Abstract

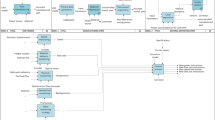

Additive manufacturing (AM) technology is becoming increasingly feasible in industrial applications. Although AM systems continue to improve, the lack of repeatability and stability of these technologies remains an obstacle to industrial breakthroughs. Thus, AM process monitoring equipment has to be set up to supervise product quality and detect defects. This study first reviews the various categories of defects, relevant AM process signatures, and optical monitoring methods of powder bed fusion processes proposed so far. Then, according to the detection requirements, an optical process monitoring system based on multiple sensors is proposed, which is equipped with a white light imaging channel, an infrared imaging channel, and a polarization imaging channel. The aberrations can be optimized using Zemax software by appropriately selecting the optimization function operands. Thus, the design requirements for the multi-sensor monitoring system for the AM process can be achieved.

Similar content being viewed by others

References

Grasso M, Colosimo BM (2017) Process defects and in situ monitoring methods in metal powder bed fusion: a review. Meas Sci Technol 28:044005

Trevisan F, Calignano F, Lorusso M, Pakkanen J, Aversa A, Ambrosio EP, Lombardi M, Fino P (2017) On the selective laser melting (SLM) of the AlSi10Mg alloy: process, microstructure, and mechanical properties. Materials 10(76):1–23

Thompson A, Senin N, Leach RK (2016) Toward an additive surface atlas. In: ASPE/Euspen conference on dimensional accuracy and surface finish from additive manufacturing 2016, pp 27–30

Peng X, Kong LB, Chen Y, Wang JH, Xu M (2019) A preliminary study of in situ defects measurement for additive manufacturing based on multi-spectrum. In: 9th international symposium on advanced optical manufacturing and testing technologies: subdiffraction-limited plasmonic lithography and innovative manufacturing technology 10842(1084217), pp 1–10

Chua ZY, Ahn IH, Moon SK (2017) Process monitoring and inspection systems in metal additive manufacturing: status and applications. Int J Precis Eng Manuf Green Technol 4(2):235–245

Schmidt M, Merklein M, Bourell D, Dimitrov D, Hausotte T, Wegener K, Overmeyer L, Vollertsen F (2017) Laser based additive manufacturing in industry and academia. CIRP Ann Manuf Technol 66(2017):561–583

Tapia G, Elwany A (2014) A review on process monitoring and control in metal-based additive manufacturing. J Manuf Sci Technol 136:060801

Everton SK, Hirsch M, Stravroulakis P, Leach RK, Clare AT (2016) Review of in situ process monitoring and in situ metrology for metal additive manufacturing. Mater Des 95(2016):431–445

Galati M, Luliano L (2018) A literature review of powder-based electron beam melting focusing on numerical simulations. Addit Manuf 19(2018):1–20

Gibson I, Rosen DW, Stucker B (2010) Additive manufacturing technologies. Springer, New York

Clijsters S, Craeghs T, Buls S, Kempen K, Kruth JP (2014) In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int J Adv Manuf Technol 75(2014):1089–1101

Bahador K, Alaa K, Fakhreddine OK, Saiedeh NR (2013) Multi-sensor data fusion: a review of the state-of-the-art. Inf Fusion 14(2013):28–44

Doubenskaia M, Grigoriev S, Zhirnov I, Smurov I (2016) Parametric analysis of SLM using comprehensive optical monitoring. Rapid Prototyp J 22(2016):40–50

Edwards P, O’Conner A, Ramula M (2013) Electron beam additive manufacturing of titanium components: properties and performance. J Mater Sci Eng 135(6):061016

Sharratt BM (2015) Non-destructive techniques and technologies for qualification of additive manufactured parts and processes: a literature review. Contract Report, DRDC-RDDC-2015-C035

Williams ST, Zhao H, Léonard F, Derguti F, Todd I, Prangnell PB (2015) XCT analysis of the influence of melt strategies on defect population in Ti–6Al–4V components manufactured by selective electron beam melting. Mater Charact 102(2015):47–61

Li R, Liu J, Shi Y, Wang L, Jiang W (2012) Balling behavior of stainless steel and nickel powder during selective laser melting process. Int J Addit Manuf Technol 59(2012):1025–1035

Attar H, Calin M, Zhang LC, Scudino S, Eckert J (2014) Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater Sci Eng A 593(2014):170–177

Zaeh M, Branner G (2010) Investigations on residual stresses and deformations in selective laser melting. Prod Eng Res Dev 4(1):35–45

Casati R, Lemke J, Vedani M (2016) Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J Mater Sci Technol 32(8):738–744

Berumen S, Bechmann F, Lindner S, Kruth JP, Craeghs T (2010) Quality control of laser and powder bed-based additive manufacturing (AM) technologies. Phys Procedia 5(Part B):617–622

Doubenskaia M, Pavlov M, Grigoriev S, Tikhonova E, Smurov I (2012) Comprehensive optical monitoring of selective laser melting. J Micro/Nanoeng 7(3):236–243

Krauss H, Eschey C, Zaeh M (2012) Thermography for monitoring the selective laser melting process. In: Proceeding of the solid freeform fabrication symposium

Bayle F, Doubenskaia M (2008) Selective laser melting process monitoring with high speed infra-red camera and pyrometer. In: Proceedings of SPIE 6985, fundamentals of laser assisted micro-and nanotechnologies (International Society for Optics and Photonics) 698505

Acknowledgements

The authors are grateful for the financial support from Shanghai Science and Technology Committee Innovation Grand (Grant Nos. 17JC1400601, 19ZR1404600) and the National Key R&D Program of China (Project Nos. 2017YFA0701200 and 2016YFF0102003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, X., Kong, L., Chen, Y. et al. Design of a Multi-sensor Monitoring System for Additive Manufacturing Process. Nanomanuf Metrol 3, 142–150 (2020). https://doi.org/10.1007/s41871-020-00062-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41871-020-00062-7