Abstract

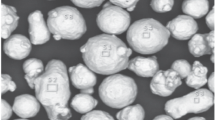

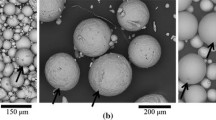

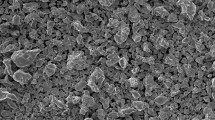

Balling phenomenon, as a typical selective laser melting (SLM) defect, is detrimental to the forming quality. In this work, a detailed investigation into the balling behavior of selective laser melting of stainless steel and pure nickel powder was conducted. It was found that the SLM balling phenomenon can be divided into two types generally: the ellipsoidal balls with dimension of about 500 μm and the spherical balls with dimension of about 10 μm. The former is caused by worsened wetting ability and detrimental to SLM quality; the latter has no obvious detriment to SLM quality. The oxygen content plays an important role in determining the balling initiation, which can be considerably lessened by decreasing the oxygen content of atmosphere to 0.1%. A high laser line energy density, which can be obtained by applying high laser power and low scan speed, could enable a well-wetting characteristic. The effect of scan interval on balling initiation is not obvious as long as the scan track is continuous. The surface remelting procedure can also alleviate the balling effect in a certain extent, due to the melting and wetting of metal balls. Moreover, the balling phenomenon of pure nickel was also studied, and the results implied that the balling discipline had a universality.

Similar content being viewed by others

References

Tolosa I, Garciandia F, Zubiri F, Zapirain F, Esnaola A (2010) Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int J Adv Manuf Technol 51(5–8):639–647

Zhang WX, Shi YS, Liu B, Xu L, Jiang W (2009) Consecutive sub-sector scan mode with adjustable scan lengths for selective laser melting technology. Int J Adv Manuf Technol 41(7–8):706–713

Yadroitsev I, Bertrand P, Smurov I (2007) Parametric analysis of the selective laser melting process. Appl Surf Sci 253(19):8064–8069

Li RD, Shi YS, Liu JH, Xie Z, Wang ZG (2010) Selective laser melting W-10 wt.% Cu composite powders. Int J Adv Manuf Technol 48(5–8):597–605

Jhabvala J, Boillat E, André C, Glardon R (2011) An innovative method to build support structures with a pulsed laser in the selective laser melting process. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3470-8

Wang FD (2011) Mechanical property study on rapid additive layer manufacture Hastelloy® X alloy by selective laser melting technology. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3423-2

Gu DD, Shen YF (2007) Balling phenomena during direct laser sintering of multi-component Cu-based metal powder. J Alloy Compd 432(1–2):163–166

Kruth JP, Froyen L, Van Vaerenbergh J, Mercelis P, Rombouts M, Lauwers B (2004) Selective laser melting of iron-based powder. J Mater Process Technol 149(1–3):616–622

Niu HJ, Chang ITH (1999) Instability of scan tracks of selective laser sintering of high speed steel powder. Scripta Mater 41(11):1229–1234

Li RD, Shi YS, Wang ZG, Wang L, Liu JH, Jiang W (2010) Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci 256(13):4350–4356

Simchi A (2006) Direct laser sintering of metal powders: mechanism, kinetics and microstructural features. Mater Sci Eng A 428(1–2):148–158

Simchi A, Petzoldt F, Pohl H (2001) Direct metal laser sintering: material considerations and mechanisms of particle bonding. Int J Powder Metall 37(2):49–61

Tolochko NK, Mozzharov SE, Yadroitsev IA, Laoui T, Froyen L, Titov VI, Ignatiev MB (2004) Balling processes during selective laser treatment of powders. Rapid Prototyping J 10(2):78–87

Gu DD, Shen YF (2009) Balling phenomena in direct laser sintering of stainless steel powder: metallurgical mechanisms and control methods. Mater Design 30(8):2903–2910

Gu DD, Shen YF, Yang JL, Wang Y (2006) Effects of processing parameters on direct laser sintering of multicomponent Cu based metal powder. Mater Sci Technol 22(12):1449–1455

Simchi A, Pohl H (2003) Effects of laser sintering processing parameters on the microstructure and densification of iron powder. Mater Sci Eng A 359(1–2):119–128

Childs THC, Hauser C, Badrossamay M (2004) Mapping and modelling single scan track formation in direct metal selective laser melting. Cirp Ann-Manuf Technol 53(1):191–194

Li RD, Shi YS, Liu JH, Yao HS, Zhang WX (2009) Effects of processing parameters on the temperature field of selective laser melting metal powder. Powder Metall Met Ceram 48(3–4):186–195

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, R., Liu, J., Shi, Y. et al. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int J Adv Manuf Technol 59, 1025–1035 (2012). https://doi.org/10.1007/s00170-011-3566-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3566-1