VI) (10 mg/L) for different time intervals up to 180 min. Percentage of Cr(VI) removal on TiO2, ZnO, and CdS increases with increasing in concentration of photocatalyst (Fig. 4).

Though the percentage of removal increases with photcatalysts concentration and it is constant after equilibrium time. The removal of Cr(VI) on TiO2 was 96.4% for 50 mg/L, 45.4% for 30 mg/L and 21.5% for 10 mg/L. For ZnO the removal was 78.2%, 36.7% and 11.3% for 50, 30 and 10 mg/L respectively, with CdS it was 48.2% for 50 mg/L, 25% for 30 mg/L and it was just 6.3% for removal of Cr(VI) respectively. It was observed that as the amount of photocatalyst increases from 1.0 to 5.0 g/L, the degradation of Cr(VI) increases with increase the concentration of photocatalysts.

Effect of pH

The removal of chromium from wastewater using photocatalysts is highly dependent on the pH of the solution (Ku and Jung 2001). Degradation of typical inorganic pollutants from water is increased with decreasing pH. The effect of pH on the removal of chromium by different photocatalysts like TiO2, ZnO, and CdS on of different influent chromium concentrations was studied (Senthilkumar et al. 2006). The Cr(VI) removed with different time interval at pH 2 shown in Fig. 5. The effect of pH 2 has highest removal of Cr(VI) at 96.8%; at pH 3 it was 85.6% and for pH 4 it was 67.2%, pH 2 was chosen for the further reaction.

Effect photocatalyst dosage

The effect of photocatalyst dosage on removal of chromium from aqueous solution is shown in Fig. 6. It is observed that, the percentage removal of chromium increases with increase in photocatalyst dosage. At highest photocatalyst loading the removal is more accessible and because of this, the removal per unit weight of photocatalysts is higher (Kelar et al. 2004). It is observed that the chromium removal rate increases with increase in photocatalyst dosage. It was observed that the chromium removal percentage is found to be 96.8% at photocatalyst loading of 5 g L−1. As the TiO2 loading is increased from 1 to 5 g L−1, the chromium removal percentage also increases from 38.7 to 96.8%. As the photocatalyst dosage increases from 1 to 5 g L−1, the percentage increases from 22.6 to 78.5% for ZnO and 13.8 to 49.2% for CdS.

Dark adsorption and photodegradation of Cr(VI)

Dark adsorption of Cr(VI) was very low as compared to photodegradation under UV light. Maximum adsorption of 51.3% was obtained in absence of light. Rate of reduction was very low in spite of the presence of hole scavengers, due to less thermodynamic driving force. In the presence of UV light degradation was better Fig. 7.

Chemical oxygen demand

The chemical oxygen demand test is widely used as effective technique to measure the organic strength of wastewater. The test allows the measurement of waste in terms of the total quantity of oxygen required for the oxidation of organic matter to CO2 and water. In the present work result of COD were taken as one of the parameter to judge the feasibility of photocatalytic process for the degradation of Cr(VI) metal solution. In this experiment the Cr(VI) metal solution (100 ml) and the photocatalysts 0.05 g L−1 were taken in the reactor and exposed to UV light for 120 min. Metal sample of about 10 mL was taken out at regular intervals from the test solution, centrifuged for 10–15 min and the absorbance was recorded at 540 nm Comparison of the COD values of the initial dye concentration with ht irradiated solution indicates that the COD values are substantially reduced. It is observed that the COD values decreases from 875 to 116 mg L−1.

The influence of Cr(VI)metal concentration on percentage of COD removal over photcatalyst TiO2, ZnO, and CdS is shown in Fig. 8. It is clearly understood that the percentage of COD reduction increases with increasing concentration of Cr(VI) ions for the same irradiation time. Thus, higher concentration of Cr(VI) may need longer illustration time.

Infrared spectra

The FT-IR spectra of before and after degradation nanomaterials TiO2 were recorded with the help of Perkin_Elmer, PE-RXI to study the functional group and binding sites. For FT-IR study, 1 g of fine powder was encapsulated in 20 mg of KBr in order to prepare translucent sample disks. The IR spectra of titanium dioxide exhibiting a stretching vibration at 752 cm−1 is attributed to the presence of CH2 group. A broadband at 1,205 cm−1 is due to amine group. In addition with this, the IR spectrum shows the absorption band at 1,506, 1,510 cm−1, indicates the presence of aromatic ring. The sharp peak at 2,341 and 2,353 cm−1 shows nitrile group. A stretchable vibration band at 2,931, 2,993 cm−1 confirms the presence of C–H group and NH3 residue present in the TiO2, the OH stretching vibrations at 3,410 and 3,419 cm−1 and NH2 stretching vibrations at 3,718, 3,724 cm−1 (Fig. 9).

XRD analysis

The XRD pattern of TiO2 and CdS shows the peak at 25.25°, 46.78° and 25.24°, 46.38° respectively. X ray diffraction of TiO2 and CdS was recorded by Philips Holland. Xpert-MPD model using.

Cu-Kα target. The d values obtained for TiO2 and CdS were 0.5764, 0.4706 corresponding to 0.4583 and 0.4012, respectively, Table 1. It indicates that after photocatalytic degradation the size of particles increases. The diffractogram of TiO2 is shown before and after Fig. 10, 11 and 12 shows X ray diffraction of CdS.

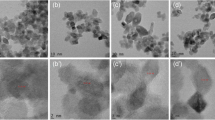

SEM

The scanning electron micrographs are recorded with Philips XL-30 SEM analyzer for characterization the surface morphology of TiO2 and ZnO photocatalyst (Fig. 13 and 14) on the Cr(VI) before and after degradation. The SEM photographs depict the surface texture and porosity, before and after treatment of photocatalysts. It is clear that TiO2 has rough surface with heterogeneous porous nature. It indicates that there is good possibility for adsorption Cr(VI)on TiO2. The SEM image of nano-TiO2 film prepared by sol–gel method calcined at 300°C is shown in Fig. 15. The SEM micrograph is spherical and highly micro-porous in nature. The pore size ranges from 20 to 100 nm in diameter. The porosity occurs by using polyethylene glycol (PEG) which is used as binder leaves the surface of substrate at higher calcination temperature.

EDX

Energy dispersive X ray spectroscopy (EDX) is chemical microanalysis technique is a co-junction with SEM, EDX analysis. It was characterized the element composition of the typical EDX pattern of TiO2 as well as ZnO (Fig. 16 and 17). The chemical composition of TiO2 was found to be Ti = 69, 0 = 16, Cr = 12 and carbon = 3% confirmed the presence of Cr after degradation of Cr(VI) metal on TiO2. The EDX of ZnO was C = 10, O = 15, Zn = 61, K = 6, and Cr = 8% found. It is also confirmed that Cr can be removed after degradation of Cr(VI) metal from waste water.

Conclusion

Removal of toxic hexavalent form of Cr(VI) from wastewater was possible using selected photocatalysts like TiO2, ZnO, and CdS. Photocatalysis has been ascertained to be a promising technique for the removal of heavy metals from industrial effluents. The removal of chromium is maximum at pH 2 for different amount of photocatalysts. The removal of Cr(VI) at lower pH values may be attributed to the large number of the H+ ions was neutralized the negatively charged or convert a neutral group. The chromium removal percentage increases as dosage of photocatalysts increases and mass removal rate increases with increase in photocatalyst loading. The highest photodegradation rate was found on TiO2; a nanocrystalline powder was the most effective for degradation of Cr(VI). than TiO2 thin film prepared by by sol–gel method. It removed only 46.5% Cr(VI) with same time. More than 96% removal of Cr(VI) is possible at the 50-ppm concentration. With increase in the dose of photocatalysts, initial concentration of Cr(VI) and increase in contact time up to 180 min are favorable. TiO2 was found to be the best photocatalyst. ZnO was a less effective photocatalyst than TiO2 as it removes 80% Cr(VI), and CdS is very poor photocatalyst as it removes only 45% Cr(VI). The TiO2 thin film prepared by sol–gel method removed only 46.5% Cr(VI) with same time. The removal of metals using thin film technique is less effective than that using the nanosized powder. By using XRD it is found that the size of the photocatalytic particles increases after the dye reacted with these particles. SEM photographs show that the TiO2 and ZnO have heterogeneous pores in nature as well as the surface is rough in nature.

References

Acer FN, Malkoc E (2004) The removal of chromium (VI) from aqueous solution by Fagus Orientals L. Bioresour Technol 94:13–15

Barkat MA, Chen YT, Huang CP (2004) Removal of toxic cyanide and Cu(II) ion from water illuminated TiO2 catalyst. Appl Catal B: Environ 53:13–20

Bhatkhande DS, Pangarkar VG, Beenackers AACM (2001) Photocatalytic degradation for environmental application—a review. J Chem Technol Biotechnol 77:102–116

Butler EC, Davis AP (1993) Photocatalytic oxidation in aqueous titanium dioxide suspension: the influence of dissolved transition metals. J Photochem Photobiol A: Chem 70(3):273–283

Chenthamarakshan CR, Rajeshwar K, Wolfrum EJ (2000) Hetrogeneous photcatalytic reduction of Cr(VI) in UV irradiation titania suspension effect of protons ammonium ions and other interfacial aspects. Langmuir 16(6):2715–2721

Gimenez J, Aguado MA, Cervera-March S (1996) Photocatalytic reduction of Chromium(VI) with titania powders in flow system. Kinetics and catalyst activity. J Mol Catal A: Chem 105(1–2):67–78

Kabra K, Chaudhari R, Sawhney RL (2008) Solar photocatalytic removal of Cu(II), Zn(II) and Pb(II): speciation modeling of metal–citric acid complexes. J Hazard Mater 155(3):424–432

Kajitvichyanukul P, Pattarchai JA, Pongpom S (2005) Sol–gel preparation and properties study of TiO2 thin film for photocatalytic reduction of Cr(VI) in photocatalysis process. Sci Technol Adv Mater 6:352–358

Kelar N, Kellar V, Gavin F, Ledoux MJ (2004) A new TiO2–SiC material for use of photocatalyst. Mater Lett 58:970–974

Kowalski Z (1994) Treatment of chromium tannery wastes. J Hazard Mater 37:137–144

Ku Y, Jung IL (2001) Photocatalytic reduction of Cr(VI) in aqueous solution by UV irradiation with the presence of titanium dioxide. Water Res 35(1):135–142

Lee K, Lee NH, Shin SH, Lee HG, Kima SJ (2006) Hydrothermal synthesis and photocatalytic characterizations of transition metals doped nano TiO2 sols. Mater Sci Eng: B 129:109–115

Lin WY, Wei C, Rajeshwar K (1993) Photocatalytic reduction and immobilization of hexavalent chromium at titanium dioxide in aqueous basic media. J Electrochem Soc 140(9):2477–2482

Lozano A, Garcia J, Domenech X, Casado J (1992) Heterogeneous photocatalytic oxidation of Mn(II) over TiO2. J Photochem Photobiol A 69(2):237–240

Mills A, Belghazi A, Rodman D (1996) Bromate removal from drinking water by semiconductor photocatalysis. Water Res 30:1973–1978

Sarin V, Pant KK (2006) Removal of chromium from industrial waste by using eucalyptus bark. Bioresour Technol 97:15–20

Senthilkumar S, Kalaamani P, Porkodi K, Varadrajan PR (2006) Adsorption of dissolved from aqueous phase on to activated carbon prepared from agricultural waste. Bioresour Technol 97:1618–1625

Shrivastava SK, Gupta VK, Mohan D (1996) Kinetic parameters for removal of lead and chromium from wastewater using activated carbon developed fertilizer wastewater. J Environ Model Assess 1:281–290

Suksabye P, Thiravetyan P, Nakbanpot W (2007) Chromium removal from electroplating wastewater by coir pith. J Hazard Mater 141(3):637–644

Suksabyea P, Nakajimab A, Thiravetyan P (2009) Mechanism of Cr(VI) adsorption by coir pith studied by ESR and adsorption kinetic. J Hazard Mater 161:1103–1108

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Joshi, K.M., Shrivastava, V.S. Photocatalytic degradation of Chromium (VI) from wastewater using nanomaterials like TiO2, ZnO, and CdS. Appl Nanosci 1, 147–155 (2011). https://doi.org/10.1007/s13204-011-0023-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-011-0023-2